Documente Academic

Documente Profesional

Documente Cultură

Durecure Pac Sep 2018

Încărcat de

Biju_PottayilDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Durecure Pac Sep 2018

Încărcat de

Biju_PottayilDrepturi de autor:

Formate disponibile

DURECURE™ PAC

Direct to Prepared Metal Polyaspartic Coating PC 750

FEATURES • CONTAINS CORROSION INHIBITING PIGMENT

• INCREASE PRODUCTIVITY, NO PRIMER REQUIRED IN MILD CORROSIVE CONDITIONS

• GOOD UV RESISTANCE AND GLOSS RETENTION

• EXCELLENT DRYING AND RECOAT PROPERTIES

• AVAILABLE IN GLOSS AND SATIN FINISH

USES DURECURE™ PAC is a two-component polyaspartic coating that incorporates rust inhibitive pigmentation,

allowing for direct application to abrasive blast or power tool cleaned steel. For more severe corrosive

environments (C4) DURECURE™ PAC can be used over a specified Dulux® Protective Coatings range of zinc

rich primer as a fast drying intermediate/topcoat. In mild to moderate (C1-3) environments, one coat of

DURECURE™ PAC provides an alternative to a two-coat system. The fast curing and direct to metal properties

of DURECURE™ PAC allows for the fast coating of steel – allowing for quicker return to service of assets and

improve throughput.

Typical areas of application of DURECURE™ PAC include structural frames and trusses for factories and

warehouses, farm and heavy engineering equipment.

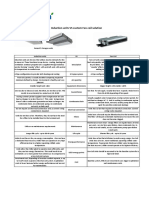

SPECIFICATIONS

RESISTANCE GUIDE

WEATHERABILITY Good gloss and colour retention on exterior SOLVENTS Unaffected by splash and spillage of

exposure common alcohols, aliphatic and

aromatic hydrocarbons, esters and

ketones

HEAT RESISTANCE Up to 120°C dry heat WATER Excellent resistance to fresh and salt

water but not suitable for immersion

SALTS Unaffected by splash and spillage of most salt ALKALIS Good resistance to incidental splash

solutions and spillage of most common alkalis

ACIDS Good resistance to incidental splash and ABRASION Good when fully cured

spillage of most common acids

TYPICAL PROPERTIES AND APPLICATION DATA

CLASSIFICATION Two pack polyaspartic coating APPLICATION CONDITIONS

FINISH Gloss and Satin Min Max

COLOUR White and an extensive range of tinted Air Temp. 10°C 40°C

colours Substrate Temp. 10°C 40°C

Relative Humidity 80%

COMPONENTS Two

VOLUME SOLIDS 72 ± 4% COATING THICKNESS (MICRONS)

VOC LEVEL <260 g/L Min Max Recommended

FLASH POINT 25°C Wet film per coat (μm) 115 170 140

POT LIFE 30 minutes (4 litre kit, 25°C) Dry film per coat (μm) 80 120 100

MIXING RATIO V/V Part A : 3 Part B : 1

THINNER –BRUSH 965-H0189 Dulux® Duthin 799 SUITABLE Abrasive blast cleaned, hand cleaned

THINNER –SPRAY 965-H0189 Dulux® Duthin 799 SUBSTRATES or power tool cleaned metal

PRODUCT CODE 768-63001 Gloss Light Base PRIMERS Dulux® Protective Coatings range of

768-63003 Gloss Clear Base epoxy primers

768-00026 Gloss White Base

763-63001 Satin Light Base APPLICATION Conventional and airless spray

763-63003 Satin Clear Base METHODS

763-00026 Satin White Base

976-H0225 Standard Hardener

DRYING CHARACTERISTICS AT 100 μm DRY FILM THICKNESS

OVERCOAT*

Temperature Humidity Touch Handle Full Cure Min Max**

10° C 50% 3 Hours 9 Hours 7 Days 9 Hours 7 days

15° C 50% 2 Hours 6 Hours 7 Days 6 Hours 7 days

25° C 50% 1 Hour 3 Hours 7 Days 3 Hours 7 days

* These figures are a guide only, as ventilation, film thickness, humidity, thinning and other factors will influence the rate of drying.

** If the maximum recoat time has been exceeded, then the surface MUST be abraded to ensure intercoat adhesion.

SPREADING RATE 7.2 square metres per litre equals 100 μm dry film thickness

ASSUMING NO LOSSES NOTE: Practical spreading rates will vary depending on such factors as colour, application method,

ambient conditions and surface porosity and roughness.

PC 750 September 2018 Page 1 of 2

DURECURE™ PAC

TYPICAL SYSTEMS

This is a guide only and not to be used as a specification. Your specific project needs must be discussed with a Dulux Protective Coatings Representative.

SURFACE ENVIRONMENT PREPARATION GUIDE SYSTEM DFT (μm)

STEEL – NEW High (AS2312.1 Cat Abrasive blast clean AS1627.4 1st Coat Zincanode® 402 75 μm

C4). Equivalent to Class 2.5 2nd Coat Durecure™ PAC 100 μm

PUR4 3rd Coat Durecure™ PAC 100 μm

Mild - Moderate Power tool clean AS1627.2 St 3 st

STEEL 1 Coat Durecure™ PAC 120 μm

(AS2312.1 Cat C1-3) Abrasive blast AS1627.4 Class 2.5

NOTE: If application is by brush or roller, additional coats will be necessary to achieve the minimum DFT and full opacity.

SURFACE Steel: Round off all rough welds, sharp edges and remove weld spatter. Remove grease, oil and other

PREPARATION contaminants in accordance with AS1627.1 with Gamlen CA 1 (a free-rinsing, alkaline detergent) according to the

manufacturer’s written instructions and all safety warnings. Abrasive blast clean to a minimum of AS1627.4 Class

2.5 with a blast profile of 40 – 70 microns. Remove all dust brushing or vacuum. Non-ferrous metals: Round off

all sharp edges. Remove grease, oil and other contaminants in accordance with AS1627.1. Whip blast with fine

non-metallic media such as plastic, glass or garnet to provide a key. Remove all dust with compressed air.

APPLICATION Mix each can thoroughly using a power mixer until the contents are uniform. Ensure bases have been tinted to the

correct colour before use. DULUX® ASSUMES NO RESPONSIBILITY FOR THE APPLICATION OF INCORRECT

COLOUR. Mix the contents of both packs together thoroughly with a power mixer (minimum 5 mins) and let stand

for 10 minutes. Box all containers before use to ensure colour consistency. Remix thoroughly before application.

BRUSH/ROLLER Suitable for small areas only. Thin with up to 100 ml/litre with Dulux® Duthin 799 (965-H0189) to aid application.

When brushing and rolling additional coats may be required to attain the specified thickness.

CONVENTIONAL Thin up to 150ml/litre with Dulux® Duthin 799 (965-H0189) to aid atomisation. Apply in multiple wet coats

SPRAY overlapping each pass 50%.

Typical Set-up Graco AirPro 1.8mm (239543)

Pressure at Triton 308: 70-100 kPa (10-15 p.s.i.)

Pressure at Gun: 380-410 kPa (55-60 p.s.i.)

AIRLESS SPRAY Standard airless spray equipment such as a Graco Xtreme 30:1 with a fluid tip of 15-17 thou (0.38-0.43mm) and

an air supply capable of delivering 550-690 kPa (80-100 p.s.i.) at the pump. Thinning is not normally required but

up to 100 ml/litre of Dulux Duthin 799 (965-H0189) may be added to aid application.

PRECAUTIONS This is an industrial product designed for use by experienced Protective Coating applicators. Ensure that you read

and understand the safety precautions on the relevant Safety Data Sheets before using. The surface to be coated

must be totally free of moisture and contaminants. Do not apply at temperatures below 10°C. Do not apply at

relative humidity above 80% or when the surface is less than 3°C above the dewpoint. The rate of cure is dependent

upon temperature. Where application conditions are outside the parameters stated in this Product Data Sheet, or

where any variation to the recommendations are sought, contact your Dulux® Consultant for written specifications

prior to application. The recommended thinner MUST be used as some solvents react with the isocyanate hardener

seriously degrading the life of the coating. Under no circumstances should water or non-recommended thinner be

allowed to contaminate the product.

CLEAN UP Clean all equipment with Dulux® Duclean™ 646 (965-H0226) immediately after use.

OVERCOATING Degrease with Gamlen CA 1 according to the data sheet. Test adhesion of existing coating by standard cross hatch

adhesion test. If the coating fails, remove it. High-pressure water wash at 8.3 to 10.3 MPa (1,200-1,500 p.s.i) to

remove chalk and dust. Abrade surface to provide a good key for the new coating. Epoxies must be abraded if

recoated outside the recoat window.

SAFETY Read Data Sheet, SAFETY DATA SHEET and any precautions on container labels. SAFETY DATA SHEET

PRECAUTIONS is available from Customer Service (13 23 77) or www.duluxprotectivecoatings.com.au

STORAGE Store as required for a flammable liquid Class 3 in a bunded area under cover. Store in well-ventilated area away

from sources of heat or ignition. Keep containers closed at all times.

HANDLING As with any chemical, ingestion, inhalation and prolonged or repeated skin contact should be avoided by good

occupational work practice. Eye protection approved to AS1337 must be worn while handling and using. Always

wash hands before smoking, eating, drinking or using the toilet.

USING Use with good ventilation and avoid inhalation of spray mists and fumes. When spraying, wear combined organic

vapour/particulate respirator. Users must always comply with their respective State Spray Painting Regulations at

all times.

FLAMMABILITY This product is flammable. All sources of ignition must be eliminated in, or near the working area. DO NOT SMOKE.

Fight fire with foam, CO2 or dry chemical powder. On burning will emit toxic fumes.

WELDING Avoid inhalation of fumes if welding surfaces coated with this paint. Grind off coating before welding.

COMPANY INFORMATION PACKAGING, TRANSPORT AND STORAGE

Dulux Protective Coatings a division of PACKAGING Available in 15 litre packs

DuluxGroup (Australia) Pty Ltd DuluxGroup (New Zealand) Pty Ltd TRANSPORTATION WEIGHT 1.68 kg/litre (Average of components)

1956 Dandenong Road, Clayton 3168 150 Hutt Park Road, Lower Hutt, NZ Part A: Class 3 UN 1263

DANGEROUS GOODS

A.B.N. 67 000 049 427 A.B.N. 55 133 404 118 Part B: Class 3 UN 1263

Dulux, Duthin, and Zincanode are registered trade marks of DuluxGroup (Australia) Pty Ltd. Durecure and Duclean are trade marks of DuluxGroup (Australia) Pty Ltd.

Any advice, recommendation, information, assistance or service provided by Dulux Australia in relation to goods manufactured by it or their use and application is given

in good faith and is believed by Dulux to be appropriate and reliable. However, any advice, recommendation, information, assistance or service provided by Dulux is

provided without liability or responsibility PROVIDED THAT the foregoing shall not exclude, limit, restrict or modify the right entitlements and remedies conferred upon

any person or the liabilities imposed upon Dulux by any condition or warranty implied by Commonwealth, State or Territory Act or ordinance void or prohibiting such

exclusion limitation or modification. Products can be expected to perform as indicated in this sheet so long as applications and application procedures are as

recommended. Specific advice should be sought from Dulux for application in highly corrosive areas and for large projects to ensure proper performance.

PC 750 September 2018 Page 2 of 2

S-ar putea să vă placă și

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- Tankguard StorageDocument5 paginiTankguard StorageBiju_PottayilÎncă nu există evaluări

- StyreneDocument2 paginiStyreneBiju_PottayilÎncă nu există evaluări

- Pioner PrimerDocument4 paginiPioner PrimerBiju_PottayilÎncă nu există evaluări

- Jotun Malathon TDSDocument5 paginiJotun Malathon TDSBiju_PottayilÎncă nu există evaluări

- Technical Data Sheet for Signal Orange Alkyd CoatingDocument4 paginiTechnical Data Sheet for Signal Orange Alkyd CoatingBiju_PottayilÎncă nu există evaluări

- Jotun Siloxane Acrylic PrimerDocument3 paginiJotun Siloxane Acrylic PrimerBiju_PottayilÎncă nu există evaluări

- Jotrun TDSDocument4 paginiJotrun TDSBiju_PottayilÎncă nu există evaluări

- Jotrun TDSDocument4 paginiJotrun TDSBiju_PottayilÎncă nu există evaluări

- Solvalitt MidthermDocument5 paginiSolvalitt MidthermBiju_PottayilÎncă nu există evaluări

- Penguard PrimerDocument5 paginiPenguard PrimerPutroedidohÎncă nu există evaluări

- Muki EPSDocument5 paginiMuki EPSBiju_PottayilÎncă nu există evaluări

- Corro-Coat PE Series 50: Technical Data SheetDocument3 paginiCorro-Coat PE Series 50: Technical Data SheetBiju_PottayilÎncă nu există evaluări

- Technical Data Sheet for Pilot QD PrimerDocument4 paginiTechnical Data Sheet for Pilot QD PrimerBiju_PottayilÎncă nu există evaluări

- Jotun TDSDocument2 paginiJotun TDSBiju_PottayilÎncă nu există evaluări

- Jotatemp 1000 CeramicDocument5 paginiJotatemp 1000 CeramicBiju_PottayilÎncă nu există evaluări

- Jotatherm TB550Document5 paginiJotatherm TB550Biju_PottayilÎncă nu există evaluări

- Technical Data Sheet for Epoxy Mastic CoatingDocument5 paginiTechnical Data Sheet for Epoxy Mastic CoatingBiju_PottayilÎncă nu există evaluări

- Pilot ACR: Technical Data SheetDocument4 paginiPilot ACR: Technical Data SheetBiju_PottayilÎncă nu există evaluări

- Jotamastic Plus: Technical Data SheetDocument5 paginiJotamastic Plus: Technical Data SheetBiju_PottayilÎncă nu există evaluări

- Jotamastic 87 MIO50Document5 paginiJotamastic 87 MIO50Biju_PottayilÎncă nu există evaluări

- Jotamastic 80 MIO Epoxy Mastic Technical Data SheetDocument5 paginiJotamastic 80 MIO Epoxy Mastic Technical Data SheetBiju_PottayilÎncă nu există evaluări

- Jotamastic 87 GFDocument5 paginiJotamastic 87 GFBiju_PottayilÎncă nu există evaluări

- CharDocument4 paginiCharBiju_PottayilÎncă nu există evaluări

- Jotamastic 87 AluminiumDocument5 paginiJotamastic 87 AluminiumBiju_PottayilÎncă nu există evaluări

- Penguard Special: Technical Data SheetDocument5 paginiPenguard Special: Technical Data SheetBiju_PottayilÎncă nu există evaluări

- Imperite 300: Technical Data SheetDocument4 paginiImperite 300: Technical Data SheetBiju_PottayilÎncă nu există evaluări

- JOTUN Jotamastic 80Document5 paginiJOTUN Jotamastic 80Hafiz KamalÎncă nu există evaluări

- Jotun TDSDocument2 paginiJotun TDSBiju_PottayilÎncă nu există evaluări

- Jotachar 1709 PDFDocument5 paginiJotachar 1709 PDFBiju_PottayilÎncă nu există evaluări

- ArmourDocument5 paginiArmourBiju_PottayilÎncă nu există evaluări

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (119)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- SMS LteaDocument11 paginiSMS LteaArdi CikaÎncă nu există evaluări

- Company Directive: Standard Technique: Sd8A/3 Relating To Revision of Overhead Line RatingsDocument33 paginiCompany Directive: Standard Technique: Sd8A/3 Relating To Revision of Overhead Line RatingsSathish KumarÎncă nu există evaluări

- 1981 - Leeper - Wet Cooling Tower - Rule of Thumb Design and SimulationDocument32 pagini1981 - Leeper - Wet Cooling Tower - Rule of Thumb Design and SimulationGuilherme Venturi RonchiÎncă nu există evaluări

- De Electric Circuits EeDocument16 paginiDe Electric Circuits EeLilet P. DalisayÎncă nu există evaluări

- 2015-04-21 - 3 - LPE Firemans SyllabusDocument9 pagini2015-04-21 - 3 - LPE Firemans SyllabusSumanÎncă nu există evaluări

- 2 B.tech Biotechnology 27 38Document38 pagini2 B.tech Biotechnology 27 38Anju GuptaÎncă nu există evaluări

- Introduction To Tribology and Tribological ParametersDocument13 paginiIntroduction To Tribology and Tribological ParametersEsteban CorderoÎncă nu există evaluări

- Astm F1717-21Document11 paginiAstm F1717-21wenhsiaochuanÎncă nu există evaluări

- T3-Revision-Internal-ResistanceDocument22 paginiT3-Revision-Internal-Resistancejordan2gardnerÎncă nu există evaluări

- GEC 104 Week 1 Lesson 1 Math Modern WorldDocument4 paginiGEC 104 Week 1 Lesson 1 Math Modern WorldJahnna Marie PomaresÎncă nu există evaluări

- 2019 Hydropower Status Report 0Document56 pagini2019 Hydropower Status Report 0Titos Nicosio ComéÎncă nu există evaluări

- Induction Heating - VerDocument2 paginiInduction Heating - Verdenivaldo2009Încă nu există evaluări

- 400 KV Tender Docs PDFDocument356 pagini400 KV Tender Docs PDFtanujaayerÎncă nu există evaluări

- HotelSolution: Induction Units VS Fan-Coil SolutionDocument1 paginăHotelSolution: Induction Units VS Fan-Coil SolutionMoriyasu NguyenÎncă nu există evaluări

- Gujarat Technological University: Page 1 of 3Document3 paginiGujarat Technological University: Page 1 of 3DaxÎncă nu există evaluări

- The Mode of Eruptions and Their Tephra Deposits: Tetsuo K and Mitsuru ODocument8 paginiThe Mode of Eruptions and Their Tephra Deposits: Tetsuo K and Mitsuru OAnggit Tri AtmajaÎncă nu există evaluări

- Methods of Re-Apportioning Service Cost Centre CostsDocument7 paginiMethods of Re-Apportioning Service Cost Centre CostsUserÎncă nu există evaluări

- Nonnewtonian and Newtonian Blood Flow in Human Aorta A Transient AnalysisDocument10 paginiNonnewtonian and Newtonian Blood Flow in Human Aorta A Transient AnalysisDivyaVatsÎncă nu există evaluări

- MD2 Exam PDFDocument319 paginiMD2 Exam PDFSiN XÎncă nu există evaluări

- About The Company: Machined and Forged ComponentsDocument18 paginiAbout The Company: Machined and Forged ComponentsankitÎncă nu există evaluări

- Mousavi, Aliha, Imani - 2020 - On The Use of Edge Cracked Short Bend Beam Specimen For PMMA Fracture Toughness Testing Under Mixed-ModeDocument1 paginăMousavi, Aliha, Imani - 2020 - On The Use of Edge Cracked Short Bend Beam Specimen For PMMA Fracture Toughness Testing Under Mixed-ModeMorteza AtaeiÎncă nu există evaluări

- HW2 Solutions FinalDocument5 paginiHW2 Solutions Finalpande_100Încă nu există evaluări

- Data Sheet Otdr Fho5000 enDocument2 paginiData Sheet Otdr Fho5000 enJulio RoDriguezÎncă nu există evaluări

- Electromagnetic SpectrumDocument74 paginiElectromagnetic SpectrumGuiller Lanuza100% (1)

- Magnetism Workhsheet Siap EditDocument10 paginiMagnetism Workhsheet Siap EditMamberamo ClassÎncă nu există evaluări

- 4-1 r14Document12 pagini4-1 r14hafizgÎncă nu există evaluări

- Stiffness of Cable-Based Parallel Manipulators With Application To Stability AnalysisDocument8 paginiStiffness of Cable-Based Parallel Manipulators With Application To Stability AnalysisNhật MinhÎncă nu există evaluări

- Chapter 4: Dynamics: Force and Newton'S Laws of Motion: Net F Ma (63.0 KG) (4.20 M/s ) 265 NDocument15 paginiChapter 4: Dynamics: Force and Newton'S Laws of Motion: Net F Ma (63.0 KG) (4.20 M/s ) 265 NCedric KouakouÎncă nu există evaluări

- Analytical PS A01 A10 Solutions 2Document14 paginiAnalytical PS A01 A10 Solutions 2MarieÎncă nu există evaluări