Documente Academic

Documente Profesional

Documente Cultură

Swaraj 735 Fe Tractor - T - 768-1276-2011

Încărcat de

Amit Chopra AmitTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Swaraj 735 Fe Tractor - T - 768-1276-2011

Încărcat de

Amit Chopra AmitDrepturi de autor:

Formate disponibile

T- 768/1276/2011 SWARAJ 735 FE TRACTOR – Commercial (Initial)

Manufacturer : M/s. Mahindara & Mahindra Ltd.

Swaraj Division, Phase-IV, Industrial

Area,S.A.S. Nagar ,

Distt. Mohali (Punjab)

Near Chandigarh-160 055

Month: May Test Report No. T- 768/1276/2011 Year : 2011

GOVERNMENT OF INDIA

CENTRAL FARM MACHINERY TRAINING & TESTING INSTITUTE

TRACTOR NAGAR, BUDNI (MADHYA PRADESH) 466445, INDIA

Email: fmti-mp@nic.in

Web site: dacnet.nic.in/cfmtti

Telephone: 07564-234729 FAX: 07564-234743

CENTRAL FARM MACHINERY TRAINING & TESTING INSTITUTE - BUDNI Page 1 of 13

T- 768/1276/2011 SWARAJ 735 FE TRACTOR – Commercial (Initial)

Type of Test : COMMERCIAL (INITIAL)

Test code/Procedure : IS: 5994-1998 (Reaffirmed in 2009),

IS: 9253-2001(Reaffirmed in 2007), and

IS: 12207-2008

Period of Test : July, 2010 to January, 2011

Test Report No. : T-768/1276/2011

Month/Year : May, 2011

i) The results reported in this report are observed values and no corrections have been

applied for atmospheric and site conditions.

ii) The data given in this report pertain to the particular machine submitted by the applicant

for test.

iii) The results presented in this report do not in any way attribute to the durability of the

machine.

iv) This report should not be reproduced in part or full without prior permission of the

Director, Central Farm Machinery Training and Testing Institute, Budni (M.P.).

v) This test report supersedes the following test reports on this tractor.

S. No. Make & Model of the tractor Nature of test Test report No.

1. Swaraj 735 FE Tractor Commercial (Initial) T-249/578, 1991

2. Swaraj 735 FE Tractor Commercial (Batch) T-298/662, 1994

3. Swaraj 735 FE Tractor Commercial (Batch) T-383/792, August,

1999

4. Swaraj 735 FE (8+2) Commercial (Initial) T-416/843, May, 2001

speed gearboxTractor

5. Swaraj 735 XM Commercial T-677/1183, June, 2009

(Variant)

SELECTED CONVERSIONS

SELECTED CONVERSIONS ABBREVIATIONS

S. No Units Conversion Factor

1 Force: As per applicant apa

1 kgf 9.80665 N Top Dead Centre TDC

2.20462 lbf Indian Standard IS

2 Power: Left Hand Side/ LHS/RHS

Right Hand Side

1 hp 1.01387metric hp (Ps) Mercury Hg.

745.7 W Temperature Temp.

1 Ps 735.5 W Not recorded N.R.

1 kW 1.35962 Ps Revolutions per minute rpm

3 Pressure: Outer diameter/ O.D/I.D

Inner diameter

1 psi 6.895 kPa Not available/ N.A.

Not applicable

2

1 kgf/cm 98.067 kPa = 735.56 Power take-off PTO

mm of Hg

2

1 bar 100 kPa = 10 N/cm Relative Humidity R.H.

1 mm of Hg 1.3332 m-bar

CENTRAL FARM MACHINERY TRAINING & TESTING INSTITUTE - BUDNI Page 2 of 13

T- 768/1276/2011 SWARAJ 735 FE TRACTOR – Commercial (Initial)

17. SUMMARY OF OBSERVATIONS, COMMENTS & RECOMMENDATIONS

17.1 Evaluative (mandatory) / Non-evaluation (Non-mandatory) parameter applicable for

qualifying Minimum Performance criteria as per Clause-4 (Table-1) of IS: 12207-2008 for

acceptance of the tractor for the purpose of subsidies/NABARD financing are

summarized as under:

Values Whether

Category Requirements declared by As meets

S. No. Characteristic (Evaluative as per IS: 12207-2008 the observed the

/ Non applicant(D)/ requirem

Evaluative) Requirement ents

(R) (Yes/No.)

1 2 3 4 5 6 7

17.1.1 PTO Performance :

a) - Maximum power Declared value to be

under 2 h test, Evaluative achieved with a 24.1(D) 24.3 Yes

(kW ) (Natural tolerance of: -5 / +10%

ambient condition) for PTO power >35hp.

–7.5/+10% for PTO

power 35 hp

b) Power at rated Non -do- 24.1(D) 24.3 Yes

engine speed, (kW) Evaluative

c) Specific fuel Non

consumption Evaluative 5% 258 (D) 245 Yes

corresponding to

maximum power,

(g/kWh)

d) Maximum Non

equivalent Evaluative 8% 150.0 (D) 158.5 Yes

crankshaft torque,

(Nm)

e) Back-up torque, Non 7 percent, min. 7 percent 22.9 Yes

percent Evaluative

O

f) Maximum operating temperature ( C):

1) Engine oil Non The declared value

Evaluative should not exceed the

max. value specified by

the oil company and the 130 (D) 121 Yes

observed value under

high ambient condition

should not exceed the

declaration.

2) Coolant Evaluative The declared value

(water) should not exceed the

boiling temperature of

coolant under the 115 (D) 106 Yes

pressurized or otherwise

and the observed value

under high ambient

condition should not

exceed the declaration.

g) Engine oil Evaluative Not exceeding 1% of

consumption, SFC at max. power 2.50 (R ) 0.32 Yes

(g/kWh) under High ambient

conditions

h) Smoke level Evaluative Maximum light

absorption coefficient 3.25 0.26 Yes

of 3.25 per metre or per meter per

equivalent BOSCH

meter

No. 5.2 or 75 Hatridge

value (As per CMVR)

CENTRAL FARM MACHINERY TRAINING & TESTING INSTITUTE - BUDNI Page 3 of 13

T- 768/1276/2011 SWARAJ 735 FE TRACTOR – Commercial (Initial)

1 2 3 4 5 6 7

17.1.2 Drawbar performance :

a) Max. drawbar pull Non Minimum 65% of

with ballast Evaluative static mass with 17.90 (D) 19.30 Yes

corresponding to ballast

15 percent wheel 16.80 (R)

slip, (kN)

b) Max. drawbar pull Evaluative Minimum 65% of

without ballast static mass of tractor 13.20 (D) 13.45 Yes

corresponding to without ballast 11.79 (R)

15 percent wheel

slip, (kN)

c) Maximum drawbar Evaluative Min. 80% of PTO

power without power as referred in 20.0 (D) 20.0 Yes

ballast (kW). 16.1.1 (a) of PTO 19.4 (R)

performance

d) Max. transmission Non The declared value

oil temperature Evaluative should not exceed the 115 78 Yes

o

( C) maximum value

specified by oil

company

17.1.3 Power lift and hydraulic pump performance :

a) Maximum lifting capacity throughout the range of lift, (kN):

1) At hitch Non [Tolerance of minus 8.83 (D) Yes

points Evaluative 10%] 11.94

2) With the Evaluative The lift capacity

standard should at least be 18 6.90 (D) Yes

frame kg/PTO hp. and it 5.75 (R)

should be 16

kg/engine hp where

9.28

the tractor is not

provided with a PTO

shaft

b) Maximum drop in Non 150 (D)

the height of the Evaluative [Tolerance of plus 25 Yes

point 0f application 5 mm] 50 (R)

of the force after

each 5 minutes

interval for a total

duration of 30

minute, (mm)

17.1.4 Brake performance at 25 kmph:

a) Maximum stopping distance at a force, equal to or less than 600 N on brake pedal with

road ballast, (m):

1) Cold brake Evaluative 10 10 (R) 6.60 Yes

2) Hot brake Evaluative 10 10 (R) 7.75 Yes

b) Maximum force Evaluative

exerted on the 600 600 (R) 355

brake pedal to to Yes

achieve a 390

deceleration of

2

2.5 m/s (N)

c) Whether parking

brake is effective Evaluative Yes Yes Yes Yes

at a force of 600

N at foot pedal(s)

or 400 N at hand

lever

CENTRAL FARM MACHINERY TRAINING & TESTING INSTITUTE - BUDNI Page 4 of 13

T- 768/1276/2011 SWARAJ 735 FE TRACTOR – Commercial (Initial)

1 2 3 4 5 6 7

17.1.5 Noise measurement :

a) Maximum ambient Evaluative As per CMVR 88 (R) 83 Yes

noise emitted by

the tractor dB(A)

b) Maximum noise at Evaluative As per CMVR 98 (R) 97 Yes

operator’s ear level

dB(A)

17.1.6 Amplitude of mechanical vibrations at :

1) Left foot rest 100 (R) 80 Yes

Right food rest 100 microns (max) 100 (R) 220 No

Non

2) Seat (with Evaluative 100 (R) 100 Yes

driver seated)

3) Steering wheel 100 (R) 140 No

17.1.7 Haulage requirements :

a) Gross mass of the trailers, (tones):

1) Two wheel Non -- 4.0 (D) 4.0 Yes

2) Four wheel Evaluative -- 5.5 (D) 5.5 Yes

b) Distance travelled / litre of fuel consumption, (km):

1) Two wheel -- 5.0 to 6.55 to Yes

Non 6.5 (D) 6.68

2) Four wheel Evaluative -- 5.0 to 6.24 to Yes

6.5 (D) 6.30

c) Fuel consumption (ml/km/tonne):

1) Two wheel -- 30 to 45 37.4 to Yes

Non (D) 38.2

2) Four wheel Evaluative -- 30 to 45 28.9 to Yes

(D) 29.1

17.1.8 Wetland cultivation :

Sealing for the Evaluative The identified

following assemblies should

assemblies: essentially meet the

requirement of IS: There No

1) Clutch -do-

assembly

11082. No water ingress should ingress

in the identified be no of mud Yes

2) Brake -do- assembly given in

column-2. ingress and / or

housings

If tractor does not meet of water water

3) Front axle -do-

the requirements of and/or was

hubs wetland cultivation, it mud (R) observed

may be recommended

for dry land operation

only.

17.1.9 Safety features :

a) Guards against Evaluative As per CMVR At present --- --

moving and hot no

parts require-

ments

b) Lighting Evaluative As per CMVR -- Provided Yes

arrangement

17.1.10 Labelling of tractors (Provision of labelling plate):

1) Make Evaluative Should conform to Swaraj Yes

2) Model Evaluative the requirements of 735 FE Yes

CMVR along-with

3) Year of Evaluative declared value of WQ (2010) Yes

manufacture PTO HP

4) Engine Evaluative 39.1350/SMD Yes

number 01552

CENTRAL FARM MACHINERY TRAINING & TESTING INSTITUTE - BUDNI Page 5 of 13

T- 768/1276/2011 SWARAJ 735 FE TRACTOR – Commercial (Initial)

1 2 3 4 5 6 7

5) Chassis Evaluative WQTF Yes

number 30605016088

6) Declaration Evaluative 24.1 Yes

of PTO

power, (kW)

17.1.11 Discard limit for:

(a) Cylinder bore Evaluative To be specified by 100.22 100.00 to Yes

diameter, (mm) the manufacturer 5 100.02

(b) Clearance between Non -do- 0.60 0.105 to Yes

piston & cylinder Evaluative 0.125

liner at skirt, (mm)

(c) Ring end gap (mm):

- Top comp. -do- 2.50 0.35 to 0.45 Yes

ring.

nd

- 2 comp. Evaluative -do- 2.50 0.25 to 0.55 Yes

ring.

- Oil ring. -do- 2.00 0.45 Yes

(d) Ring groove clearance (mm):

- Top comp. -do- 0.50 Tapper Yes

ring.

nd

- 2 comp. ring. -do- 0.50 0.047 to Yes

Evaluative

0.072

- Oil ring. -do- 0.15 0.035 to Yes

0.045

(e) Clearance of main bearings (mm):

- Diametrical 0.20 0.045 to Yes

clearance Evaluative -do-

0.105

- Crankshaft 0.50 0.25 Yes

Evaluative -do-

end float

(f) Clearance of big end bearings, (mm):

- Diametrical 0.20 0.043 to Yes

Evaluative -do-

0.129

- Axial Evaluative -do- 0.60 0.50 Yes

(g) Clearance Yes

Non

between king pin -do- 0.60 0.10 to 0.13

Evaluative

and bush, (mm)

(h) Clearance 0.80 0.10 to 0.11 Yes

between center Non

-- do--

pin and bush, Evaluative

(mm)

17.1.12 CATEGORY OF BREAKDOWNS / DEFECTS :

Category Whether

S. No. Characteristic (Evaluative / Requirements As meets the

Non as per IS: 12207-2008 observed requirements

Evaluative) (Yes/No.)

1. Critical C-1 Yes*

Evaluative No critical breakdown

(One)

2. Major Not more than two and neither of Mj-3 Yes*

Evaluative

them should be repetitive in nature

3. Minor Not more than five and frequency of None Yes

Evaluative

each should not be more than two.

4. Total In no case, the total number of Two Yes

breakdowns breakdowns should exceed five, that

Evaluative

is, (2 major + 3 minor) or 5 minor

breakdowns

* No defect/breakdown was observed after the supplementary test.

CENTRAL FARM MACHINERY TRAINING & TESTING INSTITUTE - BUDNI Page 6 of 13

T- 768/1276/2011 SWARAJ 735 FE TRACTOR – Commercial (Initial)

17.2 Optional requirements as per Clause-4 (Table-2) of IS:12207-2008:

Whether

S. No. Characteristic Requirements As observed meets the

requirements

as per IS: 12207-2008

(Yes/No.)

1 2 3 4 5

1 Air cleaner oil pull over, 0.25% (max.) 0.05 Yes

max. oil pull over (%)

2. Seating requirements Should meet the requirements of Does not meet No

IS: 12343-1998 the requirements

3. Fitment of ROPS With a provision for fitment of Provided Yes

ROPS.

If ROPS fitted it should meet the ROPS not fitted Not

requirement of IS: 11821-1992 applicable

4. Technical requirements Should meet the requirements of Meets the Yes

for PTO shaft IS: 4931 -1995 requirements

5. Dimensions of three Should meet the requirements of Does not meets No

point linkage IS: 4468 (Part-I)-1997 the requirements

6. Specifications of linkage Should meet the requirements of Meets the Yes

drawbar IS: 12953-1990 requirements

Specifications of Should meet the requirements of Not provided Not

swinging drawbar IS: 12362 Part 3-1994. applicable

7. Accessories Trailer hitch, front tow hook, Provided Yes

linkage drawbar may be provided.

17.3 Conformity with following IS:

i) Guide lines for declaration of power and specific fuel : Conforms

consumption and labeling of agricultural tractors (First

revision) [IS 10273:1987 (Reaffirmed in March, 2009)]

ii) Agricultural tractors – Rear mounted power take-off - : Conforms

Types 1, 2 and 3 (third revision) [IS: 4931-1995

(Reaffirmed in March, 2009)]

iii) Agricultural wheeled tractors - Rear mounted three- : Does not conform

point linkage: Part 1 Categories 1, 2, 3 & 4 (fourth

revision) [IS:4468(Part-I):1997(Reaffirmed in March,

2009)/ISO730-1:1994]

iv) Drawbar for agricultural tractors – Link type : Conforms

[IS 12953:1990 (Reaffirmed in March, 2009)]

v) Agricultural tractors - Operator’s seat technical : Does not conform

requirement [IS 12343 –1998 (First revision) (Re-

affirmed in March, 2009)]

vi) Guide for safety & comfort of operator of agricultural : Conforms

tractors: Part 1 General requirements (first revision):

[IS 12239 (PT-1) 1996 (Reaffirmed in March,

2007)/ISO 4254-1:1989]

vii) Tractors and machinery for agriculture and forestry, : Conforms

powered lawn and garden equipment – Symbols for

operator controls and other displays [IS: 6283 (Part-

1) – 2006 (Reaffirmed in March, 2009) and IS: 6283

(Part-2)-2007 (Reaffirmed in March, 2009)]

viii) Tractors and machinery for agriculture and forestry – : Does not conform

Technical means for ensuring safety Part 2: Tractors

(first revision) [(IS 12239 (PT-2) 1999) (Re-affirmed

in March, 2009)]

CENTRAL FARM MACHINERY TRAINING & TESTING INSTITUTE - BUDNI Page 7 of 13

T- 768/1276/2011 SWARAJ 735 FE TRACTOR – Commercial (Initial)

ix) Guide lines for location and operation of operator : Conforms

controls on agricultural tractors and machinery (first

revision) (IS: 8133 – 1983) (Re-affirmed in March,

2009).

x) Agricultural Tractor & Machinery Lighting device for : Conforms

travel on public roads (IS: 14683-1999) (Re-affirmed

in March, 2009)

17.4 Salient Observations:

17.4.1 Laboratory tests:

17.4.1.1 PTO Performance:

i) The backup torque is 22.9 %.

ii) The specific fuel consumption corresponding to maximum power was recorded

as 245 g/kWh, against the declaration of 258 g/kWh, which meet the

requirement of IS: 12207-2008 with regard to tolerance.

iii) The defect reported in chapter No. 15 of this report has been rectified by the

manufacturer at the design/production level. No further breakdown/defect

observed during course of testing.

It is therefore recommended that, the modified water pump mounting

bracket (Part No. P219409B) as given in Annexure-II should be used in

regular production of the tractor.

17.4.1.2 Mechanical Vibration:

The amplitude of mechanical vibration on various assemblies marked as (*) in

Chapter-9 of this test report is on higher side, especially at the steering control wheel

and foot rests. This calls for dampening down of vibrations to improve the operational

comfort and service life of components.

17.4.1.3 Three point linkage:

Lateral distance from lower hitch point to centre line of tractor does not meet the

requirements of IS 4468: 1997. It should be looked into for compliance.

17.4.1.4 Operator’s Seat:

The longitudinal distance from seat index point to centre of steering control wheel

does not meet the requirements of IS: 12343-1999. It should be looked into for

compliance.

17.4.2 Field Performance:

17.4.2.1 Wet land cultivation (Puddling Operation):

No ingress of mud/or water was observed during wetland cultivation. Hence the

tractor meets the requirements for wet land cultivation as per IS: 11082-1984 and

found suitable for wetland cultivation

17.5 Recommendation with regard to safety on tractor:

The following requirements, inter alia, may be considered for incorporation on the

tractor:

i) Provision for spark arresting device in exhaust system.

CENTRAL FARM MACHINERY TRAINING & TESTING INSTITUTE - BUDNI Page 8 of 13

T- 768/1276/2011 SWARAJ 735 FE TRACTOR – Commercial (Initial)

17.6 Maintenance / Service Problems:

No noticeable maintenance or service problem was observed during the test.

17.7 Adequacy of Literature supplied with machine:

The following literature was supplied with the tractor for reference during the test:

i) Operator’s Manual

ii) Spare parts catalogue

17.7.1 Therefore it is recommended that, the service/workshop manual for this tractor model

should be brought out as per IS: 8132-1999 (Reaffirmed in march, 2009) for the

guidance of users and service personnel in national as well as other regional

languages.

TESTING AUTHORITY:

J.J.R. NARWARE

SENIOR AGRICULTURAL ENGINEER

V.N. KALE

DIRECTOR

Test Report compiled by: Shri Sanjay Kumar, Senior Technical Assistant.

18. APPLICANT’S COMMENTS

Para No. Our Reference Applicant’s comments

Collar has been provided in the design and has

18.1 3.1,16.1(1.2,1.3,1.4),17.4.1.1(iii)

been implemented on regular production.

These requirements are being revisited for

18.2 17.3(iii,v,viii)

necessary corrective action at our end.

These requirements are being revisited for

18.3 17.4.1.3,17.4.1.4

necessary corrective action at our end.

CENTRAL FARM MACHINERY TRAINING & TESTING INSTITUTE - BUDNI Page 9 of 13

T- 768/1276/2011 SWARAJ 735 FE TRACTOR – Commercial (Initial)

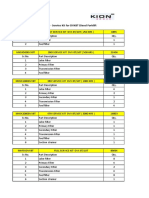

ANNEXURE-I

COMPARATIVE MAJOR MODIFICATION IN THE SPECIFICATION OF THE TRACTOR

S. No. Particulars Previous sample Present sample

1 Model

2 Engine model RV3TR RV3 XM +3A

3 Compression ratio 17:1 20 .4± 0.5 :1

4 High idle speed (rpm) 2135 ± 35 1900 -2000

5 Low idle speed (rpm) 700 ± 50 580 -700

6 Rated engine speed (rpm) 2000 ± 35 1800

7 Speed at maximum torque (rpm) 1350 ± 150 1000-1400

8 Stroke (mm) 110 116

9 Capacity as specified (cc) 2592 2734

10 Inlet valve clearance (mm) 0.15 0.25 – 0.30

11 Exhaust valve clearance (mm) 0.20 0.30 – 0.35

12 Capacity of A/C bowel (l) 0.55 0.8

13 Range of suction pressure (kPa) 2.0 ±0.5 1.6 ± 0.5

14 Capacity of expansion flask (l) Not provided 0.5

15 Total coolant capacity (l) 7.2 8.2

16 Length of discharge pipe above silencer 395 605

portion (mm)

17 Range of exhaust gas pressure (kPa) 5.0 ±2.0 4.0 ± 2.0

18 Model / group combination number of F002 AOZ 021 E B 40 244 100

FIP PES3A90D320RS

2888

19 Injection timing 22O ± 1O 10O ± 1O

20 Fuel delivery (mm3) 39.3 ± 3 44 ± 3

21 Model / group combination number of RSV 325…1000 RSV 325....900 A 1 C 1601 R

governor A1C 893 R

22 Speed range (rpm) 300 to 1085 580 to 2000

23 Model / group combination number of 9430 031 261 F 002 C 70 552

Injector

24 Injector opening pressure (Mpa) 20.6 + 0.98 25.0 + 0.8

25 Location of battery Behind operator On RHS of clutch housing in a

seat separate metallic box

26 Material of clutch lining Asbestos moulded Organic, F410 (Valeo)

27 Range of speed- Forward (Kmph) 2.30 to 24.90 2.30 to 27.75

28 Range of speed – Reverse(Kmph) 3.20 to 12.5 2.87 to 11.29

29 Reduction ratio through crown wheel & 1: 3.64 (11/40T) 1: 3.23(13:42T)

pinion

30 Reduction through final drive 1: 4.92 (12 / 59 T ) 1: 4.462(13/58 T )

31 Front tyre road inflation pressure (kPa) 200 200

32 Area of brake lining (cm2) 610.4 720.2

33 PTO speed corresponding to rated 976 986

engine speed (rpm)

34 Engine to PTO speed ratio 2.047:1 (21/43T) 1.826 :1 (23/43T)

35 Speed of hydraulic pump corresponding 1500 1350

to rated engine speed (rpm)

36 Discharge of hydraulic pump at 16 ± 2 14 ± 2

minimum pressure (l)

37 Maximum hydraulic power (kW) 1.04 ± 0.74 3.7 ± 0.74

39 Pump delivery at maximum power (l) 15 ± 3 13 ± 3

40 Height of rear towing hook (mm) 560 620/500

41 Masses (kgf) 710/1110/1820 760/1110/1890

42 Maximum PTO power (kW) 22.8 24.1

CENTRAL FARM MACHINERY TRAINING & TESTING INSTITUTE - BUDNI Page 10 of 13

T- 768/1276/2011 SWARAJ 735 FE TRACTOR – Commercial (Initial)

ANNEXURE-II

WATER PUMP MOUNTING BRACKET

OLD DESIGN (Part no. P219409A)

NEW DESIGN (Part no. P219409B)

CENTRAL FARM MACHINERY TRAINING & TESTING INSTITUTE - BUDNI Page 11 of 13

T- 768/1276/2011 SWARAJ 735 FE TRACTOR – Commercial (Initial)

ANNEXURE - III

BRIEF SPECIFICATION OF IMPLEMENTS USED DURING FIELD TEST

S.

No. Item Disc Plough Rotavator Puddler

1. Make M&M NA Not available

2. Type Mounted Mounted Mounted

3. No. of bottom / blades 2 36 blade in 7 12 (6 in each

flanges gang)

4. Type of bottom / blades Plane Concave Hatchet Notched

5. Size of bottom / blades, (mm) 590 270 x 65 x 10 460

6. Spacing of bottom/blades, (mm) 500 260 164

7. Lower hitch point span, (mm) 680 685 680

8. Mast height, (mm) 465 480 680

9. Overall dimensions, (mm):

- Length 1600 800 1190

- Width 870 1000 1810

- Height 1110 995 1330

10. Gross mass, (kg) 310 345 240

ANNEXURE-IV

BRIEF SPECIFICATION OF CAGE WHEEL

S. No. Items Specification

1. Type Half cage wheel

2. Diameter, (mm) 1085

3. Width, (mm) 340

4. No. and type of lugs 12, straight lugs made of MS angle

section welded to angle iron frame

5. Size of angle section, (mm) 50x50x5

6. Length of lugs, (mm) 340

7. Spacing of lugs, (mm) 275

8. Weight of each cage wheel, (kg) 60

CENTRAL FARM MACHINERY TRAINING & TESTING INSTITUTE - BUDNI Page 12 of 13

T- 768/1276/2011 SWARAJ 735 FE TRACTOR – Commercial (Initial)

ANNEXURE-V

TRACTOR RUN HOURS DURING TEST

A. LABORATORY AND TRACK TESTS: HOURS

1. Running-in 28.0

2. PTO performance test 10.3

3. Power lift and hydraulic pump performance test 1.8

4. Drawbar performance test 13.4

5. Turning ability 0.2

6. Location of centre of gravity 0.2

7. Operator’s field of vision --

8. Brake test 2.0

9. Noise measurement 2.0

10. Mechanical vibration test 1.0

11. Theoretical speed test 1.0

12 Air cleaner oil pull over 3.5

B. FIELD TEST:

1. Disc ploughing 10.1

2. Rotavation 11.6

3. Puddling (Including water proof test) 15.4

C. HAULAGE TEST: 9.1

D. Miscellaneous test and other run hours including idle run, 9.8

transportation, trials and preparation for test

TOTAL: 119.4

CENTRAL FARM MACHINERY TRAINING & TESTING INSTITUTE - BUDNI Page 13 of 13

S-ar putea să vă placă și

- HMT Tractor Oil SealsDocument17 paginiHMT Tractor Oil SealsAmit Chopra Amit100% (2)

- R 45 F17 10 Introduction of New Mahindra YUVODocument13 paginiR 45 F17 10 Introduction of New Mahindra YUVODipen patraÎncă nu există evaluări

- 245 JIVO Service Manual36 PDFDocument87 pagini245 JIVO Service Manual36 PDFSamsher Ali100% (4)

- Recommended Price List (RPL) RPL RS.: RheinlandDocument16 paginiRecommended Price List (RPL) RPL RS.: RheinlandHemant Panpaliya100% (2)

- Tata PricelistDocument4 paginiTata Pricelistbaritone18m100% (1)

- Swaraj 717 Catalogue March 201619Document114 paginiSwaraj 717 Catalogue March 201619basayya shirur100% (4)

- RSJ PartsDocument32 paginiRSJ PartsAmit Chopra Amit100% (1)

- Powertrac Price List 2023Document968 paginiPowertrac Price List 2023Ashutosh Ashish0% (1)

- India's First Smart Truck Guarantees Higher MileageDocument22 paginiIndia's First Smart Truck Guarantees Higher MileageabcÎncă nu există evaluări

- TML BS6Document82 paginiTML BS6Ankur MestryÎncă nu există evaluări

- Swaraj 834 735 724Document5 paginiSwaraj 834 735 724Dadasaheb MoreÎncă nu există evaluări

- Chota ChilliDocument1 paginăChota ChilliRishu ranaÎncă nu există evaluări

- 3516 Tractor Al Bs 2Document239 pagini3516 Tractor Al Bs 2Mohan Preeth100% (1)

- Catalogues$ci LPK 2518HD BS3 Cum PDFDocument322 paginiCatalogues$ci LPK 2518HD BS3 Cum PDFSajan AhmedÎncă nu există evaluări

- Service kits for DVX8T diesel forkliftDocument1 paginăService kits for DVX8T diesel forkliftJohnson JamesÎncă nu există evaluări

- GS Kamani Spares LCVDocument6 paginiGS Kamani Spares LCVHemant PanpaliyaÎncă nu există evaluări

- Luman Industries LTD.: July 2019Document28 paginiLuman Industries LTD.: July 2019Jay KumarÎncă nu există evaluări

- HOW TO USE PARTS CATALOGUEDocument139 paginiHOW TO USE PARTS CATALOGUEKanhaiya AgrawalÎncă nu există evaluări

- 735fe, 735xm, 834xm CatlougeDocument143 pagini735fe, 735xm, 834xm Catlougedadu tractor83% (30)

- Luk Tractors Price List Jan 2022Document8 paginiLuk Tractors Price List Jan 2022ANURAGÎncă nu există evaluări

- Tafe TrainingDocument20 paginiTafe TrainingDarshan Gajera100% (1)

- Swaraj 744 Fe Xtra - 1Document8 paginiSwaraj 744 Fe Xtra - 1Subhasis Mishra100% (2)

- Catalogues$lpt 1615 Tcic Bs-IiiDocument234 paginiCatalogues$lpt 1615 Tcic Bs-IiiAbdul Samad KhanÎncă nu există evaluări

- 744fe 855fe Parts Cata June11Document119 pagini744fe 855fe Parts Cata June11manish yadav100% (2)

- 4WH Electrical - NPD Circular - Nov'20Document63 pagini4WH Electrical - NPD Circular - Nov'20JB Thusthehir100% (1)

- LPK 2523C (6X4) BS-II Parts ListDocument330 paginiLPK 2523C (6X4) BS-II Parts ListvipulÎncă nu există evaluări

- LPT 709-34 EX E-II CAT - DT 30.03.07Document289 paginiLPT 709-34 EX E-II CAT - DT 30.03.07Harneak Singh GujralÎncă nu există evaluări

- Price List 4Wh 2015 16Document76 paginiPrice List 4Wh 2015 16Amit Chopra Amit0% (1)

- TATA LPT-613 Parts Catalog PDFDocument260 paginiTATA LPT-613 Parts Catalog PDFJörgen Mannberg100% (1)

- Cars Radiator Banco PricelistDocument42 paginiCars Radiator Banco PricelistMM SparesÎncă nu există evaluări

- Boschkbx Price 2013 PDFDocument40 paginiBoschkbx Price 2013 PDFvivek0630Încă nu există evaluări

- Tata Hyva 2523 TC 38 Bs3Document324 paginiTata Hyva 2523 TC 38 Bs3V M VARMA100% (1)

- 30 Series PC Low Resolution PDFDocument226 pagini30 Series PC Low Resolution PDFJose Luis Correa ArangoÎncă nu există evaluări

- Regular Parts Catalogue Inclusive 235DI 245DI 12MAY09Document268 paginiRegular Parts Catalogue Inclusive 235DI 245DI 12MAY09PSChatrathÎncă nu există evaluări

- Mahindra New Price List 22.2.2014Document113 paginiMahindra New Price List 22.2.2014Satya Magoo100% (3)

- FT 6065 NewDocument3 paginiFT 6065 Newprathamesh100% (1)

- Commercial Vehicle Business Unit: Product Spare Parts CatalogueDocument162 paginiCommercial Vehicle Business Unit: Product Spare Parts Catalogueabdul samadÎncă nu există evaluări

- LPO Y1-7.5T/42 Parts List (34 Seater 497 VP37 BS-IIIDocument280 paginiLPO Y1-7.5T/42 Parts List (34 Seater 497 VP37 BS-IIIbhushan kalwaÎncă nu există evaluări

- Catlog Hyva 2518Document386 paginiCatlog Hyva 2518nkr4726923100% (1)

- FUSI Aftermarket PricelistDocument24 paginiFUSI Aftermarket PricelistSanjay Kumar BansalÎncă nu există evaluări

- JCB-3DX KIRLOSKAR ENGINE parts list for repoweringDocument1 paginăJCB-3DX KIRLOSKAR ENGINE parts list for repoweringDhru TiÎncă nu există evaluări

- Tata LPT 70921-30Document10 paginiTata LPT 70921-30Niten GuptaÎncă nu există evaluări

- Holdwell Inventory JCB Catalogue 2020Document16 paginiHoldwell Inventory JCB Catalogue 2020Epure GabrielÎncă nu există evaluări

- Yuvo Service Manual95Document342 paginiYuvo Service Manual95Dadasaheb More67% (3)

- Service Sheet LubricantsDocument62 paginiService Sheet LubricantsAbhishek Bawa100% (2)

- LuK Tractor Price List 2020Document6 paginiLuK Tractor Price List 2020Amit Chopra AmitÎncă nu există evaluări

- After Market Price List: W.E.F. 01 January 2016Document24 paginiAfter Market Price List: W.E.F. 01 January 2016P.p. Arul IlancheeranÎncă nu există evaluări

- Da10 Air Cooled Engine (Appn Code D3.2007 & D3Document26 paginiDa10 Air Cooled Engine (Appn Code D3.2007 & D3Sandeep NikhilÎncă nu există evaluări

- FAIR BROTHER AUTO SALES Price List for Alternators and StartersDocument4 paginiFAIR BROTHER AUTO SALES Price List for Alternators and StartersJhousep steven Mesia gonzales100% (1)

- Filter Price List Doka MakesDocument15 paginiFilter Price List Doka Makesboobalan_shriÎncă nu există evaluări

- Illustrated Part List FOR: Kirloskar Oil Engines LimitedDocument84 paginiIllustrated Part List FOR: Kirloskar Oil Engines LimitedBraian HuertasÎncă nu există evaluări

- JCB 3DX undercarriage and attachment bushings and sealsDocument1 paginăJCB 3DX undercarriage and attachment bushings and sealsayush bansalÎncă nu există evaluări

- Full Spares 8Document1 paginăFull Spares 8Parveen KashyapÎncă nu există evaluări

- Lamps Catalog For 4 Wheelers PDFDocument20 paginiLamps Catalog For 4 Wheelers PDFBharathÎncă nu există evaluări

- Compare John Deere 5310 vs Mahindra Arjun NOVO 605 DI-i TractorsDocument2 paginiCompare John Deere 5310 vs Mahindra Arjun NOVO 605 DI-i TractorsPrashant PatilÎncă nu există evaluări

- Deutz-Fahr Agrolux-55 e tractor test reportDocument12 paginiDeutz-Fahr Agrolux-55 e tractor test reportMamta RaybageÎncă nu există evaluări

- Mahindra 475 DI Tractor BUDNI TEST REPORTDocument15 paginiMahindra 475 DI Tractor BUDNI TEST REPORTShyam Katare0% (1)

- Swaraj 855 Fe Xtra Tractor - T - 852-1362-2012Document12 paginiSwaraj 855 Fe Xtra Tractor - T - 852-1362-2012Surajit SarkarÎncă nu există evaluări

- Mahindra 605 Di PS Tractor-T-954-1472-2015Document12 paginiMahindra 605 Di PS Tractor-T-954-1472-2015Prashant PatilÎncă nu există evaluări

- MahindraDocument13 paginiMahindraCvsiva Krishna ReddyÎncă nu există evaluări

- # Name Quantity Units Unit Price Discount Total: "Goods Once Sold Will Not Be Taken Back or Exchanged"Document1 pagină# Name Quantity Units Unit Price Discount Total: "Goods Once Sold Will Not Be Taken Back or Exchanged"Amit Chopra AmitÎncă nu există evaluări

- # Name Quantity Units Unit Price Discount Total: Invoice Number: 00128 Invoice Date: Billing AddressDocument3 pagini# Name Quantity Units Unit Price Discount Total: Invoice Number: 00128 Invoice Date: Billing AddressAmit Chopra AmitÎncă nu există evaluări

- # Name Quantity Units Unit Price Discount Total: "Goods Once Sold Will Not Be Taken Back or Exchanged"Document1 pagină# Name Quantity Units Unit Price Discount Total: "Goods Once Sold Will Not Be Taken Back or Exchanged"Amit Chopra AmitÎncă nu există evaluări

- Plant Setup: Bharat Industrial Corporation A - 10, Industrial Area Jodhpur (Rajasthan) INDIADocument18 paginiPlant Setup: Bharat Industrial Corporation A - 10, Industrial Area Jodhpur (Rajasthan) INDIAAmit Chopra AmitÎncă nu există evaluări

- FT NEW PRICE LIST 4.10.2021-Converted-UnlockedDocument693 paginiFT NEW PRICE LIST 4.10.2021-Converted-UnlockedAmit Chopra AmitÎncă nu există evaluări

- "Goods Once Sold Will Not Be Taken Back or Exchanged": # Name Quantity Units Unit Price Discount TotalDocument1 pagină"Goods Once Sold Will Not Be Taken Back or Exchanged": # Name Quantity Units Unit Price Discount TotalAmit Chopra AmitÎncă nu există evaluări

- # Name Quantity Units Unit Price Total: "Goods Once Sold Will Not Be Taken Back or Exchanged"Document2 pagini# Name Quantity Units Unit Price Total: "Goods Once Sold Will Not Be Taken Back or Exchanged"Amit Chopra AmitÎncă nu există evaluări

- Tavefujixig Rapegimuvopi FadudirekevevaDocument2 paginiTavefujixig Rapegimuvopi FadudirekevevaAmit Chopra AmitÎncă nu există evaluări

- FENNER - TOTAL OIL SEALS LISTDocument34 paginiFENNER - TOTAL OIL SEALS LISTArpit VermaÎncă nu există evaluări

- 4" Rear Combination Lamp Stop/ Rear Indicator/ Position/ ReverseDocument1 pagină4" Rear Combination Lamp Stop/ Rear Indicator/ Position/ ReverseAmit Chopra AmitÎncă nu există evaluări

- LuK Tractor Price List 2020Document6 paginiLuK Tractor Price List 2020Amit Chopra AmitÎncă nu există evaluări

- Front Hub & Spindle PartsDocument13 paginiFront Hub & Spindle PartsAmit Chopra AmitÎncă nu există evaluări

- 2021 03 15result - 08 00 PMDocument1 pagină2021 03 15result - 08 00 PMAmit Chopra AmitÎncă nu există evaluări

- Switches Catalog For 2 Wheeler PDFDocument40 paginiSwitches Catalog For 2 Wheeler PDFMidhun P Madhav50% (4)

- User GuideDocument14 paginiUser Guidenayla amarÎncă nu există evaluări

- Training Regulations: Motorcycle/ Small Engine Servicing NC IiDocument102 paginiTraining Regulations: Motorcycle/ Small Engine Servicing NC IiAmit Chopra AmitÎncă nu există evaluări

- 2021 03 15result - 08 00 PMDocument1 pagină2021 03 15result - 08 00 PMAmit Chopra AmitÎncă nu există evaluări

- 2 37Document10 pagini2 37Amit Chopra AmitÎncă nu există evaluări

- Price List 4Wh 2015 16Document76 paginiPrice List 4Wh 2015 16Amit Chopra Amit0% (1)

- PNB Cash Payinslip PDFDocument1 paginăPNB Cash Payinslip PDFAmit Chopra AmitÎncă nu există evaluări

- Ashutam Fuel Lines Price List 2020Document12 paginiAshutam Fuel Lines Price List 2020Amit Chopra AmitÎncă nu există evaluări

- Exhibitors 2017 PDFDocument25 paginiExhibitors 2017 PDFDhananjayan GopinathanÎncă nu există evaluări

- Super Seal List April-2015Document17 paginiSuper Seal List April-2015Amit Chopra AmitÎncă nu există evaluări

- Front Hub & Spindle PartsDocument14 paginiFront Hub & Spindle PartsAmit Chopra Amit100% (1)

- Yamaha RX G Service ManualDocument122 paginiYamaha RX G Service Manualdesmon31690% (42)

- STARTER MOTOR TEST PROCEDURE GUIDEDocument13 paginiSTARTER MOTOR TEST PROCEDURE GUIDEwei fooÎncă nu există evaluări

- Important Product Catalogue Covers Piston RangeDocument236 paginiImportant Product Catalogue Covers Piston RangeAmit Chopra AmitÎncă nu există evaluări

- SKF Price ListDocument7 paginiSKF Price Listsenior section engineer Scly100% (2)

- Kirloskar MRP Price ListDocument141 paginiKirloskar MRP Price Listd-fbuser-6927133670% (10)

- Company ProfileDocument24 paginiCompany ProfilePutra Satyam Naidu Bandi100% (2)

- TH407 Parts PDFDocument2 paginiTH407 Parts PDFEric Tweneboah KoduaÎncă nu există evaluări

- New CoilDocument10 paginiNew Coiltoninhomelotti_53173Încă nu există evaluări

- Specs RD5200-serienDocument6 paginiSpecs RD5200-serienesauth gonzalezÎncă nu există evaluări

- Partes Motor M-100Document1 paginăPartes Motor M-100Jose GuillermoÎncă nu există evaluări

- 165T-5 Triplex Plunger Pump SpecsDocument2 pagini165T-5 Triplex Plunger Pump SpecsReivaj JavierÎncă nu există evaluări

- In-Use Testing of BS6 Passenger and Light Commercial VehiclesDocument11 paginiIn-Use Testing of BS6 Passenger and Light Commercial VehiclesThe International Council on Clean TransportationÎncă nu există evaluări

- Anbussa City Bus Service Enterprise HistoryDocument10 paginiAnbussa City Bus Service Enterprise HistorySeyfeAlemayehuÎncă nu există evaluări

- Troubleshooting G3600A4 PDFDocument9 paginiTroubleshooting G3600A4 PDFEustacio MenesesÎncă nu există evaluări

- Course Title: Diesel Engine Service Lab Course Code: 4057 Course Category: B Periods/Week: 6 Periods/Semester: 84 Credits: 3Document2 paginiCourse Title: Diesel Engine Service Lab Course Code: 4057 Course Category: B Periods/Week: 6 Periods/Semester: 84 Credits: 3VaisakVenugopalÎncă nu există evaluări

- Wiring Diagrams PetrolDocument201 paginiWiring Diagrams PetrolLourens SchlebuschÎncă nu există evaluări

- Instruction ManualDocument52 paginiInstruction ManualEka RoksÎncă nu există evaluări

- 2014 Volkswagen Tiguan 88297Document418 pagini2014 Volkswagen Tiguan 88297Mab294Încă nu există evaluări

- PBM Group Company Profile 2023Document12 paginiPBM Group Company Profile 2023Aljosa PavelinÎncă nu există evaluări

- CARB Daewoo-Tico-Incomplete Dismantling - TranslatedDocument5 paginiCARB Daewoo-Tico-Incomplete Dismantling - TranslatedAble TonÎncă nu există evaluări

- TX TagDocument3 paginiTX TagrwoodzzÎncă nu există evaluări

- Jet Engines - ExplainedDocument12 paginiJet Engines - ExplainedAsamir AlHaidarÎncă nu există evaluări

- Form-04 Piston & Liner 2004Document2 paginiForm-04 Piston & Liner 2004YeremiaÎncă nu există evaluări

- Double Pinion Power SteeringDocument5 paginiDouble Pinion Power Steeringkhalil bouadilaÎncă nu există evaluări

- Yamaha Virago 535 XV535 - Owners Manual EnglishDocument98 paginiYamaha Virago 535 XV535 - Owners Manual EnglishAlexis Monroy LeoneÎncă nu există evaluări

- Practice Automotive Industries Tarea 2Document3 paginiPractice Automotive Industries Tarea 2Oscar FerÎncă nu există evaluări

- Giti PCR Catalogue GlobalDocument54 paginiGiti PCR Catalogue GlobalFrank Rodriguez MiranoÎncă nu există evaluări

- Volvo B11R Sunsundegui SC7 Benchmark Economy Productivity ComfortDocument1 paginăVolvo B11R Sunsundegui SC7 Benchmark Economy Productivity Comfortpedro perez MarinÎncă nu există evaluări

- Design and Analysis of Turbochargers: March 2016Document12 paginiDesign and Analysis of Turbochargers: March 2016Irah ZinirahÎncă nu există evaluări

- CAT C7 C9 HEUI CatalogueDocument24 paginiCAT C7 C9 HEUI CatalogueDodik Cahyono100% (2)

- X Ride Part CatalogueDocument46 paginiX Ride Part CatalogueMahful Irvay MukhlisÎncă nu există evaluări

- SESV1661Document128 paginiSESV1661Yapi Yapi100% (1)

- 1ST CLUTCH - Wheel Loader Komatsu WA120-1 - TORQUE CONVERTER AND TRANSMISSION 777partsDocument2 pagini1ST CLUTCH - Wheel Loader Komatsu WA120-1 - TORQUE CONVERTER AND TRANSMISSION 777partsashraf elsayedÎncă nu există evaluări

- Columbia Maintenance ManualDocument122 paginiColumbia Maintenance ManualLuis Enrique Lopez Rojas100% (1)