Documente Academic

Documente Profesional

Documente Cultură

Alexandre Ferreira - 11 PDF

Încărcat de

Kev LhuillierTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Alexandre Ferreira - 11 PDF

Încărcat de

Kev LhuillierDrepturi de autor:

Formate disponibile

CRYOGENIC PRESSURE TEMPERATURE SWING ADSORPTION PROCESS FOR NATURAL GAS

UPGRADE

Mariana A. Moreira, LA LSRE-LCM, Department of Chemical Engineering, University of Porto

mamoreira@fe.up.pt

Ana M. Ribeiro, LA LSRE-LCM, Department of Chemical Engineering, University of Porto

Alexandre F.P. Ferreira, LA LSRE-LCM, Department of Chemical Engineering, University of Porto

Alírio E. Rodrigues, LA LSRE-LCM, Department of Chemical Engineering, University of Porto

Key Words: Cryo-PTSA; Natural gas upgrade; Binderless 13X zeolite; GERG-2008 EoS

The energy and chemical sectors are suffering remarkable changes. In this way, producing abundant quantity of

energy with high quality, economic and environmental viability and sustainability is the main concern of the

present times. One of such vital components of the world’s energy supply that fulfills the abovementioned

requirements is natural gas [1].

Natural gas consists of 85–95% methane, but it also contains considerable amounts of heavier hydrocarbons as

well as other compounds (CO2, N2, Hg, He, H2S) [1]. In order to meet the pipeline quality standard specifications

or Liquefied Natural Gas (LNG) production, impurities must be removed. Carbon dioxide is one of the major

contaminants in natural gas, reducing its energy content and becoming acidic and corrosive in the presence of

water, damaging pipelines and equipment. In LNG processing plants CO 2 can solidify, blocking the pipeline

systems and causing transportation drawbacks [1]. In order to meet the pipeline quality standard specifications

an upper limit for nitrogen and carbon dioxide of 4 and 2% is necessary, respectively. While, to inhibit the

formation of dry ice in the liquefaction step, CO2 content must be reduced to 50 ppm level [2, 3].

Among the several separation technologies available for natural gas upgrade, such as chemical absorption,

physical absorption, cryogenic distillation and membrane processes, adsorption processes are considered a

competitive solution. Removal of carbon dioxide from natural gas for LNG production, can be carried out by

cryogenic distillation using a multicolumn sequence to obtain a product stream with less than 50 ppm of CO2 [4].

Cryogenic adsorption-based processes, particularly pressure thermal swing adsorption, arise as a reliable and

innovative alternative to replace the distillation columns, in particular the last one.

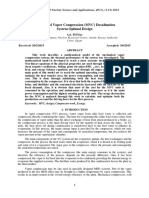

In this work, the implementation of a new

methodology to design and simulate an

industrial scale pressure and temperature

swing adsorption process at low temperature

(Cryo-PTSA) is presented, in order to

produce an almost pure methane stream,

with a maximum of 50 ppm of CO2, from a

stream containing 0.9% of CO2, maximizing

the methane recovery. Binderless 13X zeolite

was selected as adsorbent and adsorption

equilibrium isotherms of methane and carbon

dioxide were determined experimentally, in

the temperature range 183–473 K, up to 80

bar. The GERG-2008 Equation of State

(EoS) was used during the dynamic

Figure 1 – Carbon dioxide molar fraction history at the column simulations to account for deviation from

outlet for a Cryo-PTSA cycle simulation using binderless 13X ideal gas law, through the use of REFPROP

zeolite. (REFerence fluid PROPerties) software

package. A methane recovery of 90.7% and

a product stream with 41.8 ppm of CO2 in CH4 is achieved after cyclic steady state is reached. Cryo-PTSA

simulation results were then compared with an existing cryogenic distillation process. The results obtained by

process simulation showed that it is possible to replace the 3rd column of the cryogenic distillation process by a

Cryo-PTSA achieving higher CH4 recovery and lower power consumption (2.2 MW).

1. B. Shimekit and H. Mukhtar, in Advances in Natural Gas Technology, 2012, InTech.

2. Cryogenic Fuels Inc. Liquid Methane Fuel Characterization and Safety Assessment Report. 1991.

3. S. Cavenati, C.A. Grande, and A.E. Rodrigues, Adsorption, 2005. 11(1): p. 549-554.

4. D. Berstad, P. Nekså, and R. Anantharaman, Energy Procedia, 2012. 26( 2nd Trondheim Gas

Technology Conference): p. 41-48.

S-ar putea să vă placă și

- Biogas Production From LandfillsDocument11 paginiBiogas Production From LandfillsMarcus NguyễnÎncă nu există evaluări

- 1 s2.0 S1876610213003305 MainDocument10 pagini1 s2.0 S1876610213003305 MainDeva AfrgÎncă nu există evaluări

- Optimization of An Industrial Methanol Reactor UsingDocument14 paginiOptimization of An Industrial Methanol Reactor Usingguigoal2010Încă nu există evaluări

- Artigo PicheDocument14 paginiArtigo PicheEduardo PetraconiÎncă nu există evaluări

- Separation and Purification Technology: Omid Taheri Qazvini, Shohreh FatemiDocument16 paginiSeparation and Purification Technology: Omid Taheri Qazvini, Shohreh FatemidoufethiÎncă nu există evaluări

- A Computational Model of Catalyzed Carbon Sequestration: Back To Exploration - 2008 CSPG CSEG CWLS ConventionDocument4 paginiA Computational Model of Catalyzed Carbon Sequestration: Back To Exploration - 2008 CSPG CSEG CWLS ConventionsahanchemÎncă nu există evaluări

- 2005 - Pressure - Swing - Adsorption - For - Carbon - Dioxide - SequeDocument11 pagini2005 - Pressure - Swing - Adsorption - For - Carbon - Dioxide - SequeMarcela FragozoÎncă nu există evaluări

- Reff5 PDFDocument5 paginiReff5 PDFJuneeÎncă nu există evaluări

- Tar Reforming Under A Microwave Plasma TorchDocument8 paginiTar Reforming Under A Microwave Plasma Torchanura7Încă nu există evaluări

- Production of High Quality Syngas From Argonwater Plasma Gasification of Biomass and WasteDocument4 paginiProduction of High Quality Syngas From Argonwater Plasma Gasification of Biomass and WasteAyush daveÎncă nu există evaluări

- Arshad 2016Document24 paginiArshad 2016Maythee SaisriyootÎncă nu există evaluări

- Exergy Analysis of Hydrogen Production Via Steam Methane ReformingDocument20 paginiExergy Analysis of Hydrogen Production Via Steam Methane Reformingxman4243Încă nu există evaluări

- Comparison of Different CO Recovery Processes in Their Optimum Operating Conditions FromDocument6 paginiComparison of Different CO Recovery Processes in Their Optimum Operating Conditions FromFunky labsÎncă nu există evaluări

- The Partial Oxidation of Methane To Syngas in A Palladium Membrane Reactor: Simulation and Experimental StudiesDocument11 paginiThe Partial Oxidation of Methane To Syngas in A Palladium Membrane Reactor: Simulation and Experimental StudiesMehul VarshneyÎncă nu există evaluări

- S18755 AsdfDocument13 paginiS18755 AsdfRobin HoodÎncă nu există evaluări

- CO2 Absorption Simulation PaperDocument11 paginiCO2 Absorption Simulation PaperUmer AzharÎncă nu există evaluări

- Important Factors Affecting Carbon Dioxide Removal Efficiency by Using Extra-High Concentrated Monoethanolamine Solutions and High-Capacity Packings, (1998)Document4 paginiImportant Factors Affecting Carbon Dioxide Removal Efficiency by Using Extra-High Concentrated Monoethanolamine Solutions and High-Capacity Packings, (1998)Lily NurdianaÎncă nu există evaluări

- Fuel Processing Technology: Research ArticleDocument11 paginiFuel Processing Technology: Research ArticleleylaÎncă nu există evaluări

- CO2 absorption characteristics of DPTA solventDocument10 paginiCO2 absorption characteristics of DPTA solventJuan Fernando Cano LarrotaÎncă nu există evaluări

- 1 s2.0 S1876610214008881 Main PDFDocument10 pagini1 s2.0 S1876610214008881 Main PDFSanaÎncă nu există evaluări

- 11R PDFDocument7 pagini11R PDFMary Grace VelitarioÎncă nu există evaluări

- GC/MS Characterization of Liquids Generated From Low-Temperature Pyrolysis of WoodDocument13 paginiGC/MS Characterization of Liquids Generated From Low-Temperature Pyrolysis of WoodMutia Nurul OctaviaÎncă nu există evaluări

- Advances in Mud Gas Interpretation Whilst Drilling PDFDocument12 paginiAdvances in Mud Gas Interpretation Whilst Drilling PDFlakhanmukhtiarÎncă nu există evaluări

- Advances in Mud Gas Interpretation Whilst Drilling PDFDocument12 paginiAdvances in Mud Gas Interpretation Whilst Drilling PDFlakhanmukhtiarÎncă nu există evaluări

- Thermal Stability of Polyethylenimine Based Carbon Dioxide Adsorbents and Its Influence On Selection of Regeneration StrategiesDocument9 paginiThermal Stability of Polyethylenimine Based Carbon Dioxide Adsorbents and Its Influence On Selection of Regeneration StrategiesJaancaarloDiiazÎncă nu există evaluări

- Exergy Analysis of Hydrogen Production Via Biogas Dry ReformingDocument8 paginiExergy Analysis of Hydrogen Production Via Biogas Dry ReformingalimoÎncă nu există evaluări

- HYSYS Simulation For Natural Gas Dehydration and SweeteningDocument8 paginiHYSYS Simulation For Natural Gas Dehydration and SweeteningHaziq MirzaÎncă nu există evaluări

- Kinetic Modeling of Biomass Steam Gasification System For Hydrogen Production With CO AdsorptionDocument7 paginiKinetic Modeling of Biomass Steam Gasification System For Hydrogen Production With CO Adsorptionprash_13Încă nu există evaluări

- Samanta 2011Document8 paginiSamanta 2011SanaÎncă nu există evaluări

- ZEOLIT 13X A Gholipour2016Document27 paginiZEOLIT 13X A Gholipour2016Malasari NasutionÎncă nu există evaluări

- 2013-Simulation and parametric study of post combustion CO2 capture process using (AMP+PZ) blended solventDocument10 pagini2013-Simulation and parametric study of post combustion CO2 capture process using (AMP+PZ) blended solventbaohongqian2020Încă nu există evaluări

- Separation of Carbon Dioxide From Flue Gas Using Adsorption On Porous SolidsDocument25 paginiSeparation of Carbon Dioxide From Flue Gas Using Adsorption On Porous SolidsMARUFÎncă nu există evaluări

- Reformer CH4 2Document6 paginiReformer CH4 2Jose ValderramaÎncă nu există evaluări

- 1-S2.0-S0378382015302502-Main LeonardoDocument10 pagini1-S2.0-S0378382015302502-Main LeonardoCanevesi RafaelÎncă nu există evaluări

- Laminar flame speeds of syngas with CO2 dilutionDocument7 paginiLaminar flame speeds of syngas with CO2 dilutionEduardoÎncă nu există evaluări

- Optimization of A Methane Autothermal Reforming-Based Hydrogen Production System With Low CO2 Emission PDFDocument6 paginiOptimization of A Methane Autothermal Reforming-Based Hydrogen Production System With Low CO2 Emission PDFQian Jun AngÎncă nu există evaluări

- Documents 2Document18 paginiDocuments 2JIM KENNETH AMIHANÎncă nu există evaluări

- Journal of Co Utilization: SciencedirectDocument9 paginiJournal of Co Utilization: SciencedirectGustavo gomesÎncă nu există evaluări

- HPU/06 - Hydrogen Production from Fossil and Biomass FuelsDocument4 paginiHPU/06 - Hydrogen Production from Fossil and Biomass FuelsMazen OthmanÎncă nu există evaluări

- Kinetic Studies On Catalytic Decomposition of Methane To Hydrogen and Carbon Over Ni/Tio CatalystDocument7 paginiKinetic Studies On Catalytic Decomposition of Methane To Hydrogen and Carbon Over Ni/Tio CatalystAaLee IsaisÎncă nu există evaluări

- Various Configurations of Co2 CaptureDocument16 paginiVarious Configurations of Co2 CaptureMaythee SaisriyootÎncă nu există evaluări

- Absorber Intercooling Configurations Using Aqueous Piperazine For Capture From Sources With 4 To 27% CODocument20 paginiAbsorber Intercooling Configurations Using Aqueous Piperazine For Capture From Sources With 4 To 27% COasmaa aliÎncă nu există evaluări

- @@@thermodynamic Analysis of Chemical Looping Combustion Integrated Oxidative Dehydrogenation of Propane To Propylene With CO2Document9 pagini@@@thermodynamic Analysis of Chemical Looping Combustion Integrated Oxidative Dehydrogenation of Propane To Propylene With CO2Daniel Z JucaÎncă nu există evaluări

- 1 s2.0 S0360319920339227 MainDocument10 pagini1 s2.0 S0360319920339227 MainLusiana OliviaÎncă nu există evaluări

- Process simulation of hydrogen production from producer gas using HTS catalysisDocument33 paginiProcess simulation of hydrogen production from producer gas using HTS catalysisKaren GomezÎncă nu există evaluări

- Simpson 2007Document10 paginiSimpson 2007Reyner ParreirasÎncă nu există evaluări

- Chemical Engineering Science: Helei Liu, Moxia Li, Raphael Idem, Paitoon (PT) Tontiwachwuthikul, Zhiwu LiangDocument11 paginiChemical Engineering Science: Helei Liu, Moxia Li, Raphael Idem, Paitoon (PT) Tontiwachwuthikul, Zhiwu LiangJuan Fernando Cano LarrotaÎncă nu există evaluări

- Simulation of CO2 Capture Using MEA Scrubbing A Flowsheet Decomposition Method PDFDocument13 paginiSimulation of CO2 Capture Using MEA Scrubbing A Flowsheet Decomposition Method PDFSuprio KamalÎncă nu există evaluări

- A Combined Thermo-Kinetic Analysis of Various Methane ReformingDocument13 paginiA Combined Thermo-Kinetic Analysis of Various Methane ReformingShane SmithÎncă nu există evaluări

- Simulation and Experimental Results of PSA Process For Production of Hydrogen Used in Fuel CellsDocument18 paginiSimulation and Experimental Results of PSA Process For Production of Hydrogen Used in Fuel Cellswww.beatricechongÎncă nu există evaluări

- 26 - Exergy Analysis of A Conceptual CO2 CaptureDocument18 pagini26 - Exergy Analysis of A Conceptual CO2 CaptureslmokraouiÎncă nu există evaluări

- Puig Gamero2018 PDFDocument12 paginiPuig Gamero2018 PDFhelloÎncă nu există evaluări

- Pressure Swing Adsorption For Carbon Dioxide SequeDocument11 paginiPressure Swing Adsorption For Carbon Dioxide SequeyahyaÎncă nu există evaluări

- Enhancement of Catalytic Performance of Porous Membrane Reactor With Ni Catalyst For Combined Steam and Carbon Dioxide Reforming of Methane ReactionDocument6 paginiEnhancement of Catalytic Performance of Porous Membrane Reactor With Ni Catalyst For Combined Steam and Carbon Dioxide Reforming of Methane ReactionWassachol SumarasinghaÎncă nu există evaluări

- Optimization of A Six Step Pressure SwinDocument19 paginiOptimization of A Six Step Pressure SwinRudi SuwandiÎncă nu există evaluări

- Journal of Cleaner Production: Rosaria Augelletti, Maria Conti, Maria Cristina AnnesiniDocument9 paginiJournal of Cleaner Production: Rosaria Augelletti, Maria Conti, Maria Cristina AnnesiniGulzar AhmadÎncă nu există evaluări

- Plasma Pyrolysis of Methane To Hydrogen and Carbon BlackDocument11 paginiPlasma Pyrolysis of Methane To Hydrogen and Carbon BlackBamrung Sungnoen100% (1)

- Mercaptan Removal Cyclic AdsorptionDocument12 paginiMercaptan Removal Cyclic AdsorptionReynald DaluzÎncă nu există evaluări

- Monteiro 2013Document9 paginiMonteiro 2013mppatilmayurÎncă nu există evaluări

- Carbon Capture Technologies for Gas-Turbine-Based Power PlantsDe la EverandCarbon Capture Technologies for Gas-Turbine-Based Power PlantsÎncă nu există evaluări

- IRQ - Resumen R. No IdealesDocument6 paginiIRQ - Resumen R. No IdealeskevinÎncă nu există evaluări

- Kami Export - IRQ - Resumen Gas LiquidoDocument6 paginiKami Export - IRQ - Resumen Gas LiquidokevinÎncă nu există evaluări

- ALTOSONICIIIDocument20 paginiALTOSONICIIIAdiNurAshariÎncă nu există evaluări

- aspenONE Academic BrochureDocument7 paginiaspenONE Academic BrochurekevinÎncă nu există evaluări

- QBJ Dehy Brochure PDFDocument1 paginăQBJ Dehy Brochure PDFjollyÎncă nu există evaluări

- Norma Astm 1Document2 paginiNorma Astm 1kevinÎncă nu există evaluări

- Jump Start Aspen HYSYS V8Document29 paginiJump Start Aspen HYSYS V8hayfronbsterÎncă nu există evaluări

- Control Valve Sizing GuideDocument23 paginiControl Valve Sizing GuideEnerprec SASÎncă nu există evaluări

- PE 311 (13 Credits) :: Unit Operation For Petroleum IndustryDocument52 paginiPE 311 (13 Credits) :: Unit Operation For Petroleum IndustryMbarouk Shaame MbaroukÎncă nu există evaluări

- Runfeng Cryogenic CylinderDocument9 paginiRunfeng Cryogenic CylinderCrystal JiaÎncă nu există evaluări

- INA-Naftaplin's Development of Oil and Gas Production, Gathering and Transportation TechnologyDocument16 paginiINA-Naftaplin's Development of Oil and Gas Production, Gathering and Transportation TechnologyStefano SinožićÎncă nu există evaluări

- Set 3 AnsDocument13 paginiSet 3 Ansluis fernando santos narvaezÎncă nu există evaluări

- SHS Gr.12 Chap 9Document23 paginiSHS Gr.12 Chap 9Cj NacarioÎncă nu există evaluări

- Effects of C02 Solubility in Brine On The Compositional Simulation of C02 FloodsDocument6 paginiEffects of C02 Solubility in Brine On The Compositional Simulation of C02 FloodsNatalia StefaniaÎncă nu există evaluări

- Welding: Telegram - Contact - 7887811411Document4 paginiWelding: Telegram - Contact - 7887811411shreyas jadhavÎncă nu există evaluări

- Comparison of Line Pack Calculation Using Aspen Plus Dynamics and by Using Manual CalculationsDocument24 paginiComparison of Line Pack Calculation Using Aspen Plus Dynamics and by Using Manual CalculationsWalid Ben HuseinÎncă nu există evaluări

- Basic Principles and DefectsDocument18 paginiBasic Principles and DefectsAkshaj NevgiÎncă nu există evaluări

- Separation of Mixture NotesDocument5 paginiSeparation of Mixture NotesNahyan Haque SharifÎncă nu există evaluări

- Gas Laws Explained: Boyle's, Charles', and MoreDocument16 paginiGas Laws Explained: Boyle's, Charles', and MorepankajÎncă nu există evaluări

- Pressure Vessels Data SheetDocument1 paginăPressure Vessels Data SheetAndrés SepúlvedaÎncă nu există evaluări

- Guentner Subcooling EN PDFDocument18 paginiGuentner Subcooling EN PDFNotlim MarulandaÎncă nu există evaluări

- Grade (12) Chemistry (Myanmar)Document171 paginiGrade (12) Chemistry (Myanmar)HlaMinNaingÎncă nu există evaluări

- Static Pitot Tube: Flow MeasurementDocument23 paginiStatic Pitot Tube: Flow MeasurementMuthu KarthikÎncă nu există evaluări

- HeiDocument1 paginăHeiJose Nelson Moreno BÎncă nu există evaluări

- Mechanical Vapor Compression Desalination System Optimal DesignDocument13 paginiMechanical Vapor Compression Desalination System Optimal DesignSajal GuptaÎncă nu există evaluări

- Refrigerants and Oil ChemistryDocument27 paginiRefrigerants and Oil Chemistryrogelio garciaÎncă nu există evaluări

- PSV Sizing SheetDocument5 paginiPSV Sizing SheetDhanraj Vasanth100% (1)

- Welding Processes PresentationDocument101 paginiWelding Processes PresentationKentDemeterio100% (1)

- PND1000-3 Dryer ProductsDocument10 paginiPND1000-3 Dryer ProductsPartsGopher.comÎncă nu există evaluări

- Density of LiquidsDocument5 paginiDensity of LiquidsJose GalvanÎncă nu există evaluări

- 9A01304 Fluid MechanicsDocument4 pagini9A01304 Fluid MechanicssivabharathamurthyÎncă nu există evaluări

- Gas LawsDocument24 paginiGas LawsJohn Louie NocheÎncă nu există evaluări

- Steam Production and Usage: Properties of Dry SaturatedDocument13 paginiSteam Production and Usage: Properties of Dry SaturatedATUL MISRAÎncă nu există evaluări

- UNIT 4 LECTURE 2 AS DiamagnetismDocument4 paginiUNIT 4 LECTURE 2 AS DiamagnetismSaiful ShokriÎncă nu există evaluări

- Chismtry Form 2 Government BookDocument119 paginiChismtry Form 2 Government BookAmal AwaleÎncă nu există evaluări

- Form 4 Physics - HeatDocument8 paginiForm 4 Physics - HeatDenisse ChiaÎncă nu există evaluări

- Engineering Thermodynamics Real GasesDocument16 paginiEngineering Thermodynamics Real Gasesonel badroÎncă nu există evaluări