Documente Academic

Documente Profesional

Documente Cultură

Huecos de Tee Mecanicas

Încărcat de

David Gutiérrez LópezDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Huecos de Tee Mecanicas

Încărcat de

David Gutiérrez LópezDrepturi de autor:

Formate disponibile

Catalog 2011

Mechanical Tees Hole-cutting

Shurjoint mechanical tees provide a fast The hole-cut method of pipe preparation

and easy mid-point branch outlet, eliminating is required when using mechanical tees,

the need for welding or the use of multiple mechanical crosses, and saddle-lets. The

fittings. The Model M21 features a female method of pipe preparation requires the

threaded outlet and M22 features a grooved cutting or drilling of a specified hole size on

end outlet. Model 7721 (female threaded the centerline of the pipe. Always use the

outlet) and 7722 (grooved end outlet) are correct hole saw size as shown in Table 1

available in 8” sizes. The Model 723 Saddle-

let features a compact-design for making A

direct connections to sprinkler heads, drop

nipples and or gauges.

Ridgid Model No. HC-300

Hole Cutting Tool

16mm ( ⅝" )

and Table 1-b and never use a torch for

cutting a hole. After the hole has been

cut all rough edges must be removed and

the area within 5/8” (16mm) of the hole

should be inspected to ensure a clean

Gasket Upper

Housing smooth surface, free of any indentations or

projections that could affect proper gasket

Locating sealing. The area within the “A” dimension

Alignment Collar should also be inspected and must be free

Tab

of dirt, scale or any imperfection that could

affect proper seating or assembly of the

Nut

fitting.

Bolt

Bolt Pad Hole Size: The hole sizes are dictated by

the branch size of the mechanical tee.

Lower Housing

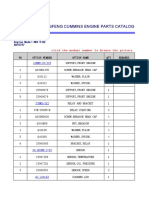

Table 1 Hole Sizes for Mechanical Tees

unit: mm/in

When bolts are tightened with a proper

Branch Hole Dimensions Surface

torque, the outlet housing makes metal to Size Hole Saw Max dia. Preparation

metal contact with the outer surface of the Size Allowed “A”

15, 20, 25 38 41 89

pipe. ½, ¾, 1 1½ 1⅝ 3½

32, 40 51* 54* 102

1¼, 1½ 2 2⅛ 4

Metal-to-metal 50 64 67 114

2 2½ 2⅝ 4½

65 70 73 121

2½ 2¾ 2⅞ 4¾

80 89 92 140

3 3½ 3⅝ 5½

Gap 100 114 118 165

4 4½ 4⅝ 6½

It is normal to see bolt pad gaps

*See Table 1-b for exception.`

Table 1-b Exception

Hole Dimensions Surface

Run x Branch Hole Saw Max dia. Preparation

The hole must be cleanly cut

Size Allowed “A”

using the correct size hole-saw 50 x 32 / 50 x 40 45 47 102

and shall have a smooth edge. Never use a 2 x1¼ / 2 x 1½ 1¾ 1⅞ 4

torch for cutting a hole.

Connect with the Best! www.shurjoint.com 33

©Copyright 2011 Shurjoint

S-ar putea să vă placă și

- Hole-Cutting Mechanical TeesDocument19 paginiHole-Cutting Mechanical TeesEdwin Collado FigueroaÎncă nu există evaluări

- Assembly InstructionsDocument8 paginiAssembly InstructionsEduardo Farrera RedondoÎncă nu există evaluări

- Field Welding InstructionsDocument6 paginiField Welding InstructionsErickÎncă nu există evaluări

- Flare37 Fittings Catalog 2020Document22 paginiFlare37 Fittings Catalog 2020Fernando A CardozoÎncă nu există evaluări

- Engineering Drawing from the Beginning: The Commonwealth and International Library: Mechanical Engineering DivisionDe la EverandEngineering Drawing from the Beginning: The Commonwealth and International Library: Mechanical Engineering DivisionEvaluare: 4.5 din 5 stele4.5/5 (3)

- 3-Piece Tube Assembly: Stainless Steel High Pressure 37° Tube Fittings 1/8'' TO 2''Document22 pagini3-Piece Tube Assembly: Stainless Steel High Pressure 37° Tube Fittings 1/8'' TO 2''Gaurav BedseÎncă nu există evaluări

- E 675 Â " 02 - RTY3NQDocument10 paginiE 675 Â " 02 - RTY3NQhans ccÎncă nu există evaluări

- Ch-6 Reaming, Boring, BroachingDocument58 paginiCh-6 Reaming, Boring, BroachingVikas PotluriÎncă nu există evaluări

- Cabinet Making for Beginners - Tools, Joints, Cabinet Construction, Veneering and Inlaying, Drawing, Cutting Lists, Etc., Timber, Fittings, Typical DesignsDe la EverandCabinet Making for Beginners - Tools, Joints, Cabinet Construction, Veneering and Inlaying, Drawing, Cutting Lists, Etc., Timber, Fittings, Typical DesignsEvaluare: 5 din 5 stele5/5 (2)

- Reinforcing Detailing of R.C.C Members - K.kaviTHADocument47 paginiReinforcing Detailing of R.C.C Members - K.kaviTHAGurupriyaÎncă nu există evaluări

- Plastic Injection Mold Design for Toolmakers - Volume III: Plastic Injection Mold Design for Toolmakers, #3De la EverandPlastic Injection Mold Design for Toolmakers - Volume III: Plastic Injection Mold Design for Toolmakers, #3Încă nu există evaluări

- Ch-6 Reaming, Boring, BroachingDocument58 paginiCh-6 Reaming, Boring, BroachingAnshul AgrawalÎncă nu există evaluări

- Plastic Injection Mold Design for Toolmakers - Volume II: Plastic Injection Mold Design for Toolmakers, #2De la EverandPlastic Injection Mold Design for Toolmakers - Volume II: Plastic Injection Mold Design for Toolmakers, #2Încă nu există evaluări

- Reinforcing Detailing of R.C.C MembersDocument47 paginiReinforcing Detailing of R.C.C MembersAmey ShettiÎncă nu există evaluări

- Classic Handplanes and Joinery: Essential Tips and Techniques for WoodworkersDe la EverandClassic Handplanes and Joinery: Essential Tips and Techniques for WoodworkersEvaluare: 3.5 din 5 stele3.5/5 (2)

- Methodology - Well Sinking-Foundation PDF-1Document7 paginiMethodology - Well Sinking-Foundation PDF-1Tina J100% (1)

- 2011 - Standard Practice For Mechanical Mixing of Hydraulic Cement Pastes and Mortars of Plastic ConsistencyDocument5 pagini2011 - Standard Practice For Mechanical Mixing of Hydraulic Cement Pastes and Mortars of Plastic ConsistencySameh AhmedÎncă nu există evaluări

- How to Build a Global Model Earthship Operation II: Concrete WorkDe la EverandHow to Build a Global Model Earthship Operation II: Concrete WorkÎncă nu există evaluări

- AK31 TurretDocument34 paginiAK31 TurretVladimirAgeev100% (1)

- Traditional Toolmaking: The Classic Treatise on Lapping, Threading, Precision Measurements, and General ToolmakingDe la EverandTraditional Toolmaking: The Classic Treatise on Lapping, Threading, Precision Measurements, and General ToolmakingEvaluare: 5 din 5 stele5/5 (2)

- Drawings Rotary Jetting SwiffelDocument5 paginiDrawings Rotary Jetting SwiffelSabre DoiÎncă nu există evaluări

- Band Saw (Missing Shop Manual): The Tool Information You Need at Your FingertipsDe la EverandBand Saw (Missing Shop Manual): The Tool Information You Need at Your FingertipsEvaluare: 5 din 5 stele5/5 (1)

- Collar BoltsDocument2 paginiCollar BoltsMahdi HocineÎncă nu există evaluări

- Collar Bolts: in Shell and Tube Heat ExchangersDocument2 paginiCollar Bolts: in Shell and Tube Heat ExchangersMahdi HocineÎncă nu există evaluări

- Collar Bolts: in Shell and Tube Heat ExchangersDocument2 paginiCollar Bolts: in Shell and Tube Heat ExchangersMahdi HocineÎncă nu există evaluări

- 2 Marks MDDocument19 pagini2 Marks MDsathiaÎncă nu există evaluări

- 800T/H 30.5 MM Push Buttons NEMA Push Button Specifications: Approximate DimensionsDocument2 pagini800T/H 30.5 MM Push Buttons NEMA Push Button Specifications: Approximate DimensionsAllen BradleyÎncă nu există evaluări

- Printed in GermanyDocument20 paginiPrinted in GermanyEdson CarvalhoÎncă nu există evaluări

- Construction Plans For PortfolioDocument16 paginiConstruction Plans For Portfolioapi-450847317Încă nu există evaluări

- الخطأ والصواب في تسليح العناصر الانشائيهDocument47 paginiالخطأ والصواب في تسليح العناصر الانشائيهBen ÂmarÎncă nu există evaluări

- SP40-Steel Portal FrameDocument82 paginiSP40-Steel Portal FrameTarun saiÎncă nu există evaluări

- Impervious Graphite Pipe and Threading: Standard Specification ForDocument3 paginiImpervious Graphite Pipe and Threading: Standard Specification ForLabeed ShamilÎncă nu există evaluări

- DownloadDocument47 paginiDownloadGajanVashishth100% (1)

- Graseras AlemitesDocument37 paginiGraseras Alemitesjoroma58Încă nu există evaluări

- Hole Cutting Machine SpecificationsDocument2 paginiHole Cutting Machine SpecificationsDavid Gutiérrez LópezÎncă nu există evaluări

- Reinforcement DetailingDocument47 paginiReinforcement DetailingLimar SetstraÎncă nu există evaluări

- Reinforcement DetailingDocument47 paginiReinforcement DetailingMuhammad Saqib Abrar94% (16)

- LOGrooved Decking Installation Instructions 3521 LRDocument4 paginiLOGrooved Decking Installation Instructions 3521 LRGhislainTremblayÎncă nu există evaluări

- Reinforcement DetailingDocument47 paginiReinforcement DetailingSun Rise100% (1)

- الخطأ والصواب في تسليح العناصر الانشائيهDocument47 paginiالخطأ والصواب في تسليح العناصر الانشائيهSwift WardÎncă nu există evaluări

- Reinforcing Detailing of R.C.C MembersDocument47 paginiReinforcing Detailing of R.C.C Membersmanumeet100% (2)

- Operation Sheet (1) - BaseDocument1 paginăOperation Sheet (1) - Basealinader20022Încă nu există evaluări

- RC DetailingDocument82 paginiRC DetailingkishoreÎncă nu există evaluări

- Shop-Tested Router Techniques and Projects From The Editors of Wood Magazine by Ben AllenDocument96 paginiShop-Tested Router Techniques and Projects From The Editors of Wood Magazine by Ben AllenGabrielÎncă nu există evaluări

- OsmaDrain Jointing Quick GuideDocument2 paginiOsmaDrain Jointing Quick GuideHatem AbdelnabiÎncă nu există evaluări

- Building: LatheDocument60 paginiBuilding: LathePierre799es86% (7)

- Cuña Segun Astm - f436Document2 paginiCuña Segun Astm - f436Roberth ChombopÎncă nu există evaluări

- Determining The Liquid Limit of Soils: Standard Method of Test ForDocument11 paginiDetermining The Liquid Limit of Soils: Standard Method of Test ForsitrakiniavoÎncă nu există evaluări

- Gear Cutters 01 PDFDocument4 paginiGear Cutters 01 PDFFabio Gilii100% (1)

- Ralph Patterson Diamond Tool HolderDocument12 paginiRalph Patterson Diamond Tool Holderian_newÎncă nu există evaluări

- List of Valves and Fittings RequiredDocument6 paginiList of Valves and Fittings RequiredDavid Gutiérrez LópezÎncă nu există evaluări

- List of Valves RequiredDocument2 paginiList of Valves RequiredDavid Gutiérrez LópezÎncă nu există evaluări

- List of Piping, Valves and Fittings RequiredDocument6 paginiList of Piping, Valves and Fittings RequiredDavid Gutiérrez LópezÎncă nu există evaluări

- Dry Barrel Fire Hydrant1Document2 paginiDry Barrel Fire Hydrant1David Gutiérrez LópezÎncă nu există evaluări

- Sheet Metal Gauge Size ChartDocument1 paginăSheet Metal Gauge Size ChartDavid Gutiérrez LópezÎncă nu există evaluări

- Formulario Disenho de Hormigon Aci 381Document1 paginăFormulario Disenho de Hormigon Aci 381David Gutiérrez LópezÎncă nu există evaluări

- Hole Cutting Machine SpecificationsDocument2 paginiHole Cutting Machine SpecificationsDavid Gutiérrez LópezÎncă nu există evaluări

- SCI Flanged Fittings - FLG0815Document10 paginiSCI Flanged Fittings - FLG0815BayuÎncă nu există evaluări

- Workshop Manual Transporter 2016 10-29Document109 paginiWorkshop Manual Transporter 2016 10-29samueleÎncă nu există evaluări

- S7-Lxje05a 3Document729 paginiS7-Lxje05a 3Andres GomezÎncă nu există evaluări

- Liebherr LR1350 1 PDFDocument54 paginiLiebherr LR1350 1 PDFRazat RanaÎncă nu există evaluări

- CSMD Al SD Tt4rev05Document48 paginiCSMD Al SD Tt4rev05lubangjarumÎncă nu există evaluări

- 2927-Connecting Rod AlignmentDocument1 pagină2927-Connecting Rod AlignmentCr250r100% (1)

- Poynting EffectDocument13 paginiPoynting EffectFernandocf90Încă nu există evaluări

- BOSS Flamco Pipe Support SystemDocument64 paginiBOSS Flamco Pipe Support Systempaulo100% (1)

- Designing A DC MotorDocument7 paginiDesigning A DC MotorPravat SatpathyÎncă nu există evaluări

- D3967-08. Splitting Tensile Strength of Intact Rock Core SpecimensDocument4 paginiD3967-08. Splitting Tensile Strength of Intact Rock Core SpecimensIgnacio Padilla100% (2)

- Split Body Trunnion: Full Bore Ends AvailableDocument20 paginiSplit Body Trunnion: Full Bore Ends AvailableHùng DươngÎncă nu există evaluări

- 4B3.9G2 So10737Document72 pagini4B3.9G2 So10737Alexis SanchezÎncă nu există evaluări

- Gas Engine - Vibration and NoiseDocument30 paginiGas Engine - Vibration and NoiseCamilo Andres Cardozo FajardoÎncă nu există evaluări

- Unit Homework Momentum Its Conservation Ans KeyDocument6 paginiUnit Homework Momentum Its Conservation Ans KeyKristyne Olicia100% (1)

- Problem Set 2.projectile MotionDocument9 paginiProblem Set 2.projectile MotionChristian OconÎncă nu există evaluări

- PPTDocument14 paginiPPTRicky SimangunsongÎncă nu există evaluări

- Standards For The Mobility Requirements of Military VehiclesDocument19 paginiStandards For The Mobility Requirements of Military VehiclesSekwah HawkesÎncă nu există evaluări

- 3.2.1.4.1-1 Trapped Vortex CombustionDocument9 pagini3.2.1.4.1-1 Trapped Vortex Combustiontesfaye awelÎncă nu există evaluări

- Lpile Group ModuleDocument2 paginiLpile Group ModuleMUHAMMAD ALIÎncă nu există evaluări

- Sherwood Pump Repair 3022Document40 paginiSherwood Pump Repair 3022ricardo_dionisi3003Încă nu există evaluări

- AC100 Training Manual Ver 2 0 PDFDocument382 paginiAC100 Training Manual Ver 2 0 PDFما ضاقت الا لتفرج80% (5)

- Stepped Columns - A Simplified Design MethodDocument23 paginiStepped Columns - A Simplified Design MethodwrayroÎncă nu există evaluări

- Top Drive ManualDocument236 paginiTop Drive ManualAlex Zaman100% (1)

- WP-8.5.1-02 Role of RWCDocument3 paginiWP-8.5.1-02 Role of RWCNitin SharmaÎncă nu există evaluări

- Iae V2500 Engine Questions: TH THDocument12 paginiIae V2500 Engine Questions: TH THRafael SantosÎncă nu există evaluări

- PHD Thesis Optimization of Bow Shape For Large, Slow Ships by NordåsDocument84 paginiPHD Thesis Optimization of Bow Shape For Large, Slow Ships by NordåsPrasad PatilÎncă nu există evaluări

- Bolt Head Fillet Stress Concentration Factors in Cylindrical Pressure VesselsDocument6 paginiBolt Head Fillet Stress Concentration Factors in Cylindrical Pressure Vesselsacadjournals. comÎncă nu există evaluări

- POGIL - Work, Power, and Kinetic Energy PDFDocument5 paginiPOGIL - Work, Power, and Kinetic Energy PDFEMERSON QUICHE VELASQUEZÎncă nu există evaluări

- Nota RobotDocument26 paginiNota RobotpnroslindaÎncă nu există evaluări

- Introduction To Particle Tracing ModuleDocument36 paginiIntroduction To Particle Tracing ModulePaulo FidelisÎncă nu există evaluări

- Flywheel ExperimentDocument4 paginiFlywheel ExperimentNasim Mammadov67% (3)