Documente Academic

Documente Profesional

Documente Cultură

WAA252 Quick Reference Guide in English Part 1

Încărcat de

JACKDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

WAA252 Quick Reference Guide in English Part 1

Încărcat de

JACKDrepturi de autor:

Formate disponibile

DESCRIPTION TECHNICAL DATA

Quick Reference Guide The WAA252 Heated Anemometer is an optimum choice,

when a non-freezing gauge is required. It offers the linearity Sensor / Cupwheel anemometer /

and sensitivity of a well-designed cup anemometer plus the Transducer type Opto-chopper

advantage of heating carried out right where it is needed - in

WAA252 Heated Anemometer the cups. Foil heaters are inserted in each cup and in the cup

Measuring range

Starting threshold

0.4 ... 75 m/s

< 0.5 m/s 1)

wheel hub. For easy maintenance the cup assembly is

removable, with a 2-pin connector for heating electricity. Distance constant 2.7 m

The transmission of heating power to the WAA252’s rotor is Transducer output 0 ... 750 Hz square wave

Description and Technical Data contactless, with no slip rings or brushes. This feature (for wind speeds 0 ... 75 m/s)

completely eliminates sparks and excessive friction or wear. Characteristic transfer function Uf = 0.39 + 0.10 x R

Power to the heaters is supplied via a rotary transformer, (R = o/p pulse rate; Uf = wind speed)

with 26 kHz low-EMI sine wave. Accuracy (within 0.4 ... 60 m/s)

An intelligent heating control circuitry is included, with with characteristic transfer function ± 0.17 m/s 2)

integral sensors for both ambient and internal temperature. with transfer function Uf = 0.1 × R –0.3/+1.0 m/s 3)

Therefore, there is no need for a separate temperature sensor Input power 24 VDC ± 10 %, 3.2 A max.

in the system.

Typical power consumption 72 W below +2 °C (heating on)

Power consumption, typically 72 watts, is very low (Uin = 24 VDC) 1 W above +6 °C (heating off)

considering the heating efficiency and the protection against

Optional xducer i/p power (Uxdr) 4.8 - 15.3VDC, 11mA typ.

freezing provided. Approximately 50 watts of the power is

on the cup wheel, 12 watts on the shaft and bearings, and 10 Transducer output high level > 11 V (or > Uxdr - 1.5V)

watts on the body. Hence also the sensor body is kept free (with Iout < +5 mA)

of ice, which is important for maintaining the gauge’s Transducer output low level < 1.5 V

aerodynamic performance. (with Iout > –5 mA)

A single 24 VDC (3.5 A) power supply is able to feed the Output power for wind xmitters 13 ± 1 VDC, 75 mA max.

whole device, including the transducer. The WAA252 can Electrical connections MIL-C-26482 type

even deliver an isolated 12V excitation to a separate wind 6-pin plug

transmitter, if needed. Thus one power supply is enough for

Operating temperature –55 ... +55 °C

the whole sensor system.

Storage temperature –60 ... +70 °C

9608-037 Optionally it is possible to take the transducer power from an

Housing material AlMgSi,

external device such as the WT521 or WAT12 wind

transmitter. This guarantees an uninterrupted transducer gray & black anodized

• Non-freezing all-weather sensor supply, independent of the heating power. The opto- Cup material PC reinforced with

chopper type transducer consumes only some 10 mA from a glass fiber; black

• Lightweight cups with integral heaters

5... 15 V excitation. Dimensions 264 (h) × 90 (Ø) mm;

• Non-contact heating power transmission The WAA252 can be mounted on Vaisala’s regular WAC151 swept radius of cup wheel: 91 mm

crossarm and its output interface is compatible with that of Weight 800 g

• Low starting threshold the regular WAA151 anemometer. Therefore, updating to a

• Excellent linearity even at low wind speeds heated-cup system is easy - just a wiring alteration is needed 1) Measured with cup wheel in position least favored by flow

in the crossarm’s junction box. direction. Optimum position yields < 0.35 m/s starting

• Fast response; distance constant only 2.7 m threshold.

Wind tunnel tests per ASTM method D5096-90 have been

2) Standard Deviation

conducted on the WAA252 in order to define its 3) Typical error versus speed, when “simple transfer function”

aerodynamical behavior. Uf = 0.1 × R is used:

The WAA252’s power inputs and signal outputs are well

RANGE (m/s) 0-5 5-10 10-15 15-20 20-24 24-29 29-34 34-39 39-44 44-48 48-58

protected against line transients and interference. The device ERROR (m/s) -0.2 -0.1 ±0.0 +0.1 +0.2 +0.3 +0.4 +0.5 +0.6 +0.7 +0.85

itself emits no unacceptable electro-magnetic noise to the

signal cables or the atmosphere.

www.vaisala.com

Mounting and Locating The input power supply leads are connected to the terminals The alterations are:

In mounting the WAA252 Heated Anemometer keep in mind E(+) and D(-) of the I/O connector (presented in Table 1).

the recommendations for locating the wind sensors. The lead diameter should be such that no excessive power is 1 The thermostat switch in the junction box's regular

Following three cases are most typical: wasted in the cable. Each 0.3 ohms in the cable will cause a wiring is useless in this application and hence its WHT

1-Volt extra drop in the operational voltage, which in turn and LGN colored wires are disconnected. Both of

Preferred location is on the top of a mast, at a site with will decrease the applicable heating power. For instance, if these wires are connected to the screw terminal #2.

1

open terrain. The recommendation is to have at least only 20 V instead of the recommended 24 V is remaining at 2 The YEL colored wire is moved from the terminal #2 to

150 m open area in all directions. Minimum distance to the anemometer end of the cable, only 70% of the specified the terminal #3.

visible obstacles is 10 times the height of the obstacle. heating power is gained.

When the gauge is mounted beside the mast, the No separate power source is required for the WAA252's

2

distance from the mast to the crossarm should be at transducer section, since this is also fed by the heating

least 3 times the diameter of the mast. supply, through a galvanically isolated voltage converter

integral to the sensor electronics.

3 If mounted on the top of the building, the gauge

should be installed on top of a mast at least 1.5 times Optionally however, if an external, no-break power supply

as high as is the height or the largest width of the should be applied for the transducer section only, this can be

building, whichever is smaller. connected to the terminals A(+) and B(-), with a voltage

range from 5 to 15 VDC. The transducer section, consuming

only about 10 mA, will manage even long power break

NOTE Following the recommendations for locating periods with just a tiny battery, whereas the heating power

the wind sensors is essential for receiving requires a big battery pack. An option for saving power is to

reliable wind data. use pulsing in power supply. For further information on that

contact Vaisala personnel.

The sensor signal output is taken from the terminals C(+) and

Electrical B(-). The output is a square wave pulse frequency 0 to 750

The WAA252 operates from a single 25 VDC +10% power Hz linearly corresponding to 0 to 75 m/s wind speed.

supply, at 3.2-ampere maximum current (@ 25 V). Most of Typically, o/p high level is 11…13 V and low level 0…1 V.

the current is consumed by the heating, typically enabled However, with e.g. 5 V external power applied to the sensor 0002-025

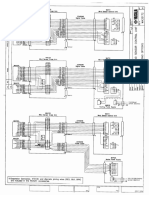

only at ambient temperature below +5 °C. With heating off, section, the o/p high level, during the time the heating Figure 1. WAC151 Standard Wiring for WAA252 and WAV252

only some 40 mA is consumed. supply is unavailable, is only about 4 V.

Table 1. WAA252 Connector The 12 V power output at the terminals F(+) and B(-) is for The signal cable wiring (ZZ45048 or equivalent) is the same

excitation of optional wind transmitters like Vaisala WAT12 as with the regular sensors, except for the sensor power

A F+ Optional power input for or WT521, in case those have no other power source inputs F+ and D+ (terminals #4 and #6). Those inputs are

transducer section, available. not necessarily needed, since the sensor can take its

5...15VDC, 10mA typ.

excitation from the integral, isolated 12V power supply fed

B SGND Signal Ground (also

NOTE SGND at terminal B and HGND at terminal D from the 25V heating power line. Optionally, however, as

GND for optional power described in the Electrical section, a no-break power supply

i/p and o/p at A and F)

are galvanically isolated from each other.

can be applied to those terminals, for example, when a

C Fout Signal Output, WT521 or WAT12 Wind Transmitter is being used.

0...750Hz square wave The power cable leads (ZZ45049 or equivalent) are applied

(for 0...75m/s), WAC151 Wiring

to the terminals #2(+) and #3(-). In case the installation

(HI>11V / LO<1V typ.) The wiring diagram for the WA252 system to the WAC151 includes both the WAA252 and WAV252, the power line

D HGND Power Ground Sensor Crossarm is shown in the Figure 1. Two alterations current exceeds 5 A. Hence a large wire dimension or several

0002-027 must be done to the regular sensor cable wiring in this wires in parallel shall be used. Each 0.2 ohms in the power

E HTG+ Power Input, junction box. The altered wire connections are highlighted

24VDC +10%, 3.2 A max. cable will cause a 1-volt extra drop in the input voltage,

in the Figure 1. which in turn will decrease the available heating power.

F 12Vout Optional power output for

external transmitter,

13VDC typ., 75 mA max. NOTE The lead diameter should be such that no

excessive power is wasted in the cable.

Ref. WAA252-U430en-1.2

S-ar putea să vă placă și

- Instruction Book Qc1112 and Qc2112 ESF 2960 0380 00 ENDocument79 paginiInstruction Book Qc1112 and Qc2112 ESF 2960 0380 00 ENКонстантин Гетьман100% (1)

- Scania Bodybuilder ElectricsDocument16 paginiScania Bodybuilder ElectricsJack Norhy100% (1)

- Layout Solns 3Document12 paginiLayout Solns 3VIKRAM KUMARÎncă nu există evaluări

- Connect PTC Thermistor to PowerFlex 520 DriveDocument3 paginiConnect PTC Thermistor to PowerFlex 520 Drivezernn100% (1)

- Guide to the Non-Freezing WAV252 Heated Wind VaneDocument2 paginiGuide to the Non-Freezing WAV252 Heated Wind VaneJACKÎncă nu există evaluări

- HWSC S A0012939215 1-3073398Document7 paginiHWSC S A0012939215 1-3073398carlosibaÎncă nu există evaluări

- Fluke Ircon Modline Spot PyrometersDocument4 paginiFluke Ircon Modline Spot PyrometersjosevazxoÎncă nu există evaluări

- AirpaxDocument46 paginiAirpaxbandaraÎncă nu există evaluări

- Danfoss Thermal Actuator Modulating ABNM A5Document5 paginiDanfoss Thermal Actuator Modulating ABNM A5Novian Hermawan HÎncă nu există evaluări

- 1508333679MP 5200Document20 pagini1508333679MP 5200engenhariahabÎncă nu există evaluări

- Pt100-Temperature-Relay Type TR600: Digital, 6 Sensors, 6 LimitsDocument2 paginiPt100-Temperature-Relay Type TR600: Digital, 6 Sensors, 6 LimitsAbu Yussif AlaboodiÎncă nu există evaluări

- Two-Terminal IC Temperature Transducer AD590: FeaturesDocument16 paginiTwo-Terminal IC Temperature Transducer AD590: FeaturesJuan DuarteÎncă nu există evaluări

- Making Your Oscillator Work: Author: Brett Duane Microchip Technology IncDocument8 paginiMaking Your Oscillator Work: Author: Brett Duane Microchip Technology IncCícero Domingos JuniorÎncă nu există evaluări

- Datasheet - 1606-XL480E-3Document2 paginiDatasheet - 1606-XL480E-3NixiusÎncă nu există evaluări

- Install and operate RH-10xP humidity and temperature sensorsDocument4 paginiInstall and operate RH-10xP humidity and temperature sensorsisaiasckÎncă nu există evaluări

- Catalog 2022Document62 paginiCatalog 2022Salsa Nadya PutriÎncă nu există evaluări

- Afsd-R5 Ul - 24 VDocument7 paginiAfsd-R5 Ul - 24 VMuhammad ShahidÎncă nu există evaluări

- AVF 234S: SUT Valve Actuator With Spring Return: FeaturesDocument8 paginiAVF 234S: SUT Valve Actuator With Spring Return: FeaturesNORODDINEÎncă nu există evaluări

- 5A IntegratorDocument5 pagini5A IntegratorWilsonÎncă nu există evaluări

- Raw 3Document31 paginiRaw 3Apik SubagyaÎncă nu există evaluări

- Janitza Datasheet-UMG96RM enDocument7 paginiJanitza Datasheet-UMG96RM enNelutu BreazuÎncă nu există evaluări

- LC 5296 atDocument2 paginiLC 5296 atRohit BerwalÎncă nu există evaluări

- BelimoDocument4 paginiBelimoAnjana2893Încă nu există evaluări

- AVM 234S: SUT Valve Actuator With Positioner: FeaturesDocument8 paginiAVM 234S: SUT Valve Actuator With Positioner: Featuresthanh nguyenÎncă nu există evaluări

- Bipolar Hall-Effect Switch For High-Temperature Operation: FeaturesDocument6 paginiBipolar Hall-Effect Switch For High-Temperature Operation: Featuresantonio aguilarÎncă nu există evaluări

- Max31856 2Document30 paginiMax31856 2Natália Borges MarcelinoÎncă nu există evaluări

- DS Secr03 en R2203Document6 paginiDS Secr03 en R2203Amic BanatÎncă nu există evaluări

- NM24A-MF-TP 1 0 enDocument8 paginiNM24A-MF-TP 1 0 enJuanÎncă nu există evaluări

- Controllogix 1756 Isolated Analog I/O ModulesDocument2 paginiControllogix 1756 Isolated Analog I/O ModulesJan Richardo GultomÎncă nu există evaluări

- FIMER VSN800 WeatherStation en Rev ADocument3 paginiFIMER VSN800 WeatherStation en Rev ABelgacem BouregaaÎncă nu există evaluări

- Fire and Smoke Spring Return Actuator FSNF24 (-S) US: Technical DataDocument3 paginiFire and Smoke Spring Return Actuator FSNF24 (-S) US: Technical DatahtanhÎncă nu există evaluări

- LM12CL 80W Operational Amplifier: General DescriptionDocument14 paginiLM12CL 80W Operational Amplifier: General Descriptionkhawar mukhtarÎncă nu există evaluări

- Model AMT: Dewpoint Transmitter 4-20ma. Ranges Available Between - 120°C To +20°C (-184°F To +68°F) DewpointDocument3 paginiModel AMT: Dewpoint Transmitter 4-20ma. Ranges Available Between - 120°C To +20°C (-184°F To +68°F) Dewpointmarcello_oliveiraÎncă nu există evaluări

- Netsure 801 Ca7 DatasheetDocument4 paginiNetsure 801 Ca7 DatasheetALEX ALEXÎncă nu există evaluări

- WA15 Datasheet B210382EN C LoResDocument2 paginiWA15 Datasheet B210382EN C LoResJACKÎncă nu există evaluări

- Max31856 PDFDocument30 paginiMax31856 PDFDiego Fernando ArpiÎncă nu există evaluări

- LG TV Plasma 60pc1d 60pc1d Service ManualDocument49 paginiLG TV Plasma 60pc1d 60pc1d Service Manualrogermb100% (1)

- Enda Ehtc7425A Humidity and Temperature Controller: Technical SpecificationsDocument8 paginiEnda Ehtc7425A Humidity and Temperature Controller: Technical SpecificationsNader MohammedÎncă nu există evaluări

- Oil Burner Safety Control Diagnostic and Programming GuideDocument6 paginiOil Burner Safety Control Diagnostic and Programming GuideSofian NasrÎncă nu există evaluări

- SG 1524 - 2524 - 3524 - (LinFinity) PDFDocument7 paginiSG 1524 - 2524 - 3524 - (LinFinity) PDFJosé AdelinoÎncă nu există evaluări

- Trafo Huawei DatasheetDocument17 paginiTrafo Huawei DatasheetWachito VarelaÎncă nu există evaluări

- Cylinder Pressure SensorDocument2 paginiCylinder Pressure SensorSaasiÎncă nu există evaluări

- Proportional Amplifier Type EV1M3: Product DocumentationDocument16 paginiProportional Amplifier Type EV1M3: Product DocumentationTounsi MahdiÎncă nu există evaluări

- DVI 980/982 Gas Burner Safety ControlDocument6 paginiDVI 980/982 Gas Burner Safety ControlSerghei BotnaruÎncă nu există evaluări

- T24Document7 paginiT24Aiman AliÎncă nu există evaluări

- 1007Document1 pagină1007sivasankarÎncă nu există evaluări

- A6V10406213 - Actuators For Fire and Smoke Protection Dampers GG - enDocument12 paginiA6V10406213 - Actuators For Fire and Smoke Protection Dampers GG - enangelesÎncă nu există evaluări

- Application Note AN1027 Current Sense Resistors and Circuit ApplicationsDocument2 paginiApplication Note AN1027 Current Sense Resistors and Circuit ApplicationsWorkshop BKUÎncă nu există evaluări

- LMV51... Burner Control With Integrated Fuel / Air Ratio Control and Load Control For Forced-Draft BurnersDocument48 paginiLMV51... Burner Control With Integrated Fuel / Air Ratio Control and Load Control For Forced-Draft BurnersEden BenÎncă nu există evaluări

- Thyristorised Power Regulator - CAT450Document4 paginiThyristorised Power Regulator - CAT450Jahidul IslamÎncă nu există evaluări

- AD590Document16 paginiAD590pecis65613Încă nu există evaluări

- KISTLER 4502a - EnglishDocument8 paginiKISTLER 4502a - EnglishDexter PoliÎncă nu există evaluări

- ABB - Ugaoni Servomotor 100 NMDocument11 paginiABB - Ugaoni Servomotor 100 NMMiroslav ProdanaÎncă nu există evaluări

- 12118-xx Service ManualDocument29 pagini12118-xx Service Manualclkent2022Încă nu există evaluări

- PX Series: Process ControllerDocument30 paginiPX Series: Process ControllerSerhiiÎncă nu există evaluări

- MicroNet VAV Controllers MNL-V3RVx Datasheet F-26366-8Document4 paginiMicroNet VAV Controllers MNL-V3RVx Datasheet F-26366-8Arthur BastosÎncă nu există evaluări

- STR6 485 Manual enDocument24 paginiSTR6 485 Manual enIgor YoshikawaÎncă nu există evaluări

- Nfa S2Document5 paginiNfa S2Trunghieu LeÎncă nu există evaluări

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1De la EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Evaluare: 2.5 din 5 stele2.5/5 (3)

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2De la EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2Încă nu există evaluări

- Analog Circuit Design: A Tutorial Guide to Applications and SolutionsDe la EverandAnalog Circuit Design: A Tutorial Guide to Applications and SolutionsEvaluare: 3.5 din 5 stele3.5/5 (6)

- 0 Gw-Energy 20111125135712Document2 pagini0 Gw-Energy 20111125135712JACKÎncă nu există evaluări

- User'S Guide: Combined Wind Sensor WMS301 and WMS302Document32 paginiUser'S Guide: Combined Wind Sensor WMS301 and WMS302JACKÎncă nu există evaluări

- 34m TallTower ManualDocument73 pagini34m TallTower ManualmadaÎncă nu există evaluări

- WAC151 Cross Arm Assembly DrawingDocument1 paginăWAC151 Cross Arm Assembly DrawingJACKÎncă nu există evaluări

- WMT700 Quick Reference Quide EN-FR-SP-RU-JP-CN PDFDocument36 paginiWMT700 Quick Reference Quide EN-FR-SP-RU-JP-CN PDFJACKÎncă nu există evaluări

- A2SEA VesselDocument22 paginiA2SEA VesselJACKÎncă nu există evaluări

- WAC151 Technical ReferenceDocument8 paginiWAC151 Technical ReferenceJACKÎncă nu există evaluări

- Hydraulic Winch Safety Mechanism 4254 InstructionsDocument1 paginăHydraulic Winch Safety Mechanism 4254 InstructionsJACKÎncă nu există evaluări

- Wind Energy DevelopmentDocument1 paginăWind Energy DevelopmentJACKÎncă nu există evaluări

- WCO-WEN - Southern California Edison Success Story B210999EN-A - HRDocument2 paginiWCO-WEN - Southern California Edison Success Story B210999EN-A - HRJACKÎncă nu există evaluări

- Engineering CAD DesignDocument2 paginiEngineering CAD DesignJACKÎncă nu există evaluări

- GL GH Position On WINDCUBE WhitepaperDocument11 paginiGL GH Position On WINDCUBE WhitepaperJACKÎncă nu există evaluări

- Service Sheet WindFarmOptimisation Oct2013Document2 paginiService Sheet WindFarmOptimisation Oct2013JACKÎncă nu există evaluări

- WAC151 Basic Wiring Options - Wa25 PDFDocument1 paginăWAC151 Basic Wiring Options - Wa25 PDFJACKÎncă nu există evaluări

- WAV252 Heated Wind Vane Installation GuideDocument2 paginiWAV252 Heated Wind Vane Installation GuideJACKÎncă nu există evaluări

- WHP25 User Guide in EnglishDocument27 paginiWHP25 User Guide in EnglishJACKÎncă nu există evaluări

- User'S Guide: Combined Wind Sensor WMS301 and WMS302Document32 paginiUser'S Guide: Combined Wind Sensor WMS301 and WMS302JACKÎncă nu există evaluări

- Turbulence Assessment With LidarsDocument26 paginiTurbulence Assessment With LidarsJACKÎncă nu există evaluări

- Lecture 17.4 Structural Analysis For Seismic ActionsDocument17 paginiLecture 17.4 Structural Analysis For Seismic ActionsJACKÎncă nu există evaluări

- Wea Ls7002 Datasheet B211284en A LowDocument2 paginiWea Ls7002 Datasheet B211284en A LowleeÎncă nu există evaluări

- HybridXT Push Pull Anemometer ManualDocument22 paginiHybridXT Push Pull Anemometer ManualJACKÎncă nu există evaluări

- Testing 110S Temperature Sensor InstructionsDocument19 paginiTesting 110S Temperature Sensor InstructionsJACKÎncă nu există evaluări

- Deutsche WindGuard LIDAR Comparison Whitepaper PDFDocument5 paginiDeutsche WindGuard LIDAR Comparison Whitepaper PDFJACKÎncă nu există evaluări

- Barlovento FCR Validation On Complex Site Whitepaper PDFDocument76 paginiBarlovento FCR Validation On Complex Site Whitepaper PDFJACKÎncă nu există evaluări

- HybridXT 4 20ma Vane ManualDocument21 paginiHybridXT 4 20ma Vane ManualJACKÎncă nu există evaluări

- HybridXT 4 20ma Anemometer ManualDocument24 paginiHybridXT 4 20ma Anemometer ManualJACKÎncă nu există evaluări

- Testing IceFree NPN Vane InstructionsDocument1 paginăTesting IceFree NPN Vane InstructionsJACKÎncă nu există evaluări

- HybridXT 4 20ma Anemometer ManualDocument24 paginiHybridXT 4 20ma Anemometer ManualJACKÎncă nu există evaluări

- t420 ThinkpadDocument11 paginit420 ThinkpadDwi RachmatÎncă nu există evaluări

- CHG 00Document2 paginiCHG 00dyaza_1Încă nu există evaluări

- IPEC Webinar For India - Part 1 - Partial Discharge OverviewDocument33 paginiIPEC Webinar For India - Part 1 - Partial Discharge OverviewHafiziAhmadÎncă nu există evaluări

- Samsung Cw29z306vbxxecDocument135 paginiSamsung Cw29z306vbxxecf17439100% (3)

- Model Pcu - Process Control Unit: C Us ListedDocument8 paginiModel Pcu - Process Control Unit: C Us Listedpayaso1234Încă nu există evaluări

- 6060B Electronic Load - Service ManualDocument95 pagini6060B Electronic Load - Service Manualv21Încă nu există evaluări

- ATV310HD11N4E Variable Speed DriveDocument6 paginiATV310HD11N4E Variable Speed DriveAdi kurniantoÎncă nu există evaluări

- Advance Optima Module Uras 14 Service ManualDocument85 paginiAdvance Optima Module Uras 14 Service ManualHammad AshrafÎncă nu există evaluări

- Exhibitor’s ListDocument4 paginiExhibitor’s ListAhmad HassanainÎncă nu există evaluări

- Microwave BenchDocument32 paginiMicrowave Benchghadei_debasishÎncă nu există evaluări

- 1SFL427001R1311-af116-30-11-13 Contactor PDFDocument5 pagini1SFL427001R1311-af116-30-11-13 Contactor PDFඅාරච්චි අයියාÎncă nu există evaluări

- PVC Bandpass FiltersDocument6 paginiPVC Bandpass Filterschirag_cs7Încă nu există evaluări

- Portable Electrical Appliance InspectionDocument26 paginiPortable Electrical Appliance InspectionTolga_34100% (1)

- Dualmode Obstacle Avoidance Robot ContentDocument43 paginiDualmode Obstacle Avoidance Robot ContentshuhaibasharafÎncă nu există evaluări

- Measurement of Resistance - PPT PDFDocument20 paginiMeasurement of Resistance - PPT PDFAmrendra kumar0% (1)

- Electrical Schedule and WiringDocument1 paginăElectrical Schedule and WiringJeremy BuelbaÎncă nu există evaluări

- Lincoln Ranger 225Document6 paginiLincoln Ranger 225fdpc1987Încă nu există evaluări

- TLW - Part A Questions & AnswersDocument14 paginiTLW - Part A Questions & AnswerspushpaÎncă nu există evaluări

- AlphaMeterUserManual-with S1 PanelDocument28 paginiAlphaMeterUserManual-with S1 PanelNandgulabDeshmukhÎncă nu există evaluări

- Batangas State University College of Engineering, Architecture & Fine ArtsDocument20 paginiBatangas State University College of Engineering, Architecture & Fine ArtsJezreel GamboaÎncă nu există evaluări

- Protection Coordination at UtpDocument57 paginiProtection Coordination at UtpEBEÎncă nu există evaluări

- 30ra 1sbDocument12 pagini30ra 1sbomarcastillogalindoÎncă nu există evaluări

- COOPER - CCH Product CatalogueDocument16 paginiCOOPER - CCH Product CatalogueAfsalÎncă nu există evaluări

- Cable Tray Rules PDFDocument8 paginiCable Tray Rules PDFHafiz Muhammad Ahmad RazaÎncă nu există evaluări

- BT138FDocument7 paginiBT138FMiloud ChouguiÎncă nu există evaluări

- Magnetizing CurrentDocument4 paginiMagnetizing CurrentSureshraja9977Încă nu există evaluări

- AV02 1413EN DS HFBR 1505FZ 04nov20110Document10 paginiAV02 1413EN DS HFBR 1505FZ 04nov20110Charoon SuriyawichitwongÎncă nu există evaluări