Documente Academic

Documente Profesional

Documente Cultură

Automotive Engine Servicing: NTQF Level-Ii

Încărcat de

GODTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Automotive Engine Servicing: NTQF Level-Ii

Încărcat de

GODDrepturi de autor:

Formate disponibile

BATU TVET COLLEGE

Automotive Engine Servicing

NTQF LEVEL-II

LEARNING GUIDE #1-3

Unit of Competence: Service Diesel Fuel Injection System

Module Title: Servicing Diesel Fuel Injection System

LG Code: AUM AES2 03 0411

TTLM Code: AUM AES2 03 0411

Prepared by;tefera megersa

Department of Automotive Engine Servicing 2006

Instruction Sheet Learning Guide #1

This learning guide is developed to provide you the necessary information regarding the

following content coverage and topics –

● Prepare for work Diesel Fuel Injection System

Identify and confirm the nature and scope of the work.

Prepare of tools, equipments manufacturer specifications workshop manuals.

Make ready and safe the workstation for servicing.

Select and prepare the appropriate methods with standard operating procedures

Identify and prepare the required tools and equipment for servicing

Identify and prepare the technical requirements for works.

Application OHS

● Learning Instructions:

1. Read the specific objectives of this Learning Guide.

2. Read the information written in the “Information Sheets”. Try to understand what

are being discussed. Ask you teacher for assistance if you have hard time

understanding them

3. To undertake this element you are required to have on hands the following

resources:

Information sheet

Operation sheet

Self Check

Answer Sheet

Prepared by;tefera megersa

Department of Automotive Engine Servicing 2006

Prepared by;tefera megersa

Department of Automotive Engine Servicing 2006

Information Sheet-1 Prepare for work Diesel Fuel Injection System

1. Identify and confirm the nature and scope of the work.

Rudolf Diesel

Rudolf Diesel, full name Rudolf

Christian Karl Diesel (1858-1913),

German engineer, who invented the

diesel engine. After studying in England,

he attended the Polytechnic School in

Munich, where he settled in 1893. In

1892 he patented the internal-

combustion engine named for him, which

employed auto ignition of fuel. While

associated with the Krupp firm in Essen,

he built the first successful diesel engine,

utilizing low-cost fuel. In 1913, while on

a voyage to England, Diesel was lost

overboard and is believed to have

drowned in the English Channel.

Brief Description of the Diesel Engine

Prepared by;tefera megersa

Department of Automotive Engine Servicing 2006

Theoretically, the diesel cycle differs from the Otto cycle in that combustion takes

place at constant volume rather than at constant pressure. Most diesels are also four-stroke

engines but they operate differently than the four-stroke Otto-cycle engines. The first, or

suction, stroke draws air, but no fuel, into the combustion chamber through an intake valve.

On the second, or compression, stroke the air is compressed to a small fraction of its former

volume and is heated to approximately 440°C (approximately 820°F) by this compression. At

the end of the compression stroke, vaporized fuel is injected into the combustion chamber

and burns instantly because of the high temperature of the air in the chamber. Some diesels

have auxiliary electrical ignition systems to ignite the fuel when the engine starts and until it

warms up. This combustion drives the piston back on the third, or power, stroke of the cycle.

The fourth stroke, as in the Otto-cycle engine, is an exhaust stroke.

The efficiency of the diesel engine, which is in general governed by the same

factors that control the efficiency of Otto-cycle engines, is inherently greater than that of

any Otto-cycle engine and in actual engines today is slightly more than 40 percent.

Diesels are, in general, slow-speed engines with crankshaft speeds of 100 to 750

revolutions per minute (rpm) as compared to 2500 to 5000 rpm for typical Otto-cycle

engines. Some types of diesel, however, have speeds up to 2000 rpm. Because diesels

use compression ratios of 14 or more to 1, they are generally more heavily built than

Otto-cycle engines, but this disadvantage is counterbalanced by their greater efficiency

and the fact that they can be operated on less expensive fuel oils

4DR5 Isuzu Diesel Engine

Application of Diesel Engines

Diesel engines are widely used as stationary power sources for electrical generation

units, pumping stations, refrigeration facilities, and factories. Heavy construction

equipment, ships, locomotives, commercial trucks, and some large pickups are powered

by diesels.

Diesel-powered automobiles enjoyed a brief period of popularity in the United

States during the oil crises of the 1970s when fuel efficiency and price were key factors.

Despite their advantages, diesel-powered cars did not retain their appeal with American

consumers. Diesels accelerate less quickly than gasoline-powered cars and are noisier,

due to the higher pressures of the compression-combustion process. However, diesel

Prepared by;tefera megersa

Department of Automotive Engine Servicing 2006

cars continue to be popular in Europe and other places where fuels are more expensive.

Likewise, diesel engines are used in a widely variety of design for many different

purposes, for example:

to drive mobile power generators (up to approximate

10kw/cylinder);

as fast-running engines for cars and light commercial

vehicles (up to approximate 50kw/cylinder);

as engines for construction-industry and agriculture

machinery (up to approximate 50kw/cylinder);

as engines for heavy trucks, omnibuses and tractor vehicles

(up to approximate 80kw/cylinder)

to drive fixed installation such as emergency power

generator (up to approximate 160kw/cylinder); and

as engines for railway locomotive and ship (up to 1,000

kw/cylinder)

Basic Operation

Diesel engine is classified as internal-combustion engine in which heat caused by

air compression ignites the fuel. As mentioned in the previous discussion, diesel engine

injects instant fuel into the combustion chambers, the air inside is hot enough to ignite

the fuel on contact. Diesel engines, therefore, do not need spark plugs, which are

required to ignite the air-fuel mixture in gasoline engines. Diesel engines burn a

petroleum product similar to kerosene, jet fuel, and home heating oil.

Advantages in Using Diesel Engine

More efficient and less expensive to operate than gasoline-powered

engines, party because diesel fuel costs less;

Consume less fuel and emit fewer waste products;

Big and heavy suitable for shipping and railroad industries; and

Still the engine choice for heavy transportation and industry.

Dis-advantage in Using Diesel Engine

Production of sooty (dirty)and smelly smoke

1.2. Prepare of tools, equipments manufacturer specifications workshop

manuals.

Running condition vehicle

Vehicle service manual

Basic hand tools and equipments

A. 10mm Socket Wrench

B. 12mm Box End Wrench

C. 13mm Socket Wrench

D. 17mm Open End Wrench

E. 27mm Socket Wrench(1-1/16)

Prepared by;tefera megersa

Department of Automotive Engine Servicing 2006

F. Flat Screw Driver and Phillips Screw Driver

Diesel Engine Characteristics

The diesel engine has the following characteristics:

1. No throttle valve (except some engines with the pneumatic governor).

2. Compresses only air on the compression stroke.

3. Heat of compression ignites fuel as it sprays into the engine cylinders.

4. Has a high compression ratio of 16:1 to 22:1.

5. Controls engine power and speed only by the amount of fuel sprayed into the

cylinders. More fuel equals more power.

6. Have glow plugs or an electric intake-manifold heater to make starting easier.

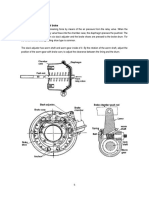

Figure 1. The four-piston strokes in a four-stroke-cycle diesel engine.

Cetane Number

The cetane number refers to the ease with which diesel fuel ignites. A high cetane

number means the fuel is fast burning andignites easily at a relatively low temperature.

A low cetane number means the fuel is slower burning and requires a

higher temperature to ignite. Diesel fuel with a low cetane number takes a little longer

to ignite. This may cause excessive ignition lag. During this slight delay, the fuel collects

in the cylinder. When ignition does occur, all the fuel ignites at once. The pressure goes

up quickly and combustion knock results. This is similar to spark knock or detonation in

a spark-ignition engine. High cetane fuel ignites as soon as it enters the cylinder.

Figure 2. The higher the cetane number of the diesel fuel, the faster the fuel burns. The higher the

octane number of gasoline, the slower it burns.

Prepared by;tefera megersa

Department of Automotive Engine Servicing 2006

1.3. Select and prepare the appropriate methods with standard operating

procedures

Diesel Starting Procedures.

Diesel engines require a different starting procedure from gasoline engines. If the

diesel engine is cold, the intake air must be preheated before cranking the engine. A

heating coil in an electric intake-manifold heater or in a glow plug in each

precombustion chamber (Figure LO1-13, page 19) supplies the heat.

A typical starting procedure follows.

1. When the engine is cold, turn the ignition key to ON or RUN. This connects the glow

plugs to the battery so they quickly heat the precombustion chambers. It also turns

on a WAIT light on the instrument panel. After a few seconds, the

precombustionchambers are heated sufficiently. The glow plugs and WAIT lights

turn off.

2. Press the accelerator pedal halfway down.

3. Turn the ignition key to start. The engine will crank and should START. If it does not

start in 15 seconds, turn the ignition key back to ON or RUN. If the WAIT light comes

on again, leave the ignition key in ON or RUN. When the light goes off again, try

starting once more. Pumping the accelerator pedal does not help starting a diesel

engine. The fuel-injectionsystem has no accelerator pump as in a carburetor

Prepared by;tefera megersa

Department of Automotive Engine Servicing 2006

Self check question Prepare for work Diesel Fuel Injection System

Direction: Select the best answer.

1. Technician A says that the diesel engine compresses air alone on the

compression stroke. Technician B says the fuel is ignited by the heat of

compression. Who is right?

a. A only

b. B only

c. Both A and B

d. Neither A nor B

2. All the following are true about diesel engines EXCEPT

a. no throttle valve

b. high compression ratio

c. speed and power controlled by quantity of fuel injected

d. spark plugs make starting easier

3. Technician A says cetane number is the same as octane rating. Technician B

says cetane number is the opposite of octane rating. Who is right?

a. A only

b. B only

c. Both A and B

d. Neither A nor B

4. The distributor injection pump has

a. a rotor that sends fuel to the injection nozzles

b. a barrel-and-plunger assembly for each cylinder

c. a helix cut in each plunger

d. a control rod attached to the accelerator pedal

Prepared by;tefera megersa

Department of Automotive Engine Servicing 2006

5. All the following are true about governors EXCEPT

a. A throttle valve in the air intake indicates a pneumatic governor

b. Moving the accelerator pedal changes the setting of the governor

c. Air-fuel ratio at full load is about 20:1

d. All automotive diesel engines use a constant-speed governor

6. The purpose of the glow plug is to

a. control engine idle speed

b. provide sparks to ignite the compressed air-fuel mixture

c. warm the fuel

d. add heat to the precombustion chamber

7. Warming the fuel with a fuel heater reduces the possibility that

a. wax in the fuel will plug the filters

b. the glow plugs will overheat

c. the coolant will freeze

d. the engine will star

8. All the following are true about servicing injection lines EXCEPT

a. cap all lines to prevent dirt from entering

b. wrap a shop towel around the connection to absorb leaking fuel

c. a kinked line can be straightened and reused

d. new lines are preformed

9. Technician A says a sticking injection nozzle may cause the diesel engine to

miss at all speeds. Technician B says an injection nozzle sticking open may cause a

puff of smoke each time the engine misfires. Who is right?

a. A only

b. B only

c. Both A and B

d. Neither A nor B

ANSWER KEY

1. c

2. d

3. b

4. a

5. d

6. d

7. a

8. c

9. c

Prepared by;tefera megersa

Department of Automotive Engine Servicing 2006

Instruction Sheet Learning Guide #2

This learning guide is developed to provide you the necessary information regarding the

following content coverage and topics –

● Service fuel system and components

2.1. Access and interpret manufacturer specifications.

2.2. Approve the service of diesel fuel injection system.

2.3. Complete the service of diesel fuel Injection system without causing

damage.

2.3.1 fuel tank

2.3.2fuel filter

2.3.3 Fuel line

2.3.4 Injection pump

2.3.5.Injector nozzle

2.4.Make the manufacturer specifications adjustments during the service

2.5.Test engine the fuel system

2.5.1.test engine fuel system

2.5.2. bleeding procedures

Learning Instructions:

1. Read the specific objectives of this Learning Guide.

2. Read the information written in the “Information Sheets”. Try to understand

what are being discussed. Ask you teacher for assistance if you have hard time

understanding them

3. To undertake this element you are required to have on hands the following

resources:

Information sheet

Operation sheet

Self Check

Answer Sheet

Prepared by;tefera megersa

Department of Automotive Engine Servicing 2006

Information Sheet-2 Test diesel fuel injection system

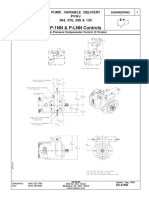

2.3.1 Injection pump

Automotive diesel engines use two types of fuel injection pumps. One is an inline cam-

operated pump. It has a plunger for each engine cylinder. The other is a rotary,

distributor-type pump. One or two plungers supply the fuel for all injection nozzles.

Inline-Plunger Injection Pump Figure LO1-1 shows an inline-plunger pump on a six-

cylinder diesel engine. The pump has a barrel-and-plunger assembly for each cylinder.

Prepared by;tefera megersa

Department of Automotive Engine Servicing 2006

Figure LO1-1. Fuel system for a six-cylinder diesel engine using an inline fuel injection pump.

Prepared by;tefera megersa

Department of Automotive Engine Servicing 2006

Rotary-Distributor Injection Pump

Figure LO1-4 shows an inline six-cylinder engine with a rotary distributor injection

pump. This pump has a rotor that sends fuel to the injection nozzles in the engine

cylinder as it rotates.

2.3.5. Injector nozzle

Figures LO1-11 and LO1-12 show typical injection nozzles. A spring holds the needle

valve or nozzle valve closed until the high injection pressure is applied through the

injection pipe. This forces the valve off its seat so fuel sprays out into the cylinder. The

instant the pressure drops, the spring reseats the valve and fuel injection stops.

Prepared by;tefera megersa

Department of Automotive Engine Servicing 2006

Figure LO1-11. Construction of a diesel-engine injection nozzle.

2.4. Make the manufacturer specifications adjustments during the service

2.5. Test engine the fuel system

2.5.1. Bleeding procedures

BLEEDING PROCEDURE:

Be sure to have some means available to catch or absorb any fuel escaping during the

bleeding process so that it will not accumulate in the engine compartment or bilge.

1. Be sure there is a sufficient supply of fuel in the fuel tank.

2. Open the fuel shut-off valve at the tank.

Prepared by;tefera megersa

Department of Automotive Engine Servicing 2006

3. Start the electric fuel pump by turning the ignition key to the "ON" position on

models 18, 20, 25, 30, 50, all models after 1986.

4. Model 15 has a mechanical fuel pump. Therefore with decompression on, turn

engine over with starter. Crank at 10 second intervals while doing steps #5 and 7.

5. Slowly loosen the air bleed plug on the fuel filter, letting air escape until an air free

flow of fuel is evident. (1986 models see item 7).

6. At this time, tighten the air bleed plug on the filter.

7. Slowly loosen the air bleed plug on the injector pump, letting air escape until an air

free flow of fuel is evident. Units with a self bleed return valve, open for a short

period then start engine, as soon as engine runs smooth close valve. Model-12 has

continuous fuel bleeding.

8. At this time, tighten the air bleed plug or knurled knob on the injector pump.

9. The fuel system should now be properly bled and ready for operation.

Operation Sheet Bleeding the fuel system

It will be necessary to bleed the fuel system to achieve a steady air free flow of fuel if

any of the following have occurred.

1. Running out of fuel.

2. If fuel shut off valve is left closed and engine runs out of fuel.

3. Replacing fuel filter.

4. Fuel injector nozzle or injector pump repair.

5. After repairing or replacing any fuel line.

6. Before putting engine back into service in the spring, if fuel system has been

drained.

7. Replacement of electric or mechanical fuel pump.

8. Any time air is permitted to enter the fuel system.

Prepared by;tefera megersa

Department of Automotive Engine Servicing 2006

Instruction Sheet Learning Guide #3

This learning guide is developed to provide you the necessary information regarding the

following content coverage and topics –

LO3:- Overhaul diesel fuel injection system

1.1 fuel tank

1.2 fuel line

Injection lines in diesel-engine fuel-injection systems are also called high-pressure fuel

lines, injection tubes and injection pipes. They carry fuel under high pressure from the

injection pump to the injection nozzles. Figure 3 shows the various shapes of injection

lines between the injection pump and the nozzles.

When the line requires replacement, always install the line specified by the vehicle

manufacturer. Variations from specified length and internal diameter may cause engine

troubles. New lines are preformed. Avoid twisting or bending them out of shape during

installation

Prepared by;tefera megersa

Department of Automotive Engine Servicing 2006

1.3 fuel flitter

The fuel filter (Figure 3) is located in the low-pressure fuel line from the fuel tank to the

Injection pump. The filter element is similar to filters used in engine lubricating

systems. The fuel must pass through the fuel element which traps any dirt particles.

Replace the filter periodically as recommended by the manufacturer.

1.4 transfer /feed/ pump

1.5 injection pump /in line type/

Automotive diesel engines use two types of fuel injection pumps. One is an inline cam-

operated pump. It has a plunger for each engine cylinder. The other is a rotary,

distributor-type pump. One or two plungers supply the fuel for all injection nozzles.

Inline-Plunger Injection Pump Figure LO1-1 shows an inline-plunger pump on a six-

cylinder diesel engine. The pump has a barrel-and-plunger assembly for each cylinder.

Prepared by;tefera megersa

Department of Automotive Engine Servicing 2006

1.6 distribute type injection pump

The fuel-injection system is responsible for supplying the diesel engine with fuel. To do

so, the injection pump generates the pressure required for fuel injection. The fuel under

pressure is forced through the high-pressure fuel-injection tubing to the injection nozzle

which then injects it into the combustion chamber. The fuel-injection system (Fig. 1)

Prepared by;tefera megersa

Department of Automotive Engine Servicing 2006

includes the following components and assemblies: The fuel tank, the fuel filter, the fuel

supply pump, the injection nozzles, the high-pressure injection tubing, the governor, and

the timing device (if required). The combustion processes in the diesel engine depend to

a large degree upon the quantity of fuel which is injected and upon the method of

introducing this fuel to the combustion chamber. The most important criteria in this

respect are the fuel-injection timing and the duration of injection, the fuel’s distribution in

the combustion chamber, the moment in time when combustion starts, the amount of

fuel metered to the engine per degree crankshaft, and the total injected fuel quantity in

accordance with the engine loading. The optimum interplay of all these parameters is

decisive for the faultless functioning of the diesel engine

2.7. injector nozzle

There are a very wide variety of different nozzle-and-holder assemblies for hole-type nozzles

on the market. In contrast to the throttling-lintel nozzles, the hole-type nozzles must be

installed in a given position. The spray holes are at different angles in the nozzle body and

must be correctly aligned with regard to the combustion chamber. The nozzle and holder

assembly is therefore fastened to the cylinder head with hollow screws or claws. A special

mount is used to lock the nozzle in the correct position. The hole-type nozzles (Fig.3)

haveneedle diameters of 4 mm (Size P) and between 5 and 6 mm (Size S). The seat hole

nozzle is only available as a Size P version. The nozzle pressure springs must be matched to

the needle diameters and to the high opening pressures which are usually above 180 bar. The

Prepared by;tefera megersa

Department of Automotive Engine Servicing 2006

nozzle-sealing function is particularly important at the end of injection because there is a risk

of the combustion gases blowing back into the nozzle and in the long run destroying it and

causing hydraulic instability. Precision matching of the pressure spring and the needle

diameter ensures efficient sealing. In certain cases, it may be necessary to take into account

the oscillations of the pressure spring. There are three designs for the arrangement of the

spray holes in the nozzle cone. These three designs also differ from each other with respect to

the amount of fuel which remains inside the injector and which can evaporate into the

combustion chamber when injection has finished. Versions with cylindrical blind hole,

conical blind hole, and seat hole, have decreasing fuel quantities in this order. Furthermore,

the less fuel that can evaporate from the nozzle, the lower are the engine's hydrocarbon

emissions. The levels of these emissions therefore also correspond to the (nozzle) order given

above.

Figures LO1-11 and LO1-12 show typical injection nozzles. A spring holds the needle

valve or nozzle valve closed until the high injection pressure is applied through the

injection pipe. This forces the valve off its seat so fuel sprays out into the cylinder. The

instant the pressure drops, the spring reseats the valve and fuel injection stops.

Lo4:-Prepare vehicle/system for customer turn-over or storage

Prepared by;tefera megersa

Department of Automotive Engine Servicing 2006

Prepared by;tefera megersa

Department of Automotive Engine Servicing 2006

S-ar putea să vă placă și

- Diesel EngineDocument32 paginiDiesel EngineWira SentanuÎncă nu există evaluări

- Edexcel HNC/D Plant and Process Principles Outcome 4 - Power Supply Equipment Tutorial 1 - Diesel EnginesDocument9 paginiEdexcel HNC/D Plant and Process Principles Outcome 4 - Power Supply Equipment Tutorial 1 - Diesel EnginescataiceÎncă nu există evaluări

- Diesel InjectorDocument15 paginiDiesel InjectorAlvin AuÎncă nu există evaluări

- Engine Governors - WoodwardDocument4 paginiEngine Governors - WoodwardJoe Discourt100% (1)

- hk1400 - NMDocument2 paginihk1400 - NMAhmet BuyrucuÎncă nu există evaluări

- Fuel System: Western Institute of Technology College of Engineering Mechanical Engineering DepartmentDocument8 paginiFuel System: Western Institute of Technology College of Engineering Mechanical Engineering DepartmentJohn Francis Pirote FriasÎncă nu există evaluări

- Common Rail ReportDocument4 paginiCommon Rail Reportnuwan_nishaÎncă nu există evaluări

- Test Equipment And Tools 最新 PDFDocument40 paginiTest Equipment And Tools 最新 PDFJe MotorÎncă nu există evaluări

- Diesel Fuel SystemDocument36 paginiDiesel Fuel SystemFeckry Ag Ghani100% (1)

- CRDiDocument18 paginiCRDiSuhel InamdarÎncă nu există evaluări

- Qip Ice 12 Fuel Injection SystemsDocument40 paginiQip Ice 12 Fuel Injection SystemsAnonymous eyxVFR100% (1)

- Ic Engine and Turbo MachineryDocument25 paginiIc Engine and Turbo MachineryEyoÎncă nu există evaluări

- Dieselland Catalog Eng 26.06.20co PDFDocument261 paginiDieselland Catalog Eng 26.06.20co PDFEphrem MichaelÎncă nu există evaluări

- Marine DieselDocument12 paginiMarine DieselNafi AnnurÎncă nu există evaluări

- HL042 - HA123 Digital Flow Display Installation, Operating and Servicing ManualDocument42 paginiHL042 - HA123 Digital Flow Display Installation, Operating and Servicing Manualvad1maaÎncă nu există evaluări

- Diesel Engine - FundamentalDocument20 paginiDiesel Engine - FundamentalSoumen BhattaÎncă nu există evaluări

- Introduction Common RailDocument2 paginiIntroduction Common Railfaris khairuddinÎncă nu există evaluări

- DieselBrochure 10-2012Document68 paginiDieselBrochure 10-2012enriÎncă nu există evaluări

- Bosch Vp44 Diesel Pump Fitted To Vauxhall Astra Corsa Combo Frontera 10816147Document3 paginiBosch Vp44 Diesel Pump Fitted To Vauxhall Astra Corsa Combo Frontera 10816147Duško GrbićÎncă nu există evaluări

- Perkins Diesel Generator P400pub 360kwDocument4 paginiPerkins Diesel Generator P400pub 360kwTariq KoyrattyÎncă nu există evaluări

- 05 Fuel Injection SystemDocument42 pagini05 Fuel Injection SystemVishal JohaheerÎncă nu există evaluări

- Delphi DDU CRSDocument2 paginiDelphi DDU CRSFaraz HaiderÎncă nu există evaluări

- Diesel Fuel InjectionDocument5 paginiDiesel Fuel Injectiondamith21Încă nu există evaluări

- Diesel Engines 12V/16V 2000 M72: For Vessels With High Load Factors (1B)Document2 paginiDiesel Engines 12V/16V 2000 M72: For Vessels With High Load Factors (1B)Alberto100% (1)

- Diesel Engine Mixture Formation: 5.4. Fuel Injection SystemDocument30 paginiDiesel Engine Mixture Formation: 5.4. Fuel Injection SystemGODÎncă nu există evaluări

- Cruces Stanadyne - JhondeeereDocument2 paginiCruces Stanadyne - JhondeeereJuan Gabriel OchoaÎncă nu există evaluări

- C. Prakash, DGM, Engine R&D, Ashok Leyland Limited, ChennaiDocument70 paginiC. Prakash, DGM, Engine R&D, Ashok Leyland Limited, ChennaiiocsachinÎncă nu există evaluări

- T2001 - S12-13 DensoDocument2 paginiT2001 - S12-13 DensomihajlovichenkelÎncă nu există evaluări

- Fuel Injection EvolutionDocument9 paginiFuel Injection EvolutioncarechimbacomemierdaÎncă nu există evaluări

- Qip Ice 02 Basic CyclesDocument45 paginiQip Ice 02 Basic Cyclespremendra mani100% (1)

- The Advanced Diesel Engine Technology and Fuel Injection System TechnologyDocument24 paginiThe Advanced Diesel Engine Technology and Fuel Injection System TechnologyMohamedBenMansourÎncă nu există evaluări

- Delphi DPGE Medium Duty Diesel Rotary Fuel Injection Pump: Powertrain SystemsDocument2 paginiDelphi DPGE Medium Duty Diesel Rotary Fuel Injection Pump: Powertrain SystemsAsif ShahÎncă nu există evaluări

- Operation of Four Stroke EngineDocument4 paginiOperation of Four Stroke EngineDaniel S. SantosÎncă nu există evaluări

- Injector: Steam Injector, Eductor-Jet Pump or Thermocompressor Is A Pump-LikeDocument5 paginiInjector: Steam Injector, Eductor-Jet Pump or Thermocompressor Is A Pump-LikeAhsan AbroÎncă nu există evaluări

- Qip Ice 01 IntroductionDocument40 paginiQip Ice 01 IntroductionTiffany Powell100% (1)

- 123Document21 pagini123Evans MagalhãesÎncă nu există evaluări

- Diesel Engine ProblemsDocument4 paginiDiesel Engine ProblemsArvind Sangeeta KothariÎncă nu există evaluări

- Qip Ice 10 Intake and Exhaust FlowsDocument28 paginiQip Ice 10 Intake and Exhaust FlowsChetanPrajapati100% (1)

- Fuel Injection SystemDocument6 paginiFuel Injection SystemvikramnikhilanshiÎncă nu există evaluări

- S Setting Value, C Check Value) OT Outside Tolerance (X Is Set)Document4 paginiS Setting Value, C Check Value) OT Outside Tolerance (X Is Set)Юрий ТрофимовÎncă nu există evaluări

- Common Rail Diesel Engine Management 1Document13 paginiCommon Rail Diesel Engine Management 1Dejan MihajlovicÎncă nu există evaluări

- Engine Spect MitsubishiDocument4 paginiEngine Spect MitsubishiFalgon IslamÎncă nu există evaluări

- TK1035 enDocument2 paginiTK1035 enSutiknoÎncă nu există evaluări

- Free-Piston Engine - Wikipedia, The Free EncyclopediaDocument4 paginiFree-Piston Engine - Wikipedia, The Free EncyclopediaSai DasÎncă nu există evaluări

- Ima Info Piezo PDFDocument14 paginiIma Info Piezo PDF30106Încă nu există evaluări

- Common-Rail Pumps Repair: Standard Equipment ForDocument10 paginiCommon-Rail Pumps Repair: Standard Equipment ForPool Quispe AlcántaraÎncă nu există evaluări

- Dual Fuel EngineDocument14 paginiDual Fuel EngineGUJJARI PREM KUMAR 19981A0344Încă nu există evaluări

- Bosch MaquinasDocument13 paginiBosch MaquinasnomecÎncă nu există evaluări

- Stanadyne de Pump Timing Instructions PDFDocument1 paginăStanadyne de Pump Timing Instructions PDFSMITIÎncă nu există evaluări

- Presentation Diesel EngineDocument50 paginiPresentation Diesel EngineEng Ahmed Fine0% (1)

- CZ 2012 2013 DieselDocument14 paginiCZ 2012 2013 DieselSoeAyeÎncă nu există evaluări

- Delphi's Diesel Unit Pump Common Rail System 2012Document6 paginiDelphi's Diesel Unit Pump Common Rail System 2012qingcaohe100% (1)

- Qip Ice 15 Alternative FuelsDocument3 paginiQip Ice 15 Alternative FuelsPratikÎncă nu există evaluări

- Service Manual Nissan PDFDocument39 paginiService Manual Nissan PDFayi darwisÎncă nu există evaluări

- Diesel Power Plant Word File Final 1Document49 paginiDiesel Power Plant Word File Final 1Diether RigorÎncă nu există evaluări

- Petrol and Diesel EnginesDocument9 paginiPetrol and Diesel EnginesgggggggÎncă nu există evaluări

- Volkswagen Service Training Tdi DieselDocument6 paginiVolkswagen Service Training Tdi Dieselchristopher100% (43)

- DesicelDocument6 paginiDesicelJohn CHarlieÎncă nu există evaluări

- Elective 2 Term Paper... TotiDocument20 paginiElective 2 Term Paper... TotiToti JabagatÎncă nu există evaluări

- 1st TimeDocument7 pagini1st TimeVinay GirdharÎncă nu există evaluări

- Electrical System MaintenanceDocument3 paginiElectrical System MaintenanceGODÎncă nu există evaluări

- T72Document6 paginiT72GODÎncă nu există evaluări

- Internal Combustion Engine Induction TuningDocument39 paginiInternal Combustion Engine Induction TuningTomás Sebastián Sanhueza Vásquez100% (2)

- Automobile Maintenance Management and TechniquesDocument2 paginiAutomobile Maintenance Management and TechniquesGODÎncă nu există evaluări

- 6-Automotive UnderchassisDocument3 pagini6-Automotive UnderchassisGOD100% (1)

- 5-Automotive Power TrainDocument3 pagini5-Automotive Power TrainGODÎncă nu există evaluări

- 6-Automotive UnderchassisDocument3 pagini6-Automotive UnderchassisGODÎncă nu există evaluări

- At 43 CH 4 Diesel Engine OperationDocument46 paginiAt 43 CH 4 Diesel Engine OperationGODÎncă nu există evaluări

- Stimulating Creative ThinkingDocument12 paginiStimulating Creative ThinkingGODÎncă nu există evaluări

- WKT MFGDocument4 paginiWKT MFGGODÎncă nu există evaluări

- Types of TeamsDocument9 paginiTypes of TeamsGODÎncă nu există evaluări

- Inline Injection Pump RemovalDocument3 paginiInline Injection Pump RemovalGOD100% (2)

- Defense University, College of Engineering Project Proposal OnDocument15 paginiDefense University, College of Engineering Project Proposal OnGODÎncă nu există evaluări

- Alternative Fuels LNG, LPG, HydrogenDocument69 paginiAlternative Fuels LNG, LPG, HydrogenGODÎncă nu există evaluări

- Ex PaintDocument1 paginăEx PaintGODÎncă nu există evaluări

- Electronic Diesel Control: Eng. Fu'ad DaoudDocument23 paginiElectronic Diesel Control: Eng. Fu'ad DaoudNimesh SilvaÎncă nu există evaluări

- AT 43 CH 24 Fuel Injection System DiagnosisDocument30 paginiAT 43 CH 24 Fuel Injection System DiagnosisGODÎncă nu există evaluări

- Engine Cooling SystemDocument16 paginiEngine Cooling SystemGODÎncă nu există evaluări

- Hydraulic Control and Lubricating System of Power Train1Document21 paginiHydraulic Control and Lubricating System of Power Train1GODÎncă nu există evaluări

- Aouto Shop Hand Tools and Precesion Measuring Tools: Chapter-TwoDocument48 paginiAouto Shop Hand Tools and Precesion Measuring Tools: Chapter-TwoGODÎncă nu există evaluări

- 6th Central Pay Commission Salary CalculatorDocument15 pagini6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Driving in Complicated AreaDocument14 paginiDriving in Complicated AreaGODÎncă nu există evaluări

- Record KeepingDocument12 paginiRecord KeepingGODÎncă nu există evaluări

- Internal Combustion Engine Induction TuningDocument39 paginiInternal Combustion Engine Induction TuningTomás Sebastián Sanhueza Vásquez100% (2)

- Air Brake (5Document1 paginăAir Brake (5GODÎncă nu există evaluări

- H 38Document3 paginiH 38Matei AlexandruÎncă nu există evaluări

- Precision MeasurementDocument33 paginiPrecision MeasurementGOD100% (1)

- Konsep El Diagnosis PDFDocument30 paginiKonsep El Diagnosis PDFJulius RonaldoÎncă nu există evaluări

- Power PlantDocument20 paginiPower PlantGODÎncă nu există evaluări

- Konsep El Diagnosis PDFDocument30 paginiKonsep El Diagnosis PDFJulius RonaldoÎncă nu există evaluări

- WWI 1919 Naval Aircraft Engines BookDocument104 paginiWWI 1919 Naval Aircraft Engines BookCAP History Library100% (5)

- Connecting Rod BoltsDocument2 paginiConnecting Rod BoltsRachitÎncă nu există evaluări

- Variable Valve Actuators - Inspect/Adjust: C11 and C13 Engines For Caterpillar Built MachinesDocument5 paginiVariable Valve Actuators - Inspect/Adjust: C11 and C13 Engines For Caterpillar Built MachinesIndiÎncă nu există evaluări

- IC EngineDocument40 paginiIC Enginepm1802Încă nu există evaluări

- FlywheelDocument8 paginiFlywheelAidil Syawani Kun100% (1)

- Me401A Lab Report: Experiment Number: 5 Group Number: B2Document9 paginiMe401A Lab Report: Experiment Number: 5 Group Number: B2Rishu KatiyarÎncă nu există evaluări

- N45sm1a 51 To 59KWDocument3 paginiN45sm1a 51 To 59KWsaiyedasadÎncă nu există evaluări

- T ManualDocument100 paginiT ManualRizal Irnandi HidayatÎncă nu există evaluări

- Cylinder Lubrication of Two Stroke Crosshead Marine Diesel EnginesDocument12 paginiCylinder Lubrication of Two Stroke Crosshead Marine Diesel EnginesdiansulaemanÎncă nu există evaluări

- Shin Trimmers PDFDocument118 paginiShin Trimmers PDFvfan100% (1)

- Milwaukee Cylinder Series H Hydraulic CylindersDocument32 paginiMilwaukee Cylinder Series H Hydraulic Cylindersnvkjayanth100% (1)

- 78 - 8 - IC Engine ComponentsDocument8 pagini78 - 8 - IC Engine Componentsrip111176Încă nu există evaluări

- DocumentsDocument58 paginiDocumentsHIDRAULICA MANSE SERVICIO TECNICOÎncă nu există evaluări

- MCT 311 Lesson 2Document22 paginiMCT 311 Lesson 2Moussa SaidÎncă nu există evaluări

- Seminar On 1400 HP Demu Engine: B. V. Raju Institute of TechnologyDocument29 paginiSeminar On 1400 HP Demu Engine: B. V. Raju Institute of Technologypranay reddyÎncă nu există evaluări

- Practical Manual: Course: SemesterDocument50 paginiPractical Manual: Course: SemesterJustus VenterÎncă nu există evaluări

- Engine TerminologyDocument13 paginiEngine Terminologyhotbuddy723Încă nu există evaluări

- Kobe FSM PDFDocument57 paginiKobe FSM PDFSokha RunÎncă nu există evaluări

- Piston Engines: 97 QuestionsDocument19 paginiPiston Engines: 97 QuestionsamilaÎncă nu există evaluări

- Unit 4: Non - Flow ProcessDocument17 paginiUnit 4: Non - Flow ProcessMarco KrugerÎncă nu există evaluări

- Oilgear Type "PVG" Pumps - 100/130 (SERIES F1U) Service InstructionsDocument28 paginiOilgear Type "PVG" Pumps - 100/130 (SERIES F1U) Service InstructionsCamilo Barrera100% (1)

- Tom Lab ManualDocument24 paginiTom Lab Manualm_er100Încă nu există evaluări

- Revue Technique Derbi Euro 2Document71 paginiRevue Technique Derbi Euro 2Hellbent BikersÎncă nu există evaluări

- Mercury Outboards PDFDocument296 paginiMercury Outboards PDFJauharul AlamÎncă nu există evaluări

- Physics - An Illustrated Guide To Science (Document209 paginiPhysics - An Illustrated Guide To Science (Phanrawee Sriprapha100% (2)

- Power Point - Agricultural Machinery and Allied SubjectsDocument627 paginiPower Point - Agricultural Machinery and Allied SubjectsLeo Mhel100% (1)

- SME5601 Advanced IC Engines Question BankDocument5 paginiSME5601 Advanced IC Engines Question BankJVCÎncă nu există evaluări

- MEHB493 - Lecture 1Document37 paginiMEHB493 - Lecture 1thineshÎncă nu există evaluări

- How to Build a Car: The Autobiography of the World’s Greatest Formula 1 DesignerDe la EverandHow to Build a Car: The Autobiography of the World’s Greatest Formula 1 DesignerEvaluare: 4.5 din 5 stele4.5/5 (54)

- Faster: How a Jewish Driver, an American Heiress, and a Legendary Car Beat Hitler's BestDe la EverandFaster: How a Jewish Driver, an American Heiress, and a Legendary Car Beat Hitler's BestEvaluare: 4 din 5 stele4/5 (28)

- Automotive Electronic Diagnostics (Course 1)De la EverandAutomotive Electronic Diagnostics (Course 1)Evaluare: 5 din 5 stele5/5 (6)

- ANSYS Workbench 2023 R2: A Tutorial Approach, 6th EditionDe la EverandANSYS Workbench 2023 R2: A Tutorial Approach, 6th EditionÎncă nu există evaluări

- Allison Transmissions: How to Rebuild & Modify: How to Rebuild & ModifyDe la EverandAllison Transmissions: How to Rebuild & Modify: How to Rebuild & ModifyEvaluare: 5 din 5 stele5/5 (1)

- Well Integrity for Workovers and RecompletionsDe la EverandWell Integrity for Workovers and RecompletionsEvaluare: 5 din 5 stele5/5 (3)

- Weld Like a Pro: Beginning to Advanced TechniquesDe la EverandWeld Like a Pro: Beginning to Advanced TechniquesEvaluare: 4.5 din 5 stele4.5/5 (6)

- Modern Engine Blueprinting Techniques: A Practical Guide to Precision Engine BlueprintingDe la EverandModern Engine Blueprinting Techniques: A Practical Guide to Precision Engine BlueprintingEvaluare: 4.5 din 5 stele4.5/5 (9)

- Small Engines and Outdoor Power Equipment: A Care & Repair Guide for: Lawn Mowers, Snowblowers & Small Gas-Powered ImplementsDe la EverandSmall Engines and Outdoor Power Equipment: A Care & Repair Guide for: Lawn Mowers, Snowblowers & Small Gas-Powered ImplementsÎncă nu există evaluări

- A Practical Handbook for Drilling Fluids ProcessingDe la EverandA Practical Handbook for Drilling Fluids ProcessingÎncă nu există evaluări

- Tips On How to Build a Street Legal Motorized Bicycle; (That Will Save You a Lot of Aggravation and Money)De la EverandTips On How to Build a Street Legal Motorized Bicycle; (That Will Save You a Lot of Aggravation and Money)Încă nu există evaluări

- How to Fabricate Automotive Fiberglass & Carbon Fiber PartsDe la EverandHow to Fabricate Automotive Fiberglass & Carbon Fiber PartsEvaluare: 5 din 5 stele5/5 (4)

- CDL Study Guide 2024-2025: Everything You Need to Know to Pass the Commercial Driver’s License Exam on your First Attempt, with the Most Complete and Up-to-Date Practice Tests - New VersionDe la EverandCDL Study Guide 2024-2025: Everything You Need to Know to Pass the Commercial Driver’s License Exam on your First Attempt, with the Most Complete and Up-to-Date Practice Tests - New VersionEvaluare: 5 din 5 stele5/5 (2)

- OBD-I and OBD-II: A Complete Guide to Diagnosis, Repair, and Emissions ComplianceDe la EverandOBD-I and OBD-II: A Complete Guide to Diagnosis, Repair, and Emissions ComplianceÎncă nu există evaluări

- Powder Coating: A How-to Guide for Automotive, Motorcycle, and Bicycle PartsDe la EverandPowder Coating: A How-to Guide for Automotive, Motorcycle, and Bicycle PartsEvaluare: 4.5 din 5 stele4.5/5 (17)

- Data Acquisition from HD Vehicles Using J1939 CAN BusDe la EverandData Acquisition from HD Vehicles Using J1939 CAN BusÎncă nu există evaluări

- Ford AOD Transmissions: Rebuilding and Modifying the AOD, AODE and 4R70WDe la EverandFord AOD Transmissions: Rebuilding and Modifying the AOD, AODE and 4R70WEvaluare: 4.5 din 5 stele4.5/5 (6)

- Troubleshooting and Repair of Diesel EnginesDe la EverandTroubleshooting and Repair of Diesel EnginesEvaluare: 1.5 din 5 stele1.5/5 (2)

- The Official Highway Code: DVSA Safe Driving for Life SeriesDe la EverandThe Official Highway Code: DVSA Safe Driving for Life SeriesEvaluare: 3.5 din 5 stele3.5/5 (25)

- Advanced Production Decline Analysis and ApplicationDe la EverandAdvanced Production Decline Analysis and ApplicationEvaluare: 3.5 din 5 stele3.5/5 (4)

- Automotive Machining: A Guide to Boring, Decking, Honing & MoreDe la EverandAutomotive Machining: A Guide to Boring, Decking, Honing & MoreEvaluare: 4.5 din 5 stele4.5/5 (11)

- Competition Engine Building: Advanced Engine Design and Assembly TechniquesDe la EverandCompetition Engine Building: Advanced Engine Design and Assembly TechniquesEvaluare: 4.5 din 5 stele4.5/5 (7)