Documente Academic

Documente Profesional

Documente Cultură

Crack Width Calculation To BS 8007 For Combined Flexure and Direct Tension 2002 PDF

Încărcat de

BinSayeedTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Crack Width Calculation To BS 8007 For Combined Flexure and Direct Tension 2002 PDF

Încărcat de

BinSayeedDrepturi de autor:

Formate disponibile

technical report: crack widths

Crack width calculation to BS 8007 for

combined flexure and direct tension

ε12

H. G. Kruger derives and sets out the equations H. G. (Erhard)

Kruger, is a

strain at face 2 ignoring stiffening

effect of concrete

for determining surface crack widths for sections specialist engineer ε2 strain due to stiffening effect of

associate in the concrete between cracks

under combined flexure and direct tension, structural division ε21 strain due to stiffening effect of

which, according to the author, are not covered of BKS (Pty) Ltd. concrete between cracks at face 1

ε22 strain due to stiffening effect of

in the BS 8007 standard concrete between cracks at face 2

εm average strain at level where

B

S 8007 includes recommendations Es modulus of elasticity of reinforce- cracking is being considered

for the calculation of design crack ment εm1 average strain at face 1

widths for sections under flexure fc compressive stress in concrete εm2 average strain at face 2

and for sections under direct tension. It fs stress in reinforcement εsm average strain in tension reinforce-

does not provide recommendations for fs1 stress in reinforcement at face 1 ment

sections under the combined forces. fs2 stress in reinforcement at face 2 εsm1 average strain in tension reinforce-

This Technical Report examines the fstif stiffening tensile stress in concrete ment at face 1

procedures given in the code, and shows fstif1 stiffening tensile stress in concrete εs strain in tension reinforcement

the separate equations for flexure and at face 1 εs1 strain in reinforcement at face 1

direct tension to be based on similar fstif2 stiffening tensile stress in concrete εs2 strain in reinforcement at face 2

premises. The situation where tension at face 2 ∆εs strain reduction in tension rein-

exists across the whole of the section is Fstif total stiffening tensile force in forcement due to tension stiffening

examined, and the limiting values of the concrete of concrete

depth of the neutral axis are calculated. Fstif1 portion of stiffening tensile force ∆εs1 strain reduction in reinforcement

Equations are developed for surface acting at the level of the steel at at face 1 due to tension stiffening of

strains and the stiffening effect of the face 1 concrete

concrete. Fstif2 portion of stiffening tensile force ∆εs2 strain reduction in reinforcement

Similar equations are developed for acting at the level of the steel at at face 2 due to tension stiffening of

the second case where some compres- face 2 concrete

sion is present on one face of the h overall depth of section ρ1 ratio of reinforcement at face 1

section. It is shown how the design

a constant < = F

a2

e= o

A

crack widths for these cases can be k1 s1

h - a1 bh

determined. Equations are developed

with variables allowing for different ρ2 ratio of reinforcement at face 2

a constant < = F

h - a2

reinforcement ratios and concrete cover k2

e= o

a1 A s2

at each face.

bh

K a constant for a particular section

Notation under a certain configuration of Note: Generally subscripts 1 and 2 refer

a’ distance from the compression face moment and direct tension to faces 1 and 2 of the section respec-

to the point at which crack width is R V tively.

being calculated S e+ h -a W 2

a1 distance from face 1 to centroid of S = 2h W Introduction

the reinforcement at face 1 SS e - 2 + a WW

1 The British Code of Practice, BS 80071

a2 distance from face 2 to centroid of includes recommendations for the calcu-

the reinforcement at face 2 M

X at the section

Tapplied moment lation of design surface crack widths for

acr distance from point considered to considered sections under flexure and for sections

surface of the nearest longitudinal under direct tension. However, the code

x

bar n1 ratio does not provide recommendations for

h

As area of tension reinforcement sections under combined flexure and

As1 area of reinforcement at face 1 T applied direct tension at the direct tension.

As2 area of reinforcement at face 2 section considered Furthermore, little guidance is given

bt width of section at the centroid of w design surface crack width in the literature. Neither Anchor2 nor

the tension steel w1 design surface crack width at face Batty3 provides a rational approach to

b width of section considered 1 allow for the effect of tension stiffening

(normally 1m) w2 design surface crack width at face for the case of combined flexure and

cmin minimum cover to tension steel 2 direct tension.

c1 minimum cover to reinforcement at x distance to the neutral axis from Since combined flexure and direct

face 1 face 2 tension often exist in structural

c2 minimum cover to reinforcement at x’ distance to the centroid of the elements of certain water-retaining

face 2 concrete stiffening force from face 2 structures (e.g. in the horizontal direc-

modular ratio b = l

d effective depth tion of walls of rectangular or square

Es

J M N αe

Ec

tanks), a need for calculating design

e eccentricity K= O crack widths for this case exists. The

T

L P ε1 strain at level considered ignoring Technical Report proposes a method for

Ec modulus of elasticity of concrete (1/2 the stiffening effect of concrete calculating the design crack widths, w1

the instantaneous value when used ε11 strain at face 1 ignoring stiffening and w2, at the two faces of a section

to determine αe) effect of concrete under these loadings.

18|The Structural Engineer – 17 September 2002

technical report: crack widths

Fig 1. The effective strain reduction at any

Stiffening effect of level in the section, therefore, is:

concrete in flexure

2bt h

f2 = ....(6)

3Es As

Similarly, it can be shown that the

value of the tensile stress at the tension

face for a design crack width of 0.1mm,

is taken as 1MPa.

Crack width formulae

The design crack width defined by eqn

(1) of BS 8007: Appendix B, is:

3acr f m

w= ....(7)

1 + 2c m

acr - cmin

h-x

BS 8007 approach bt (h - x)

In a section under direct tension,

The procedure for the calculation of Df s = ....(2) the value of the depth of the neutral

3Es As

design crack widths given in Appendix axis is x = –∞ or x = ∞. By substituting

B of BS 8007 can be summarised as The average value of the steel strain, these values in eqn (7) the design

follows: therefore, is: crack width for a section under direct

tension is:

bt (h - x)

• calculate the average strain in the f sm = f s - ....(3)

3Es As

section at the level where cracking is w = 3acr f m ....(8)

being considered allowing for the The average value of the strain at a

stiffening effect of the uncracked distance al from the compression face, Since this is the same as eqn (4) of BS

concrete between cracks where the crack width is to be calcu- 8007: Appendix B, it can, therefore, be

• calculate the design crack width lated, is: assumed that eqn (7) will also apply to

using this value of the strain. the case of combined flexure and direct

(al- x) f sm

fm = tension.

The average steel strain may, as an ad - xk

approximation, be determined by calcu- Combined flexure and direct

lating the steel stress on the basis of a

(al- x) f s b t a h - x k a al- x k tension

cracked section, and reducing this by the = - ...(4) The procedure for calculating the design

tensile force due to tension stiffening in ad - xk 3E s A s a d - x k crack width for sections under combined

the concrete (BS 8110: Part 24 Clause flexure and tension, can be summarised

3.8.3, Assessment of crack widths). =f1 - f 2 as follows:

By considering the cracked concrete bt a h - x k a al- x k

section in flexure as shown in Fig 1 (See where f2 = • determine the position of the neutral

BS 8110: Part 2 Fig 3.1), Eqn (2) of BS 3Es As a d - x k axis in the cracked section, x

8007: Appendix B, which defines the • determine the strain due to tension

stiffening effect of the concrete for a Similarly, by considering the cracked stiffening of concrete between cracks,

design crack width of 0.2mm, can be concrete section in direct tension as ε2

derived as follows5. shown in Fig 2, Eqn (5) of BS 8007: • determine the average strain at the

The value of the tensile stress at the Appendix B for the stiffening effect of level where cracking is considered, εm

tension face between cracks is assumed concrete in direct tension for a design • determine the crack width according

as 2/3MPa. The stiffening force of the crack width of 0.2mm, can be derived as to eqn (7).

concrete in tension, therefore, is: follows:

The stiffening force of the concrete in Two cases can be considered:

bt (h - x)

Fstif = ....(1) tension is:

3

• Case 1: Complete section in tension

2

The effective strain reduction in the Fstif = bt h ....(5) • Case 2: Section partially in compres-

3

steel is: sion.

Case 1: Complete section in tension

Determining the neutral axis depth

Consider the cracked concrete section

with a width, b, as shown in Fig 3. The

position of the neutral axis x, is defined

as negative when it is above face 2 of

the section, where face 2 is defined as

the side of the section under compres-

sion when the section is subjected to a

moment in an anti-clockwise direction.

The complete section would be in

tension when x ≤ 0 or x ≥ h. By consider-

ing horizontal and moment equilibrium,

and keeping in mind that x is negative

as shown in Fig 3(c), the position of the

Fig 2. neutral axis, x, is2:

Section in direct

tension (See panel at end) ....(9)

17 September 2002 – The Structural Engineer|19

technical report: crack widths

From equation 9 the following equa- Fig 3.

t1 t1

tions can be derived for the limits of x Case 1 – Complete When t 2 = - K , x = –∞ or x = ∞ the depth of the neutral axis, and t 2 , is

as indicated: section in tension shown in Fig 4.

t1 When none of the above applies,

a2

For x # 0: $ - k1 K where k1 = 0 < x < h. Determining the stiffening force

t2 h - a1

The equations for steel stresses are: Consider a section with width, b, as

....(10) M + T _ 0.5h - a2 i shown in Fig 5(a), with the neutral

and

c e + 2h - a2 m Fig 4. (Below)

Relationship

f s1 =

bht 1 _ h - a1 - a2 i

....(14) axis position at x ≤ 0. The maximum

stiffening tensile stress in the

K= ....(11) between x and concrete is:

c e - 2h + a1 m ρ1/ρ2 f s2 = t12 d T - t 1 f s1 n

bh

....(15)

Fig 5. (Bottom) f stif1 = 2 3 MPa for w = 0.2mm, and

Stiffening effect of Consider for example a concrete

t1

For x = ∞ or x = –∞: t 2 = - K ....(12) concrete, section, with b = 1000mm, h = 400mm, f stif1 =1MPa for w = 0.lmm ....(16)

complete section a1 = 50mm, a2 = 60mm, M = 10kNm and

t1

For x ≥ h: t 2 # - k 2 K in tension T = 400kN. The relationship between Since x is negative, it follows from the

figure that:

h - a2

where k 2 = a1 ....(13) _- xi

f stif2 = f stif1 ....(17)

When the eccentricity of the tension _h - xi

force coincides with the centroid of the The total stiffening force is:

reinforcement at face 1, ie when the

Fstif = e o bh

fstif1 + fstif2

denominator of eq 11 equals 0, it can be ....(18)

2

shown that the section is partially in

compression. The equations in the The centroid of the stiffening force is

following section should then be used to at:

determine x. h _ 2f stif1 + f stif2 i

In summary, provided that: x l= ....(19)

3 _ f stif1 + f stif2 i

e ≠ (h/2) – a1 Taking moments about the steel in

face 2 yields:

t1

When - k1 K # t 2 < - K , –∞ < x ≤ 0

Fstif1 = Fstif d n

x l- a2

....(20)

h - a1 - a2

When - K < t 1 # - k 2 K , h≤x<∞

t2

From horizontal equilibrium:

20|The Structural Engineer – 17 September 2002

technical report: crack widths

Fig 6. and moment equilibrium, the position of

Case 2 – Section the neutral axis x, can be found from

partially in the following equation2 by using trial

compression and error or computer methods:

(See panel at end) ....(34)

where n1 = x/h and e = M/T.

The concrete stress, fc, can be deter-

mined from eqn (35)

(See panel at end) ....(35)

The equations for steel stresses, are:

f s1 = - a e h - xx - a1 f c ....(36)

Fstif2 = Fstif - Fstif1 ....(21) a2 _ f s1 - f s2 i

f 12 = f s2 - ....(29) f s2 = a e x -x a2 f c ....(37)

When the neutral axis position is at x _ h - a1 - a2 i

≥ h (Fig 5(b)): Therefore, according to BS 8007 Determining the stiffening force

Clause B3, the average strains are as As shown in Fig 7, the maximum stiff-

f stif2 = 2 3 MPa for w = 0.2mm, and follows: ening tensile stress in the concrete is:

....(22)

f stif2 =1MPa for w = 0.1mm At face l: εm1 = ε11– ε21 ....(30) f stif1 = 2 MPa for w = 0.2mm, and

3

At face 2: εm2 = ε12– ε22 ....(31)

f stif1 = f stif2 x -

x

h ....(23) f stif1 =1MPa for w = 0.lmm ....(38)

Determining the design surface crack

As previously, the total stiffening width When 0 < x <a2:

force is as given in eqn (18), the The total stiffening force is:

3a cr f m

centroid of the stiffening force as in When x # 0: w = ....(32)

2 _ a cr - c min i

eqn (19), and the values of Fstif1 and Fstif2 1+ Fstif = 1 fstif1 _ h - x i b ....(39)

_h - xi

2

as in equations (20) and (21) respec-

tively. When x ≥ h, this equation has to be The centroid of the stiffening force is

modified by replacing (h – x) in the at:

Determining the average strain denominator by x. Therefore:

The effective reduction in strain in the x l= x + 2h ....(40)

3a cr f m 3

reinforcement due to the stiffening when x $ h: w = ....(33)

2 _ a cr - c min i

effect of the concrete is: 1+ Taking moments about the reinforce-

x

ment in face 2 yields:

Fstif1

Df s1 = , and ....(24) By substituting the values for εm1 or

E s A s1

Fstif1 = Fstif d n

x l- a2

εm2 in these eqns, the values of the ....(41)

Fstif2 h - a1 - a2

Df s2 = ....(25) design crack widths, w1 and w2 at faces

E s A s2

1 and 2 respectively, can be calculated. From horizontal equilibrium:

The effective reduction in strain at It should be noted that when A2 << A1,

the faces of the section is: w2 can actually be larger than w1, even Fstif2 = Fstif - Fstif1 ....(42)

a1 _ Df s2 - Df s1 i if the bending moment is applied in an

f 21 = Df s1 - ....(26) anti-clockwise direction as shown in Fig When a2 ≤ x < h:

_ h - a1 - a2 i 5. The complete stiffening force acts on

a2 _ Df s2 - Df s1 i the reinforcement in face 1 as in the

f 22 = Df s2 + ....(27) Case 2: Section partially in case of flexure only. Therefore,

_ h - a1 - a2 i compression

The strain in the concrete at the Determining the neutral axis position Fstif1 = 1 f stif1 _ h - x i b ....(43)

2

faces, ignoring the stiffening effect, Consider a cracked section with a

is: width, b, which is partially under b _h - xi

a1 _ f s1 - f s2 i compression, as shown in Fig 6. Define =

3

for w = 0.2mm, and

f 11 = f s1 + ....(28) fc and fs2 as negative to indicate

_ h - a1 - a2 i compression. By considering horizontal b _h - xi

= for w = 0.1mm

2

Determining the average strain

When 0<x<a2:

The effective reduction in strain in

the reinforcement due to the stiffening

effect of the concrete is:

Fstif1

Df s1 = ....(44)

E s A s1

Fstif2

Df s2 = ....(45)

E s A s2

Fig 7. Due to the section being partially in

Stiffening effect of compression, cracks can form only in

concrete, section face 1 and the crack width in face 2

partially in need not be calculated. The effective

compression reduction in strain at face 1 is:

17 September 2002 – The Structural Engineer|21

technical report: crack widths

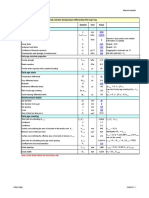

a1 _ Dfs1 - Dfs2 i Table 2: Surface crack width examples direct tension.

f21 = Dfs1 + ....(46) 2. The equations for the stiffening effect

_ h - a1 - a2 i Parameter Example

of concrete in flexure and in direct

1 2 3

The strain in the concrete at face 1, Case x<o x>h o<x<h tension given in BS 8007: Appendix B

ignoring the stiffening effect, is: a1 mm 48 48 48 can be derived from first principles by

a1 _ f s1 - f s2 i a2 mm 55 46 46 assuming the maximum stiffening

f 11 = f s1 + ....(47) tensile stress of the concrete between

_ h - a1 - a2 i

As1 T16@125mm T16@150mm T16@150mm

As2 T1O@150mm T12@150mm T12@150mm cracks as 1MPa and 2/3MPa for design

Therefore, according to BS 8007 M kNm 30 10 63 crack widths of 0.1mm and 0.2mm

Clause B3, the average strain at face 1 T kN 400 525 60 respectively. It can, therefore, be

is: ρ1/ρ2 3.07 1.78 1.78 assumed that the same principles apply

f m1 = f 11 - f 21 ....(48) –k1K 1.37 0.27 –0.22 to the case of combined flexure and

–K 6.30 1.48 –1.22 direct tension.

When a2 ≤ x < h: –k2K 32.14 7.85 –6.44 3. Two cases exist for a section

The effective reduction in strain in x mm –132.7 1289.9 72.2 subjected to combined flexure and direct

the reinforcement due to the stiffening w1 mm 0.188 0.200 0.199 tension, i.e.

effect of the concrete is: w2 mm1 –0.042 0.177 • complete section is in tension

f stif1 b _ h - x i [ b = 1000mm; h = 300mm; fy = 460MPa; Es = 200GPa; Ec = 27GPa ]

1

Negative value indicates that face is uncracked

• section is partially in compression.

Df s1 = ....(49) Equations to determine the neutral axis

2E s A s1

depth, x, for both these cases have been

The average value of the steel strain, Table 1 indicates how the values of given.

therefore, is: the design crack width at the two faces 4. The proposed method enables the

f stif1 b _ h - x i of the section vary with different config- designer to check design crack widths

f sm1 = f s1 - ....(50) urations of flexure and direct tension. It for different configurations of reinforce-

2E s A s1

shows a smooth transition in the values ment and concrete cover in the two

The average value of the strain at of design surface crack widths from faces of a section, resulting in a more

face 1 is: direct tension to combined direct economical design.

_ h - x i f sm1 tension and flexure, and from flexure to 5. Although the method involves some-

f m1 = combined flexure and direct tension. what cumbersome mathematics, the

_ h - a1 - x i

_ h - x i f s1 f stif1 b _ h - x i equations are easily programmable in

2

= - .(51) Examples spreadsheet programmes like Corel

_ h - a1 - x i 2E s A s1 _ h - a1 - x i Examples of sections checked for design Quattro Pro, Microsoft Excel etc, or in

= f 11 - f 21 surface crack widths of 0.2mm are given Mathcad.

b _h - xi in Table 2.

2

where f 21 = Acknowledgement

3E s A s1 _ h - a1 - x i

Conclusions The author thanks Robert Anchor for

for w = 0.2mm, and 1. It has been shown that the expression his assistance in the development of

b _h - xi for design crack widths in flexure as given this method, both in discussions and by

2

= in Equation (1) of BS 8007: Appendix B, correspondence which stretched over a

2E s A s1 _ h - a1 - x i

also applies to the case of direct tension. It number of years. Without his help this

for w = 0.1mm can, therefore, be assumed that it will also Technical Report would not have been

The equations for flexure in BS 8007, apply to the case of combined flexure and possible. se

therefore, applies directly to this case.

Determining the design surface crack Equations panel

width

_ h - a 1i c e - m + a 2 c e + 2h - a 2 m

In both cases, ie when 0 < x < a2 and a2 t1 h

<x < h the crack width at face 1 can be + a1

t2 2

determined as before from eqn 7. x= ....(9)

ce - 2 m + ce + 2 - a 2m

t1 h h

+ a1

Transition t2

Consider a section with the following

characteristics:

b = 1000mm; h = 350mm; c1=c2 =40mm n1 d 3 - 2n1 + 6e n + 6t2 _ ae - 1i d n1 - a2 n d1 - 2a2 + 2e n + 6t1 ae d1 - a1 - n1 n d1 - 2a1 - 2e n = 0

2

As1: T16 @ 150mm; As2: T16 @ 150mm; h h h h h h h ....(34)

fy = 460MPa; fcu = 35MPa.

The service moment and service

_ e id x n bh e d

x n bh

T = x + a - 1 1 - a2 As2 - a h - 1 - a1 As1

tension capacities of the section for a fc bh 2h x ....(35)

design surface crack width of 0.2mm,

are: Ms = 87.8kNm and Ts = 675kN.

Table 1: Design surface crack widths

for different configurations of flexure REFERENCES

and direct tension

T M x w1 w2 1. BS 8007: Design of concrete structures for retaining acqueous liquids, London, British

[kN] [kNm] [mm] [mm] [mm] Standards Institution, 1987

675 0 –∞ 0.200 0.200 2. Anchor, R. D.: Design of liquid retaining concrete structures, (2nd ed.), London,

675 1 –10712.1 0.204 0.196 Edward Arnold, 1992, pp 45 – 52

675 5 –2002.4 0.218 0.180 3. Batty, I., Westbrook, R.: The design of water-retaining structures, Harlow, Longman

675 10 –913.7 0.236 0.161 Scientific and Technical, 1991, pp 58 – 60

20 87.8 83.0 0.208 – 4. BS 8110 Structural use of concrete: Part 2: Code of practice for special circumstances,

5 87.8 84.6 0.202 – London, British Standards Institution, 1985, pp 3/2 – 3/4, 3/6 – 3/7

1 87.8 85.0 0.200 – 5. Rowe, R. E. et al: Handbook to British Standard BS 8110:1985 Structural use of

0 87.8 85.1 0.200 – concrete, Sussex, Palladian Publications Ltd, 1987, p 179

22|The Structural Engineer – 17 September 2002

verulam

Queries,

Q comments,

correspondence,

and curiosities…

tion to location in a structure, thus based.) sections for columns is inefficient.

Codes of practice showing that the use of partial This covers the general format S.H.S., R.H.S. and C.H.S. sections

safety factors negates the objective of the current codes. However there should be used, with built up or

I have received a lengthy letter of structural analysis which is to are also specific mistakes in the fabricated box section columns for

from Mr S. L. Hammond of calculate accurately the distribu- individual codes. I will try and heavier loads. With these type of

Whitstable, Kent who has tion of forces in a structure due to briefly list some of the worst errors sections the treatment and formu-

given much thought to the use a given set of loads. that I have come across in each of lae given in Chapter 1 of

of partial safety factors in Investigation of the statistical the codes: Timoshenko and Gere, ‘Beam

Codes of Practice and the basis of the ‘partial factors’ also columns’ can be applied.

design principles on which the reveals faulty mathematics. We are BS 8110: To achieve the stress As far as existing structures go,

codes are based. For the sake told that the partial factors are set distribution assumed in the section the most appropriate form of reme-

of comprehension Mr according to the degree of risk of design for beams, a considerable dial work to the columns is to weld

Hammond’s letter is published the particular type of load exceed- amount of deflection must occur, plates across the toes of the flanges,

in full. He writes: ing the factored load (whether any sufficient to lead to a rearrange- thus transforming the open section

proper assessment of real loads has ment of forces in the structure, and into a closed section and avoiding

When I entered the field of struc- ever been carried out we are not possible collapse. Certainly the the problem of torsional instability.

tural engineering the new design told). Thus for the dead load we rotations required to develop the

codes BS 8110 and BS 5950 were assume that, say, 99% of the dead design stresses in the beam negate BS 5400: Generally the same

coming into use, since then I have loads will be less than or equal to any question of elastic analysis, comments as BS 5950 apply, with

used these codes along with the 1.4 times the calculated dead load, although the code assumes an the added observation that the

masonry code which is in a similar and for the live load, 99% of the elastic distribution of forces in ratios between dead and live loads

format. As an engineer I have tried actual live loads will be less than or subframe analysis. vary more in a bridge structure

to make sense of these publications equal to 1.6 times the calculated than building structures, and

and understand the theoretical live load. Thus the actual probabil- Column design: as far as I have therefore the actual factors of

basis of the design rules. ity that the calculated factored load been able to find out (Kong and safety vary more greatly across the

Unfortunately the more closely will be exceeded depends on a Evans) the design of column structure.

these documents are examined, the combination of probabilities that sections also assumes yield in the

less sense they make from the varies with the proportion of dead steel and failure in the concrete. BS 5628: Apart from the format of

point of view of basic physical laws to live load (as the factors of safety This involves the structure in partial safety factors the method

and mathematics. are not equal). In fact the highest further contortions in order that it given for the design of elements

All these codes, and the new probability of failure occurs when may achieve the assumptions on under vertical load is wrong. The

‘Eurocodes’, make use of so called the load is all of one type (dead or which the section design is based. capacity of masonry walls and

‘partial safety factors’ in order to live load), and the minimum prob- No account is taken of elastic insta- columns is dependent on the elastic

calculate the design loads acting on ability of failure occurs when the bility or deflection of the column. properties of the masonry as well

the structure, or a particular two loads are approximately equal. The same remarks apply to the as its crushing strength. No

section of a member, the idea being –There is an appreciable difference design of concrete walls. account is taken of this.

that the various ‘partial factors’ in the probabilities of the order of a

represent different risks of the factor of 100, thus showing that the BS 5950: Allowing for the incorrect Mr Hammond says in his

calculated load being exceeded in stated objective of providing a format of safety factors the beam covering note that his

the actual structure. consistent probability of the struc- design appears to be adequate and conclusions are based on

Take the following example of a ture not failing is not met. The cover more design situations than sound mathematical

simply supported beam loaded introduction of further partial previous codes. However, the reasoning and that not only is

with a variety of non-uniform factors such as for wind load only column design is based upon he alarmed by the inadequacy

imposed and dead loads, these serves to complicate the statistics inelastic buckling, which for open of the current codes but by the

different types of load having even more. sections such as channels and H fact that they do not offer an

different partial factors applied to (As an elementary example of section columns is inadequate. adequate means of assessing

them. Then calculate the design the probability of combined events Examination of Timoshenko & existing structures for

(factored) moments and shears for consider the probability of throw- Gere’s Theory of elastic stability strength. Is there support for

the beam, and the actual (non ing two sixes in succession with a shows that the stability of open Mr Hammond’s conclusions

factored) moments and shears in dice, the probability is one in section columns is treated in among the membership? If so

the beam. Unless both types of load thirty-six as opposed to one in six Chapter 5 ‘Torsional buckling’ and please write in.

are applied in an identical way, the for a single six. Loads are continu- that for the commonly used H-

ratio (factor of safety) between ous variables and the probabilities section, failure occurs in a

actual and design forces will vary that the load will exceed the total combined torsional and lateral Promoting the profession

from location to location in the factored load varies with the ratio buckling mode. (This is not to be

beam. In the same way a calculated of the loads, but unless there is confused with the torsional buck- Andrew Sandford has sent in

example will show that the ratio only one type of load, the probabil- ling of beams). No account is taken this letter after reading the

between the calculated design ity of exceedance bears no rela- of this in allowable stresses for interview with Professor

loads and the actual loads acting tionship to the probabilities on columns either in BS 449 or BS David Blockley which

on a structure will vary from loca- which the partial factors are 5950. In any case the use of open appeared in NCE 8-15 August.

17 September 2002 – The Structural Engineer|23

S-ar putea să vă placă și

- Improved Crack Width Calculation Method To BS 8007 For Combined Flexure and Direct Tension 2005Document3 paginiImproved Crack Width Calculation Method To BS 8007 For Combined Flexure and Direct Tension 2005BinSayeedÎncă nu există evaluări

- Crack Width Analysis Software VerificationDocument8 paginiCrack Width Analysis Software VerificationSuhail Ahamed100% (1)

- Holding Down Bolts To BS 8110-1Document5 paginiHolding Down Bolts To BS 8110-1Elias MinaÎncă nu există evaluări

- Conc. Folded SlabDocument17 paginiConc. Folded SlabBenedict CharlesÎncă nu există evaluări

- Design For Shear (Columns BS 8110)Document2 paginiDesign For Shear (Columns BS 8110)dhanya1995Încă nu există evaluări

- MASONRY CANTILEVER RETAINING WALL DESIGNDocument7 paginiMASONRY CANTILEVER RETAINING WALL DESIGNDerek AngÎncă nu există evaluări

- Design For Early Thermal CrackingDocument10 paginiDesign For Early Thermal Crackingdhruvgoku100% (1)

- Crack control of internal restraint in Pile Cap TopDocument5 paginiCrack control of internal restraint in Pile Cap TopSravanthi Mehar100% (1)

- Early Thermal Cracking ConcreteDocument13 paginiEarly Thermal Cracking ConcreteOttawa Canada100% (2)

- Design For 11early Thermal CrackingDocument9 paginiDesign For 11early Thermal CrackingdhruvgokuÎncă nu există evaluări

- Egcostud design according to BS 8110Document1 paginăEgcostud design according to BS 8110MohammedÎncă nu există evaluări

- Confirmed parapet thickness for impact speedsDocument56 paginiConfirmed parapet thickness for impact speedsVicky Munien100% (3)

- Crack Width BS 8110Document2 paginiCrack Width BS 8110nhulugallaÎncă nu există evaluări

- THERMAL CRACK CHECK FOR BD 28/87Document1 paginăTHERMAL CRACK CHECK FOR BD 28/87lakshmi1011Încă nu există evaluări

- Arup Strengthening of Concrete Framed BuidlingsDocument14 paginiArup Strengthening of Concrete Framed Buidlingsmgonelli14Încă nu există evaluări

- H.F.C.Post Tension Design Criteria (BS)Document9 paginiH.F.C.Post Tension Design Criteria (BS)Ayman Badr100% (2)

- Wall Design 01Document20 paginiWall Design 01cloud652167% (3)

- Crack Width Calculation BS 8100 BS 8007Document2 paginiCrack Width Calculation BS 8100 BS 8007abdul khader100% (3)

- Bs 8110 Punching ShearDocument1 paginăBs 8110 Punching Shearhidayat665287Încă nu există evaluări

- 2 3 2 PD6694 1Document17 pagini2 3 2 PD6694 1hellios8502Încă nu există evaluări

- Design As Per BS 8110Document35 paginiDesign As Per BS 8110Cibin Britto AntonyÎncă nu există evaluări

- Guide to IS 3370 Part 1 & 2 liquid storage codeDocument25 paginiGuide to IS 3370 Part 1 & 2 liquid storage codeRajesh KumarÎncă nu există evaluări

- 02-Dr Ooi-Design of Jacked-In Piles & Case Studies in SingaporeDocument39 pagini02-Dr Ooi-Design of Jacked-In Piles & Case Studies in SingaporefreezefreezeÎncă nu există evaluări

- Calculation of Strut StiffnessDocument1 paginăCalculation of Strut Stiffnesskeroro18Încă nu există evaluări

- PD Comparison of BS 8110 With en 1992Document40 paginiPD Comparison of BS 8110 With en 1992Paul Devine100% (1)

- BS5950 Load CasesDocument46 paginiBS5950 Load CasesthespecifierÎncă nu există evaluări

- Diaphargm Wall DesignDocument24 paginiDiaphargm Wall Designsurajoffshore75% (4)

- Crack Width Evaluation For Flexural RC MembersDocument10 paginiCrack Width Evaluation For Flexural RC MembersAly AnisÎncă nu există evaluări

- Reinforced Concrete Column by ZinabDocument15 paginiReinforced Concrete Column by Zinabasdlibya100% (2)

- Column Design EC2Document41 paginiColumn Design EC2Azrai AzizÎncă nu există evaluări

- RC Beam Torsion Design (BS8110)Document2 paginiRC Beam Torsion Design (BS8110)Osarieme Osakue100% (3)

- Holding Down Bolts To Eurocode 2Document5 paginiHolding Down Bolts To Eurocode 2Elias MinaÎncă nu există evaluări

- Crack Width Calculation BS 8110 FormulaDocument1 paginăCrack Width Calculation BS 8110 Formulamvap2856Încă nu există evaluări

- BS 8500 Cement Concrete RequirementsDocument2 paginiBS 8500 Cement Concrete RequirementsLava Sat100% (2)

- Designing A Concrete Beam: Icon LegendDocument5 paginiDesigning A Concrete Beam: Icon LegendNitish TakalkarÎncă nu există evaluări

- Pipe Strut Vs Laced Strut - CSPDocument39 paginiPipe Strut Vs Laced Strut - CSPAnonymous hhdd4mOmOh100% (1)

- Design of Water Retaining Structures To ECDocument44 paginiDesign of Water Retaining Structures To ECVincent Teng100% (4)

- 11 Ehe08 PDFDocument7 pagini11 Ehe08 PDFDagoberto PereiraÎncă nu există evaluări

- Allowable Stress Design of Concrete MasonryDocument6 paginiAllowable Stress Design of Concrete Masonrying_fernandogalvez2015Încă nu există evaluări

- Ncma Tek: Allowable Stress Design of Concrete Masonry TEK 14-7ADocument6 paginiNcma Tek: Allowable Stress Design of Concrete Masonry TEK 14-7AEmad KhanÎncă nu există evaluări

- Calculation of Crack Width and Crack Spacing: Ingemar - Lofgren@tcg - NuDocument12 paginiCalculation of Crack Width and Crack Spacing: Ingemar - Lofgren@tcg - NuSmit KotakÎncă nu există evaluări

- Resistance and Stiffness of Concrete in CompDocument15 paginiResistance and Stiffness of Concrete in CompMurat AcarÎncă nu există evaluări

- ANALYSIS OF SECTIONS AND STRESS-STRAIN RELATIONSHIPSDocument18 paginiANALYSIS OF SECTIONS AND STRESS-STRAIN RELATIONSHIPSisaacssebulibaÎncă nu există evaluări

- 028 CCC 2014 NavratilDocument6 pagini028 CCC 2014 NavratilkstayroskÎncă nu există evaluări

- Concrete Crack Width MeasurementDocument6 paginiConcrete Crack Width MeasurementcedaserdnaÎncă nu există evaluări

- ASD Analysis in Beams (Old Way)Document13 paginiASD Analysis in Beams (Old Way)Bry RamosÎncă nu există evaluări

- Effect of Lap Splices On Flexural Resistance and Cyclic Deformation Capacity of RC MembersDocument9 paginiEffect of Lap Splices On Flexural Resistance and Cyclic Deformation Capacity of RC Membershasan aziziÎncă nu există evaluări

- Lec-5-Flexural Analysis and Design of BeamnsDocument17 paginiLec-5-Flexural Analysis and Design of Beamnskashifsaeed52Încă nu există evaluări

- C-Balok Tul. TunggalDocument36 paginiC-Balok Tul. TunggalDita LestariÎncă nu există evaluări

- Non-Linear Mechanics of Reinforced Concrete - (2 Two-Dimensional Analysis of Reinforced Concrete)Document112 paginiNon-Linear Mechanics of Reinforced Concrete - (2 Two-Dimensional Analysis of Reinforced Concrete)Alejandro SerratoÎncă nu există evaluări

- TCE E Consul Lting Eng Gineers L Limited: Design Nofstr AS Ructural Per Is: 8 L Steel E 00-2007 Element TSDocument1 paginăTCE E Consul Lting Eng Gineers L Limited: Design Nofstr AS Ructural Per Is: 8 L Steel E 00-2007 Element TSNeeraj DubeyÎncă nu există evaluări

- 34 Design of Joints With Variable LoadingDocument8 pagini34 Design of Joints With Variable LoadingPRASAD326100% (1)

- Toniolo-DiPrisco2017 Chapter CentredAxialForceDocument85 paginiToniolo-DiPrisco2017 Chapter CentredAxialForceÉnio Elias Gonçalves NtambalicaÎncă nu există evaluări

- 028 CCC 2014 NavratilDocument7 pagini028 CCC 2014 NavratilBogdanBÎncă nu există evaluări

- Ultimate Limit States Design: Article 41. Equilibrium Limit StateDocument35 paginiUltimate Limit States Design: Article 41. Equilibrium Limit StateAyad TalibÎncă nu există evaluări

- Nonlinear Finite Element Analysis of Composite Concrete BeamsDocument16 paginiNonlinear Finite Element Analysis of Composite Concrete BeamsMhnd Al-SherrawiÎncă nu există evaluări

- Design of RC Membrane ElementsDocument11 paginiDesign of RC Membrane ElementsRodain NajjarÎncă nu există evaluări

- Shear Peeling of Steel Plates Adhesively Bonded To The Sides of Reinforced Concrete BeamsDocument11 paginiShear Peeling of Steel Plates Adhesively Bonded To The Sides of Reinforced Concrete BeamsAbualtayef KhalilÎncă nu există evaluări

- Steel Design LRFD GuideDocument5 paginiSteel Design LRFD GuidesokainaÎncă nu există evaluări

- Flexural Analysis and Design of Beamns 1Document17 paginiFlexural Analysis and Design of Beamns 1Adil Javed ChaudharyÎncă nu există evaluări

- BS 6031-2009 FOS For Slope StabilityDocument5 paginiBS 6031-2009 FOS For Slope StabilityBinSayeedÎncă nu există evaluări

- Slope Stabilisation and Soil Nailing With TITAN MicropilesDocument20 paginiSlope Stabilisation and Soil Nailing With TITAN MicropilesThanh Tam Nguyen100% (1)

- Fosroc Nitoprime Zincrich Plus: Declaration of PerformanceDocument2 paginiFosroc Nitoprime Zincrich Plus: Declaration of PerformanceBinSayeedÎncă nu există evaluări

- Rock Socketted Piles Chris HaberfieldDocument54 paginiRock Socketted Piles Chris HaberfieldBinSayeedÎncă nu există evaluări

- Pile Skin Friction Correlation From UCS Based On Test Piles Back Analysis For Dubai, UAEDocument28 paginiPile Skin Friction Correlation From UCS Based On Test Piles Back Analysis For Dubai, UAEBinSayeedÎncă nu există evaluări

- Nitoprime Zincrich PlusDocument2 paginiNitoprime Zincrich PlusBinSayeedÎncă nu există evaluări

- Tomorrow's Geotechnical Toolbox EN 1997-1-202x - General RulesDocument9 paginiTomorrow's Geotechnical Toolbox EN 1997-1-202x - General RulesBinSayeedÎncă nu există evaluări

- ACI - Crack CalculationsDocument3 paginiACI - Crack CalculationsLuis Ariel B. MorilloÎncă nu există evaluări

- Tomorrow's Geotechnical Toolbox EN 1997-3-202x - Geotechnical StructuresDocument9 paginiTomorrow's Geotechnical Toolbox EN 1997-3-202x - Geotechnical StructuresBinSayeedÎncă nu există evaluări

- BS 8002 Design Situations and CalculationsDocument1 paginăBS 8002 Design Situations and CalculationsBinSayeedÎncă nu există evaluări

- BS 8002 Retaining Wall Design ConsiderationsDocument1 paginăBS 8002 Retaining Wall Design ConsiderationsBinSayeedÎncă nu există evaluări

- Final - Report - Part - 2 Breakwater EngineeringDocument76 paginiFinal - Report - Part - 2 Breakwater EngineeringBinSayeedÎncă nu există evaluări

- Finite Element Analysis of A Deep Excavation in Kenny Hill Formation 2018Document7 paginiFinite Element Analysis of A Deep Excavation in Kenny Hill Formation 2018BinSayeedÎncă nu există evaluări

- Case History of Osterberg Cell Testing of A 1500mm Bored Pile and The Interpretation of The Strain Measurements For Princess TowerDocument9 paginiCase History of Osterberg Cell Testing of A 1500mm Bored Pile and The Interpretation of The Strain Measurements For Princess TowerBinSayeedÎncă nu există evaluări

- DEVELOPING A CAVITY PROBABILITY MAP FOR ABU DHABI USING GISDocument12 paginiDEVELOPING A CAVITY PROBABILITY MAP FOR ABU DHABI USING GISBinSayeedÎncă nu există evaluări

- Drilled Micropiles - Design and Practice in FranceDocument51 paginiDrilled Micropiles - Design and Practice in FranceHyunkyoun JinÎncă nu există evaluări

- Osterberg Test As An Alternative Pile Testing MethodDocument6 paginiOsterberg Test As An Alternative Pile Testing MethodBinSayeedÎncă nu există evaluări

- Challenges in Construction Over Soft Soil - Case Studies in MalaysiaDocument9 paginiChallenges in Construction Over Soft Soil - Case Studies in MalaysiamaizansofiaÎncă nu există evaluări

- ICP Brochure Technical Specs January 2019 HR PDFDocument16 paginiICP Brochure Technical Specs January 2019 HR PDFLavanyanÎncă nu există evaluări

- EC7 for Deep Foundations: Dragload Design and AnalysisDocument66 paginiEC7 for Deep Foundations: Dragload Design and AnalysisEmily ShumÎncă nu există evaluări

- Construction of Infrastructure On Peat Case StudieDocument7 paginiConstruction of Infrastructure On Peat Case StudieBinSayeedÎncă nu există evaluări

- Drilled Micropiles - Design and Practice in FranceDocument51 paginiDrilled Micropiles - Design and Practice in FranceHyunkyoun JinÎncă nu există evaluări

- Piles Through Soft Clay for a Metro ProjectDocument9 paginiPiles Through Soft Clay for a Metro ProjectBinSayeedÎncă nu există evaluări

- Finite Element Analysis of A Deep Excavation in Kenny Hill Formation 2018Document7 paginiFinite Element Analysis of A Deep Excavation in Kenny Hill Formation 2018BinSayeedÎncă nu există evaluări

- Tech Data - PF Alidrain AD230 - 250Document1 paginăTech Data - PF Alidrain AD230 - 250BinSayeed100% (1)

- Load Resistance Behaviour and Installation Assessment of Driven Spun Pile Vigneshwaran Karunanidee Universiti Teknologi MalaysiaDocument124 paginiLoad Resistance Behaviour and Installation Assessment of Driven Spun Pile Vigneshwaran Karunanidee Universiti Teknologi MalaysiaBinSayeedÎncă nu există evaluări

- Tencate Solutions For Soft Foundation ConsolidationDocument8 paginiTencate Solutions For Soft Foundation ConsolidationBinSayeedÎncă nu există evaluări

- G&P-Design and Construction of Driven Piles Over Soft Marine Clay 2019Document4 paginiG&P-Design and Construction of Driven Piles Over Soft Marine Clay 2019BinSayeedÎncă nu există evaluări

- Challenges in Construction Over Soft Soil - Case Studies in MalaysiaDocument9 paginiChallenges in Construction Over Soft Soil - Case Studies in MalaysiaMike MikeÎncă nu există evaluări

- CPA-Karnaphuli River Tide Tables 2020Document76 paginiCPA-Karnaphuli River Tide Tables 2020BinSayeedÎncă nu există evaluări

- Scania 12-M SeriesDocument64 paginiScania 12-M Seriesw6r100% (1)

- Metrology Chapter 13Document70 paginiMetrology Chapter 13Sweekar KhadkaÎncă nu există evaluări

- As (One Touch)Document105 paginiAs (One Touch)carlos223344Încă nu există evaluări

- Powerplant Quizlet 492Document63 paginiPowerplant Quizlet 492Jecah Angelu S. SaquianÎncă nu există evaluări

- 3039exq Week 11 Session 1 Notes Example The Design of Slender RC ColumnsDocument8 pagini3039exq Week 11 Session 1 Notes Example The Design of Slender RC ColumnsengkjÎncă nu există evaluări

- Filters For Atlas CopcoDocument7 paginiFilters For Atlas Copcosuraj pandeyÎncă nu există evaluări

- Analysis of Water Hammering in Pipeline and Its CFD SimulationDocument6 paginiAnalysis of Water Hammering in Pipeline and Its CFD SimulationDuzzysÎncă nu există evaluări

- Mechanical Engineer Muhammad Ibtisam's ResumeDocument1 paginăMechanical Engineer Muhammad Ibtisam's ResumeshoaibÎncă nu există evaluări

- TRX2319 Crane Escorts Parts BookDocument383 paginiTRX2319 Crane Escorts Parts BookRaghavendra Mestha100% (5)

- Honda Gs390 Owners Manual (Powerwasher)Document60 paginiHonda Gs390 Owners Manual (Powerwasher)Nate SpaydÎncă nu există evaluări

- Properties of Fluids ExplainedDocument13 paginiProperties of Fluids ExplainedGie Andal0% (3)

- Ies 1997 - II ScanDocument21 paginiIes 1997 - II ScanK.v.SinghÎncă nu există evaluări

- CAT C13 2007 Service Bulletin (Cooling Sys, DPF, and Diagnostic Trouble Codes)Document34 paginiCAT C13 2007 Service Bulletin (Cooling Sys, DPF, and Diagnostic Trouble Codes)Jonathan Carlson100% (4)

- Bombas de Lodo Blackmer MODELS: MLX4B, MLXW4B, MRLX4B, MRLXW4BDocument4 paginiBombas de Lodo Blackmer MODELS: MLX4B, MLXW4B, MRLX4B, MRLXW4Bnardo_ingÎncă nu există evaluări

- Steel Sheet Pile CatalogueDocument80 paginiSteel Sheet Pile CatalogueBrian TanÎncă nu există evaluări

- 87 s10Document12 pagini87 s10carlosestayÎncă nu există evaluări

- Anexo 1 - Generac SG625-PG563 PDFDocument6 paginiAnexo 1 - Generac SG625-PG563 PDFJuly E. Maldonado M.Încă nu există evaluări

- Steam System Properties and Energy SavingsDocument34 paginiSteam System Properties and Energy SavingsArnav KothiyalÎncă nu există evaluări

- B&J Fuel InjectionDocument24 paginiB&J Fuel InjectionZeeshan Ahmad100% (1)

- Technology of Heat Treating-Straightening of Long Shafts With Low RigidityDocument8 paginiTechnology of Heat Treating-Straightening of Long Shafts With Low RigidityShariq KhanÎncă nu există evaluări

- Kinematics and Kinetics of RigidbodiesDocument190 paginiKinematics and Kinetics of RigidbodiesmadhurivelpulaÎncă nu există evaluări

- AVK Dams - Reservoirs - HydroPower BrochureDocument15 paginiAVK Dams - Reservoirs - HydroPower Brochureindra putraÎncă nu există evaluări

- Scope: TIP Category: Automatically Periodically Reviewed (Five-Year Review)Document138 paginiScope: TIP Category: Automatically Periodically Reviewed (Five-Year Review)Kirk RodriguezÎncă nu există evaluări

- Alexco - Co.nz T Slot Catalogue 07-2019Document5 paginiAlexco - Co.nz T Slot Catalogue 07-2019Sarah WoodÎncă nu există evaluări

- Bleed Air Manual Control Modes Task CardDocument34 paginiBleed Air Manual Control Modes Task CardTony GarrisonÎncă nu există evaluări

- Modes of Heat Transfer: O Q (Gate, Ies, Ias)Document7 paginiModes of Heat Transfer: O Q (Gate, Ies, Ias)ankitÎncă nu există evaluări

- Shankar DurgamDocument9 paginiShankar DurgamasdfÎncă nu există evaluări

- Park Brake Recall ActionDocument13 paginiPark Brake Recall Actionrobocop81Încă nu există evaluări

- CATDocument149 paginiCATSuat YamanÎncă nu există evaluări

- ENFLO 0110 Wind Turbine Data SheetDocument2 paginiENFLO 0110 Wind Turbine Data SheetCriss MereutaÎncă nu există evaluări