Documente Academic

Documente Profesional

Documente Cultură

WAV252 Heated Wind Vane Installation Guide

Încărcat de

JACK0 evaluări0% au considerat acest document util (0 voturi)

78 vizualizări2 paginiWAV252 Quick Reference Guide in English Part 2

Titlu original

WAV252 Quick Reference Guide in English Part 2

Drepturi de autor

© © All Rights Reserved

Formate disponibile

PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentWAV252 Quick Reference Guide in English Part 2

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

78 vizualizări2 paginiWAV252 Heated Wind Vane Installation Guide

Încărcat de

JACKWAV252 Quick Reference Guide in English Part 2

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 2

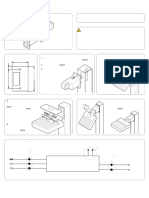

INSTALLATION 3.

Mount the sensor to the flange by twisting, and tighten

the screws.

Quick Reference Guide 4. Finally, mount the cup assembly. Align the planes in

Initial Check the shaft and inside the hub. The bottom edges of the

Prior to the installation check that the WAV252 is not hub and the shoulder should reach approximately the

WAV252 Heated Wind Vane damaged during transportation. Check also that the shaft

rotates smoothly without any detectable noise. It is

same level (see Figure 1). Tighten the set screw.

recommended to mount the sensor body when the vane

WAC151 Wiring

assembly is removed. Be careful not to cause damage to the

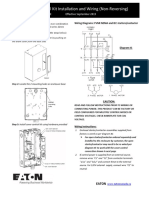

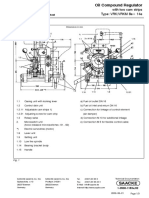

shaft of the sensor body or to the connector pins. The wiring diagram for the WA252 system to the WAC151

Installation and Maintenance Sensor Crossarm is presented in the Figure 2. The power

input wire connections are highlighted, since they differ from

Mechanical those for regular wind sensors.

The Heated Wind Vane WAV252 is preferably installed into

the WAC151 sensor cross arm. On bottom of the WAV252

there is a special button-shaped temperature sensor

(diameter 22 mm), elastically attached to the bottom plate.

This is for sensing the ambient temperature and should

therefore be set in good thermal contact with the mounting

support.

NOTE The three mounting screws properly tightened

will force the temperature sensor button firmly

enough against the support.

0002-025

Figure 2. WAC151 Standard Wiring for WAA252 and WAV252

When using standard power and signal cables ZZ45049 and

ZZ45048 the connections are following:

1. For power supply, connect the YEL, GRN, and PNK

colored wires to the screw terminal #2 and the WHT,

BRN, and GRY colored wires to the terminal #3.

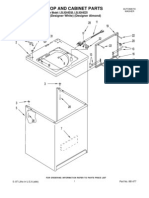

0002-024 2. For signal output connect wires GRN, YEL, WHT, VIO,

Figure 1. Mounting of the Wind Sensor and the Hub GRY, and PNK to terminals #7 … #12. For signal

grounding, connect BLK to the terminal #5.

When installed to the WAC151 cross arm, the WAV252 is 3. For the optional sensor power input connect BRN to

0002-028

mounted at the northern end, the southern end is reserved the terminal #6.

for the WAA252 Heated Anemometer.

1. First pre-assemble the three mounting screws, with As a power source use the Vaisala WHP25 Mains Power

plastic washers, to the anemometer's mounting legs. Supply, which has a mast mountable, all-weather enclosure.

2. Fit the 10-pin cable plug through the mounting flange For a typical installation see the figure on the front page.

www.vaisala.com and connect it to the sensor.

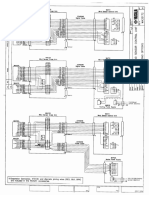

MAINTENANCE AND REPAIR For reassembling the sensor:

Ball bearings must be checked once a year visually and by B1. Install the bearings in reverse order.

rotating the sensor shaft. To do this, remove first the vane

NOTE Be careful when assembling the

assembly as instructed below (A1). The shaft should spin

bearings.

smoothly and should not create any detectable noise.

Replacement of the bearings should be done only by a B2. The rotating transformer assembly (7) is reinstalled

trained technician. Steps A1 to A15 are for disassembling and together with the sensor board (9). Its (7) set screw is

steps B1 to B10 are for reassembling. The numbers in not fastened until in step B7, when the power supply

parenthesis refer to Figure 3. board has been reinstalled and the gap adjusted.

B3. In assembling, push the transformer (7) as far up as

A1. Loosen the set screw (use allen key) and carefully possible towards the shaft tunnel.

remove the vane assembly. B4. Reassemble the spacer screws (8), the power supply

board (4) and tighten the nuts (5).

CAUTION Be careful with the connector pins, do

not bend them. NOTE Make sure the four pin connector (15)

installs properly.

A2. Loosen the hex nut of the green MIL-connector at the

bottom of the sensor body (use 22 mm tool). B5. For adjusting the gap, place a 0.4 mm feeler gauge

between ferrite coils (parts 4 and 7) (preferably use 30

A3. Loosen the three capnuts (1) at the bottom of the

sensor body (use 7 mm tool). mm wide feeler gauge).

B6. Place a screwdriver tip into the slot between the top

A4. Remove the body cover and the O-rings (2).

end of rotating transformer assembly (7) and the shaft

A5. Release the connector (3) of two white wires from the tunnel, and pry until the air gap between ferrite coils

power supply board (4). is 0.4 mm (0.016”) (use feeler gauge for measuring).

A6. Loosen the three nuts (5) at the bottom of the power

supply board (4) and remove it (use 7 mm tool). CAUTION The ferrite coils are breakable, do not

A7. Loosen the shaft heating foil (6) (use pliers). try to adjust the gap by prising them.

A8. Loosen the set screw of the rotating transformer When the gap is right, fasten the set screw of the

assembly (7) (use allen key). B7.

rotating transformer assembly (7).

A9. Loosen the spacer screws (8) (use 6 mm tool).

A10. Remove the sensor board (9) together with the rotating CAUTION Make sure the rotating transformer

transformer assembly (7). assembly rotates freely without

touching the lower part at any rotary

CAUTION Handle the rotating transformer position of the shaft.

carefully, do not drop or hit.

B8. Reconnect the shaft heating foil (6) and the connector

A11. Remove the retaining ring (10) (use narrow-pointed of two white wires (3).

pliers) and the bushing from the shaft tunnel. B9. Reassemble the body cover (2) with new O-rings.

A12. Remove the upper bearing (12) after pulling out the B10. Tighten the three capnuts (1) and the connector nut.

shaft.

B11. Install the vane as instructed in mechanical section.

CAUTION Handle the shaft carefully, do not drop

or hit. Spare parts: Order number:

Vane assembly for WAV252 WA35336 0002-029

A13. Remove the retaining ring (13) at the shaft. Set of bearings and gasket 16644WA

Figure 3. WAV252 Assembly

A14. Remove the lower bearing (14).

Ref. WAV252-U433en-1.1

S-ar putea să vă placă și

- WAA252 Quick Reference Guide in English Part 2Document2 paginiWAA252 Quick Reference Guide in English Part 2aseÎncă nu există evaluări

- Uai B 0214Document4 paginiUai B 0214Jose Puc ManzanillaÎncă nu există evaluări

- SI0240Document12 paginiSI0240Kavi SaikrishnaÎncă nu există evaluări

- Kenwood KD 65F InstructionManualDocument11 paginiKenwood KD 65F InstructionManualdjr01749Încă nu există evaluări

- AWK-4121 QIG 4eDocument13 paginiAWK-4121 QIG 4eJonathan Montes coronaÎncă nu există evaluări

- WON0502-B: Installation Instructions FOR Electric FurnacesDocument15 paginiWON0502-B: Installation Instructions FOR Electric FurnacesRobÎncă nu există evaluări

- Pioneer vsx-714 PDFDocument75 paginiPioneer vsx-714 PDFJimÎncă nu există evaluări

- IS15 NMEA RepeaterDocument28 paginiIS15 NMEA RepeaterHannes ValbergssonÎncă nu există evaluări

- Denon AVR-4810 - CIDocument245 paginiDenon AVR-4810 - CIrd6i100% (1)

- GFE H ManualDocument2 paginiGFE H Manualparallax1957Încă nu există evaluări

- Installation Instructions: For EVS Security SystemsDocument14 paginiInstallation Instructions: For EVS Security SystemsMichel TanusÎncă nu există evaluări

- Service Manual: Color TelevisionDocument16 paginiService Manual: Color TelevisionYoyneer SalinasÎncă nu există evaluări

- 14FES1BN AkiraDocument36 pagini14FES1BN AkiraIleana RuvalcabaÎncă nu există evaluări

- Wizmart: Installation Wiring DiagramDocument2 paginiWizmart: Installation Wiring DiagramAlejandro CabreraÎncă nu există evaluări

- Installation NDA 12-16Document4 paginiInstallation NDA 12-16Sergei KurpishÎncă nu există evaluări

- 54) - 56) J400K - (455,456,457)Document5 pagini54) - 56) J400K - (455,456,457)cyrano1091Încă nu există evaluări

- KMC THE 1003 User GuideDocument2 paginiKMC THE 1003 User GuideJavier GuapisacaÎncă nu există evaluări

- Tekel Incremental Encoder User ManualDocument8 paginiTekel Incremental Encoder User ManualAyman ElotaifyÎncă nu există evaluări

- Bose - Wave - Radio - I - II - III - TL Troubleshooting - GuideDocument77 paginiBose - Wave - Radio - I - II - III - TL Troubleshooting - GuideNestor AmayaÎncă nu există evaluări

- WCAIM2051 - EN - AQ Atomising Air ValveDocument2 paginiWCAIM2051 - EN - AQ Atomising Air ValveMohammed YasinÎncă nu există evaluări

- TG - NB326 - S - Smoke DetectorDocument2 paginiTG - NB326 - S - Smoke DetectordepozitankoÎncă nu există evaluări

- Installation Manual of The Solar Weather Monitoring StationDocument40 paginiInstallation Manual of The Solar Weather Monitoring Stationsamwel kariukiÎncă nu există evaluări

- Downloaded From Manuals Search EngineDocument13 paginiDownloaded From Manuals Search EngineMar CabÎncă nu există evaluări

- Quick Guide: Replacement of The SUN2000 - (8KTL-12KTL) andDocument25 paginiQuick Guide: Replacement of The SUN2000 - (8KTL-12KTL) andWagner FerreiraÎncă nu există evaluări

- Solenoid Valves: Fitters NotesDocument12 paginiSolenoid Valves: Fitters Notes2nd engineerÎncă nu există evaluări

- Switzer Pressure SwitchDocument8 paginiSwitzer Pressure SwitchSSFLOWENGINEERING SSFLOWENGINEERING100% (2)

- USSLxxxWPL Installation InstructionDocument6 paginiUSSLxxxWPL Installation InstructionHarlen Joan Pardo BergaminÎncă nu există evaluări

- LCD-46XAZ10FH: Service ManualDocument41 paginiLCD-46XAZ10FH: Service Manualserrano.flia.coÎncă nu există evaluări

- SERVICE MANUAL TV SETS 14", 21Document37 paginiSERVICE MANUAL TV SETS 14", 21Mersija CelikÎncă nu există evaluări

- Service Manual: Colour TelevisionDocument21 paginiService Manual: Colour TelevisionTecnico GenioÎncă nu există evaluări

- Cooper Nova Manual S280421 Part3Document7 paginiCooper Nova Manual S280421 Part3Arliel John GarboÎncă nu există evaluări

- Product Information Specifications: DescriptionDocument4 paginiProduct Information Specifications: DescriptionAndresGalvisSarmientoÎncă nu există evaluări

- Awk-3121 Quick Installation Guide: Moxa AirworksDocument14 paginiAwk-3121 Quick Installation Guide: Moxa AirworksMohamedElsawiÎncă nu există evaluări

- Carrier Ducted Controller ManualDocument33 paginiCarrier Ducted Controller ManualMechanical PowerÎncă nu există evaluări

- Manual TocadiscosDocument8 paginiManual TocadiscosimmavÎncă nu există evaluări

- Haier: Color Television & DVDDocument29 paginiHaier: Color Television & DVDWilinton PissoÎncă nu există evaluări

- Antena TV ShakespeareDocument4 paginiAntena TV ShakespearenachoborjasÎncă nu există evaluări

- Pillow Block SensorsDocument8 paginiPillow Block SensorsBilly BetancourtÎncă nu există evaluări

- Vibration RPM Acoustic RPM For Diesel and Petrol Engines cdss1-700 Installation Crypton ManualDocument8 paginiVibration RPM Acoustic RPM For Diesel and Petrol Engines cdss1-700 Installation Crypton Manualjaouad samnajiÎncă nu există evaluări

- ECB-VAV Install 05DI-HIBVAVT-17Document12 paginiECB-VAV Install 05DI-HIBVAVT-17Chakib AutomationÎncă nu există evaluări

- Xoceco xt2599 2579 2599 2759 2799Document37 paginiXoceco xt2599 2579 2599 2759 2799Ileana RuvalcabaÎncă nu există evaluări

- Bobinas HansenDocument4 paginiBobinas HansenJose Ignacio Figueroa CortesÎncă nu există evaluări

- Autometer Water Temp 4337 InstructionsDocument2 paginiAutometer Water Temp 4337 InstructionsVimaceÎncă nu există evaluări

- 54-1217 V7HTS IgDocument61 pagini54-1217 V7HTS IgagbalouÎncă nu există evaluări

- Inverter - Solaredge - Installation-Manual - SE3800A-US InstallationDocument7 paginiInverter - Solaredge - Installation-Manual - SE3800A-US InstallationAl0% (1)

- Aiwa Tv-Se2130 PDFDocument33 paginiAiwa Tv-Se2130 PDFSekoÎncă nu există evaluări

- PRD - 3407 - Archivo - Preventive Om Checklist Inverter StationDocument7 paginiPRD - 3407 - Archivo - Preventive Om Checklist Inverter StationRichie RimbaniÎncă nu există evaluări

- Manual TV TRCDocument14 paginiManual TV TRCPedro MoraÎncă nu există evaluări

- Quick Start Guide: 1. Unpack The Switch and Check Contents 2. Mount The SwitchDocument15 paginiQuick Start Guide: 1. Unpack The Switch and Check Contents 2. Mount The SwitchnwaraÎncă nu există evaluări

- C600M Cover Control Kit Installation GuideDocument4 paginiC600M Cover Control Kit Installation GuideReggieÎncă nu există evaluări

- Data Book - RCN-T-36W-E_remote for KX6Document9 paginiData Book - RCN-T-36W-E_remote for KX6fakir mohammadÎncă nu există evaluări

- InstallingDocument11 paginiInstallingMatthewÎncă nu există evaluări

- Chassis CY-PH2529TOP-EW-21US Manual de ServicioDocument25 paginiChassis CY-PH2529TOP-EW-21US Manual de Servicioelectronico69Încă nu există evaluări

- Power Supply Projects: A Collection of Innovative and Practical Design ProjectsDe la EverandPower Supply Projects: A Collection of Innovative and Practical Design ProjectsEvaluare: 3 din 5 stele3/5 (2)

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1De la EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Evaluare: 2.5 din 5 stele2.5/5 (3)

- User'S Guide: Combined Wind Sensor WMS301 and WMS302Document32 paginiUser'S Guide: Combined Wind Sensor WMS301 and WMS302JACKÎncă nu există evaluări

- 34m TallTower ManualDocument73 pagini34m TallTower ManualmadaÎncă nu există evaluări

- 0 Gw-Energy 20111125135712Document2 pagini0 Gw-Energy 20111125135712JACKÎncă nu există evaluări

- WAC151 Basic Wiring Options - Wa25 PDFDocument1 paginăWAC151 Basic Wiring Options - Wa25 PDFJACKÎncă nu există evaluări

- Wind Energy DevelopmentDocument1 paginăWind Energy DevelopmentJACKÎncă nu există evaluări

- Hydraulic Winch Safety Mechanism 4254 InstructionsDocument1 paginăHydraulic Winch Safety Mechanism 4254 InstructionsJACKÎncă nu există evaluări

- WMT700 Quick Reference Quide EN-FR-SP-RU-JP-CN PDFDocument36 paginiWMT700 Quick Reference Quide EN-FR-SP-RU-JP-CN PDFJACKÎncă nu există evaluări

- WAC151 Cross Arm Assembly DrawingDocument1 paginăWAC151 Cross Arm Assembly DrawingJACKÎncă nu există evaluări

- WCO-WEN - Southern California Edison Success Story B210999EN-A - HRDocument2 paginiWCO-WEN - Southern California Edison Success Story B210999EN-A - HRJACKÎncă nu există evaluări

- WAC151 Technical ReferenceDocument8 paginiWAC151 Technical ReferenceJACKÎncă nu există evaluări

- A2SEA VesselDocument22 paginiA2SEA VesselJACKÎncă nu există evaluări

- WAA252 Quick Reference Guide in English Part 1Document2 paginiWAA252 Quick Reference Guide in English Part 1JACKÎncă nu există evaluări

- Lecture 17.4 Structural Analysis For Seismic ActionsDocument17 paginiLecture 17.4 Structural Analysis For Seismic ActionsJACKÎncă nu există evaluări

- User'S Guide: Combined Wind Sensor WMS301 and WMS302Document32 paginiUser'S Guide: Combined Wind Sensor WMS301 and WMS302JACKÎncă nu există evaluări

- Engineering CAD DesignDocument2 paginiEngineering CAD DesignJACKÎncă nu există evaluări

- HybridXT Push Pull Anemometer ManualDocument22 paginiHybridXT Push Pull Anemometer ManualJACKÎncă nu există evaluări

- Service Sheet WindFarmOptimisation Oct2013Document2 paginiService Sheet WindFarmOptimisation Oct2013JACKÎncă nu există evaluări

- WHP25 User Guide in EnglishDocument27 paginiWHP25 User Guide in EnglishJACKÎncă nu există evaluări

- Barlovento FCR Validation On Complex Site Whitepaper PDFDocument76 paginiBarlovento FCR Validation On Complex Site Whitepaper PDFJACKÎncă nu există evaluări

- Wea Ls7002 Datasheet B211284en A LowDocument2 paginiWea Ls7002 Datasheet B211284en A LowleeÎncă nu există evaluări

- Deutsche WindGuard LIDAR Comparison Whitepaper PDFDocument5 paginiDeutsche WindGuard LIDAR Comparison Whitepaper PDFJACKÎncă nu există evaluări

- Guide to the Non-Freezing WAV252 Heated Wind VaneDocument2 paginiGuide to the Non-Freezing WAV252 Heated Wind VaneJACKÎncă nu există evaluări

- Turbulence Assessment With LidarsDocument26 paginiTurbulence Assessment With LidarsJACKÎncă nu există evaluări

- HybridXT 4 20ma Anemometer ManualDocument24 paginiHybridXT 4 20ma Anemometer ManualJACKÎncă nu există evaluări

- GL GH Position On WINDCUBE WhitepaperDocument11 paginiGL GH Position On WINDCUBE WhitepaperJACKÎncă nu există evaluări

- HybridXT 4 20ma Vane ManualDocument21 paginiHybridXT 4 20ma Vane ManualJACKÎncă nu există evaluări

- Testing 110S Temperature Sensor InstructionsDocument19 paginiTesting 110S Temperature Sensor InstructionsJACKÎncă nu există evaluări

- HybridXT 4 20ma Anemometer ManualDocument24 paginiHybridXT 4 20ma Anemometer ManualJACKÎncă nu există evaluări

- Testing IceFree NPN Vane InstructionsDocument1 paginăTesting IceFree NPN Vane InstructionsJACKÎncă nu există evaluări

- 2022.10.17 Quotation of AE55Y Slant Bed CNC LatheDocument15 pagini2022.10.17 Quotation of AE55Y Slant Bed CNC LathebhaaÎncă nu există evaluări

- 5 Categories of Computer Types and ComponentsDocument10 pagini5 Categories of Computer Types and Componentsamalinazai0% (1)

- Nokia Tool Kit Checklist - From TI GuidelinesDocument4 paginiNokia Tool Kit Checklist - From TI GuidelinesakkmalÎncă nu există evaluări

- WB Grundlagen Antriebstechnik I2 enDocument60 paginiWB Grundlagen Antriebstechnik I2 enmarcelodias99Încă nu există evaluări

- New ChangeDocument68 paginiNew ChangeAnoop Kamla PandeyÎncă nu există evaluări

- Power Mirrors Function TestDocument3 paginiPower Mirrors Function TestandreasnevesÎncă nu există evaluări

- Knifesharpener HR 2577: Philips Domestic Appliances and Personal CareDocument2 paginiKnifesharpener HR 2577: Philips Domestic Appliances and Personal CarepukymottoÎncă nu există evaluări

- Top Bangalore diagnostic labsDocument2 paginiTop Bangalore diagnostic labsSumanth PÎncă nu există evaluări

- Error Codes HP LaserJet Enterprise Flow MFP M880 Page 24 PDFDocument4 paginiError Codes HP LaserJet Enterprise Flow MFP M880 Page 24 PDFAfonso OnoiaÎncă nu există evaluări

- Kempomat: EN FI SV NO DA DE NL FR ES PL RUDocument26 paginiKempomat: EN FI SV NO DA DE NL FR ES PL RUmcombaleÎncă nu există evaluări

- Installation & Maintenance Instructions: For The MIC Electronic Drain ValveDocument2 paginiInstallation & Maintenance Instructions: For The MIC Electronic Drain ValveLIÎncă nu există evaluări

- Teile Und Zubehör - Einbauanleitung: Park Distance Control (PDC)Document17 paginiTeile Und Zubehör - Einbauanleitung: Park Distance Control (PDC)وسام فوزي100% (1)

- Electrical Layout Design and Load Calculation GuideDocument75 paginiElectrical Layout Design and Load Calculation Guide2GI20AT021 Devki HanamshetÎncă nu există evaluări

- Fisa Tehnica - Panou Fotovoltaic 375 W MonocristalinDocument2 paginiFisa Tehnica - Panou Fotovoltaic 375 W MonocristalinAlexandru PielmusÎncă nu există evaluări

- LCM-40 (DA), LCM-60 (DA) Installation Manual: FeaturesDocument2 paginiLCM-40 (DA), LCM-60 (DA) Installation Manual: FeaturespericaÎncă nu există evaluări

- Milo V1.5 Sourcing Guide - Milo V1.5 SourcingDocument1 paginăMilo V1.5 Sourcing Guide - Milo V1.5 SourcingMartijn PetersÎncă nu există evaluări

- 9096940455-01 CPB NewDocument32 pagini9096940455-01 CPB Newsuresh avhadÎncă nu există evaluări

- Sensors PDFDocument192 paginiSensors PDFAsith SavindaÎncă nu există evaluări

- 9866 0180 01 Secoroc COP 64 Gold Service Poster - LOWDocument1 pagină9866 0180 01 Secoroc COP 64 Gold Service Poster - LOWPaula ArrascaetaÎncă nu există evaluări

- Unilab Laboratory: Programmable Automatic Power Supply Unit DL 1067Document5 paginiUnilab Laboratory: Programmable Automatic Power Supply Unit DL 1067Ivan VillanevaÎncă nu există evaluări

- 994K Wheel Loader Electrical SystemDocument8 pagini994K Wheel Loader Electrical SystemHéctorHernándezDíazÎncă nu există evaluări

- WAVE Doble Central Station Air Handler Product ReportDocument20 paginiWAVE Doble Central Station Air Handler Product ReportRodrigo SantosÎncă nu există evaluări

- Whirlpool LSL9244EQ0 Repair Part ListDocument14 paginiWhirlpool LSL9244EQ0 Repair Part ListkenygomezÎncă nu există evaluări

- 1 3500 1183a 02 PDFDocument3 pagini1 3500 1183a 02 PDFTolias EgwÎncă nu există evaluări

- Solar Panel Cleaning SystemDocument4 paginiSolar Panel Cleaning SystemMohammed safarulla HÎncă nu există evaluări

- Rcma470ly (Monitor de Corrente Residual)Document4 paginiRcma470ly (Monitor de Corrente Residual)gilvandroÎncă nu există evaluări

- Model: PIR 4150200A: PIR 41502 Curtain (LLPL03) PIR 41502 Corridor Lens (LLPL02) PIR 41502 Wide Angle LensDocument2 paginiModel: PIR 4150200A: PIR 41502 Curtain (LLPL03) PIR 41502 Corridor Lens (LLPL02) PIR 41502 Wide Angle Lenshr1sÎncă nu există evaluări

- Cost Conscious Coker Unheading Valve Hydraulic System Design Cammy Blac DCU Mumbai 2016 PDFDocument24 paginiCost Conscious Coker Unheading Valve Hydraulic System Design Cammy Blac DCU Mumbai 2016 PDFFayaz MohammedÎncă nu există evaluări

- Thermostat in DetailDocument16 paginiThermostat in DetailNirjal GiriÎncă nu există evaluări

- Faulty CAN messages and sensors in BS codesDocument8 paginiFaulty CAN messages and sensors in BS codesJoel AgbekponouÎncă nu există evaluări