Documente Academic

Documente Profesional

Documente Cultură

Stainless Steel 321 Technical Data

Încărcat de

smith willTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Stainless Steel 321 Technical Data

Încărcat de

smith willDrepturi de autor:

Formate disponibile

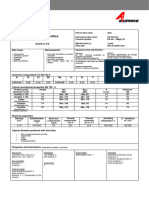

Stainless Steel 321 Mechanical Properties

Tensile properties after water quenching

Minimum guaranteed values * Typical values (10mm plates)

Stainless steel 321 is a 18Cr-9Ni austenitic stainless steel stabilised with some

°C °F Y.S. 0.2% Y.S. 1% UTS Y.S. 0.2% Y.S. 1% UTS El %

titanium additions.

MPa Ksi MPa Ksi MPa Ksi MPa Ksi MPa Ksi MPa Ksi

20 68 200 29 240 35 500 73 280 40 310 45 600 89 45

This kind of steel is one of the basic grades of the stainless steels range. / 700 / 102

Titanium bearing (carbide forming element) avoids intergranular corrosion, even 100 212 176 25 208 30 460 67 236 34 260 38 550 82 40

on welded pieces without ulterior water quenching. 200 392 157 23 186 27 410 60 200 29 230 33 450 66 35

300 572 136 20 167 24 390 57 186 26 210 30 435 64 35

Alloys stainless steel 321 exhibit austenitic microstructures free of deleterious 400 752 125 18 156 23 390 57 175 25 200 29 420 61 30

carbide precipitations but with CNTi precipitations at the grain boundaries. 500 932 119 17 149 22 310 45 168 24 195 28 340 50 30

The grade contains some residual ferrite (≈4%) after solution annealing

(1000-1100°C - 1832-2012°F) and water quenching. * Following EN 10088 hot rolled plates.

The EN guaranteed values are valid for a thickness from 5-75mm.

The main properties are:

Impact values

• Basic corrosion resistance °C -269 -196 +20

• Resistance against intergranular corrosion °F -452 -320 68

KCV (J/cm²)

62 100 150

• Heat resistant alloy (medium temperature) Minimum

KCV (J/cm²)

138 160 25

• High ductility Typical

Standards Physical Properties

EURONORM 1.4541 X6CrNiTi 18-10

Interval Thermal °C °F Resistivity Thermal Specific Young Shear

AFNOR Z6 CNT 18-10

temper expansion conductivity heat modulus modulus

E G

αx10-6K-1

DIN W1.4541

°C (μΩ cm) (W.m-1.K-1) (J.kg-1.K-1) (GPa) (GPa)

A 240 – TP 321

ASTM UNS S32100

20-100 16 20 68 73 15 500 200 77

20-200 16.5 100 212 77 16 500 194 75

Chemical Analysis 20-300 17 200 392 84 17.5 520 186 71

20-400 17.5 300 572 91 19 530 179 68

Typical values (weight %)

20-500 18 400 752 97 20.5 540 172 65

C Cr Ni Mo N Ti

500 932 102 22 540 165 62

0.050 17.5 9.2 - - =5x%C ; up to 0.70

PREN (=%Cr+3.3%Mo+16%N) ≥ 18

Stainless Steel 321 17 18 Stainless Steel 321

Corrosion Resistance

Quality corrosion tests guaranteed (special request may be discussed)

TEST Other name Corrosion (1) Results

ASTM A 262 A Intergranular Step or dual structure

ASTM A 262 B STREICHER Intergranular Not recommended

ASTM A 262 C HUEY Intergranular Not recommended

ASTM A 262 E

DIN 50914 STRAUSS Intergranular No cracking after bending

RCCM

Not recommended

ASTM G48 A Pitting

(typical CPT = 5°C-41°F)

Not recommended

ASTM G48 B ASTM G78 Crevice

(typical CCT ≤ 0°C-32°F)

(1) kind of corrosion mechanism investigated

Applications

Stainless steel 321 is corrosion resistant in:

• Urban media

• Most of diluted organic acids at moderate temperatures

• Most of food and pharmaceutical products

• Pure phosphoric - Whatever concentration in cold solution

- Up to 10% diluted hot solution

• Caustic solutions free of chlorides or fluorides at medium temperatures

The alloys is not corrosion resistant in chloride containing solutions, even

diluted, and in sulphuric acid media.

So, the main applications are:

• Food processing and storage

• Chemical industry

• High temperature

Stainless Steel 321 19

S-ar putea să vă placă și

- CLC 18.10LN: A Nitrogen Containing 18Cr-10Ni Austenitic Stainless Steel (304LN Grade)Document4 paginiCLC 18.10LN: A Nitrogen Containing 18Cr-10Ni Austenitic Stainless Steel (304LN Grade)PeterWayÎncă nu există evaluări

- CLC 18-12-4LN: A 3%mo Austenitic Stainless Steel With Nitrogen Addition (317LN Grade)Document4 paginiCLC 18-12-4LN: A 3%mo Austenitic Stainless Steel With Nitrogen Addition (317LN Grade)PeterWayÎncă nu există evaluări

- CLC 18-9L: General Purpose 18Cr-9Ni Austenitic Stainless Steel (304L Grade)Document4 paginiCLC 18-9L: General Purpose 18Cr-9Ni Austenitic Stainless Steel (304L Grade)MichaelÎncă nu există evaluări

- CLC 18-10L: General Purpose 18Cr-10Ni Austenitic Stainless Steel (304L Grade)Document4 paginiCLC 18-10L: General Purpose 18Cr-10Ni Austenitic Stainless Steel (304L Grade)PeterWayÎncă nu există evaluări

- CLC 17-13-5LN - High corrosion resistant austenitic stainless steelDocument4 paginiCLC 17-13-5LN - High corrosion resistant austenitic stainless steelPeterWayÎncă nu există evaluări

- Alloy 410s Spec SheetDocument2 paginiAlloy 410s Spec SheetALONSO GOMEZÎncă nu există evaluări

- CLC 17-12-2ti: A Ti Stabilized 18Cr-11Ni-2Mo Austenitic Stainless Steel (316ti Grade)Document4 paginiCLC 17-12-2ti: A Ti Stabilized 18Cr-11Ni-2Mo Austenitic Stainless Steel (316ti Grade)PeterWayÎncă nu există evaluări

- CLC 18-10Nb: A NB Stabilized 18Cr-10Ni Austenitic Stainless Steel (347 Grade)Document4 paginiCLC 18-10Nb: A NB Stabilized 18Cr-10Ni Austenitic Stainless Steel (347 Grade)PeterWayÎncă nu există evaluări

- Alloy 410S Spec SheetDocument2 paginiAlloy 410S Spec SheetPrakash SundharamÎncă nu există evaluări

- CuZn33 CatalogueDocument9 paginiCuZn33 CataloguefedericoÎncă nu există evaluări

- Extrusion Ingot: ApplicationDocument4 paginiExtrusion Ingot: ApplicationilkerÎncă nu există evaluări

- CLC 18-10ti: A Ti Stabilized 18Cr-10Ni Austenitic Stainless Steel (321 Grade)Document4 paginiCLC 18-10ti: A Ti Stabilized 18Cr-10Ni Austenitic Stainless Steel (321 Grade)PeterWayÎncă nu există evaluări

- Nas - 185N - e - 254 Smo - Uns - S31254Document4 paginiNas - 185N - e - 254 Smo - Uns - S31254Marvin BasdenÎncă nu există evaluări

- kme_STOL76_C19010_enDocument1 paginăkme_STOL76_C19010_enMattia Terri TerrandoÎncă nu există evaluări

- Cusn8 Industrial RolledDocument4 paginiCusn8 Industrial RolledPrakash MakadiaÎncă nu există evaluări

- 1 Ceramic Fiber BoardsDocument2 pagini1 Ceramic Fiber BoardsMahesh MishraÎncă nu există evaluări

- CuZn40 01 2019 PDFDocument7 paginiCuZn40 01 2019 PDFMisaelÎncă nu există evaluări

- 1.4521 444 X2Crmotinb18-2 S44400: C Si MN P S CR Mo Ti NBDocument1 pagină1.4521 444 X2Crmotinb18-2 S44400: C Si MN P S CR Mo Ti NBRodrigo TeodoroÎncă nu există evaluări

- Stainless Steel Grade AISI 321Document2 paginiStainless Steel Grade AISI 321Mitul RawatÎncă nu există evaluări

- Alloy 276 Spec SheetDocument3 paginiAlloy 276 Spec SheetJAYA BHARATHA REDDYÎncă nu există evaluări

- Eurocw617n ST enDocument4 paginiEurocw617n ST endrgilleÎncă nu există evaluări

- CuNiSi AlloyDocument6 paginiCuNiSi AlloyJdjoÎncă nu există evaluări

- Bronze C86300 SpecificationsDocument2 paginiBronze C86300 SpecificationsDoss MartinÎncă nu există evaluări

- Cu DHPDocument3 paginiCu DHPLUIGIÎncă nu există evaluări

- Structural Stainless Steel Designing With Stainless Steel: Ing. Maarten FortanDocument153 paginiStructural Stainless Steel Designing With Stainless Steel: Ing. Maarten FortanJohn Philip Neri BesedillasÎncă nu există evaluări

- Cuzn37 Industrial RolledDocument6 paginiCuzn37 Industrial RolledcvgfgÎncă nu există evaluări

- 2205 Duplex Data Sheet: Specifications Mechanical Properties FeaturesDocument2 pagini2205 Duplex Data Sheet: Specifications Mechanical Properties FeaturesJairo BarragánÎncă nu există evaluări

- DS Mold 4140Document3 paginiDS Mold 4140reza prasetiaÎncă nu există evaluări

- The Indications Are Basically Founded On Our Actual Know-How. This Technical Data Sheet Is Without Commitment and Not ContractedDocument1 paginăThe Indications Are Basically Founded On Our Actual Know-How. This Technical Data Sheet Is Without Commitment and Not ContractedRavindra ErabattiÎncă nu există evaluări

- CLC 17-13-3LN: A Nitrogen Containing 18Cr-10Ni-2Mo Austenitic Stainless Steel (316LN Grade)Document4 paginiCLC 17-13-3LN: A Nitrogen Containing 18Cr-10Ni-2Mo Austenitic Stainless Steel (316LN Grade)PeterWayÎncă nu există evaluări

- C2700Document6 paginiC2700Andrew TanÎncă nu există evaluări

- 1 4509Document2 pagini1 4509Umesh KotadiaÎncă nu există evaluări

- Stellite 21Document2 paginiStellite 21Mohsen ParpinchiÎncă nu există evaluări

- Flux Cored Arc Welding for Low Carbon 18%Cr-12%Ni-2%Mo Stainless SteelDocument1 paginăFlux Cored Arc Welding for Low Carbon 18%Cr-12%Ni-2%Mo Stainless Steelmohamed AdelÎncă nu există evaluări

- c95500 Spec SheetDocument2 paginic95500 Spec SheetOrnella MancinelliÎncă nu există evaluări

- CZLLCW511L TN enDocument4 paginiCZLLCW511L TN endrgilleÎncă nu există evaluări

- 1.4466 (310L Ug)Document4 pagini1.4466 (310L Ug)ramramjeyÎncă nu există evaluări

- High corrosion resistant stick electrode for duplex and lean duplex alloysDocument1 paginăHigh corrosion resistant stick electrode for duplex and lean duplex alloyscristian popescuÎncă nu există evaluări

- Technical Delivery Condition For: Hot Rolled Carbon (Micro Alloy) SteelDocument2 paginiTechnical Delivery Condition For: Hot Rolled Carbon (Micro Alloy) SteelManjunath UÎncă nu există evaluări

- 2205 Technical Data Sheet: Chemistry Mechanical PropertiesDocument6 pagini2205 Technical Data Sheet: Chemistry Mechanical PropertiesJandri JacobÎncă nu există evaluări

- Ampcoloy 972: Technical Data SheetDocument1 paginăAmpcoloy 972: Technical Data SheetmazaherramazaniÎncă nu există evaluări

- Westermann Table 8Document1 paginăWestermann Table 8muhd.qasimÎncă nu există evaluări

- Electrode Booklet F Web 93Document1 paginăElectrode Booklet F Web 93satnamÎncă nu există evaluări

- Adi 4 (2021 - 03 - 22 20 - 48 - 50 Utc)Document2 paginiAdi 4 (2021 - 03 - 22 20 - 48 - 50 Utc)Milton Pereira JúniorÎncă nu există evaluări

- Steel PropertiesDocument22 paginiSteel PropertiesMOHD SALMANÎncă nu există evaluări

- CZ120 (CW612N) : Technical DatasheetDocument1 paginăCZ120 (CW612N) : Technical DatasheetAmrut KanungoÎncă nu există evaluări

- Data Sheet CuZn20Al2AsDocument1 paginăData Sheet CuZn20Al2AsJean Carlos Reyna PascualÎncă nu există evaluări

- Section 2 - Nikko Welding ConsumablesDocument9 paginiSection 2 - Nikko Welding Consumablesangga franugrahaÎncă nu există evaluări

- CLC 17-12-2L: A 2%mo Containing 18 CR - 10 Ni Austenitic Stainless Steel (316L Grade)Document4 paginiCLC 17-12-2L: A 2%mo Containing 18 CR - 10 Ni Austenitic Stainless Steel (316L Grade)PeterWayÎncă nu există evaluări

- CSF-71T en 2014Document1 paginăCSF-71T en 2014HoangÎncă nu există evaluări

- CSF-71T en 2014Document1 paginăCSF-71T en 2014Yousab CreatorÎncă nu există evaluări

- 6063 ProfilesDocument1 pagină6063 ProfilesBPP-Tech PythonÎncă nu există evaluări

- P P P P: Alloy 416 Specifications: UNS S41600Document2 paginiP P P P: Alloy 416 Specifications: UNS S41600AVINASHRAJÎncă nu există evaluări

- S-8018 B2Document5 paginiS-8018 B2Abhishek AnandÎncă nu există evaluări

- X-Tract Electrical Submersible Pump CableDocument2 paginiX-Tract Electrical Submersible Pump CableHarry RincónÎncă nu există evaluări

- 1414059256wpdm - Stainless Steel Grade AISI 310Document2 pagini1414059256wpdm - Stainless Steel Grade AISI 310Riian ApriansyahÎncă nu există evaluări

- Cu-HCP: C10300 Industrial RolledDocument7 paginiCu-HCP: C10300 Industrial RolledpierocarnelociÎncă nu există evaluări

- 316 Tubeing TrisDocument1 pagină316 Tubeing Triscenter steel110Încă nu există evaluări

- E883-11 (Reapproved 2017)Document16 paginiE883-11 (Reapproved 2017)Miguel Bazaldua0% (1)

- Armco Pure Iron PDFDocument12 paginiArmco Pure Iron PDFsmith willÎncă nu există evaluări

- Catalogue Cen TC 132 November 2017 PDFDocument32 paginiCatalogue Cen TC 132 November 2017 PDFСтанислав ПодольскийÎncă nu există evaluări

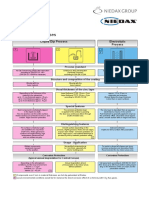

- Poka Yoke PDFDocument62 paginiPoka Yoke PDFmartinÎncă nu există evaluări

- High Nitrogen Nickel Free Austenitic SteelsDocument9 paginiHigh Nitrogen Nickel Free Austenitic Steelssmith willÎncă nu există evaluări

- Data Table For Grades Tool Steels & Die Steels 1.2327: 1.2327 Standard NumberDocument3 paginiData Table For Grades Tool Steels & Die Steels 1.2327: 1.2327 Standard Numbersmith willÎncă nu există evaluări

- Armco Pure Iron PDFDocument12 paginiArmco Pure Iron PDFsmith willÎncă nu există evaluări

- Gate Metallurgical Engineering 2014Document15 paginiGate Metallurgical Engineering 2014kgupta27Încă nu există evaluări

- Armco Pure Iron PDFDocument12 paginiArmco Pure Iron PDFsmith willÎncă nu există evaluări

- Steel Heat Treatment Handbook Chapter 12Document46 paginiSteel Heat Treatment Handbook Chapter 12Syed Shoaib Raza100% (1)

- Bible of LD and Heat Treatment by AzharDocument96 paginiBible of LD and Heat Treatment by Azharazher03100% (1)

- Steel Heat Treatment Handbook Chapter 12Document46 paginiSteel Heat Treatment Handbook Chapter 12Syed Shoaib Raza100% (1)

- Influence of bainite morphology on impact toughness of cementite-free bainitic steelsDocument8 paginiInfluence of bainite morphology on impact toughness of cementite-free bainitic steelssmith willÎncă nu există evaluări

- Fundamentals of EAF and Ladle Slags and Ladle Refining PrinciplesDocument73 paginiFundamentals of EAF and Ladle Slags and Ladle Refining Principlessatish_trivediÎncă nu există evaluări

- Crank Shaft ForgingDocument6 paginiCrank Shaft Forgingsmith willÎncă nu există evaluări

- Astm A694 F65Document1 paginăAstm A694 F65adenlanÎncă nu există evaluări

- 7 BASIC QC TOOLS - and - 7 NEW MANAGEMENT - and - PLANNING TOOLS PDFDocument3 pagini7 BASIC QC TOOLS - and - 7 NEW MANAGEMENT - and - PLANNING TOOLS PDFsmith willÎncă nu există evaluări

- Etching Specialty AlloysDocument6 paginiEtching Specialty AlloysNitin100% (1)

- MTDocument24 paginiMTNaunihal KumarÎncă nu există evaluări

- A 182Document25 paginiA 182Roger RojasÎncă nu există evaluări

- 1.2379 Tool SteelDocument8 pagini1.2379 Tool Steelsmith willÎncă nu există evaluări

- 15-5 PH Technical DataDocument7 pagini15-5 PH Technical Datasmith will100% (1)

- C Is Health Su Raksha Policy WordingDocument16 paginiC Is Health Su Raksha Policy Wordingsmith willÎncă nu există evaluări

- Fatigue Behaviors of Z2CND 18.2N Stainless Steel Under Thermal - Mechanical CyclingDocument8 paginiFatigue Behaviors of Z2CND 18.2N Stainless Steel Under Thermal - Mechanical Cyclingsmith willÎncă nu există evaluări

- Iso 2768-1: 1989Document7 paginiIso 2768-1: 1989jferreiraÎncă nu există evaluări

- Job No - 71301001 To 01004 - Af DrawingDocument1 paginăJob No - 71301001 To 01004 - Af Drawingsmith willÎncă nu există evaluări

- Structural and Wear Characterization of Heat Treated En24 SteelDocument7 paginiStructural and Wear Characterization of Heat Treated En24 Steelsmith willÎncă nu există evaluări

- ISO IEC 17025 PresentationDocument18 paginiISO IEC 17025 PresentationVishal MandlikÎncă nu există evaluări

- XC 38 H 1Document1 paginăXC 38 H 1smith willÎncă nu există evaluări

- ISO IEC 17025 PresentationDocument18 paginiISO IEC 17025 PresentationVishal MandlikÎncă nu există evaluări

- CarTech® Custom 455® StainlessDocument11 paginiCarTech® Custom 455® StainlessElkin ColoradoÎncă nu există evaluări

- Rapid Stress Relief and TemperingDocument8 paginiRapid Stress Relief and Temperingtbmari100% (1)

- Focus On Caustic Stress Corrosion CrackingDocument2 paginiFocus On Caustic Stress Corrosion Crackingcoolguy12345Încă nu există evaluări

- Rigid Liferaft - Coast Guard (G-Mse-4) Review: Drawing ListDocument12 paginiRigid Liferaft - Coast Guard (G-Mse-4) Review: Drawing ListamitbachchhasÎncă nu există evaluări

- Sorastro's Paint Conversion Chart - Sheet1Document4 paginiSorastro's Paint Conversion Chart - Sheet1Agnieszka PełkaÎncă nu există evaluări

- Complete cleaning with Scale Sniper's new non-corrosive methodDocument10 paginiComplete cleaning with Scale Sniper's new non-corrosive methodGary M TrajanoÎncă nu există evaluări

- Válvula Con Poste IndicadorDocument20 paginiVálvula Con Poste IndicadorAbel Enríquez RomeroÎncă nu există evaluări

- MCD 2Document21 paginiMCD 2Charles Nunez100% (2)

- Rotary PipeCLADDocument7 paginiRotary PipeCLADsafari7Încă nu există evaluări

- Data Sheet 124Document32 paginiData Sheet 124Vijay YadavÎncă nu există evaluări

- Shieldinggases Aws 5.32 PDFDocument3 paginiShieldinggases Aws 5.32 PDFessnelsonÎncă nu există evaluări

- Chemistry Project STPM 2016Document13 paginiChemistry Project STPM 2016Sabri Bri EDÎncă nu există evaluări

- Painting Istructions Accroding ISO 12944-5Document40 paginiPainting Istructions Accroding ISO 12944-5giulioiussich100% (5)

- Superconductivity PresentationDocument26 paginiSuperconductivity PresentationSabrina Palazzese Di BasilioÎncă nu există evaluări

- CTL - Contract of IronDocument3 paginiCTL - Contract of IronJohn R LaytonÎncă nu există evaluări

- Application of Phase DiagramDocument66 paginiApplication of Phase Diagrammm11_nedÎncă nu există evaluări

- Dgca Module 07 Part 01Document14 paginiDgca Module 07 Part 01Sanjay ChaudharyÎncă nu există evaluări

- Galvanizing Processes ComparisonDocument3 paginiGalvanizing Processes ComparisonAlin MoicaÎncă nu există evaluări

- Standard Sheet Metal GaugesDocument2 paginiStandard Sheet Metal Gaugesa_toupsÎncă nu există evaluări

- Project Standards and Specifications Piping Materials Rev01webDocument12 paginiProject Standards and Specifications Piping Materials Rev01webroy_b200933% (3)

- 3Document8 pagini3Muhammad HannanÎncă nu există evaluări

- Flottec 2000 Series Collector Product Data SheetDocument0 paginiFlottec 2000 Series Collector Product Data Sheetrichard gutierrezÎncă nu există evaluări

- Heat Treating Titanium Alloys for Strength and PropertiesDocument10 paginiHeat Treating Titanium Alloys for Strength and PropertiesPutu Calista Gitta100% (1)

- Mil DTL 1222 FastenersDocument51 paginiMil DTL 1222 Fastenersdnvrus100% (1)

- PDF Cladding TechnologyDocument65 paginiPDF Cladding TechnologyPradeep LakumÎncă nu există evaluări

- STULLER x1 WHITE GOLD ALOYDocument4 paginiSTULLER x1 WHITE GOLD ALOYFarah ShurbajiÎncă nu există evaluări

- Pengenalan TBB 2019-26 Agt-SeptDocument103 paginiPengenalan TBB 2019-26 Agt-SeptAngga GerradÎncă nu există evaluări

- Equipment Design HW01Document4 paginiEquipment Design HW01Grin NikiforovÎncă nu există evaluări

- Test Master COMPLETE FOR TESTTINGDocument2 paginiTest Master COMPLETE FOR TESTTINGHywyn Aric AlmeidaÎncă nu există evaluări

- 38 Alemite Product Catalog PDFDocument277 pagini38 Alemite Product Catalog PDFthailan100% (1)