Documente Academic

Documente Profesional

Documente Cultură

Akışkanlar Mek.

Încărcat de

Sai PranayTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Akışkanlar Mek.

Încărcat de

Sai PranayDrepturi de autor:

Formate disponibile

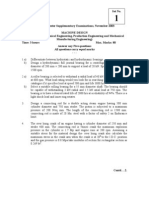

Problems of Practices

Of

Machine Design

I.C. Engine Parts

Prepared By

Brij Bhooshan

Asst. Professor

B. S. A. College of Engg. And Technology

Mathura, Uttar Pradesh, (India)

Supported By:

Purvi Bhooshan

Please welcome for any correction or misprint in the entire manuscript and your

valuable suggestions kindly mail us brijrbedu@gmail.com.

1. An automobile engine has a bore of 150 mm and stroke of 150 mm. It is expected

that the engine would develop a maximum pressure of 32.0 kg/cm2 and the engine

would run at a speed of 1100 r.p.m. The connecting rod length to crank radius ratio

is 5.0. Find the dimensions of the I-section connecting rod to be used for a safety

factor of 8 and made of medium carbon steel. The I-section cross-section be taken

as 6t x 4t, where t = flange and wed thickness. Assume that the yield strength of

steel is 3500 kg/cm2 and E = 2.0 x 106 kg/cm2.

Weight of the reciprocating parts of the engine = 0.03 kg/cm2 of piston area. Any

data not given-can be assumed suitably.

2. An equal angle section 100 mm × 100 mm × 8 mm is welded to a gusset plate to

serve as a tension member. Calculate the minimum amount of overlapping by the

angle section on the gusset plate with a view to limit the induced stress to 100

mega pascal in the angle section when only the side welds are used. The effective

area of angle may be taken as the area of the connected leg plus half the area of the

unconnected leg. The safe stress in the weld is 90 mega pascal and the shock factor

is 1.5.

3. Data given below refer to a single cylinder 4-stroke I.C. engine.

Find the suitable dimensions of cross-section of the connecting rod under gas load

and check the design under inertia load due to the self-weight of the connecting rod

OR find the suitable dimensions of crank web of a centre crank for the engine.

For more information log on www.brijrbedu.org

Brij Bhooshan Asst. Professor B.S.A College of Engg. & Technology, Mathura (India)

Copyright by Brij Bhooshan @ 2013 Page 1

2 Problems of Practices on I. C. Engine Parts

Cylinder diameter = 110 mm

Stroke = 160 mm

Power = 10 kW at 800 rpm

Max. explosion pressure = 2.2 MPa (22 kgf/cm2) at TDC

Length of connecting rod = 360 mm

At max. torque position gas pressure = 1.2 MPa (12 kgf/cm2) at = 40°

Mass of reciprocating parts = 2 kg

Density of connecting rod material = 7.2 kg per 1000 cm3.

Draw neat sketch, wherever necessary.

4. A connecting rod is required to be designed for a high speed, four stroke I.C.

engine. The following data are available.

Diameter of piston = 88 mm.

Mass of reciprocating parts = 1.6 kg

Length of connecting rod (centre to centre) = 300mm

Stroke = 125 mm

R.P.M. = 2200 (when developing 50kw)

Compressing ratio = 6.8:1 (approximately)

Probable maximum explosion pressure (assumed shortly after dead centre, say

at about 3°) = 3.5 N/mm2.

5. Design a cast iron piston for a single acting four stroke engine for the following:

Cylinder bore = 100 mm

Stroke = 120 mm

Max. gas pressure = 5 N/ mm2

Brake mean effective pressure = 0.65 N/mm2

Fuel consumption = 0.227 kg/kW/hr

Speed =2200 rpm

Assume suitable data if required.

6. Design a connecting rod for four stroke petrol engine with the following data:

Piston diameter = 0.10 m

Stroke = 0.14 m

Length of connecting rod, centre to centre = 0.315m

Weight of reciprocating parts = 18.2 N

Speed = 1500 rpm with possible over speed of 2500

Compressor ratio = 4:1,

Probable Max explosion pressure = 2.45 MPa.

7. Determine the thickness of a cast iron cylinder wall and the stresses for a 250 mm

petrol engine with a maximum gas pressure of 3.0 N/mm2. Take the reboring factor

for the cylinder wall as 7.5 mm and Poisson ratio as 0.25 for cylinder material.

Take maximum hoop stress as 45 MPa for the material.

8. Find the thickness of a piston crown for a four stroke engine developing power at

1500 rpm. Other relevant data for the engine are given as:

(1) piston diameter = 87 mm

(2) length of the stroke = 96 mm

(3) mean effective pressure = 0.7 N/mm2

(4) bsfc = 0.26 kg/kW/h

(5) L/r ratio = 4

(6) heat conducted through the crown = 10% of heat generated during

For more information log on www.brijrbedu.org

Brij Bhooshan Asst. Professor B.S.A College of Engg. & Technology, Mathura (India)

Copyright by Brij Bhooshan @ 2013 Page 2

Problems of Practices of Machine Design By Brij Bhooshan 3

combustion.

(7) Calorific value of fuel = 42 MJ/kg

Assume that the piston is made of aluminum alloy with thermal conductivity 1600

J/sm2 ° c/mm and allowed temperature difference is 111 °C.

9. Design a connecting rod for a four stroke petrol engine with the following data:

Piston dia = 0.10 m;

stroke = 0.14 m;

Length of connecting rod (centre to centre) = 0.315 m.

Wt. of reciprocating parts = 18.2 N

speed = 1500 rpm

Compression ratio = 4:1

Max. explosion pressure = 2.45 Mpa.

10. Design a centre crank for a double acting steam engine running at 150 rpm with a

stroke of 0.35 m. The overhung flywheel weights 22.70 kN and the connecting rod

force 'F' at dead centre is 45.40 kN. The engine is vertical.

11. Determine the diameter of the piston rod for a steam cylinder 1.50 m in diameter,

in which the greatest difference of pressure on the two sides of the piston is 0.2 M

Pa. Length of the rod is 2.8 m. Factor of safety is 8.

12. Determine the cross section of I section connecting rod for a single cylinder IC

engine.

Following data are provided for the engine:

(1) Piston diameter = 100 mm

(2) mass of reciprocating parts = 2.25 kg

(3) length of connecting rod = 300 mm

(4) stroke length = 125 mm

(5) speed = 1500 rpm

(6) maximum explosion pressure = 3.5N/mm2

(7) factor of safety =7

(8) density of rod material = 8000 kg/m3

(9) yield stress in compression = 330 MPa

Assume width of section as 4t and depth as 5t, where t is the web thickness of I

section.

13. A cast iron piston tor single acting tour stroke engine for the following

applications:

(1) Cyliner bore = 100 mm

(2) Stroke = 120 mm

(3) maximum gas pressure = 5 N/mm2

(4) break mean effective pressure = 0.65 N/mm2

(5) fuel consumption = 0.227 kg/k W/h

(6) Speed = 2200 rpm

Find the suitable thickness of the piston head. Thermal conductivity for cast Iron is

460 J/s m2 °c/m and allowable temperature difference is 222°C.

14. Design a connecting road for 4 stroke petrol engine, with the following data:

Piston diameter = 0.10 m

stroke length = 0.15 m

Length of connecting rod (centre to centre) = 0.30 m

Weight of reciprocating parts = 20 N

For more information log on www.brijrbedu.org

Brij Bhooshan Asst. Professor B.S.A College of Engg. & Technology, Mathura (India)

Copyright by Brij Bhooshan @ 2013 Page 3

4 Problems of Practices on I. C. Engine Parts

Speed is 1500 rpm with possible overspeed of 2500 rpm

Compression ratio = 4:1

Maximum Explosion pressure = 2.5 MPa.

15. Design a piston for a single acting four stroke engine for the following

specifications:

Cylinder bore = 0.30 m

Stroke length = 0.375 m

Maximum gas pressure = 8 MPa

Brake mean effective pressure = 1.15 MPa

Fuel consumption = 0.22 kg/kW/hr.

Speed = 500 rpm

Assume suitable data.

16. A 4 stroke diesel engine has the following specifications:

Brake power = 5 kW

Speed = 1200 rpm

Indicated mean effective = 0.35 N/mm2 Pressure

Mechanical efficiency = 80%

Determine the bore and length of the cylinder and thickness of cylinder head.

17. A four stroke IC engine is developing 50 kW power at 2200 rpm for which a

connecting rod is required to be designed for the following data:

Piston diameter = 90 mm

Mass of reciprocating parts = 1.5 kg

Length of connecting rod between the two centres = 300 mm

Stroke length = 125 mm

Approximate compression ratio = 6.8:1

Maximum explosion pressure shortly after dead centre = 3.5 N/mm2.

18. Design an aluminium alloy piston for a single acting four stroke engine for the

following specifications:

Cylinder bore = 0.30 m

Stroke = 0.375 m

Maximum gas pressure = 8 MPa

Brake mean effective pressure = 1.15 MPa

Fuel consumption = 0.22kg/kW/hr

Speed = 500 rpm

19. A four stroke petrol engine has following data:

Piston diameter = 100 mm

Stroke = 150 mm

Length of connecting rod = 315 nun

Weight of reciprocating parts = 18.2 N

Speed = 1500 rpm

Compression ratio = 4:1

Maximum explosion pressure = 2.40 MPa

Determine the size of rod cross section, dimensions of big and small ends of the

connecting rod and size of bolts for big end cap.

20. The cylinder of a slow speed steam engine is 250 mm diameter and the steam

pressure 1 N/mm2. The piston rod length is 1000 mm and the connecting rod is 1.2

m long. The engine stroke is 550 mm. Determine the dimensions of the cross

section of the connecting rod assuming the depth to be twice as thickness and a

For more information log on www.brijrbedu.org

Brij Bhooshan Asst. Professor B.S.A College of Engg. & Technology, Mathura (India)

Copyright by Brij Bhooshan @ 2013 Page 4

Problems of Practices of Machine Design By Brij Bhooshan 5

suitable diameter for the piston rod.

21. A four stroke diesel engine has the following specifications:

Brake power : 12 kW

Speed : 1500 rpm

Indicated MEP : 0.35 N/mm2

Mechanical efficiency : 80%

Determine :

(i) bore and length of the cylinder,

(ii) thickness of the cylinder head, and

(iii) size of stud for the cylinder head

22. Design a connecting rod for a Petrol Engine from the following data:

Diameter of piston =110 mm

Mass of reciprocating parts, m = 2 kg

Length of connecting rod, l = 325 mm

Stroke =150 mm

Compression ratio = 4:1

Speed = 1500 rpm with possible over speed of 2500 rpm

Maximum explosion pressure = 2.5 MPA.

23. Design a Cast Iron Piston for a single acting four stroke engine for following data:

Cylinder bore = 90 mm

Stroke = 120 mm

Maximum gas pressure = 5 N/mm2

Mean effective pressure = 0.75 N/mm2

Mechanical efficiency = 80%

Fuel consumption = 0.2 Kg per Brake power per hour

Higher Calorific value of fuel= 43 × 103 kJ/Kg

Speed = 2000 RPM

Any other data required for the design may be assumed.

24. Design an aluminium alloy piston for a single acting four stroke engine, for the

following specification:

Cylinder bore = 0.40 m;

Break mean effective pressure = 2.5MPa

Stroke = 0.480 m;

Fuel consumption = 0.36 kg/ kW/hr

Maximum gas pressure = 10 MPa;

Speed = 900 r.p.m

25. Design a connecting rod for 4 stroke petrol engine with the following data:

Piston diameter = 0.20 m

Stroke length = 0.30 m

Length of connecting rod (centre to centre) = 50 m

Weight of reciprocating parts = 50 N

Speed is 1440 r.p.m with possible overspeed of 3000 r.p.m

Compression ratio = 3:1

Maximum explosion pressure = 3 MPa.

26. A four stroke diesel engine has the following specifications:

Brake power = 5 kW; Speed = 1200 rpm; Indicated mean effective pressure = 0.35

N/mm2; Mechanical efficiency = 80 %.

Determine: 1. Bore and length of the cylinder; 2 thickness of the cylinder head; and

For more information log on www.brijrbedu.org

Brij Bhooshan Asst. Professor B.S.A College of Engg. & Technology, Mathura (India)

Copyright by Brij Bhooshan @ 2013 Page 5

6 Problems of Practices on I. C. Engine Parts

3. Size of studs for the cylinder head.

27. Design a cast iron for a single acting four stroke engine for the following data:

Cylinder bore = 100 mm; Stroke = 125 mm; Maximum gas pressure = 5 N/mm2;

Indicated mean effective pressure = 0.75 N/mm2; Mechanical efficiency = 80%; Fuel

consumption = 0.15 kg per brake power per hour; Higher calorific value if fuel = 42

103 kJ/kg; Speed=2250 rpm.

28. The bore of a cylinder of the four stroke diesel engine is 150 mm. The maximum

gas pressure inside the cylinder is limited to 3.5 Mpa. The cylinder head is made of

grey cast iron FG 200 (ut = 200 N/mm2) and the FOS is 5. Determine the thickness

of the cylinder head. Studs is made of steel FeE 250 (yt = 250 N/mm2) and the FOS

is 5. Calculate:

(i) Number of studs

(ii) Nominal diameter of studs

(iii) Pitch of studs

29. Determine the dimensions of cross-sections of the connecting rod (I-section), for a

diesel engine with the following data:

(i) Cylinder bore = 100 mm

(ii) Length of connecting rod = 320 mm

(iii) Maximum gas pressure = 2.45 Mpa

(iv) FOS against buckling failure = 5.

30. A four stroke diesel engine has the following specifications:

Brake power = 5 kW; Speed = 1200 r.p.m.; Indicated mean effective pressure = 0.35

N/mm2; Mechanical efficiency = 80 %.

Determine: 1. bore and length of the cylinder; 2. thickness of the cylinder head; and

3. size of studs for the cylinder head.

31. Design a cast iron piston for a single acting four stroke engine for the following

data:

Cylinder bore = 100 mm; Stroke = 125 mm; Maximum gas pressure = 5 N/mm 2;

Indicated mean effective pressure = 0.75 N/mm2; Mechanical efficiency = 80%; Fuel

consumption = 0.15 kg per brake power per hour; Higher calorific value of fuel = 42

× 103 kJ/kg ; Speed = 2000 r.p.m. Any other data required for the design may be

assumed.

For more information log on www.brijrbedu.org

Brij Bhooshan Asst. Professor B.S.A College of Engg. & Technology, Mathura (India)

Copyright by Brij Bhooshan @ 2013 Page 6

S-ar putea să vă placă și

- 3 Tutorial IC EngineDocument3 pagini3 Tutorial IC EnginevattuÎncă nu există evaluări

- rr321401 Principles of Machine DesignDocument8 paginirr321401 Principles of Machine DesignSRINIVASA RAO GANTA100% (1)

- AT8611 Lab QuestionsDocument9 paginiAT8611 Lab QuestionsChirpiÎncă nu există evaluări

- AECD QuestionsDocument7 paginiAECD QuestionssbkÎncă nu există evaluări

- IC engine component design problemsDocument4 paginiIC engine component design problemsTamene TesfayeÎncă nu există evaluări

- r05320305 Design of Machine Members IIDocument9 paginir05320305 Design of Machine Members IISRINIVASA RAO GANTAÎncă nu există evaluări

- r05320305 Design of Machine Members IIDocument11 paginir05320305 Design of Machine Members IISrinivasa Rao G100% (4)

- 21751-6838-Principles of Machine DesignDocument8 pagini21751-6838-Principles of Machine DesignMacasaet Al-awnÎncă nu există evaluări

- Dmm-II Assignment TestDocument2 paginiDmm-II Assignment TestSai Srinivas BodapatiÎncă nu există evaluări

- 1 ST Assignment Section-A&B 3-1 Semester Dmm-2: Sir CR Reddy College of EngineeringDocument3 pagini1 ST Assignment Section-A&B 3-1 Semester Dmm-2: Sir CR Reddy College of EngineeringChadaram JagadishÎncă nu există evaluări

- nr321401 Principles of Machine DesignDocument2 pagininr321401 Principles of Machine DesignSRINIVASA RAO GANTAÎncă nu există evaluări

- 9A14503 Principles of Machine DesignDocument8 pagini9A14503 Principles of Machine DesignsivabharathamurthyÎncă nu există evaluări

- Doec Question Bank: Ut 2 and Yt 2)Document4 paginiDoec Question Bank: Ut 2 and Yt 2)Aditya DeshmukhÎncă nu există evaluări

- DMM 2Document6 paginiDMM 2Shubham MahajanÎncă nu există evaluări

- DMM-III Assignment TestDocument2 paginiDMM-III Assignment TestSaibabu SoloÎncă nu există evaluări

- rr321401 Principles of Machine DesignDocument8 paginirr321401 Principles of Machine DesignSRINIVASA RAO GANTAÎncă nu există evaluări

- r05321403 Principles of Machine DesignDocument8 paginir05321403 Principles of Machine DesignSRINIVASA RAO GANTAÎncă nu există evaluări

- 2018sme 7 Sem Design of Mechanical Drives Summer 2018Document2 pagini2018sme 7 Sem Design of Mechanical Drives Summer 2018Komal HingeÎncă nu există evaluări

- NR 320301 Machine DesignDocument8 paginiNR 320301 Machine DesignSrinivasa Rao GÎncă nu există evaluări

- 4363 111 Machine Design IDocument6 pagini4363 111 Machine Design Iyogesh_b_k100% (2)

- Me1302 DmeDocument4 paginiMe1302 DmesumikannuÎncă nu există evaluări

- Design IC Engine Components and Optimize ParametersDocument4 paginiDesign IC Engine Components and Optimize ParametersSankit IngaleÎncă nu există evaluări

- Design of Machine Elements Exam with Questions on Shafts, Couplings, Keys, Springs, Bearings, FlywheelsDocument3 paginiDesign of Machine Elements Exam with Questions on Shafts, Couplings, Keys, Springs, Bearings, FlywheelsHariharanAutoÎncă nu există evaluări

- An Sys PaperDocument13 paginiAn Sys PaperHitesh Kumar PrajapatiÎncă nu există evaluări

- Machine Design-II Question BankDocument32 paginiMachine Design-II Question BankAbhishek SakatÎncă nu există evaluări

- Cylinder Design and AnalysisDocument5 paginiCylinder Design and AnalysisVikas RathodÎncă nu există evaluări

- Gujarat Technological UniversityDocument3 paginiGujarat Technological Universityrajushamla9927Încă nu există evaluări

- Diploma Board Examination - December 2020Document2 paginiDiploma Board Examination - December 2020Pradeep AppuÎncă nu există evaluări

- r05312401 Design of Machine ElementsDocument8 paginir05312401 Design of Machine ElementsSrinivasa Rao GÎncă nu există evaluări

- Design of Machine Members II R5320305 Set 3Document2 paginiDesign of Machine Members II R5320305 Set 3Ravi Kumar KamarthiÎncă nu există evaluări

- MODEL QUESTION PAPER Mechanical VibrationsDocument3 paginiMODEL QUESTION PAPER Mechanical VibrationsDarani PriyaÎncă nu există evaluări

- Supp Nov 2009Document10 paginiSupp Nov 2009prk74Încă nu există evaluări

- 12ME5DCDM2Document3 pagini12ME5DCDM2Abhyudaya SinghÎncă nu există evaluări

- R07-SUPPLY-DecemberJanuary 2014-15 - Design of Machine Members - IIDocument2 paginiR07-SUPPLY-DecemberJanuary 2014-15 - Design of Machine Members - IIPraveen KumarÎncă nu există evaluări

- Machine Design I TutorialDocument3 paginiMachine Design I TutorialbngelotrÎncă nu există evaluări

- DMM-2 3 1 Q&aDocument6 paginiDMM-2 3 1 Q&aAnand vinayÎncă nu există evaluări

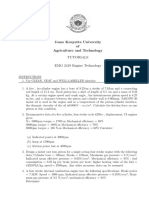

- Jomo Kenyatta University of Agriculture and Technology Tutorials EMG 2419 Engine TechnologyDocument2 paginiJomo Kenyatta University of Agriculture and Technology Tutorials EMG 2419 Engine TechnologyEric MajaoÎncă nu există evaluări

- DME Model QuesDocument3 paginiDME Model QuesSiva RamanÎncă nu există evaluări

- MD-III - TUT - 5 and 6Document5 paginiMD-III - TUT - 5 and 6Sushil ThakkarÎncă nu există evaluări

- MD II Machine Design AssignmentsDocument5 paginiMD II Machine Design Assignmentsrishabhk28995Încă nu există evaluări

- Dme Quest Ut-2Document9 paginiDme Quest Ut-2aadhithyarajasekaranÎncă nu există evaluări

- 05-04 Machine Design & Cad-II (Me)Document2 pagini05-04 Machine Design & Cad-II (Me)Abdul AhadÎncă nu există evaluări

- AT2351 Automotive Engine Components Design May - Jun 2014Document3 paginiAT2351 Automotive Engine Components Design May - Jun 2014pavanraneÎncă nu există evaluări

- ME 331 - DESIGN OF MACHINE ELEMENTS EXAMDocument5 paginiME 331 - DESIGN OF MACHINE ELEMENTS EXAMarumugam_rÎncă nu există evaluări

- WWW - Manaresults.Co - In: (Common To Ame, Me)Document3 paginiWWW - Manaresults.Co - In: (Common To Ame, Me)Vikranth DeepakÎncă nu există evaluări

- rr320305 Design of Machine Members IIDocument8 paginirr320305 Design of Machine Members IISrinivasa Rao GÎncă nu există evaluări

- MEE3001 Class 43 Dated 27 April 2022Document17 paginiMEE3001 Class 43 Dated 27 April 2022Satwik GuptaÎncă nu există evaluări

- Computer Aided DesignDocument2 paginiComputer Aided DesignRushabh PatelÎncă nu există evaluări

- DME Question Bank - 3171917Document4 paginiDME Question Bank - 3171917fgyjnsv786Încă nu există evaluări

- Assignment 2Document3 paginiAssignment 2sonawanepmsÎncă nu există evaluări

- Dme Model 2Document6 paginiDme Model 2YashwanthI-StyleKuttiÎncă nu există evaluări

- IC Engine PartsDocument2 paginiIC Engine PartsSushil Kumar SinghÎncă nu există evaluări

- Machine Design Elements and AssembliesDe la EverandMachine Design Elements and AssembliesEvaluare: 3.5 din 5 stele3.5/5 (2)

- Solution Manual for 100 Genesys Design Examples: Second EditionDe la EverandSolution Manual for 100 Genesys Design Examples: Second EditionÎncă nu există evaluări

- Study of a reluctance magnetic gearbox for energy storage system applicationDe la EverandStudy of a reluctance magnetic gearbox for energy storage system applicationEvaluare: 1 din 5 stele1/5 (1)

- Bilge Alarm Monitor OMD 11Document22 paginiBilge Alarm Monitor OMD 11Lucian Iftemie100% (3)

- Usn LM2500 Asme Paper GT2010-22811 61410 JalDocument7 paginiUsn LM2500 Asme Paper GT2010-22811 61410 Jalferrerick0% (1)

- Wrangling Logs With Logstash and ElasticSearch PresentationDocument38 paginiWrangling Logs With Logstash and ElasticSearch PresentationMohammad Syafiq Bin HussainÎncă nu există evaluări

- Technical Presentation - Arik Ethan Kinajil (25231)Document5 paginiTechnical Presentation - Arik Ethan Kinajil (25231)Arik EthanÎncă nu există evaluări

- Achievements Under EpiraDocument6 paginiAchievements Under EpiraLyn Dela Cruz DumoÎncă nu există evaluări

- Government Engineering College Surveying Lab ManualDocument26 paginiGovernment Engineering College Surveying Lab ManualNittin BhagatÎncă nu există evaluări

- NPTEL Science and Technology of PolymersDocument2 paginiNPTEL Science and Technology of PolymersAzhagiri PonÎncă nu există evaluări

- Smart Access 1105Document12 paginiSmart Access 1105Gerson Freire De Amorim FilhoÎncă nu există evaluări

- Kepb003404 PDFDocument472 paginiKepb003404 PDFELIAS100% (1)

- The Causes and Prevention of Crowd DisastersDocument10 paginiThe Causes and Prevention of Crowd DisastersVarun SwaminathanÎncă nu există evaluări

- ESAB Welding HandbookDocument31 paginiESAB Welding Handbookhooky1100% (4)

- DMD Documentation Error - Freetronics ForumDocument3 paginiDMD Documentation Error - Freetronics ForumapofviewÎncă nu există evaluări

- JDA SCE Standard Release NotesDocument3 paginiJDA SCE Standard Release Notesgolcha_edu532Încă nu există evaluări

- Batch Profile - 2017Document57 paginiBatch Profile - 2017Praneet TÎncă nu există evaluări

- Account Manager Business Development in San Jose CA Resume Mark WestonDocument2 paginiAccount Manager Business Development in San Jose CA Resume Mark WestonMarkWeston2Încă nu există evaluări

- YZ250 Off-Road Bike Parts CatalogDocument55 paginiYZ250 Off-Road Bike Parts Catalogdwiyanti20Încă nu există evaluări

- SRSUNTOUR General Fork GlossaryDocument23 paginiSRSUNTOUR General Fork GlossaryThomas JunkersfeldÎncă nu există evaluări

- Online Institute Reporting Slip of The Application Number - 200310422837 PDFDocument1 paginăOnline Institute Reporting Slip of The Application Number - 200310422837 PDFRohith RohanÎncă nu există evaluări

- BTS Training Fiber Optic Advanced SplicingDocument5 paginiBTS Training Fiber Optic Advanced Splicingjama99Încă nu există evaluări

- Epc of Well Pad D For Sorik Marapi Geothermal Project Recovery ScheduleDocument1 paginăEpc of Well Pad D For Sorik Marapi Geothermal Project Recovery ScheduleGema SuryaÎncă nu există evaluări

- List of Linkages2016Document74 paginiList of Linkages2016engrwho0% (1)

- Vehicle Air Conditioning (VAC) : System Operation and The Refrigerant CycleDocument49 paginiVehicle Air Conditioning (VAC) : System Operation and The Refrigerant CycleVarun RaizadaÎncă nu există evaluări

- MI MetadataDocument310 paginiMI MetadataMatthew McCreadyÎncă nu există evaluări

- Partlist Smsport 110RDocument74 paginiPartlist Smsport 110RThai YunÎncă nu există evaluări

- Dewatering SystemDocument124 paginiDewatering SystemSpyros NannosÎncă nu există evaluări

- Unit 4 - Software Engineering - WWW - Rgpvnotes.inDocument12 paginiUnit 4 - Software Engineering - WWW - Rgpvnotes.inNazma QureshiÎncă nu există evaluări

- 06 HVAC Plumbing PDFDocument727 pagini06 HVAC Plumbing PDFTamÎncă nu există evaluări

- 2 CAD Connecting Rod ForgingDocument56 pagini2 CAD Connecting Rod ForgingIsrar EqubalÎncă nu există evaluări

- Hydraulic Mining Shovel 6040AC: 08. Attachment Functions - FSDocument20 paginiHydraulic Mining Shovel 6040AC: 08. Attachment Functions - FShector50% (2)