Documente Academic

Documente Profesional

Documente Cultură

Positive Displacement Pump: PVDF PVDF

Încărcat de

anon_884425478Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Positive Displacement Pump: PVDF PVDF

Încărcat de

anon_884425478Drepturi de autor:

Formate disponibile

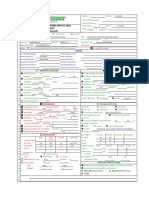

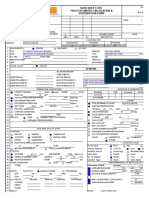

POSITIVE DISPLACEMENT PUMP

DATASHEET

P-6006A, P-6006B, P6106A, P6106B

1 CLIENT International Pharmaceuticals Inc. EQUIP. NO. P6206A and P6306A

Qty. 6

2 PROJECT IPI Manufacturing Plant EQUIP. SERVICE Methyl Salicylate Intake Pump

3 SITE Cebu City PUMP TYPE Pneumatic Diaphgram Pump

4 VENDOR By Client MODEL

5 MANUFACTURER SERIAL NO.

6 OPERATING CONDITIONS PERFORMANCE

7 Rated Max. Nor. Min. Rated Capacity L/min.

8 Capacity m3/hr 5.00 NPSH required at design m

9 Suction Pressure barg Rated Speed (rpm)

10 Discharge Pressure barg Displacement L/min.

11 Differential Pressure bar 1.94 Volumetric Efficiency (%)

12 Hydraulic Power kW Mechanical Efficiency (%)

13 NPSH Available m Power @ Max. Viscosity kW

14 Service Continuous Intermittent (Starts/Day) Power @ Relief Valve Setting kW

15 FLUID DATA Max. Allowable Speed (rpm)

16 Pumped Fluid Methyl Salicylate Min. Allowable Speed (rpm)

17 Rated Max. Nor. Min. WEIGHTS

18 Pumping Temperature °C 30 Pump Weight kg Motor Weight kg

19 Specific Gravity 1.17 Base Weight kg Total Weight kg

20 Vapor Pressure mmHg 0.1 SITE CONDITIONS

21 Viscosity cP 1.3 Location Outdoor

22 Specific Heat kJ/kg·K Altitude m

23 Corrosion/Erosion Caused By Ambient Temp. Range (Min./Max.)

24 Solid Characteristics %/µ Electrical Classification Cl. Gr. Div.

25 MOTOR DRIVER MATERIALS

26 No. of Motors 1 Motor Provided By Pump Supplier Casing PVDF Vanes

27 Motor Item No. Motor Mounted By Pump Supplier Stator PVDF Shaft

28 Manufacturer Type End Plate(s) Sleeve(s)

29 Enclosure TEFC Frame Rotors Gland(s)

30 Motor Rating kW 2.) Voltz/Phase/Hertz 440V/3-PH/60 Timing Gear Bearing House

31 Speed (rpm) 2.) Constant Speed INSPECTION & TESTING

32 Service Factor Variable Speed Compliance with Inspector's Checklist

33 CONSTRUCTION Certification of Materials

34 Nozzles Size Rating Facing Location Final Assembly Clearances

35 Suction 2.) 2.) FF Cleanliness Prior to Final Assembly

36 Discharge 2.) 2.) FF Non-Witnessed Witnessed Certificate

37 Pump Type Internal Gear Twin Screw Hydrostatic

38 External Gear Three Screw Mechanical Run

39 Vane Progressing Cavity Performance

40 Gear Type Spur Helical NPSHR

41 Other Other:

42 Casing NOTE/S

43 Max. Allowable Pressure barg @ °C 1. Pump per ANSI Standard.

44 Hydrostatic Test Pressure barg 2. By Pump Supplier.

45 Steam Jacket Pressure barg

46 Rotor Mount Between Bearings Overhung

47 Timing Gears Yes No

48 Mechanical Seal

49 Manufacturer Model No.

50 Manufacturer Code

51 Packing Lantern Ring

52 Manufacturer Type

53 No. of Rings

54 Lubrication Type

55 Drive Mechanism

56 Direct Coupled

57 V-Belt

58 Gear

59 Coupling Manufacturer

REV ISSUE STATUS DATE BY CHK'D APP'D CLNT Project No. A28P09

0 Issued for Quotation 30-Jul-18 GPF KLC RCJ DJF Unit/Area 600

1 Issued for Quotation 10-May-19 RRA SRT RCJ DJF P.O. No.

Inquiry No.

Datasheet No. A28P09-P6006A/B-P6106/B-P6206A-P6306A-EDS-00 R1

Notice: This document contains confidential and proprietary information not to be published, disclosed to others, reproduced or used for any purpose other than the purpose for which it is furnished

without the prior written permission from PTI.

Page 1 of 1

S-ar putea să vă placă și

- Microturbines: Applications for Distributed Energy SystemsDe la EverandMicroturbines: Applications for Distributed Energy SystemsEvaluare: 5 din 5 stele5/5 (1)

- DSA Scrubber Pump DatasheetDocument10 paginiDSA Scrubber Pump DatasheetNavÎncă nu există evaluări

- Sulphuric Acid Dosing Pump Motor ManualDocument28 paginiSulphuric Acid Dosing Pump Motor ManualmohammedsfÎncă nu există evaluări

- UntitledDocument5 paginiUntitledJuan Bautista Rojas VillegasÎncă nu există evaluări

- Mechanical Data Sheet Backwash Pump: Pt. Yusonda Mahayasa NusantaraDocument5 paginiMechanical Data Sheet Backwash Pump: Pt. Yusonda Mahayasa NusantaraAhmad RifaiÎncă nu există evaluări

- Brown & Root, Inc.: Rotary Pump (Api 676-2Nd) Data Sheet Si UnitsDocument4 paginiBrown & Root, Inc.: Rotary Pump (Api 676-2Nd) Data Sheet Si UnitsLipika GayenÎncă nu există evaluări

- Data Sheet Multiphase Pump BornermanDocument5 paginiData Sheet Multiphase Pump BornermanUmar Ijaz KhanÎncă nu există evaluări

- Booster Pump, 5 HP, 80 GPM X 180 FTDocument4 paginiBooster Pump, 5 HP, 80 GPM X 180 FTRutchelle BrunoÎncă nu există evaluări

- API 675 Pump DatasheetDocument2 paginiAPI 675 Pump DatasheetArun CPÎncă nu există evaluări

- Ac0041402 Pb1i3 MD17006Document5 paginiAc0041402 Pb1i3 MD17006Jhonny Rafael Blanco CauraÎncă nu există evaluări

- Lavalin Bomba SumergibleDocument3 paginiLavalin Bomba SumergibleEyffer Cabrera PalominoÎncă nu există evaluări

- Página: 1 De: 5Document6 paginiPágina: 1 De: 5Rathawit SingpanjanateeÎncă nu există evaluări

- Api 674 Pump Data SheetDocument5 paginiApi 674 Pump Data Sheetroronoa_zorro11Încă nu există evaluări

- Brown & Root, Inc.: Centrifugal Pump (Api 610-8Th) Data Sheet Si UnitsDocument15 paginiBrown & Root, Inc.: Centrifugal Pump (Api 610-8Th) Data Sheet Si UnitsLipika GayenÎncă nu există evaluări

- Data Sheet Centrifugal Pump: Client: Location: Service: Plant: Supplier MFR.: Equipment No.Document4 paginiData Sheet Centrifugal Pump: Client: Location: Service: Plant: Supplier MFR.: Equipment No.zvlcar nainÎncă nu există evaluări

- Data Sheet Mks Units Centrifugal Pump Api-610: Operating Conditions Site and Utility Data (Cot D)Document3 paginiData Sheet Mks Units Centrifugal Pump Api-610: Operating Conditions Site and Utility Data (Cot D)André HeunisÎncă nu există evaluări

- Reciprocating Pump (Api 674-2Nd) Data Sheet Si Units: GeneralDocument10 paginiReciprocating Pump (Api 674-2Nd) Data Sheet Si Units: GeneraltxagusÎncă nu există evaluări

- Acceptance Test Protocol: MAN Diesel & TurboDocument25 paginiAcceptance Test Protocol: MAN Diesel & TurboManretyÎncă nu există evaluări

- Cam 200-390-110kwDocument4 paginiCam 200-390-110kwbocahjeblogÎncă nu există evaluări

- Feuilles Des Données de Nouveau Groupe de Pompage Moteur DieselDocument7 paginiFeuilles Des Données de Nouveau Groupe de Pompage Moteur DieselBilel MahjoubÎncă nu există evaluări

- Pzem 33H224 3 Pumps 10 HPDocument4 paginiPzem 33H224 3 Pumps 10 HPRutchelle BrunoÎncă nu există evaluări

- Datasheet Torishima 30kWDocument1 paginăDatasheet Torishima 30kWendy putraÎncă nu există evaluări

- Operating Conditions Liquid: Client: ServiceDocument1 paginăOperating Conditions Liquid: Client: ServiceAde IskandarÎncă nu există evaluări

- Data Sheet 65 DS 51.5Document4 paginiData Sheet 65 DS 51.5Gokula Krishnan CÎncă nu există evaluări

- Data Sheet Pompa HydrantDocument3 paginiData Sheet Pompa HydrantAnonymous 6S9tcbhÎncă nu există evaluări

- BFP - Part 1Document1 paginăBFP - Part 1nejatihosseinÎncă nu există evaluări

- Ebara 90M3H@39M 100X80 FSS2GC 5 15KWDocument4 paginiEbara 90M3H@39M 100X80 FSS2GC 5 15KWtrungÎncă nu există evaluări

- Centrifugal PumpsDocument7 paginiCentrifugal PumpsNhutÎncă nu există evaluări

- Feuilles Des Données de Nouveau Groupe de Pompage Moteur ÉlectriqueDocument6 paginiFeuilles Des Données de Nouveau Groupe de Pompage Moteur ÉlectriqueBilel MahjoubÎncă nu există evaluări

- Data Sheet 150X125 FSS4KC 5 37 HDocument4 paginiData Sheet 150X125 FSS4KC 5 37 HPakin SornÎncă nu există evaluări

- Hoja de Datos de BombaDocument5 paginiHoja de Datos de Bombaluis zambranoÎncă nu există evaluări

- AgitatorDocument3 paginiAgitatorMarcelo PerettiÎncă nu există evaluări

- Documents For Approval Rev-1 - ApprovedDocument42 paginiDocuments For Approval Rev-1 - ApprovedAbhijeet WayaseÎncă nu există evaluări

- MDBFP Sop KSK-1Document12 paginiMDBFP Sop KSK-1SonratÎncă nu există evaluări

- 附件1 海水泵浦之泵浦及馬達數據規格表Document3 pagini附件1 海水泵浦之泵浦及馬達數據規格表駱建澄Încă nu există evaluări

- Magnetic Drive Pump Hot Oil UnitDocument1 paginăMagnetic Drive Pump Hot Oil Unitarun manchekarÎncă nu există evaluări

- Hoja API Vs4 001Document9 paginiHoja API Vs4 001brujula24Încă nu există evaluări

- Ppgj-Pro-Cal-190 Hot Oil Return Pump (P-1004)Document10 paginiPpgj-Pro-Cal-190 Hot Oil Return Pump (P-1004)Tifano KhristiyantoÎncă nu există evaluări

- Pump ScheduleDocument1 paginăPump ScheduleZUCEL ARLLETTE MAJUS CASTANEDAÎncă nu există evaluări

- Specification Datasheet For Instrument Air Compressor PackageDocument5 paginiSpecification Datasheet For Instrument Air Compressor PackageBarata RendengÎncă nu există evaluări

- CDM 400x300 enDocument5 paginiCDM 400x300 enbocahjeblogÎncă nu există evaluări

- 14960-000-ME-DAS-003 Data Sheet For Sump PumpsDocument8 pagini14960-000-ME-DAS-003 Data Sheet For Sump PumpsAshish TIwariÎncă nu există evaluări

- Api 610 Datasheet PDF FreeDocument7 paginiApi 610 Datasheet PDF FreeRisyda PutriÎncă nu există evaluări

- Evmsg10 6f5q1bege 2.2Document7 paginiEvmsg10 6f5q1bege 2.2sara jamalÎncă nu există evaluări

- Condensate Extraction Pump 1Document6 paginiCondensate Extraction Pump 1sambhu100% (1)

- Centrifugal Pump Datasheet Api 610 11Th Edition: US CustomaryDocument1 paginăCentrifugal Pump Datasheet Api 610 11Th Edition: US CustomaryAthiphap Srisupareerath100% (1)

- Submersible - Semi-Vortex - Pump (Sewage Pump) 100 LPM 10 MeterDocument4 paginiSubmersible - Semi-Vortex - Pump (Sewage Pump) 100 LPM 10 MeterHandrawan Han-han SugiantoÎncă nu există evaluări

- Technical Data - Ebara Pump - 200 DL 57.5 - 1Document1 paginăTechnical Data - Ebara Pump - 200 DL 57.5 - 1hamparan nightwatchÎncă nu există evaluări

- DatasheetDocument71 paginiDatasheetRhadityo Shakti BudimanÎncă nu există evaluări

- Technical Bid Tabulation: Vendor Description SpecificationDocument8 paginiTechnical Bid Tabulation: Vendor Description SpecificationGunturMudaAliAkbarÎncă nu există evaluări

- Data Sheet No. Ds-P-5984 Rev. 0: Centrifugal Pump Data Sheet U.S. Customary UnitsDocument10 paginiData Sheet No. Ds-P-5984 Rev. 0: Centrifugal Pump Data Sheet U.S. Customary Unitsrajindo1Încă nu există evaluări

- Air Leak in Test of Esp ProcedureDocument5 paginiAir Leak in Test of Esp Procedurenetygen1Încă nu există evaluări

- API 610 10th Edition (Iso 13709) Pump DatasheetDocument3 paginiAPI 610 10th Edition (Iso 13709) Pump DatasheetMuhammad Azka50% (4)

- Rotary Pump Data SheetDocument6 paginiRotary Pump Data SheetCarlos GomezÎncă nu există evaluări

- Mech-Pu 207 Ab-001 Rev 0Document4 paginiMech-Pu 207 Ab-001 Rev 0Harun Al-RasyidÎncă nu există evaluări

- Data Sheet For Jockey Pumps (Rev.a) - Returned (P-1101)Document7 paginiData Sheet For Jockey Pumps (Rev.a) - Returned (P-1101)Panisa BanimaÎncă nu există evaluări

- Data Sheet 100 DLB 57.5Document4 paginiData Sheet 100 DLB 57.5absshopofficialÎncă nu există evaluări

- Annexure To Be AttachedDocument12 paginiAnnexure To Be AttachedAnonymous vspGaH8Încă nu există evaluări

- Chery A21 Service Manual Mechanism of 2.0nalc EngineDocument45 paginiChery A21 Service Manual Mechanism of 2.0nalc Enginehusnihameed74Încă nu există evaluări

- PI Controller PMSGDocument8 paginiPI Controller PMSGKhiem NguyenÎncă nu există evaluări

- CRSL Fan Coil Units with EC MotorsDocument16 paginiCRSL Fan Coil Units with EC MotorsDejan DosljakÎncă nu există evaluări

- Cpd1702f10s1 Servo Drive Berger Lahr ManualDocument8 paginiCpd1702f10s1 Servo Drive Berger Lahr Manual1piotr1Încă nu există evaluări

- AlcoControls 2013 enDocument175 paginiAlcoControls 2013 enDaria Gabriela ValimareanuÎncă nu există evaluări

- Assembly Guide For Motor Parts PDFDocument23 paginiAssembly Guide For Motor Parts PDFkhalidÎncă nu există evaluări

- Cyclo BBB PDFDocument124 paginiCyclo BBB PDFNguyenHuanÎncă nu există evaluări

- Dfig ThesisDocument86 paginiDfig ThesisAshwin Venkata100% (1)

- The AQUA ProjectDocument36 paginiThe AQUA ProjectParvez KhanÎncă nu există evaluări

- Design and Development of Three-Lift Elevator Instructional Device Utilizing PLC ControlsDocument4 paginiDesign and Development of Three-Lift Elevator Instructional Device Utilizing PLC ControlsIJRASETPublicationsÎncă nu există evaluări

- IEEE 2007 Paper - Capacitor Application IssuesDocument13 paginiIEEE 2007 Paper - Capacitor Application IssuespasswordÎncă nu există evaluări

- Electrical Field Test Procedures TPD2006 v6 PDFDocument38 paginiElectrical Field Test Procedures TPD2006 v6 PDFbaljeetjatÎncă nu există evaluări

- Panimalar Engineering College: Answer ALL Questions, Choose The Best Answer Part - A (30 X 1 30)Document6 paginiPanimalar Engineering College: Answer ALL Questions, Choose The Best Answer Part - A (30 X 1 30)sivaÎncă nu există evaluări

- Application of Speed and Load Torque Observers in High-Speed Train Drive For Diagnostic PurposesDocument9 paginiApplication of Speed and Load Torque Observers in High-Speed Train Drive For Diagnostic Purposesr_berthetÎncă nu există evaluări

- En Acs880 PCP Esp CTRL PRG FW B A5Document494 paginiEn Acs880 PCP Esp CTRL PRG FW B A5Jezer LugoÎncă nu există evaluări

- Fiat Barchetta: Electrical SystemDocument12 paginiFiat Barchetta: Electrical SystemHallex OliveiraÎncă nu există evaluări

- Maintenance Instructions For Electric Point Machine - March 2020Document40 paginiMaintenance Instructions For Electric Point Machine - March 2020Ramesh kumarÎncă nu există evaluări

- Features of Rotating MachinesDocument17 paginiFeatures of Rotating MachinesAngelu TarvenaÎncă nu există evaluări

- Industrial Sliding Gate Operator: D10 and D10 Turbo Installation ManualDocument72 paginiIndustrial Sliding Gate Operator: D10 and D10 Turbo Installation ManualJoshua HobsonÎncă nu există evaluări

- Em - Ii PPT - 0Document138 paginiEm - Ii PPT - 0krishnandrkÎncă nu există evaluări

- LNH LNL LNQ and LNX Series Remote Condenser Installation Operation ManualDocument20 paginiLNH LNL LNQ and LNX Series Remote Condenser Installation Operation ManualMohamed IbrahimÎncă nu există evaluări

- Global Service Learning: 300D Series Hydraulic Excavators - Tier Iii EnginesDocument49 paginiGlobal Service Learning: 300D Series Hydraulic Excavators - Tier Iii EnginesKJDNKJZEFÎncă nu există evaluări

- LG Air Conditioning Universal & Multi Split Fault Codes SheetDocument19 paginiLG Air Conditioning Universal & Multi Split Fault Codes Sheettonares100% (1)

- Wear Testing RigDocument6 paginiWear Testing Rigibson045001256Încă nu există evaluări

- Catalogo Motores Siemens PDFDocument176 paginiCatalogo Motores Siemens PDFgiovanni1912Încă nu există evaluări

- 32 073 XX B40 EN PDFDocument2 pagini32 073 XX B40 EN PDFZuyeffÎncă nu există evaluări

- Biostat B: Operating ManualDocument139 paginiBiostat B: Operating ManualHydroPotatoes100% (6)

- ELP-D&RS User Manual PDFDocument201 paginiELP-D&RS User Manual PDFluisotaviomachadoÎncă nu există evaluări

- Motor Starting SagsDocument4 paginiMotor Starting SagscdkÎncă nu există evaluări

- ZT75 Libro de Instrucciones Atlas CopcoDocument167 paginiZT75 Libro de Instrucciones Atlas CopcoCARLITOS 25Încă nu există evaluări

- Manual Book Liebherr R9200 Swing SystemDocument27 paginiManual Book Liebherr R9200 Swing SystemYudi AriantoÎncă nu există evaluări