Documente Academic

Documente Profesional

Documente Cultură

Ceo Neo Differance

Încărcat de

rustydfcTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Ceo Neo Differance

Încărcat de

rustydfcDrepturi de autor:

Formate disponibile

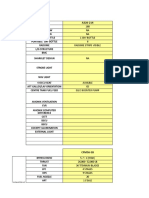

A320-214 A320-271N

SEATS 180 186

PAX WINDOW NA ADDITIONAL WINDOW

EVACUATION NA WIDER ESCAPE SLIDES (FWD,AFT DOOR)

CREW OXY BOTTLE 1 OXY BOTTLE 2 OXY BOTTLE

RADOME RADOME STRIPS VISIBLE RADOME STRIP NOT VISIBLE

BMC MONITORS OPERATION CONTROLS OPERATION

SHARKLET DESIGN NA NEW SHAPE OF L/E FOR LOW SPEED PERFORMANCE

SHUTTER TO REDUCE GLARE IN COCKPIT, STRUCURAL DESIGN CHANGE FOR EASY

STROBE LIGHT NA MAINTENANCE

REARWARD FACING LIGHTS,STRUCURAL DESIGN CHANGE FOR EASY

NAV LIGHT NA MAINTENANCE

4 OCCU SEAT AVAILBLE NOT AVAILABLE

AFT GALLEY/LAV G5 G4B-SPACE FLEX

ORIENTATION

CENTRE TANK FUEL FEED ELEC BOOSTER PUMP JET PUMP + TRANSFER VALES

NEW DEMISTER + AIR FILTER CARTRIDGE PROVIDES 100% WATER SEPERATION &

AVIONIX VENTILATION NA DUST PROTECTION

CVR NA 90 DAYS ULB

AVIONIX COMPUTER

DIFFERENCE NA RMP,CVR,DFDR,FWC,FDIMU WITH WEFA,WEATHER RADAR,

BSCU NA WITH IMPROVED TACHOMETER MONITORING,STEERING TOW KEY MONITORING

COCKPIT ILLUMINATION LED

EXTERNAL LIGHT LED

CFM56-5B PW1100G/GA*-JM

BYPASS RATIO 5.7 : 1 (HIGH) 12 : 1 (ULTRA HIGHT)

THRUST 26,000 -32,000 LB 24,000 -35,000 LB

FAN 36 TITANIUM BLADES 20 ALUMINIUM HOLLOW BLADES

LPC 4 STAGES 3 STAGES

HPC 9 STAGES 8 STAGES

FUEL NOZZLE 20 18 (6 + 12)

HPT 1 STAGE 2 STAGES

CONSTRUC LPT 4 STAGES 3 STAGES

TION

STATION 2/12/25/3/49.5/5/13/17 2/2.5/3/4/4.5/5/14

BEARINGS 5 7 (1,1.5,2,3,4,5,6)

INLET NOSE CONE NA CONTINOUOS ON

ENG. ANTI ICE 1 ANTI ICE VALVE 2 ANTI ICE VALVE

NEW 8TH STAGE HPC ROTOR, AIR SEAL, MODIFIED ABRADABLE COATING

GA* MATERIAL , ALTERNATE CLIMB

DUAL COOLING PUSHBUTTON

FLAT RATING 45 DEG C

N1 100% 5000 RPM 10047

MAX N1 104% 105%

N2 100% 14460 RPM 22300

MAX N2 105%

PARAMETE Nf 100% N/A

RS VIB N1 MAX 6 5

VIB N2 MAX 4.3 5

VIB Nf MAX N/A 5

NACELLE TEMP MAX 240

MAX EGT 725 START,915MCT,950 MAX 1080 START,1980 TO,1900MCT

OIL TANK 24 QTS 35 QTS

OIL QTY INDICATION FADEC GRD OFF FADEC GRD ON

OIL CONSUMPTION 0.6 QTS/HR 0.2 QTS/HR

MAX OIL TEMP 140/155 DEG C 150 DEG C

HIGH OIL PRESSURE 90 PSI 259 PSI

OIL

LOP 13 PST 65 PSI ?

OIL PUMP PACK 1+ 4 1+ 6

DEAERATOR ONLY DEARETATOR & DEOILER

HEAT EXCHANGERS MAIN OIL/FUEL HE, SERVO HEATER,

IDG OIL COOLER FOHE,AOHE,IDGFOHE, IDGOOHE

P SENSOR P0, PS3, PS12, (PS13, P25) Pamb,P2.5, PS14, Pb

T SENSOR T12, T25, T3, T49.5, TCASE, TEO, (T5) T2.5, T2, T3,T5

FADEC

VIB COMPUTER EVMU PHMU

FADEC COPUTER ECU EEC

ENGINE IDENTIFIER DEP/ID PLUG DSU

CUTOMER BLEED PICKUP 5,9 HPC 3, 8 HPC

LPC AIR SYSTEM VBV LPC VIGV, 2.5 BLEED VALVE

HPC AIR SYSTEM VIGV+VSV, TBV HPC VIGV+VSV, 2 (ACTIVE + PASSIVE)BLEED VALVES

LPT 1 NOZZLE COOLING BY 4 STAGE

LPT COOLING 3 STAGE CONTINUOUS FLOW TO TIC, LPT CASE, ROTOR(15 TUBES)

CONTINUOUS FLOW (4 TUBES)

AIR

HPT COOLING CDP DIRECT DISCHARGE ON HPT DISK 6 STAGE CONTINOUS FLOW TO HPT 2 NOZZLE (4 TUBES)

ENGINE BEARING LPC DISCHARGE AIR (2.5) USED FOR

VENTILATION BEARING SUMP PRESSURISATION HPC 3 STAGE AIR USED FOR BEARING COMPARTMENT PRESSURISATION AT LOW

ENGINE POWER, LPC (2.5) STAGE AT ENGINE START AND HIGH POWER SETTING

ENGINE BEARING LPC DISCHARGE AIR (2.5) USED FOR COOLS # 4 BEARING BY HPC 3 STAGE AIR COOLED THROUG BUFFER AIR HE, BY

COOLING BEARING SUMP COOLING STATION 2.5 AIR

ACC LPTCCV (FAN AIR),HPTCCV (4 + 9) ACC VALVE(FAN AIR)

START VALVE POSITION MICRO SWITCH IN START VALVE SPEED SENSOR ON STARTER

ENGINE START LOGIC NA COOLING (10% N2 DRY CRANK) MTS

ENGINE START TIME 20 SEC ~ 2:20 MIN-4:40 MIN

MANUAL START VALVE ALLOWED NOT ALLOWED

OVERRIDE

MISCLLANEO

STARTER INDEPENDENT OIL USES OIL FROM ENGINE OIL SYSTEM VIA MGB

TR BLOCKER DOORS TRANSLATING SLEEVE & CASCADE VANES

FIRE LOOP FIRE LOOP IN FAN AREA NO FIRE LOOP IN FAN AREA, AS MGB/AGB IN CORE AREA

FIRE BOTTLE NA SMALL SIZE BOTTLES

S-ar putea să vă placă și

- HolyCrapItsFast TuningGuide PDFDocument50 paginiHolyCrapItsFast TuningGuide PDFMarcelo Tapia Maureira100% (3)

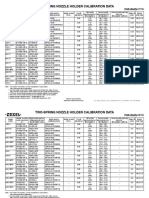

- Zexel Two Spring Nozzle Holder Calibration DataDocument63 paginiZexel Two Spring Nozzle Holder Calibration DataИльнур Султанов100% (6)

- Engine Change BootstrapDocument5 paginiEngine Change Bootstrapolegprikhodko2809Încă nu există evaluări

- CFM AMM ExtractsDocument126 paginiCFM AMM ExtractsIsrael De Sousa Oliveira (LATAM)Încă nu există evaluări

- How To Use TSMDocument26 paginiHow To Use TSMAhmed ElFekyÎncă nu există evaluări

- A320 Ata38-00Document1 paginăA320 Ata38-00Panagiotis DiakidisÎncă nu există evaluări

- Airbus A320neo Family Project - Docx-1Document54 paginiAirbus A320neo Family Project - Docx-1ashik hussainÎncă nu există evaluări

- BLOWBAGETS: 10 Things To Check Before You Drive: Venus ZoletaDocument4 paginiBLOWBAGETS: 10 Things To Check Before You Drive: Venus Zoletaearl sorianoÎncă nu există evaluări

- Neo InfoDocument9 paginiNeo InfoAnurag MishraÎncă nu există evaluări

- Braking and Steering System Trouble Shooting GuidelinesDocument9 paginiBraking and Steering System Trouble Shooting GuidelinesSon NguyenÎncă nu există evaluări

- A330 Important PointsDocument4 paginiA330 Important PointsArindam Dutta100% (1)

- Iae Engine: Oat Colder ThenDocument1 paginăIae Engine: Oat Colder ThenBharat Bhushan100% (1)

- Review B777 B1 Phase 9Document6 paginiReview B777 B1 Phase 9rizwan15Încă nu există evaluări

- Rmoval of NLGDocument6 paginiRmoval of NLGje_carD23100% (1)

- NeoDocument12 paginiNeoAnurag MishraÎncă nu există evaluări

- Breaker A330Document33 paginiBreaker A330Anh TuanÎncă nu există evaluări

- Computer Reset AirbusDocument10 paginiComputer Reset AirbusAlexander Aguirre Calderón100% (1)

- A330 Air CondDocument44 paginiA330 Air CondTienek Lee100% (1)

- A330 Ata 79-00-00Document1 paginăA330 Ata 79-00-00essid zouhaierÎncă nu există evaluări

- A320 - 36 Pneumatic System - GFC-1Document30 paginiA320 - 36 Pneumatic System - GFC-1belinda koyaiyeÎncă nu există evaluări

- Airbus A318/A319/A320/A321: Maintenance TrainingDocument1 paginăAirbus A318/A319/A320/A321: Maintenance TrainingAnonymous QRVqOsa5100% (1)

- Brake Alternate Servovalve Fault - WISEDocument2 paginiBrake Alternate Servovalve Fault - WISERizwan100% (1)

- A320 NEO Abbreviations LEAP-1ADocument5 paginiA320 NEO Abbreviations LEAP-1AwenjukwaxÎncă nu există evaluări

- Relationship Between PFR and Three Fault ClassificationDocument6 paginiRelationship Between PFR and Three Fault ClassificationSuman BajracharyaÎncă nu există evaluări

- M.E.L of Crew Oxigen at A320 NeoDocument2 paginiM.E.L of Crew Oxigen at A320 NeobnmmauricioÎncă nu există evaluări

- CB RESET A320 and ProcedureDocument74 paginiCB RESET A320 and ProcedureHasry RitongaÎncă nu există evaluări

- 787故障快速处理参考手册R2Document211 pagini787故障快速处理参考手册R2Chen AndyÎncă nu există evaluări

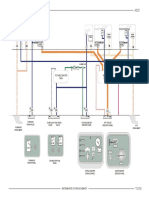

- Figure 29-00-00-13400-00-U / SHEET 1/5 - Hydraulic Power - Schematic ON A/C 101-199, 201-300, 902-999Document1 paginăFigure 29-00-00-13400-00-U / SHEET 1/5 - Hydraulic Power - Schematic ON A/C 101-199, 201-300, 902-999Pankaj SrivastavaÎncă nu există evaluări

- Iae v2500 FlyerDocument2 paginiIae v2500 FlyerkevnwongÎncă nu există evaluări

- Full Authority Digital Engine ControlDocument17 paginiFull Authority Digital Engine Controlberjarry5938100% (2)

- Avionics Ventilation SystemDocument6 paginiAvionics Ventilation SystemIbrahim AyyilÎncă nu există evaluări

- V2500-RR-Line and Base Maintenance - Course NotesDocument541 paginiV2500-RR-Line and Base Maintenance - Course NotesM AliÎncă nu există evaluări

- A320 FacDocument16 paginiA320 FachhgaffadfÎncă nu există evaluări

- A333 Elec PDFDocument1 paginăA333 Elec PDFStephanie JohnsonÎncă nu există evaluări

- Airbus NotesDocument128 paginiAirbus NotesmartinbutlerÎncă nu există evaluări

- Airbus Commercial Aircraft AC A320 PDFDocument399 paginiAirbus Commercial Aircraft AC A320 PDFTania AriasÎncă nu există evaluări

- CFM DebrisGuideBoeingProgramsGEK11919307 2017 (Incoming)Document81 paginiCFM DebrisGuideBoeingProgramsGEK11919307 2017 (Incoming)Andrian Putranto EdogawaÎncă nu există evaluări

- Quick Reference Guide General Pneumatic: SR TechnicsDocument2 paginiQuick Reference Guide General Pneumatic: SR TechnicsPanagiotis Diakidis0% (1)

- Cf6 80c2 Engine.Document7 paginiCf6 80c2 Engine.Harsh Ambhore100% (1)

- A320 Alpha Call Up N CB LocationDocument20 paginiA320 Alpha Call Up N CB LocationReksa Karisma YogasmaraÎncă nu există evaluări

- A320 Exam A PDFDocument102 paginiA320 Exam A PDFnaziaÎncă nu există evaluări

- A 330 Oral Study GuideDocument19 paginiA 330 Oral Study GuideShimeonÎncă nu există evaluări

- AMM - A318, A319, A320, A321 - PGT - Rev. Num 34 - 01-Aug-2021 - 71-11-00-000-041-A - Removal of The Air Intake Cowl. MSN 05879Document1 paginăAMM - A318, A319, A320, A321 - PGT - Rev. Num 34 - 01-Aug-2021 - 71-11-00-000-041-A - Removal of The Air Intake Cowl. MSN 05879hamdÎncă nu există evaluări

- A330-200 Flight ControlsDocument20 paginiA330-200 Flight ControlsTarik BenzinebÎncă nu există evaluări

- Figure 29-00-00-13400-00-U / SHEET 4/5 - Hydraulic Power - Schematic ON A/C 101-199, 201-300, 902-999Document1 paginăFigure 29-00-00-13400-00-U / SHEET 4/5 - Hydraulic Power - Schematic ON A/C 101-199, 201-300, 902-999Pankaj SrivastavaÎncă nu există evaluări

- A330 PressDocument33 paginiA330 PressTienek LeeÎncă nu există evaluări

- ATA 76 PW1100 - Rev. 0 (16-12-19)Document38 paginiATA 76 PW1100 - Rev. 0 (16-12-19)JOSE SANDOVALÎncă nu există evaluări

- A320 ENG BASIC A3 E (1 CMP) Einseitig PDFDocument9 paginiA320 ENG BASIC A3 E (1 CMP) Einseitig PDFranjitÎncă nu există evaluări

- Alpha Call ListDocument8 paginiAlpha Call ListRaby AbidiÎncă nu există evaluări

- B787 CCS Schematic DiagramDocument1 paginăB787 CCS Schematic DiagramΠολύδωρος Μπουρδανιώτης100% (1)

- V2500 Line and Base Maintenance Power PlantDocument42 paginiV2500 Line and Base Maintenance Power PlantHENIGUEDRIÎncă nu există evaluări

- 544-09 - Heat MGMTDocument22 pagini544-09 - Heat MGMTHENIGUEDRIÎncă nu există evaluări

- British CFM 56Document86 paginiBritish CFM 56Dragos Si Irina AionesieÎncă nu există evaluări

- Training Manual A319 / 320 / 321: ATA 22 AutoflightDocument158 paginiTraining Manual A319 / 320 / 321: ATA 22 AutoflightŞevval YalınÎncă nu există evaluări

- QB A320 FA NEO DifferencesDocument10 paginiQB A320 FA NEO DifferencesPhạm Hà Tiến0% (2)

- Iae V2500 Engine Questions: TH THDocument12 paginiIae V2500 Engine Questions: TH THRafael SantosÎncă nu există evaluări

- 00 20 General PDFDocument67 pagini00 20 General PDFkpilÎncă nu există evaluări

- 71-0008 Issue 002Document9 pagini71-0008 Issue 002Panneer Selvam0% (1)

- Airbus 32 A300 A310 Landing GearDocument190 paginiAirbus 32 A300 A310 Landing GearRaph 1123Încă nu există evaluări

- 180 NA NA 1 Oxy Bottle 6 Radome Strips VisibleDocument6 pagini180 NA NA 1 Oxy Bottle 6 Radome Strips Visibleame7871Încă nu există evaluări

- Lubrication Specification of OPALDocument1 paginăLubrication Specification of OPALRADHAKRISHNANÎncă nu există evaluări

- Pa 34 - Seneca LimitationsDocument9 paginiPa 34 - Seneca Limitationssebastian fonsecaÎncă nu există evaluări

- Engine Differences (Leap Added) - 1Document1 paginăEngine Differences (Leap Added) - 1Kshitiz RastogiÎncă nu există evaluări

- Ecas in The Towing Vehicle: System Description and Installation InstructionsDocument20 paginiEcas in The Towing Vehicle: System Description and Installation InstructionsКонстантин ДубенкоÎncă nu există evaluări

- 265366-93-Instructions - 63 Corvette StingrayDocument2 pagini265366-93-Instructions - 63 Corvette StingrayEdson ReisÎncă nu există evaluări

- (Engine Control Module) - Me7.9.9 (Fam Ii 2Document25 pagini(Engine Control Module) - Me7.9.9 (Fam Ii 2jorge luis guevara martinezÎncă nu există evaluări

- YTO X704-X904 Parts Catalogue 2010Document265 paginiYTO X704-X904 Parts Catalogue 2010CENTURYBROTHERÎncă nu există evaluări

- Holland FifthWheelDocument92 paginiHolland FifthWheelrobertÎncă nu există evaluări

- PC - Training Manual - Pt-2Document47 paginiPC - Training Manual - Pt-2Josef JoestarÎncă nu există evaluări

- Design A Parking LotDocument6 paginiDesign A Parking LotDinesh YadavÎncă nu există evaluări

- The Walschaerts Valve GearDocument2 paginiThe Walschaerts Valve Gearstaustell92Încă nu există evaluări

- Caterpillar Parts Book PDFDocument24 paginiCaterpillar Parts Book PDFB.HÎncă nu există evaluări

- 1Gcf530K0000-Brake Shoe Set - Rear/Front 1Gcf530K0000-Brake Shoe Set - Rear/FrontDocument6 pagini1Gcf530K0000-Brake Shoe Set - Rear/Front 1Gcf530K0000-Brake Shoe Set - Rear/FrontArif MamunÎncă nu există evaluări

- 22 M350 Single Spec Sheet REVISEDaDocument2 pagini22 M350 Single Spec Sheet REVISEDaMichael BecherÎncă nu există evaluări

- 2001 RacingDocument224 pagini2001 RacingdensrxÎncă nu există evaluări

- Technical Manual: Departments of The Army, The Air Force, and Headquarters, Marine Corps JANUARY 1996Document908 paginiTechnical Manual: Departments of The Army, The Air Force, and Headquarters, Marine Corps JANUARY 1996Asmro BelayÎncă nu există evaluări

- Enclosed With The Form (A) Original RC Book (B) Original Insurance Policy (C) Original Driving License (D) PUCDocument2 paginiEnclosed With The Form (A) Original RC Book (B) Original Insurance Policy (C) Original Driving License (D) PUCVijay Kumar reddyÎncă nu există evaluări

- Jeep Compass Brochure PDFDocument16 paginiJeep Compass Brochure PDFKishore JohnÎncă nu există evaluări

- 10318-Isuzu Engines 4H-Series 4HF1 4HG1 4HE1Document691 pagini10318-Isuzu Engines 4H-Series 4HF1 4HG1 4HE1Len Earsom100% (1)

- Dedham Transcript Feb. 3, 2011 Feeding The Stomach and Soul Through Meals On WheelsDocument1 paginăDedham Transcript Feb. 3, 2011 Feeding The Stomach and Soul Through Meals On WheelsAndreaECalvinÎncă nu există evaluări

- TGX 6x2 Midlift Tractor: Chassis SpecificationDocument4 paginiTGX 6x2 Midlift Tractor: Chassis SpecificationDarÎncă nu există evaluări

- Other Than Passenger Cars:: Earthmoving Equipment Division (HMEED)Document5 paginiOther Than Passenger Cars:: Earthmoving Equipment Division (HMEED)Lovedeep ChaudharyÎncă nu există evaluări

- DCS A-10c Warthog GuideDocument432 paginiDCS A-10c Warthog GuideJacek SłabyÎncă nu există evaluări

- Pedestrian Stacker Truck: W-SeriesDocument4 paginiPedestrian Stacker Truck: W-SeriesXb ZÎncă nu există evaluări

- Auto Components November 20162Document47 paginiAuto Components November 20162vishalmechieÎncă nu există evaluări

- $RLHCG0FDocument107 pagini$RLHCG0FChomiÎncă nu există evaluări

- 2002 EditionDocument2 pagini2002 Editionsiva anandÎncă nu există evaluări

- Stihl 028 Service ManualDocument20 paginiStihl 028 Service ManualJörn Matthaei50% (2)

- Parts Manual: Z-45/25 Z-45/25J IC PowerDocument396 paginiParts Manual: Z-45/25 Z-45/25J IC PowerJose Sanchez0% (1)

- 3378405M4 en 1200 Massey Ferguson 6400 Series Service Manual Chapter 11 ElectronicsDocument1.200 pagini3378405M4 en 1200 Massey Ferguson 6400 Series Service Manual Chapter 11 ElectronicsMartin ZaehÎncă nu există evaluări