Documente Academic

Documente Profesional

Documente Cultură

Wps Register Last Updated May 12

Încărcat de

Abdullah Al JubayerDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Wps Register Last Updated May 12

Încărcat de

Abdullah Al JubayerDrepturi de autor:

Formate disponibile

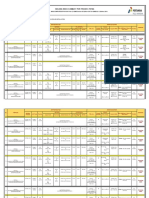

EMPLOYER : PROJECT TITLE : CONTRACTOR :

3000 BBL/DAY CAPACITY SEMI REGENERATIVE

CATALYTIC REFORMING UNIT & ASSOCIATED FACILITIES AT

RASHIDPUR, BAHUBOL, HABIGANJ, BANGLADESH

WELDING PROCEDURE SPECIFICATION Page Number :

SYLHET GAS FIELDS LIMITED (DRAFT) 4 OF 50

WPS LIST TO BE QUALIFIED (MANUAL WELDING)

Preheat maintenance (°C)

Interpass temp. Max (°C)

Preheat temp. Min (°C)

Charpy Impact Test

Weld Metal

SL Pipe NPS Base Metal Base Metal Thickness of

Piping Class WPS NO. PQR NO. Welding process Deposited Max. Filler Metal PWHT GTAW SMAW Remark

No. (inch) Base Metal Spec Qualified to Qualified to Base Metal

(mm)

(mm)

P no. Group No. P no. Group No. GTAW SMAW GTAW SMAW FILLER ELECTRODE

A3-1F, A3-3F, Z0- SGFL/EPGL-IKL/ SGFL/EPGL-IKL/

1 3"< GTAW A106 Gr. B 1 1,2 1 1,2 3.91 7.82 NA F6 N/A AMBIENT 250°C N/A N/A N/A ER 70S-6 OR ER 70S-2 N/A

1F, Z3-1F RPT/WPS-001 RPT/PQR-001

A3-1F, A3-3F, Z0- SGFL/EPGL-IKL/ SGFL/EPGL-IKL/

2 4" ~ 16" GTAW+SMAW A106 Gr. B 1 1,2 1 1,2 7.11 6 8.22 F6 F4 AMBIENT 250°C N/A N/A N/A ER 70S-6 OR ER 70S-2 E7018

1F, Z3-1F RPT/WPS-002 RPT/PQR-002

SGFL/EPGL-IKL/ SGFL/EPGL-IKL/

3 A3C-1F, A3C-3F 3"< GTAW A106 Gr. B 1 1,2 1 1,2 3.91 7.82 NA F6 N/A AMBIENT 300°C N/A N/A 595°C-650°C ER 70S-6 OR ER 70S-2 N/A

RPT/WPS-003 RPT/PQR-003

SGFL/EPGL-IKL/ SGFL/EPGL-IKL/

4 A3C-1F, A3C-3F 4" ~ 16" GTAW+SMAW A106 Gr. B 1 1,2 1 1,2 7.11 6 8.22 F6 F4 AMBIENT 300°C N/A N/A 595°C-650°C ER 70S-6 OR ER 70S-2 E7018-1

RPT/WPS-004 RPT/PQR-004

SGFL/EPGL-IKL/ SGFL/EPGL-IKL/ A333 Gr. 6 to

5 B3-1F,B3-3F 3"< GTAW 1 1 1 2 3.91 7.82 NA F6 N/A AMBIENT 250°C N/A YES N/A ER 70S-6 OR ER 70S-2 N/A

RPT/WPS-005 RPT/PQR-005 A350 LF2CL.1

SGFL/EPGL-IKL/ SGFL/EPGL-IKL/ A333 Gr. 6 to

6 B3-1F,B3-3F 4" ~ 16" GTAW+SMAW 1 1 1 2 7.11 6 8.22 F6 F4 AMBIENT 250°C N/A YES N/A ER 70S-6 OR ER 70S-2 E7018-1

RPT/WPS-006 RPT/PQR-006 A350 LF2CL.1

SGFL/EPGL-IKL/ SGFL/EPGL-IKL/

7 M 1 1-1F, M11-3F 3"< GTAW A312 304L 8 1 8 1 3.91 7.82 NA F6 N/A AMBIENT 150°C N/A N/A N/A ER 308L N/A

RPT/WPS-007 RPT/PQR-007

SGFL/EPGL-IKL/ SGFL/EPGL-IKL/

8 N1-3F 3"< GTAW A312 321 8 1 8 1 3.91 7.82 NA F6 N/A AMBIENT 150°C N/A N/A N/A ER 347 N/A

RPT/WPS-008 RPT/PQR-008

SGFL/EPGL-IKL/ SGFL/EPGL-IKL/

9 N1-3F 4" ~ 16" GTAW+SMAW A312 321 8 1 8 1 8.18 6 10.36 F6 F4 AMBIENT 150°C N/A N/A N/A ER 347 E 347

RPT/WPS-009 RPT/WPS-009

SGFL/EPGL-IKL/ SGFL/EPGL-IKL/

10 C3-3F 4"< GTAW A333 Gr.3 9B 1 9B 1 3.91 7.82 NA F6 N/A 90 °C 250°C N/A YES N/A ER 80S-Ni2 N/A

RPT/WPS-010 RPT/PQR-010

SGFL/EPGL-IKL/ SGFL/EPGL-IKL/

11 E1-3F,E3-3F,E1-6F 3"< GTAW A335 P11 4 1 4 1 3.91 7.82 NA F6 N/A 200°C 300°C 200°C- 300°C YES N/A ER 80S-G N/A

RPT/WPS-011 RPT/WPS-011

SGFL/EPGL-IKL/ SGFL/EPGL-IKL/

12 E1-3F,E3-3F,E1-6F 4" ~ 16" GTAW+SMAW A335 P11 4 1 4 1 7.11 6 8.22 F6 F4 200°C 300°C 200°C- 300°C YES N/A ER 80S-G E8018-B2

RPT/WPS-012 RPT/PQR-012

A3H-1F, A3S-1F, SGFL/EPGL-IKL/ SGFL/EPGL-IKL/ A106B NACE tp

13 3"< GTAW 1 1 1 2 3.91 7.82 NA F6 N/A AMBIENT 300°C N/A YES 595°C-650°C ER 70S-2 N/A

A3H-3F, A3S-3F RPT/WPS-013 RPT/PQR-013 A105 NACE

A3H-1F, A3S-1F, SGFL/EPGL-IKL/ SGFL/EPGL-IKL/ A106B NACE tp

14 4"-6" GTAW+SMAW 1 1 1 2 7.11 6 8.22 F6 F4 AMBIENT 300°C N/A YES 595°C-650°C ER 70S-2 E7018-1

A3H-3F, A3S-3F RPT/WPS-014 RPT/PQR-014 A105 NACE

Structural Steel SGFL/EPGL-IKL/ SGFL/EPGL-IKL/

15 NA SMAW A572 NA 2 NA 2 12 NA 12 N/A F4 AMBIENT 250°C N/A N/A N/A N/A E7018

A572 Gr 50, A36 RPT/WPS-015 RPT/PQR-015

Structural Steel SGFL/EPGL-IKL/ SGFL/EPGL-IKL/

16 A572 Gr 50, A36 NA SMAW A572 NA 2 NA 2 12 NA 12 N/A F4 AMBIENT 250°C N/A N/A N/A N/A E7018

RPT/WPS-016 RPT/PQR-016

SGFL/EPGL-IKL/ SGFL/EPGL-IKL/ A333 Gr. 6 to

17 B3H-3F, B3S-3F 3"< GTAW 1 1 1 2 3.91 7.82 NA F6 N/A AMBIENT 250°C N/A YES 595°C-650°C ER 70S-6 OR ER 70S-2 N/A

RPT/WPS-017 RPT/PQR-017 A350 LF2CL.1

SGFL/EPGL-IKL/ SGFL/EPGL-IKL/ A333 Gr. 6 to

18 B3H-3F, B3S-3F 4" ~ 16" GTAW+SMAW 1 1 1 2 7.11 6 8.22 F6 F4 AMBIENT 250°C N/A YES 595°C-650°C ER 70S-6 OR ER 70S-2 E7018-1

RPT/WPS-018 RPT/PQR-018 A350 LF2CL.1

SGFL/EPGL-IKL/ SGFL/EPGL-IKL/ A312 304 to

19 P8 to P1 3"< GTAW 8 1 1 1,2 3.91 7.82 NA F6 N/A AMBIENT 150°C N/A N/A N/A ER 309L N/A

RPT/WPS-019 RPT/PQR-019 A106 Gr.B

SGFL/EPGL-IKL/ SGFL/EPGL-IKL/ A312 321 to

20 P8 to P1 4" ~ 16" GTAW+SMAW 8 1 1 1,2 8.18 6 10.36 F6 F4 AMBIENT 150°C N/A N/A N/A ER309L E309L-16

RPT/WPS-020 RPT/PQR-020 A106 Gr.B

SGFL/EPGL-IKL/ SGFL/EPGL-IKL/ A335 P11 to

21 P4 to P8 3"< GTAW 4 1 8 1 3.91 7.82 NA F6 N/A 200°C 300°C 200°C- 300°C N/A N/A ER 309 N/A

RPT/WPS-021 RPT/PQR-021 A312 304L

SGFL/EPGL-IKL/ SGFL/EPGL-IKL/ A335 P11 to

22 P4 to P8 4" ~ 16" GTAW+SMAW 4 1 8 1 7.11 6 8.22 F6 F4 200°C 300°C 200°C- 300°C N/A N/A ER 309 E309

RPT/WPS-022 RPT/PQR-022 A312 304L

SGFL/EPGL-IKL/ SGFL/EPGL-IKL/ A335 P11 to

23 P4 to P8 3"< GTAW 4 1 5B 1 3.91 7.82 NA F6 N/A 200°C 300°C 200°C- 300°C YES N/A ER 502 N/A

RPT/WPS-023 RPT/PQR-023 SA213

SGFL/EPGL-IKL/ SGFL/EPGL-IKL/ A335 P11 to

24 P4 to P8 4" ~ 16" GTAW+SMAW 4 1 5B 1 7.11 6 8.22 F6 F4 200°C 300°C 200°C- 300°C YES N/A ER 502 E502

RPT/WPS-024 RPT/PQR-024 SA213

227 Q PR 022 _ Rev.B2 IFR Welding Procedure Specification

- - - - -

S-ar putea să vă placă și

- WPS-2 InchDocument2 paginiWPS-2 InchKarthikeyan MpÎncă nu există evaluări

- Stainless steel welding procedure qualification recordDocument1 paginăStainless steel welding procedure qualification recordchandraÎncă nu există evaluări

- Aws A5.11 - A5.11m - 2010Document53 paginiAws A5.11 - A5.11m - 2010Claudio SampaioÎncă nu există evaluări

- Inspection & Test Plan For Fabrication, Erection & Testing of Piping SystemDocument4 paginiInspection & Test Plan For Fabrication, Erection & Testing of Piping SystemAbdullah Al Jubayer100% (4)

- Weldspec ASME PQRDocument2 paginiWeldspec ASME PQRSunil KumarÎncă nu există evaluări

- Glycol Reboiler Still Welding Procedure Specification (PWPSDocument2 paginiGlycol Reboiler Still Welding Procedure Specification (PWPSstdshopÎncă nu există evaluări

- Welding Electrodes Classification and Selection for Thermal Power PlantsDocument2 paginiWelding Electrodes Classification and Selection for Thermal Power Plantskiki270977Încă nu există evaluări

- BS 638-4Document24 paginiBS 638-4Santhosh V RaajendiranÎncă nu există evaluări

- Ultimate Guide To Cast Iron WeldingDocument16 paginiUltimate Guide To Cast Iron WeldingMohamedÎncă nu există evaluări

- List WPS For Piping Package-B. Rev.0.1 (Att-B)Document14 paginiList WPS For Piping Package-B. Rev.0.1 (Att-B)Ferdie OSÎncă nu există evaluări

- Weld Book - Flare KOD - Structure Rev ADocument169 paginiWeld Book - Flare KOD - Structure Rev ARajesh K PillaiÎncă nu există evaluări

- WELDING BOOK SUMMARY FOR PIPING PROCESS REFERENCEDocument6 paginiWELDING BOOK SUMMARY FOR PIPING PROCESS REFERENCEFerdie OSÎncă nu există evaluări

- PQRDocument2 paginiPQRafqzfieÎncă nu există evaluări

- AWS A5.32-1997 Specification For Welding Shielding GasesDocument26 paginiAWS A5.32-1997 Specification For Welding Shielding GasesIngrid Elena Pardo CadenasÎncă nu există evaluări

- Qa&qc-Log-04 PQR Log Sheet With CSD CommentsDocument2 paginiQa&qc-Log-04 PQR Log Sheet With CSD CommentsasiqÎncă nu există evaluări

- Welding Electrode Specification ChartDocument2 paginiWelding Electrode Specification ChartMahesh Kumar100% (2)

- Wps - Asme Ix - Gtaw - Plat SteDocument6 paginiWps - Asme Ix - Gtaw - Plat SteMuhammad Fitransyah Syamsuar PutraÎncă nu există evaluări

- PQRDocument2 paginiPQRalokbdasÎncă nu există evaluări

- GMAW welding parameters for SS400 pipeDocument2 paginiGMAW welding parameters for SS400 pipeAnonymous zfC1zo9C100% (1)

- QAP For Ducting V1 R0Document1 paginăQAP For Ducting V1 R0Hema NandhÎncă nu există evaluări

- Inspection & Test Plan: For Non Slam Check Valve (Axial Type)Document4 paginiInspection & Test Plan: For Non Slam Check Valve (Axial Type)Jeroan AyamÎncă nu există evaluări

- Welding Procedure Specification: Aws D.1.1 / D.1.1 M - Structural Welding Code - SteelDocument3 paginiWelding Procedure Specification: Aws D.1.1 / D.1.1 M - Structural Welding Code - SteelBudi Setia RahmanÎncă nu există evaluări

- Replace No.3 API Oil Separator Project: Daily Fitup ReportDocument20 paginiReplace No.3 API Oil Separator Project: Daily Fitup Reportsajay2010Încă nu există evaluări

- Weld Map Details Joints and SpecificationsDocument22 paginiWeld Map Details Joints and Specifications9913489806100% (2)

- MIG Welding PWPSDocument1 paginăMIG Welding PWPSelectronicmail2ughf6525Încă nu există evaluări

- eni Iraq b.v. - Zubair Oil Field Development Project Work Package Welder Qualification CertificateDocument1 paginăeni Iraq b.v. - Zubair Oil Field Development Project Work Package Welder Qualification CertificateSamer BayatiÎncă nu există evaluări

- Condensate Tank WELDING LOGDocument6 paginiCondensate Tank WELDING LOGhasan shahriarÎncă nu există evaluări

- Material GradesDocument1 paginăMaterial GradesshisÎncă nu există evaluări

- WPS-6 Doc Rev00 On 17 Sept 2018 Final FormatDocument3 paginiWPS-6 Doc Rev00 On 17 Sept 2018 Final FormatSWARUP CHUGUGLEÎncă nu există evaluări

- Welder Visual Inspection ReportsDocument24 paginiWelder Visual Inspection ReportsKyÎncă nu există evaluări

- Procedure Qualification Record (PQR) : Jl. Brigjend Katamso KM 5.6 Tanjung Uncang - Batam IndonesiaDocument2 paginiProcedure Qualification Record (PQR) : Jl. Brigjend Katamso KM 5.6 Tanjung Uncang - Batam IndonesiaMulPXÎncă nu există evaluări

- European Standard Norme Européenne Europäische Norm: Qualification Test of Welders - Fusion Welding - Part 6: Cast IronDocument24 paginiEuropean Standard Norme Européenne Europäische Norm: Qualification Test of Welders - Fusion Welding - Part 6: Cast IronUmur KaçamaklıÎncă nu există evaluări

- Three Weeks Plan Mechanical Works For Week#262728Document4 paginiThree Weeks Plan Mechanical Works For Week#262728Abdullah Al JubayerÎncă nu există evaluări

- Welding Project Report PDFDocument61 paginiWelding Project Report PDFEzzadin Baban50% (6)

- F07-Visual Inspection Report NEWDocument1 paginăF07-Visual Inspection Report NEWmohd as shahiddin jafriÎncă nu există evaluări

- Wps & PQR and Weld Map and Test PlanDocument67 paginiWps & PQR and Weld Map and Test PlanmarghoobÎncă nu există evaluări

- Welding Map: PROJECT: Repair of Damaged Pipelines & Process Lines - MARETAP - EZZAOUIA FIELDDocument1 paginăWelding Map: PROJECT: Repair of Damaged Pipelines & Process Lines - MARETAP - EZZAOUIA FIELDMajdi Jerbi100% (1)

- Wps Mma PipeDocument2 paginiWps Mma PipeDimitris NikouÎncă nu există evaluări

- Welders MatrixDocument1 paginăWelders Matrixalinor_tn100% (1)

- Welding Procedure Specification (WPS) ASME CODE: BPVC Section IX, Edition 2015/ B31.3, Edition 2014 & ABS 2016 PART 2Document3 paginiWelding Procedure Specification (WPS) ASME CODE: BPVC Section IX, Edition 2015/ B31.3, Edition 2014 & ABS 2016 PART 2Ahmad DanielÎncă nu există evaluări

- JNK Heaters Co - LTD: Ferrite Test ReportDocument1 paginăJNK Heaters Co - LTD: Ferrite Test ReportUzorÎncă nu există evaluări

- WPS Format For Asme Ix - Wps - Gtaw SmawDocument1 paginăWPS Format For Asme Ix - Wps - Gtaw SmawThe Welding Inspections Community100% (1)

- QW 483Document2 paginiQW 483delta lab sangliÎncă nu există evaluări

- WPS and PQR of GMAWDocument8 paginiWPS and PQR of GMAW魏利强Încă nu există evaluări

- GTAW Welding Process ParametersDocument12 paginiGTAW Welding Process Parametersmiteshpatel191Încă nu există evaluări

- WPS FGPDocument1 paginăWPS FGPShabbir HussainÎncă nu există evaluări

- TES-WELD-API - Welding of Pipelines and Facilities SpecificationDocument37 paginiTES-WELD-API - Welding of Pipelines and Facilities SpecificationFederico QuintanaÎncă nu există evaluări

- SURIA ENGINEERING WELDING PROCEDURE SPECIFICATION (WPS) FOR GTAW & SMAWDocument1 paginăSURIA ENGINEERING WELDING PROCEDURE SPECIFICATION (WPS) FOR GTAW & SMAWsuria qaqcÎncă nu există evaluări

- WPS ListDocument2 paginiWPS ListAdeel OmerÎncă nu există evaluări

- PT Kuwera Karya Me: PanduDocument2 paginiPT Kuwera Karya Me: PanduGalang Pratama PutraÎncă nu există evaluări

- Company Logo Added to QAP DocumentDocument4 paginiCompany Logo Added to QAP Documentmanoj thakkar100% (1)

- WPS API1104 A516 GR 70Document1 paginăWPS API1104 A516 GR 70Erick HoganÎncă nu există evaluări

- 1662 15Document117 pagini1662 15RajamanikkamÎncă nu există evaluări

- Offshore Marinetech PVT - LTD: Electrode Baking RegisterDocument3 paginiOffshore Marinetech PVT - LTD: Electrode Baking RegisterPrathamesh OmtechÎncă nu există evaluări

- S-8018 B2Document5 paginiS-8018 B2Abhishek AnandÎncă nu există evaluări

- WPQ Sample PrintoutDocument1 paginăWPQ Sample PrintoutKannan VelÎncă nu există evaluări

- Approved Welding Procedures List RegioDocument2 paginiApproved Welding Procedures List Regiogabriel__regio100% (1)

- Wps GT 9b Cvn90 Rev 1 PDFDocument6 paginiWps GT 9b Cvn90 Rev 1 PDFM. Zaki RahmaniÎncă nu există evaluări

- Form UT, MT, PT, RTDocument5 paginiForm UT, MT, PT, RTLuong Ho Vu100% (1)

- Procedure Qualification Record (PQR) Pipeline: Metal Nonfusing Metal Nonmetallic OtherDocument2 paginiProcedure Qualification Record (PQR) Pipeline: Metal Nonfusing Metal Nonmetallic OtherPanneer SelvamÎncă nu există evaluări

- QC FORMDocument3 paginiQC FORMRicardo LourençoÎncă nu există evaluări

- Cahier de Soudage G 11950 - Ver B - WPS 14Document1 paginăCahier de Soudage G 11950 - Ver B - WPS 14YassineElabdÎncă nu există evaluări

- Welding Procedure Specification For GTAW & GMAWDocument4 paginiWelding Procedure Specification For GTAW & GMAWanh thoÎncă nu există evaluări

- IRCLASS Systems and Solutions Pvt. Ltd. (A Wholy Owned Subsidiary of Indian Register of Shipping)Document4 paginiIRCLASS Systems and Solutions Pvt. Ltd. (A Wholy Owned Subsidiary of Indian Register of Shipping)Mostafizur RahmanÎncă nu există evaluări

- Line List: Project: Date Rev. No. Serial No. Doc. Type Discipline Phase Unit Plan/Project/SubDocument1 paginăLine List: Project: Date Rev. No. Serial No. Doc. Type Discipline Phase Unit Plan/Project/SubAli AsadiÎncă nu există evaluări

- Welder Qualification Register 01Document3 paginiWelder Qualification Register 01Andrei UrsacheÎncă nu există evaluări

- WPQR Welding Procedure QualificationDocument3 paginiWPQR Welding Procedure QualificationThanasis KyrgiazoglouÎncă nu există evaluări

- WPS Updated PDFDocument2 paginiWPS Updated PDFRaja Muaz Ahmad KhanÎncă nu există evaluări

- WPS SummaryDocument33 paginiWPS SummaryMidhun K ChandraboseÎncă nu există evaluări

- Eppm-Wps-Jtf-Cs-13 Rev. 0 Gtaw+ FcawDocument18 paginiEppm-Wps-Jtf-Cs-13 Rev. 0 Gtaw+ FcawBassem Ben FrajÎncă nu există evaluări

- Test PackageDocument29 paginiTest PackageAbdullah Al JubayerÎncă nu există evaluări

- Bill of Materials: Roof SheetDocument1 paginăBill of Materials: Roof SheetAbdullah Al JubayerÎncă nu există evaluări

- Width B Edge Bar (EFB-1) : Typ. Plan of Grating (LXB)Document1 paginăWidth B Edge Bar (EFB-1) : Typ. Plan of Grating (LXB)Abdullah Al JubayerÎncă nu există evaluări

- Equipment Installation Plan From 12 11 19 To - 25 11 19Document4 paginiEquipment Installation Plan From 12 11 19 To - 25 11 19Abdullah Al JubayerÎncă nu există evaluări

- Heater Installation Sequence and Plan PDFDocument7 paginiHeater Installation Sequence and Plan PDFAbdullah Al JubayerÎncă nu există evaluări

- WPS & PQR - 04Document17 paginiWPS & PQR - 04Abdullah Al JubayerÎncă nu există evaluări

- WPS & PQR - 05Document17 paginiWPS & PQR - 05Abdullah Al JubayerÎncă nu există evaluări

- Pressure Test Execution Plan Mar 24 Rev.cDocument12 paginiPressure Test Execution Plan Mar 24 Rev.cAbdullah Al JubayerÎncă nu există evaluări

- WPS & PQR GTAW A106 GR.BDocument12 paginiWPS & PQR GTAW A106 GR.BAbdullah Al Jubayer100% (1)

- WPS For GTAW+SMAW A106 Gr. BDocument12 paginiWPS For GTAW+SMAW A106 Gr. BAbdullah Al Jubayer50% (2)

- Structural Steel WPSDocument6 paginiStructural Steel WPSAbdullah Al Jubayer100% (1)

- Nitrogen Blanketing ScheduleDocument1 paginăNitrogen Blanketing ScheduleAbdullah Al JubayerÎncă nu există evaluări

- 3 SmawDocument55 pagini3 SmawPutra Daha PratamaÎncă nu există evaluări

- St. Peter Velle Technical Training Center Inc. No.: Email Add: Office Tel No.: 709-6283/366-5576Document16 paginiSt. Peter Velle Technical Training Center Inc. No.: Email Add: Office Tel No.: 709-6283/366-5576Mark MarasiganÎncă nu există evaluări

- 099 005560 Ew501Document68 pagini099 005560 Ew501dat.luongtuandatÎncă nu există evaluări

- WELDING Is A Fabrication or Sculptural Process That Joins Materials, Usually Metals or Thermoplastics, by CausingDocument8 paginiWELDING Is A Fabrication or Sculptural Process That Joins Materials, Usually Metals or Thermoplastics, by CausingNaeemrindÎncă nu există evaluări

- Welding Abstracts Dec 2011Document86 paginiWelding Abstracts Dec 2011Avinash KumarÎncă nu există evaluări

- A5 32-A5 32mPVDocument7 paginiA5 32-A5 32mPVAnonymous 1GK9Hxp5YKÎncă nu există evaluări

- Pg-Gmaw-Xi TPLDocument30 paginiPg-Gmaw-Xi TPLmjsolihinÎncă nu există evaluări

- Internship-Report Fahad NewDocument50 paginiInternship-Report Fahad NewAbdullah LiaqatÎncă nu există evaluări

- UTP For LNG PDFDocument5 paginiUTP For LNG PDFkamals55Încă nu există evaluări

- SRM University Project ReportDocument56 paginiSRM University Project ReportTony Joanne67% (3)

- Smaw 9 Summative Test Q1Document2 paginiSmaw 9 Summative Test Q1Jose Intraboy Arais Tabugoc Jr.Încă nu există evaluări

- Industrial Summer Training Report at ONGC Mehsana AssetDocument29 paginiIndustrial Summer Training Report at ONGC Mehsana AssetPrince PatelÎncă nu există evaluări

- Chapter01 PDFDocument12 paginiChapter01 PDFRanjanÎncă nu există evaluări

- Zoznam NoriemDocument4 paginiZoznam NoriemPeter TvardzíkÎncă nu există evaluări

- Cold-Formed Member Joint DesignDocument15 paginiCold-Formed Member Joint DesignmabuhamdÎncă nu există evaluări

- 1.1 Submerged Arc Welding: Fig. 1.1 SAW Setup DiagramDocument54 pagini1.1 Submerged Arc Welding: Fig. 1.1 SAW Setup DiagramMayank Girdhar So CoolÎncă nu există evaluări

- UntitledDocument640 paginiUntitledkumar3727Încă nu există evaluări

- Wps No. 0 Rev. No. 19: Asme Section Ix Welding Procedure SpecificationDocument5 paginiWps No. 0 Rev. No. 19: Asme Section Ix Welding Procedure SpecificationAmit ChapagainÎncă nu există evaluări

- Trainings For 2021Document14 paginiTrainings For 2021greatcenter registrarÎncă nu există evaluări

- Lincoln Electric Svm170-A Power Mig 255cDocument109 paginiLincoln Electric Svm170-A Power Mig 255cBuitinės Technikos RemontasÎncă nu există evaluări

- Solar Panel CleanerDocument25 paginiSolar Panel CleanerE7011 BHAVYA PRATAP SINGHÎncă nu există evaluări

- List of Welding Processes - Wikipedia, The Free EncyclopediaDocument6 paginiList of Welding Processes - Wikipedia, The Free Encyclopediaangelakopoulou6791Încă nu există evaluări