Documente Academic

Documente Profesional

Documente Cultură

2 HBI in EAF Fact Sheet Rev3 PDF

Încărcat de

Aaquil RaziTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

2 HBI in EAF Fact Sheet Rev3 PDF

Încărcat de

Aaquil RaziDrepturi de autor:

Formate disponibile

a unified voice for the metallics industry

Use of Hot Briquetted Iron (HBI) in the Electric Arc Furnace (EAF)

for Steelmaking

• Steel production in the EAF continues to grow both in North America and worldwide.

The past 5 years have seen increases in the supply and use of Pig Iron, Direct Reduced

Iron (DRI), and Hot Briquetted Iron (HBI) in the EAF.

• HBI should not be considered as a scrap substitute but rather as a source of clean iron

units that can be used to supplement and enhance the scrap charge

• HBI is a high Fe, low residual metallic material for producing high quality iron and steel

products in a wide variety of furnaces

The value-in-use of HBI is different for each melt shop and will depend on local scrap supply,

production facilities, metallurgical practice and steel product mix.

Benefits of Using HBI in the EAF

• Very low residual element content enables production of high quality steel products or

use of higher percentage of lower cost scrap in the charge mix

• Known and consistent chemistry, certified by analysis, assists melt consistency

• Consistent shape and form enable efficient material handling and storage

• High density can reduce the number of bucket charges, allows for increased use of lower

cost, less dense feedstock and reduces storage space requirements

• Can be continuously charged to the furnace

• Acts as N scavenger = low N content in steel

Hot Briquetted Iron (HBI)

www.metallics.org IIMA Fact Sheet #2 (2017) info@metallics.org

a unified voice for the metallics industry

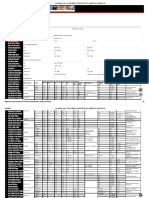

General Specifications for HBI (Ranges % by Weight)

(based on 65.5 — 68.0% Fe Iron Ore)

Metallization 94.0%

Fe (Total) 88.3 - 94.0%

Fe (Metallic) 83.0 - 88.4%

C 0.5 - 1.6

S 0.001 - 0.03%

P2O5 0.005 - 0.09%

Gangue* 3.9 - 8.6%

Mn, Cu, Ni, Cr, Mo, Sn, Pb, Zn Traces

Size (typical) (90 - 140) x (48 - 58) x (32 - 34) mm

Fines & chips ≤ 5.0%

Apparent Density > 5.0 t/m3

Bulk Density 2.5 - 3.3 t/m3

* residual unreduced oxides, mainly SiO2 and Al2O3,, but also CaO, MgO, MnO, etc.

EU steel scrap specifications

Category Grade Cu % Sn % Cr, Ni, Mo %

E3 ≤ 0.250 ≤ 0.010 Ʃ ≤ 0.250

Old scrap

E1 ≤ 0.400 ≤ 0.020 Ʃ ≤ 0.300

E2 Ʃ ≤ 0.300

New scrap, low residuals, uncoated E8 Ʃ ≤ 0.300

E6 Ʃ ≤ 0.300

Shredded E40 Ʃ ≤ 0.250 Ʃ ≤ 0.020

Steel turnings E5M ≤ 0.400 Ʃ ≤ 0.030 Ʃ ≤1.0

EHRB ≤ 0.450 Ʃ ≤ 0.030 Ʃ ≤ 0.350

High residual scrap

EHRM ≤ 0.400 Ʃ ≤ 0.030 Ʃ ≤1.0

Fragmented scrap from incineration E46 ≤ 0.500 ≤ 0.070

Ore-based metallics * pig iron, DRI, HBI 0.002 trace Ʃ ≤ 0.15

* Dependent on source iron ore

Copyright International Iron Metallics Association Ltd. The information presented in this Fact Sheet is intended as general information only and should not be

relied upon in relation to any specific application. Those making use thereof or relying thereon assume all risks and liability arising from such use or reliance.

www.metallics.org info@metallics.org

S-ar putea să vă placă și

- ELEMENT 5 Physical and Psychological Health1Document26 paginiELEMENT 5 Physical and Psychological Health1asn qureshiÎncă nu există evaluări

- G.I. 8.001 Issue Date 10-01-2011Document17 paginiG.I. 8.001 Issue Date 10-01-2011Ruben Vasquez Laurente82% (17)

- Syllabus 2012 Singing 20190122Document91 paginiSyllabus 2012 Singing 20190122suzypienaarÎncă nu există evaluări

- 3S LIFE SAFE AKADEMIE MONITORINGDocument21 pagini3S LIFE SAFE AKADEMIE MONITORINGasn qureshi100% (1)

- Health and Safety Risk Management 5th EditionDocument505 paginiHealth and Safety Risk Management 5th EditionAaquil Razi100% (2)

- How Health and Safety Systems WorkDocument13 paginiHow Health and Safety Systems WorkAaquil RaziÎncă nu există evaluări

- Field Level Risk Assessment Manager’s HandbookDocument31 paginiField Level Risk Assessment Manager’s HandbookAaquil RaziÎncă nu există evaluări

- Crane Lift Plan InstructionsDocument4 paginiCrane Lift Plan InstructionsSamuel LumbanrajaÎncă nu există evaluări

- 4 5994641624901094407Document20 pagini4 5994641624901094407Success100% (1)

- ISO 3506 2 Mechanical Properties PDFDocument2 paginiISO 3506 2 Mechanical Properties PDFp2pcreep100% (1)

- Health and Safety Electricity at WorkDocument27 paginiHealth and Safety Electricity at WorkLaisattrooklai PhisitÎncă nu există evaluări

- Module 4 and 6: Luckman MuhmoodDocument54 paginiModule 4 and 6: Luckman MuhmoodAman PanchalÎncă nu există evaluări

- Cp-117-Project EngineeringDocument67 paginiCp-117-Project Engineeringkattabomman100% (1)

- D5092 - Design and Installation of Ground Water Monitoring Wells in AquifersDocument14 paginiD5092 - Design and Installation of Ground Water Monitoring Wells in Aquifersmaxuelbestete100% (1)

- Carbon FootprintDocument6 paginiCarbon FootprintANUZ DUETÎncă nu există evaluări

- Record of Appropriations and Obligations: TotalDocument1 paginăRecord of Appropriations and Obligations: TotaljomarÎncă nu există evaluări

- Social AuditDocument7 paginiSocial AuditShofiq100% (2)

- Reference Guide for Pineapple JuiceDocument5 paginiReference Guide for Pineapple JuiceLayfloÎncă nu există evaluări

- Differential Scanning CalorimetryDocument60 paginiDifferential Scanning CalorimetryMariyam100% (2)

- 3 HBI in BOF Fact Sheet Rev3Document2 pagini3 HBI in BOF Fact Sheet Rev3Andre OliveiraÎncă nu există evaluări

- 4 HBI in BF Fact Sheet - Rev3Document2 pagini4 HBI in BF Fact Sheet - Rev3Anindya RoyÎncă nu există evaluări

- 1 What Are OBMs Fact Sheet Rev3Document2 pagini1 What Are OBMs Fact Sheet Rev3Uday Dasrao BokilÎncă nu există evaluări

- Material Data Sheet Thermally Broken Steel USADocument2 paginiMaterial Data Sheet Thermally Broken Steel USAYungfang HuangÎncă nu există evaluări

- Babbitt Bearing AlloysDocument2 paginiBabbitt Bearing AlloysMurad Alam100% (1)

- NiAll-HX-M290-400W Material Data Sheet 10-15 enDocument5 paginiNiAll-HX-M290-400W Material Data Sheet 10-15 enAmit PowarÎncă nu există evaluări

- 11 - DRI in EAF Fact Sheet V2Document2 pagini11 - DRI in EAF Fact Sheet V2BEAUTIFUL WORLDÎncă nu există evaluări

- FrictionDocument14 paginiFrictionManvendra YadavÎncă nu există evaluări

- ASTM A563 Specification for Carbon and Alloy Steel NutsDocument5 paginiASTM A563 Specification for Carbon and Alloy Steel NutspoerwntiÎncă nu există evaluări

- BM Full CatalogueDocument109 paginiBM Full CatalogueMiguelÎncă nu există evaluări

- Applications and Processing of Metal AlloysDocument39 paginiApplications and Processing of Metal Alloysjulito paquitÎncă nu există evaluări

- Existing EN AW 5251 H14 Al-Mg2Mn0,3 CompositionDocument8 paginiExisting EN AW 5251 H14 Al-Mg2Mn0,3 Compositionamh.fpdÎncă nu există evaluări

- USPAS 2002 Materials, Fabrication TechniquesDocument46 paginiUSPAS 2002 Materials, Fabrication Techniquesgangappa birajadarÎncă nu există evaluări

- Metalcor 1.4436 Aisi 316Document1 paginăMetalcor 1.4436 Aisi 316Ahmed GhonimÎncă nu există evaluări

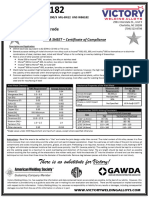

- NI-182 Victory ENICRFE-3 Electrode Data SheetDocument1 paginăNI-182 Victory ENICRFE-3 Electrode Data SheetgianÎncă nu există evaluări

- Metalcor - 1.4507 - Alloy - F255 - Uranus 52N - S32520Document1 paginăMetalcor - 1.4507 - Alloy - F255 - Uranus 52N - S32520NitinÎncă nu există evaluări

- Edelstahl PDFDocument2 paginiEdelstahl PDFKOMATSU SHOVELÎncă nu există evaluări

- SS 316L-0407 Powder For Additive Manufacturing: Process SpecificationDocument2 paginiSS 316L-0407 Powder For Additive Manufacturing: Process SpecificationMuhammad LuqmanÎncă nu există evaluări

- OBM Introduction V2Document25 paginiOBM Introduction V2NtlÎncă nu există evaluări

- Grating Raw Material Tolerance & SpecificationDocument4 paginiGrating Raw Material Tolerance & SpecificationBASKARANÎncă nu există evaluări

- Stainless Steel SummaryDocument2 paginiStainless Steel SummarybbÎncă nu există evaluări

- %C %MN %si %CR %S %P %mo %niDocument7 pagini%C %MN %si %CR %S %P %mo %nismith willÎncă nu există evaluări

- Ok 347 AutrodDocument2 paginiOk 347 Autrodjoao guilhermeÎncă nu există evaluări

- ASTM A36 MildDocument4 paginiASTM A36 MildjyothiÎncă nu există evaluări

- Compositon of Martensitic SteelDocument1 paginăCompositon of Martensitic SteelMahesh PandyaÎncă nu există evaluări

- KT-100S PMI App Note Ver 2.0 2020feb03Document4 paginiKT-100S PMI App Note Ver 2.0 2020feb03Recsa Cahaya ErlanggaÎncă nu există evaluări

- Leichtmetall Data Sheet EN AW 6082T6Document1 paginăLeichtmetall Data Sheet EN AW 6082T6Satendra ThakurÎncă nu există evaluări

- 36CrB4 Rod - Wire Rev4 PDFDocument6 pagini36CrB4 Rod - Wire Rev4 PDFKarthi KeyanÎncă nu există evaluări

- Homework 1Document3 paginiHomework 1Hussain Ali MurtazaÎncă nu există evaluări

- Metal Alloys Application and ProcessingDocument57 paginiMetal Alloys Application and ProcessingtbmariÎncă nu există evaluări

- Laboratory ELCA Laboratories, Plot No. A-444, Road No. 37, Ram Nagar, Wagle Industrial Estate, Thane, MaharashtraDocument56 paginiLaboratory ELCA Laboratories, Plot No. A-444, Road No. 37, Ram Nagar, Wagle Industrial Estate, Thane, MaharashtraProsenjit RoyÎncă nu există evaluări

- Böhler Er Ti 2-Ig: Classifications EN ISO 24034 AWS A5.16Document1 paginăBöhler Er Ti 2-Ig: Classifications EN ISO 24034 AWS A5.16Thanh TamÎncă nu există evaluări

- Metalcor 1.4410 Alloy 2507Document1 paginăMetalcor 1.4410 Alloy 2507Ahmed GhonimÎncă nu există evaluări

- OK 67.70 ESAB 309moDocument1 paginăOK 67.70 ESAB 309moSadashiva sahooÎncă nu există evaluări

- Chapter 1 (Part II)Document32 paginiChapter 1 (Part II)malikwaleedsher68Încă nu există evaluări

- Timfold Product Page PDFDocument2 paginiTimfold Product Page PDFVlado KaucicÎncă nu există evaluări

- Aisi 8640Document2 paginiAisi 8640Engineering ProductionÎncă nu există evaluări

- AS/NZS 3678 - 300 XLERPLATE Steel: General Description Australian StandardsDocument2 paginiAS/NZS 3678 - 300 XLERPLATE Steel: General Description Australian StandardsAdamÎncă nu există evaluări

- Technical Center 1Document3 paginiTechnical Center 1nimeshchanchaniÎncă nu există evaluări

- Alloy 5754 - Aimg3: Key FeaturesDocument1 paginăAlloy 5754 - Aimg3: Key FeaturessatnamÎncă nu există evaluări

- UNS S31254 F44 - Super Austenitic Stainless Steel: Related SpecificationsDocument1 paginăUNS S31254 F44 - Super Austenitic Stainless Steel: Related SpecificationsLeon PeterÎncă nu există evaluări

- B978 075064284 2 - 50008 9Document5 paginiB978 075064284 2 - 50008 9Tarun ChakrabortyÎncă nu există evaluări

- Eos Stainless Steel 316 LDocument5 paginiEos Stainless Steel 316 LsameeraÎncă nu există evaluări

- 1.4435 - C Stainless Steel DetailsDocument3 pagini1.4435 - C Stainless Steel DetailsmeenakshiÎncă nu există evaluări

- INDIA - Hot Rolled Coils - ROLEX METAL DISTRIBUTORS - A - SA516-70, A - SA515-70Document6 paginiINDIA - Hot Rolled Coils - ROLEX METAL DISTRIBUTORS - A - SA516-70, A - SA515-70Roberto AlvarezÎncă nu există evaluări

- Corus Tinplate Packaging Products Range 2006Document8 paginiCorus Tinplate Packaging Products Range 2006gtorre77Încă nu există evaluări

- Minfm10385 Astm b150 Grade c64200 hr50Document3 paginiMinfm10385 Astm b150 Grade c64200 hr50akramÎncă nu există evaluări

- Full CatalogDocument36 paginiFull Cataloglearsipi061Încă nu există evaluări

- Requerimientos ABS Pruebas MecanicasDocument7 paginiRequerimientos ABS Pruebas MecanicasGilberto ZamudioÎncă nu există evaluări

- Metalcor Cual10fe3mn2Document1 paginăMetalcor Cual10fe3mn2robertjob34Încă nu există evaluări

- Carbo 4370 Mpr-E307Document1 paginăCarbo 4370 Mpr-E307ali torabiÎncă nu există evaluări

- S-8018 B2Document5 paginiS-8018 B2Abhishek AnandÎncă nu există evaluări

- Chapter 7 Ferrous and Non-Ferrous MetalsDocument60 paginiChapter 7 Ferrous and Non-Ferrous MetalsStephen IgatÎncă nu există evaluări

- NALCO ALLOY INGOT Specification PDFDocument2 paginiNALCO ALLOY INGOT Specification PDFAnil NegiÎncă nu există evaluări

- Raw MaterialDocument14 paginiRaw MaterialAbhijeet AnkushÎncă nu există evaluări

- Metalcor 1.4571 Aisi 316 TiDocument1 paginăMetalcor 1.4571 Aisi 316 TirezaÎncă nu există evaluări

- ch11 - 2metal Alloys Application and ProcessingDocument75 paginich11 - 2metal Alloys Application and ProcessingZuhaÎncă nu există evaluări

- CAUSATIVEDocument7 paginiCAUSATIVEAaquil RaziÎncă nu există evaluări

- Musculoskeletal Disorders (MSDS) - Controls: Safety TalksDocument1 paginăMusculoskeletal Disorders (MSDS) - Controls: Safety TalksAaquil RaziÎncă nu există evaluări

- Safety StretchesDocument1 paginăSafety StretchesAaquil RaziÎncă nu există evaluări

- Musculoskeletal Disorders (MSDS) : WeldingDocument1 paginăMusculoskeletal Disorders (MSDS) : WeldingAaquil RaziÎncă nu există evaluări

- 2014 04 Machine Guarding All in OneDocument27 pagini2014 04 Machine Guarding All in OneAaquil RaziÎncă nu există evaluări

- Trench Excavation FsDocument2 paginiTrench Excavation FsMUHAMMAD LUQMANÎncă nu există evaluări

- West Nile Quick CardDocument1 paginăWest Nile Quick CardAaquil RaziÎncă nu există evaluări

- ELEMENT 9 Work Equipment1Document24 paginiELEMENT 9 Work Equipment1Aaquil RaziÎncă nu există evaluări

- ELEMENT 10 Fire1Document13 paginiELEMENT 10 Fire1Aaquil RaziÎncă nu există evaluări

- Confined Spaces DefinitionDocument1 paginăConfined Spaces DefinitionAaquil RaziÎncă nu există evaluări

- Hazard ChecklistDocument3 paginiHazard ChecklistAaquil RaziÎncă nu există evaluări

- Eyewash Ansi 2015 DUCHASDocument6 paginiEyewash Ansi 2015 DUCHASbrujula24Încă nu există evaluări

- HSG 53Document59 paginiHSG 53i7mq6ptzÎncă nu există evaluări

- 7 April IG1 AnswerDocument8 pagini7 April IG1 AnswerAaquil Razi100% (1)

- Best Risk Assessment PDFDocument6 paginiBest Risk Assessment PDFAaquil RaziÎncă nu există evaluări

- One Direct Method Statement: Main Hazards Preventative MeasuresDocument4 paginiOne Direct Method Statement: Main Hazards Preventative MeasuresAyu Wanda SaraswatiÎncă nu există evaluări

- HF acid dangers in car wash cleanersDocument2 paginiHF acid dangers in car wash cleanersAaquil RaziÎncă nu există evaluări

- Bloodborne PathogensDocument2 paginiBloodborne PathogensAaquil RaziÎncă nu există evaluări

- Electrical Safety and YouDocument6 paginiElectrical Safety and Younikolay0674Încă nu există evaluări

- Sheet: OSHA's Bloodborne Pathogens StandardDocument2 paginiSheet: OSHA's Bloodborne Pathogens StandardAaquil RaziÎncă nu există evaluări

- Agricultural Tailgate Safety Training: Module Title: Arc Welding SafetyDocument3 paginiAgricultural Tailgate Safety Training: Module Title: Arc Welding SafetyAaquil RaziÎncă nu există evaluări

- The Spurgeon Library - Spurgeon's Secret For Raising Godly ChildrenDocument8 paginiThe Spurgeon Library - Spurgeon's Secret For Raising Godly ChildrenGlenn VillegasÎncă nu există evaluări

- Complex Vector Model of The Squirrel Cage Induction Machine Including Instantaneous Rotor Bar CurrentsDocument8 paginiComplex Vector Model of The Squirrel Cage Induction Machine Including Instantaneous Rotor Bar CurrentsJorge Luis SotoÎncă nu există evaluări

- Villanueva - Taxation and Regulatory ComplianceDocument8 paginiVillanueva - Taxation and Regulatory ComplianceEDRICK ESPARRAGUERRAÎncă nu există evaluări

- Business Analytics ModuleDocument22 paginiBusiness Analytics ModuleMarjon DimafilisÎncă nu există evaluări

- Chartered Accountants and Accountans in AmbalaDocument3 paginiChartered Accountants and Accountans in AmbalaGurmeet kaurÎncă nu există evaluări

- Thesis NewDocument55 paginiThesis NewHasan juwelÎncă nu există evaluări

- Excel File - Business Computing - End Term (To Be Shared Vide Email)Document301 paginiExcel File - Business Computing - End Term (To Be Shared Vide Email)Aman SankrityayanÎncă nu există evaluări

- AI vs ML: A Brief ExplanationDocument3 paginiAI vs ML: A Brief Explanationkhaoula BelghitiÎncă nu există evaluări

- Contract Law 17Document1 paginăContract Law 17lorraineÎncă nu există evaluări

- Che 430 Fa21 - HW#5Document2 paginiChe 430 Fa21 - HW#5Charity QuinnÎncă nu există evaluări

- Optimize Your Portfolio With Modern TheoriesDocument65 paginiOptimize Your Portfolio With Modern Theoriesastro9jyotish9asim9mÎncă nu există evaluări

- O Ring Design ParametersDocument2 paginiO Ring Design ParametersHatim KapasiÎncă nu există evaluări

- Numerical Methods NotesDocument21 paginiNumerical Methods Notesdean427Încă nu există evaluări

- M and S - Capstone Marketing Across Cultures Fons TrompenaarsDocument398 paginiM and S - Capstone Marketing Across Cultures Fons TrompenaarsBof BeosÎncă nu există evaluări

- SYKES Home Equipment Agreement UpdatedDocument3 paginiSYKES Home Equipment Agreement UpdatedFritz PrejeanÎncă nu există evaluări

- Socsci 032 Midterm Compilation NotesDocument12 paginiSocsci 032 Midterm Compilation NotesCarla AbalaÎncă nu există evaluări

- Kiribati, Gilbertese BibleDocument973 paginiKiribati, Gilbertese BibleAsia BiblesÎncă nu există evaluări

- Durgah Ajmer Sharif 1961Document19 paginiDurgah Ajmer Sharif 1961Deepanshu JharkhandeÎncă nu există evaluări

- IT Department - JdsDocument2 paginiIT Department - JdsShahid NadeemÎncă nu există evaluări

- Checking battery control unitDocument3 paginiChecking battery control unitjuanÎncă nu există evaluări

- Anselm's Ontological Argument ExplainedDocument8 paginiAnselm's Ontological Argument ExplainedCharles NunezÎncă nu există evaluări

- INDIAMART 25012022003631 Investor Presentation Q3FY2021-22Document84 paginiINDIAMART 25012022003631 Investor Presentation Q3FY2021-22geethvazÎncă nu există evaluări