Documente Academic

Documente Profesional

Documente Cultură

Inducton Cooker

Încărcat de

Willy Octopasz MuiruDescriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Inducton Cooker

Încărcat de

Willy Octopasz MuiruDrepturi de autor:

Formate disponibile

Applications & Cases

Components for induction cookers April 2008

Energy efficiency in the kitchen

Induction cookers are extremely energy efficient. EPCOS supplies a full

range of components, including film capacitors, chokes, transformers,

thermistors and varistors.

Induction cookers are the true king among cookers. Their high efficiency,

increasingly important in times of rapidly rising energy costs, greatly

distinguishes them from their conventional counterparts. With an efficiency

rate of close to 90 percent, they are far superior to gas cookers (40 percent)

or conventional electric cookers (50 to 60 percent). Leading European manufacturers of kitchen appliances such as

BSH Bosch Siemens Hausgeraete, Fagor and Arcelik now manufacture these high-tech appliances in series.

Induction cookers achieve this high efficiency by means of a sophisticated technology that heats up only special

cookware that has a ferromagnetic base. The induction cooker itself produces no heat, but generates an alternating

magnetic field in the cooking zone via a coil operated at a frequency of 20 to 50 kHz. This field in turn generates eddy

currents in the base of the cookware, thus producing the required heat. This effect is further reinforced by hysteresis

losses that generate more heat. The cookware acts like a short-circuited secondary winding of a transformer. Figure 1

shows the basic configuration of the power circuit of an induction cooker.

FIG. 1: BLOCK DIAGRAM OF THE POWER CIRCUIT OF AN INDUCTION COOKER

From left to right: EMC/EMI input filter, rectifier with intermediate-circuit capacitor, inverter with snubber and resonance

capacitors. EPCOS offers all the passive electronic components required for the power section of induction cookers.

EMC input filters

Due to the relatively high frequencies and steep switching edges of the IGBTs, sufficient EMC filtering is required.

Figure 2 shows the circuit diagram of the filter used. The B32923A2105M* series with a capacitance of 1 µF is

particularly suitable for the two X2 capacitors. Its outstanding feature is a low insertion height of only 22 mm. Among

the Y1 capacitors, which suppress symmetrical interference and transients, EPCOS offers the B81122C1222M* type

with 2.2 nF and the B81122A1153M* type with 15 nF. EPCOS currently offers the most space-saving X2 and Y1

capacitors on the market.

EPCOS also implements an extensive range of power chokes in normal and power compensation variants in its

B82726* series.

© EPCOS AG 2010 • All rights reserved • www.epcos.com 1 / 4

Direct Link 1116

Applications & Cases

FIG. 2: BASIC CIRCUIT DIAGRAM OF THE EMC INPUT FILTER

The input filter ensures that no reactions

occur in the power line due to the high

frequencies generated in the power circuit.

Circuit protection

The input section also contains the key protective functions of inrush current limiting and overvoltage protection (Fig.

2).

The current limiter performs two important functions:

First, because the intermediate circuit capacitors are still uncharged at the moment of turn-on, direct application of

the power would cause high charging currents to flow for a brief period, thus endangering the rectifier. An inrush

current limiter (ICL) based on a leaded disk NTC thermistor reduces the inrush current to a tolerable level. These

thermistors are cold at the moment of turn-on and thus have a relatively high resistance. As the current flows

through them, they heat up and their resistance drops. Thanks to this behavior, they not only protect the rectifier but

also prevent the power fuse from blowing. In induction cookers and other household appliances, this task may be

performed by the ICL of the B57153S* series, for example.

Second, to protect the electronics from overvoltages, the use of varistors is recommended. For this function,

EPCOS offers the B7221* series that covers all typical power voltages.

Figure 3 shows a selection of EPCOS protective components typically used in the input circuit of induction cookers.

FIG. 3: EPCOS PROTECTIVE COMPONENTS

From left to right: Y1 capacitor, X2 capacitor, current-compensated power choke, NTC inrush current limiter, disk varistor.

The basic circuit diagram of the power circuit that supplies the induction coil is shown in Figure 4. In addition to the

IGBT power switches, this subassembly contains capacitors with various functions.

© EPCOS AG 2010 • All rights reserved • www.epcos.com 2 / 4

Direct Link 1116

Applications & Cases

FIG. 4: POWER CIRCUIT OF INDUCTION COOKERS

The power circuit needs snubber,

intermediate circuit and resonance capacitors.

Snubber capacitors

Because switching of the induction coil produces high induction-voltage peaks, the collector-emitter path of the IGBT

must be suitably protected. This function is performed by snubber capacitors: numerous types are available from

EPCOS. In addition to the leaded versions of the B32652A1153K* series, special types with strap terminals are

available that can be screwed directly onto the power semiconductors of frequency converters. These capacitors

feature extremely low ESR and ESL values. As with all film capacitors from EPCOS, their self-healing design greatly

improves their reliability.

Intermediate circuit capacitors

Intermediate circuit (DC link) capacitors are needed to smooth the rectified AC voltage and to minimize ripple voltages.

As a rule, aluminum electrolytic capacitors with snap-in or screw terminals are used for this purpose in industrial

electronics applications, such as rectifiers and power supply systems. In the case of induction cookers, however, film

capacitors are often preferred for space reasons. EPCOS offers a wide range of capacitance and voltage values for

this purpose in its B32564* series. These capacitors are also distinguished by low parasitic ESR and ESL values,

depending on their type.

Resonance capacitors

Operation of induction coils requires resonant capacitors to be connected with them in series. Here too, film capacitors

are used. The B32653* series was designed for this purpose.

Temperature protection and control

Suitable temperature monitoring is required to prevent thermal overload of the IGBT power switches. A fast and heat

resistant surface mount temperature sensor is used in induction cookers: K560 with aluminium housing and K1560 with

ceramic housing

Main Features and Benefits:

NTC thermistor potted into aluminium/ceramic case with cable outlet

Temperature range: -10°C to 250°C, short-term peak temperature up to 280°C

Short response time in air stream

High insulation voltage

Virtually no influence by electromagnetic energy

Flange housing for good thermal coupling to hot surface

© EPCOS AG 2010 • All rights reserved • www.epcos.com 3 / 4

Direct Link 1116

Applications & Cases

FIG. 5: SENSOR REGULATES COOKING TEMPERATURE

EPCOS has developed a special temperature

sensor for induction cookers that is positioned

centrally in the induction coil.

Electronic components from EPCOS also perform key functions in the control and operating units of induction cookers.

Thus, SMT inductors and transformers are used in DC/DC converters. Single-ended aluminum electrolytic capacitors

or multilayer varistors are other indispensable components.

© EPCOS AG 2010 • All rights reserved • www.epcos.com 4 / 4

S-ar putea să vă placă și

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (587)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (265)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (119)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Electricalindia - in Our MagazinesDocument6 paginiElectricalindia - in Our MagazinesDILEPÎncă nu există evaluări

- Chapter 8 - Magnetism and Its UsesDocument2 paginiChapter 8 - Magnetism and Its UsesCassie BÎncă nu există evaluări

- IIT Kharagpur EE11003 Electrical Technology SyllabusDocument3 paginiIIT Kharagpur EE11003 Electrical Technology SyllabusadityaÎncă nu există evaluări

- 745 PDFDocument104 pagini745 PDFPeraÎncă nu există evaluări

- Verification of The Distance Protection Relay OperDocument12 paginiVerification of The Distance Protection Relay OperSamer RasheedÎncă nu există evaluări

- P99x EN TDS B11Document14 paginiP99x EN TDS B11Razvan SasuÎncă nu există evaluări

- Ficha Tecnica Sensor PunzonadoraDocument2 paginiFicha Tecnica Sensor PunzonadoraDwing SanchÎncă nu există evaluări

- 3 A 12 V Battery Is Connected To A Component, X, and A Fixed Resistor, R, As ShownDocument15 pagini3 A 12 V Battery Is Connected To A Component, X, and A Fixed Resistor, R, As ShownEvan YEUNG [09N12]Încă nu există evaluări

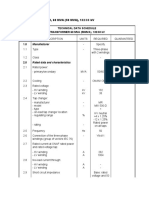

- Technical Data Schedule TRANSFORMER 60 MVA (50MVA), 132/33 KVDocument10 paginiTechnical Data Schedule TRANSFORMER 60 MVA (50MVA), 132/33 KVGboyega AwelewaÎncă nu există evaluări

- Inverter 12VDC To 220VAC 100 Watt by Power Transistor 2N3055Document19 paginiInverter 12VDC To 220VAC 100 Watt by Power Transistor 2N3055Bank100% (1)

- Ahmed Taleb Mohamed Shebl Electrical EngineerDocument2 paginiAhmed Taleb Mohamed Shebl Electrical EngineerAhmed SaadÎncă nu există evaluări

- PCS-902 - X - Instruction Manual - EN - Overseas General - X - R1.05 - (EN - XLBH5102.0086.0016) PDFDocument470 paginiPCS-902 - X - Instruction Manual - EN - Overseas General - X - R1.05 - (EN - XLBH5102.0086.0016) PDFKAREEM OLAWALE100% (1)

- Applications of Solar EnergyDocument18 paginiApplications of Solar EnergyEbook DownloadÎncă nu există evaluări

- SL 360Document1 paginăSL 360JaimeÎncă nu există evaluări

- T3C 250 TMD63-630 3p F F: General InformationDocument2 paginiT3C 250 TMD63-630 3p F F: General InformationWilverCorreaBravoÎncă nu există evaluări

- Three Phase Induction Motors: List of FormulaeDocument9 paginiThree Phase Induction Motors: List of FormulaekkkÎncă nu există evaluări

- ABB Low Voltage Power Circuit BreakersDocument198 paginiABB Low Voltage Power Circuit BreakersrostfrajÎncă nu există evaluări

- Aif - PFC TRN Rev12 1484268447 TechrefDocument40 paginiAif - PFC TRN Rev12 1484268447 TechrefmigsantÎncă nu există evaluări

- LV7000 - Manual (Ud701s) - 310507Document104 paginiLV7000 - Manual (Ud701s) - 310507Alessandro Sena0% (1)

- 7 DC Machimes - DC MotorsDocument31 pagini7 DC Machimes - DC MotorsIan VillaseñorÎncă nu există evaluări

- Aquavit eDocument4 paginiAquavit eAnonymous 1zdddnyJÎncă nu există evaluări

- BISOL Laminate BBO M6 ENDocument2 paginiBISOL Laminate BBO M6 ENNedim HadžiaganovićÎncă nu există evaluări

- PCC1302 Service InstructionsDocument62 paginiPCC1302 Service InstructionsCuong Tran100% (18)

- Information On SCR1Document10 paginiInformation On SCR1Anesu ChimhowaÎncă nu există evaluări

- Power Electronics Guide Covering Rectification, Inverters, Choppers & MoreDocument276 paginiPower Electronics Guide Covering Rectification, Inverters, Choppers & MoreBikrant PoudelÎncă nu există evaluări

- 03 User ManualAMF Controller and Monitoring With EStone-IIUpto 32kVA DG RatingDocument37 pagini03 User ManualAMF Controller and Monitoring With EStone-IIUpto 32kVA DG RatingSangram NayakÎncă nu există evaluări

- Natural Gas Generator Set QSK60 Series Engine: 995 KW - 1540 KWDocument4 paginiNatural Gas Generator Set QSK60 Series Engine: 995 KW - 1540 KWJohn YangÎncă nu există evaluări

- Generator Neutral Earthed Resistor SpecsDocument4 paginiGenerator Neutral Earthed Resistor SpecsChava TejaÎncă nu există evaluări

- Lecture 9: Transmission Lines: Instructor: Dr. Gleb V. Tcheslavski ContactDocument55 paginiLecture 9: Transmission Lines: Instructor: Dr. Gleb V. Tcheslavski Contactkprk414Încă nu există evaluări