Documente Academic

Documente Profesional

Documente Cultură

Sieve Analysis Lab Report

Încărcat de

Jelaiza GuiasDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Sieve Analysis Lab Report

Încărcat de

Jelaiza GuiasDrepturi de autor:

Formate disponibile

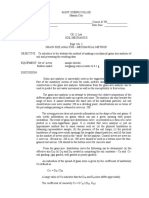

Name: Jerwin M.

Tadifa Score:_________________

Course: MET 103 Mineral Processing

Term: 2nd Sem. AY 2018-2019

ACTIVITY NO. 4 SIEVE ANALYSIS

LABORATORY REPORT

INTRODUCTION

A sieve analysis (or gradation test) is a practice or procedure used (commonly used in civil

engineering) to assess the particle size distribution (also called gradation) of a granular material

by allowing the material to pass through a series of sieves of progressively smaller mesh size

and weighing the amount of material that is stopped by each sieve as a fraction of the whole

mass.

The size distribution is often of critical importance to the way the material performs in use. A

sieve analysis can be performed on any type of non-organic or organic granular materials

including sands, crushed rock, clays, granite, feldspars, coal, soil, a wide range of manufactured

powders, grain and seeds, down to a minimum size depending on the exact method. Being such

a simple technique of particle sizing, it is probably the most common

TOOLS & EQUIPEMENT: (Specify the different tools and equipment used in the activity including PPE)

PROCEDURE

1. Prepare sample results from the previous laboratory activity. (Coarse Grained, Fine Grained)

2. Heat the samples on the oven @ 100-200 °C for 10-20 minutes to remove the moisture

content.

3. Weigh the two samples to determine the true mass of each sample.

4. Stack the mesh containers from lower mesh # to higher mesh # ordering it from top to

bottom in preparation for mechanical sieving.

5. Place a determined weight of coarse-grained sample to the stacked mesh container and

proceed to mechanical sieving for 15 minutes.

6. After sieving, weigh the lowest parts of the stacked mesh container to determine whether or

not its weight is less than 5% of the total mass of the sample. If not add another container with

higher mesh # and repeat sieving procedure. Repeat this step until less than 5% mass is

achieved at the very bottom part of the stacked containers.

7. Weigh the mass captured by each container with specific mesh #/size to determine the mass

captured by the container. Record the Data acquired.

8. Repeat steps 4-7 using the Fine-grained sample.

Results and Discussions: Present the data collected and discuss the significance of these results.

I. Results and Discussion (40%) (Additional pages maybe added). Present your results as discussed in the class

(with table and graphs). Make discussions on the results.

A. Before Pulverizer or After Roll Crusher

Present a table here and provide discussion on your findings.

MET 103 Mineral Processing

College of Engineering and Geosciences

CARAGA STATE UNIVERSITY

Page 1 of 3

Name: Jerwin M. Tadifa Score:_________________

Course: MET 103 Mineral Processing

Term: 2nd Sem. AY 2018-2019

Insert Figure

Discuss the figure..

B. After Pulverizer

Insert Table and discuss

Insert Figure and Discuss

Provide a discussion comparing the results from A and B.

II. Knowledge and Comprehension (30%)

MET 103 Mineral Processing

College of Engineering and Geosciences

CARAGA STATE UNIVERSITY

Page 2 of 3

Name: Jerwin M. Tadifa Score:_________________

Course: MET 103 Mineral Processing

Term: 2nd Sem. AY 2018-2019

Q1: What is the importance of sieve analysis in mineral processing?

_____________________________________________________________________________________________

_____________________________________________________________________________________________

__________________________________________________________________________________________.

Q2: What are the factors that affect the accuracy of sieve analysis results?

_____________________________________________________________________________________________

_____________________________________________________________________________________________

_____________________________________________________________________________________________

Q3: Describe your learnings from this activity.

_____________________________________________________________________________________________

_____________________________________________________________________________________________

_____________________________________________________________________________________________

____________________________________________________________________________________________.

III. Demonstration of Skills (30%)

Score

Cleanliness in the laboratory – 30% _____

Orderliness in performing the procedure – 30% _____

Participation in performing the activity – 20% _____

Wearing proper PPE (20%) _____

Total _____

MET 103 Mineral Processing

College of Engineering and Geosciences

CARAGA STATE UNIVERSITY

Page 3 of 3

S-ar putea să vă placă și

- Determining The Moisture Content of Soil (Conventional Oven Method)Document3 paginiDetermining The Moisture Content of Soil (Conventional Oven Method)atang0101Încă nu există evaluări

- Sieve Analysis 1Document10 paginiSieve Analysis 1Aniruddha ChakrabortyÎncă nu există evaluări

- Multi Storey Building FramesDocument24 paginiMulti Storey Building Framespriyanka0% (2)

- Che Lab Report On Flow Over WeirsDocument14 paginiChe Lab Report On Flow Over WeirsJonelou Cusipag100% (1)

- Quality Assurance and ValidationDocument62 paginiQuality Assurance and ValidationMacharia ZachariaÎncă nu există evaluări

- Civil Lab Test 1Document4 paginiCivil Lab Test 1Kalomenni90% (10)

- Traxial Test Lab Full ReportDocument14 paginiTraxial Test Lab Full ReportMohd Nik Harith Fawwaz100% (3)

- Plastic LimitDocument9 paginiPlastic LimitPoovan Rajaratnam100% (1)

- A Report On Workability of Fresh Concrete by Slump TestDocument5 paginiA Report On Workability of Fresh Concrete by Slump TestRishabhJain100% (1)

- Basic Design of AHU (General)Document64 paginiBasic Design of AHU (General)Dimyati Es100% (5)

- GROUP - (5 Members) : Specific Gravity (GS)Document6 paginiGROUP - (5 Members) : Specific Gravity (GS)Katy PerryÎncă nu există evaluări

- Standard Practice For Reducing Samples of Aggregates To Testing SizeDocument5 paginiStandard Practice For Reducing Samples of Aggregates To Testing SizeCJPATAGANÎncă nu există evaluări

- Concrete Lab ReportDocument10 paginiConcrete Lab ReportMadalin-Cristian SalcianuÎncă nu există evaluări

- Constant Head Permeability TestDocument6 paginiConstant Head Permeability TestSalih MohayaddinÎncă nu există evaluări

- 34) Extraction of Bitumen From Paving MixturesDocument6 pagini34) Extraction of Bitumen From Paving MixturesPn EkanayakaÎncă nu există evaluări

- db2 Fundamentals Aix PDFDocument503 paginidb2 Fundamentals Aix PDFpndeepika50% (2)

- Sieve Analysis ReportDocument15 paginiSieve Analysis ReportTjia Tjie100% (1)

- Sieve Analysis Lab ReportDocument1 paginăSieve Analysis Lab ReportJohn Pierce Gumapac85% (33)

- Experiment No.1 Specific Gravity and Absorption of Coarse AggregateDocument2 paginiExperiment No.1 Specific Gravity and Absorption of Coarse AggregateJohn Robert Banez50% (10)

- Proctor Test and Field Density TestsDocument7 paginiProctor Test and Field Density TestsRamprasad RakhondeÎncă nu există evaluări

- Constant N Permeability ReportDocument24 paginiConstant N Permeability Reportilasensei50% (2)

- Conclusion Shear Box TestDocument1 paginăConclusion Shear Box TestFarhana Hussin100% (1)

- 4) Hydrometer Analysis TestDocument4 pagini4) Hydrometer Analysis TestPn Ekanayaka100% (4)

- Specific Gravity and Absorption of Coarse and Fine AggregatesDocument6 paginiSpecific Gravity and Absorption of Coarse and Fine AggregatesAlexandr Ignatenco50% (2)

- Concrete Mixing and Testing Lab ReportDocument8 paginiConcrete Mixing and Testing Lab ReportSoundMan56100% (4)

- Grain Size Analysis 2Document25 paginiGrain Size Analysis 2chiemenaÎncă nu există evaluări

- Sieve AnalysisDocument8 paginiSieve Analysisr6Yamaha100% (5)

- 84D8CDocument17 pagini84D8CDWNLD USRML100% (1)

- Unconfined Compression Test DataDocument6 paginiUnconfined Compression Test DataMehdi Hasan0% (1)

- Gi 7.030 Asme B30.16, Asme B30.7 BS 3243, BS 4898Document3 paginiGi 7.030 Asme B30.16, Asme B30.7 BS 3243, BS 4898engmuhmudÎncă nu există evaluări

- Unconfined Compression TestDocument8 paginiUnconfined Compression TestMohdIkrami100% (1)

- Los Angeles Abrasion TestDocument8 paginiLos Angeles Abrasion TestMuhammad Zulhusni Che RazaliÎncă nu există evaluări

- Exp 3aDocument4 paginiExp 3aKenneth PeraÎncă nu există evaluări

- Amine Gas Sweetening Systems PsDocument3 paginiAmine Gas Sweetening Systems Pscanada_198020008918Încă nu există evaluări

- CH12-Inventory Management PoliciesDocument32 paginiCH12-Inventory Management PoliciesChristian John Linalcoso AranteÎncă nu există evaluări

- Lab Materials (Bulk Density Course Aggregate)Document4 paginiLab Materials (Bulk Density Course Aggregate)Khairunnisa Zakiri33% (3)

- Experiment #3 Sieve AnalysisDocument3 paginiExperiment #3 Sieve AnalysisChristelle KharratÎncă nu există evaluări

- Slump Test of Portland Cement ConcreteDocument3 paginiSlump Test of Portland Cement ConcreteKevin P MendozaÎncă nu există evaluări

- CONCLUSION Bitumen TestDocument1 paginăCONCLUSION Bitumen TestFirash Imran100% (1)

- Liquid Limit Test of Soil Using Casagrande Apparatus PDFDocument2 paginiLiquid Limit Test of Soil Using Casagrande Apparatus PDFAkash SahuÎncă nu există evaluări

- Geotechnics Moisture Content Lab ReportDocument3 paginiGeotechnics Moisture Content Lab ReportNicole Harripersad63% (19)

- Lab Sheet - Atterberg LimitsDocument6 paginiLab Sheet - Atterberg LimitsLuqman YusofÎncă nu există evaluări

- Specific Gravity and Absorption of Coarse Aggregate (Astm C127) Testing ObjectivesDocument4 paginiSpecific Gravity and Absorption of Coarse Aggregate (Astm C127) Testing ObjectivesCucio, Chadric Dhale V.Încă nu există evaluări

- Dry Sieve AnalysisDocument9 paginiDry Sieve AnalysisHamierul Mohamad0% (1)

- Discussions Design Mix Concrete (Slump, Compacting, Design Form)Document6 paginiDiscussions Design Mix Concrete (Slump, Compacting, Design Form)Salmah AbasÎncă nu există evaluări

- HydrometerDocument13 paginiHydrometerShubhrajit MaitraÎncă nu există evaluări

- Specific Gravity Lab ReportDocument5 paginiSpecific Gravity Lab ReportOsama Al Mazrouai100% (1)

- ConclusionDocument5 paginiConclusionkhairulhakam50% (2)

- Determination of Consistency of Standard Cement PasteDocument3 paginiDetermination of Consistency of Standard Cement PasteAfifah FauziÎncă nu există evaluări

- Direct Shear Test ReprtDocument4 paginiDirect Shear Test ReprtShivaraj SubramaniamÎncă nu există evaluări

- Aggregate Crushing Value Test Lab ReportDocument2 paginiAggregate Crushing Value Test Lab ReportComr A Y ZarginaÎncă nu există evaluări

- Ductility TestDocument14 paginiDuctility TestTenzin Kesang100% (1)

- Experiment No.2 Specific Gravity and Absorption of Fine AggregateDocument2 paginiExperiment No.2 Specific Gravity and Absorption of Fine AggregateJohn Robert Banez60% (5)

- Experiment 3 Compaction TestDocument5 paginiExperiment 3 Compaction TestAnis Nurfarahanim Abdul Halim0% (1)

- Consolidation TestDocument2 paginiConsolidation TestTenzinKesang100% (1)

- ConclusionDocument1 paginăConclusionmacs_smac100% (3)

- Experiment No 1Document20 paginiExperiment No 1Israr MuhammadÎncă nu există evaluări

- CE162 Lab Report Abstract Atterberg LimitsDocument1 paginăCE162 Lab Report Abstract Atterberg LimitsAileen R. FaderÎncă nu există evaluări

- Liquid Limit Lab ReportDocument12 paginiLiquid Limit Lab ReportPoovan Rajaratnam0% (2)

- Specific Gravity of Coarse AggregatesDocument5 paginiSpecific Gravity of Coarse AggregatesMayolitesÎncă nu există evaluări

- Grain Size Analysis - Mechanical MethodDocument3 paginiGrain Size Analysis - Mechanical MethodRian BernanteÎncă nu există evaluări

- Experiment #2 Specific Gravity & Absorption of Fine and Coarse AggregatesDocument4 paginiExperiment #2 Specific Gravity & Absorption of Fine and Coarse AggregatesChristelle Kharrat100% (1)

- Experiment No. 7 Bulking of SandDocument1 paginăExperiment No. 7 Bulking of SandShubham GautamÎncă nu există evaluări

- Determination of Softening Point of Bituminous Material: ObjectiveDocument5 paginiDetermination of Softening Point of Bituminous Material: ObjectiveSudip ShresthaÎncă nu există evaluări

- Sieve Analysis of Coarse Aggregate TerkiniDocument8 paginiSieve Analysis of Coarse Aggregate TerkiniShazrin Zakaria0% (2)

- Lab Report 1 DETERMINATION OF AGGREGATE IMPACT VALUE (AIV) (BS 812-112)Document3 paginiLab Report 1 DETERMINATION OF AGGREGATE IMPACT VALUE (AIV) (BS 812-112)Kashif IqbaljÎncă nu există evaluări

- Highway Lab Report 9,10 and 11Document22 paginiHighway Lab Report 9,10 and 11Abdallah AlhasanÎncă nu există evaluări

- Final-Laboratory-Manual Group-4 2F CMTDocument49 paginiFinal-Laboratory-Manual Group-4 2F CMTTubal Ma. Aubrey G.Încă nu există evaluări

- Ep-15 CCTV, Telephone Fdas Riser DiagramDocument1 paginăEp-15 CCTV, Telephone Fdas Riser DiagramNyel ArmstrongÎncă nu există evaluări

- Cost Estimation-Case Study PDFDocument11 paginiCost Estimation-Case Study PDFTausique Sheikh100% (1)

- EBM Pabst - CPAP - BlowerDocument4 paginiEBM Pabst - CPAP - BlowerlouisÎncă nu există evaluări

- A Survey of Serviceable Spacecraft Failures PDFDocument8 paginiA Survey of Serviceable Spacecraft Failures PDFjuanra3171Încă nu există evaluări

- Industrial Training ReportDocument19 paginiIndustrial Training ReportRam PandeyÎncă nu există evaluări

- kd625 3 Om PDFDocument136 paginikd625 3 Om PDFLuis Quispe ChuctayaÎncă nu există evaluări

- ESP32 S2 DevKit Lipo - Rev - B1Document1 paginăESP32 S2 DevKit Lipo - Rev - B1Inventor TestÎncă nu există evaluări

- Dowsil 51 AdditiveDocument5 paginiDowsil 51 AdditiveYến HoàngÎncă nu există evaluări

- Redland Bonding Gutter Installation Instructions 3Document9 paginiRedland Bonding Gutter Installation Instructions 3JÎncă nu există evaluări

- Scoliosis BraceDocument8 paginiScoliosis BraceChandralina PakpahanÎncă nu există evaluări

- An ARN 147V Data SheetDocument2 paginiAn ARN 147V Data SheetStrawichDanielÎncă nu există evaluări

- Mvi56e MCMMCMXT Setup GuideDocument78 paginiMvi56e MCMMCMXT Setup GuidepaplusÎncă nu există evaluări

- SRB ProcessingDocument26 paginiSRB Processingsudheer92Încă nu există evaluări

- Effectos de Cromado en Microestrutura y Propiedades de Anticorrosion 316LDocument11 paginiEffectos de Cromado en Microestrutura y Propiedades de Anticorrosion 316Lraulpalma93Încă nu există evaluări

- Rod Lock CylindersDocument7 paginiRod Lock CylindersmaciasrobÎncă nu există evaluări

- APIs and Business Functions GuideDocument104 paginiAPIs and Business Functions GuideSindhu RamÎncă nu există evaluări

- MP720E47HT: Technical DescriptionsDocument18 paginiMP720E47HT: Technical DescriptionsBroCactusÎncă nu există evaluări

- Engineering Software Research Center SANSPRO V.5.20Document4 paginiEngineering Software Research Center SANSPRO V.5.20Nathan M7Încă nu există evaluări

- Passive Trap Filter For Harmonic ReductionDocument9 paginiPassive Trap Filter For Harmonic ReductionShiva KumarÎncă nu există evaluări

- Brosur SikaDocument7 paginiBrosur SikachaerulÎncă nu există evaluări

- CommsII Problem Set 3 With AddendumDocument2 paginiCommsII Problem Set 3 With AddendumMarlon BoucaudÎncă nu există evaluări

- "Campus Placement" Has Been Always A Dream For Me in GraduationDocument3 pagini"Campus Placement" Has Been Always A Dream For Me in GraduationvivekÎncă nu există evaluări