Documente Academic

Documente Profesional

Documente Cultură

Daily Plant Inspection Checklist

Încărcat de

Feroz Gull0 evaluări0% au considerat acest document util (0 voturi)

684 vizualizări2 paginiTitlu original

DAILY PLANT INSPECTION CHECKLIST.doc

Drepturi de autor

© © All Rights Reserved

Formate disponibile

DOC, PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca DOC, PDF, TXT sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

684 vizualizări2 paginiDaily Plant Inspection Checklist

Încărcat de

Feroz GullDrepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca DOC, PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 2

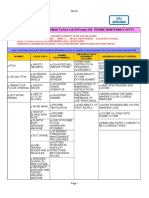

DAILY PLANT INSPECTION CHECKLIST

DATE: COMPANY NAME: Collective Civil Pty Ltd

WORKING FOR: JOB SITE:

PLANT DESCRIPTION: REGISTRATION or PERMIT NO:

MAKE & MODEL: EXPIRY DATE:

SERIAL NO: HOUR METRE/ KM READING:

PLANT OPERATOR DAILY SAFETY CHECKLIST:

Operators are required to check the following items before commencing work. These

records form the basis of a plant maintenance procedure and will be subject to random

inspection. Keep record with machine at all times.

Fault Item not

OK, no obvious defect identified, use N/A applicable to

report below machine or

operator

BEFORE COMMENCING OPERATIONS CHECK M T W T F S S

Cabin- Access, egress seating, seatbelts, loose objects, controls, rops or fops

Visibility- windscreen, windows, wipes, washers, mirrors

Electrical system- lights, amber beacon, horn, rev travel alarm

Hydraulics- rams, hoses, leaks, wear

Leaks- engine, transmission, final drives, cooling systems

Brakes- emergency and service

Neutral start

Compulsory signs, reflective tape, reflectors

Misc- air con, fire extinguisher

Damage to- panels / guards- cracks to chassis/frame/body.

Wheels, tyres, tracks- wear/tension/pressure

Hitch (safety pin) - wear

Articulated joint/linkage

Environmental spill kit

Daily checklist in machine- plant security information list

Plant security

Operators Operators Drivers Plant Induction card Track safety Supervisors

Name Initials Licence no operators no Awar. Cert no Signature

ticket no

Details of faults or defects and action taken:

Fault reported to________________ Position ____________________Date ________________

Does fault constitute a safety hazard YES/NO

Does machine require immediate repair? Y/N Does machine require immediate repair? Y/N

If yes to either PARK MACHINE UP. Contact the hirer or supervisor and plant operator- detail

inside front cover. Machine should not be used until supervisor or plant operator gives clearance

for use.

S-ar putea să vă placă și

- Daily Plant Inspection ChecklistDocument2 paginiDaily Plant Inspection ChecklistFeroz Gull100% (1)

- Check ListDocument88 paginiCheck ListRaafat SaadÎncă nu există evaluări

- Chiller Daily ChecklistDocument1 paginăChiller Daily ChecklistamuronegaduÎncă nu există evaluări

- Satip-P-103-01 Rev 1Document6 paginiSatip-P-103-01 Rev 1AdamuÎncă nu există evaluări

- Conveyor Check ListDocument2 paginiConveyor Check Listh1549697100% (1)

- SHEM-SP-08.10 Work Permits ProcedureDocument74 paginiSHEM-SP-08.10 Work Permits ProcedureAjith Kumar AjithÎncă nu există evaluări

- Borang Pemeriksaan Air KompressorDocument1 paginăBorang Pemeriksaan Air KompressorAndara Asifa YudianaÎncă nu există evaluări

- 238 Preventive Check Sheet of Press Brake MachineDocument4 pagini238 Preventive Check Sheet of Press Brake MachineAjay100% (2)

- Risk Assessment - Hot Water BoilersDocument4 paginiRisk Assessment - Hot Water BoilersUgonnaÎncă nu există evaluări

- Dust Collector Service ChecklistDocument1 paginăDust Collector Service ChecklistFatemeh AziziÎncă nu există evaluări

- Transformer Preventive Maintenance ChecklistDocument7 paginiTransformer Preventive Maintenance Checklistdhannaraj3dewasiÎncă nu există evaluări

- Erection ProtocolsDocument17 paginiErection ProtocolsSam50% (2)

- 7 QC ToolsDocument155 pagini7 QC Toolswintoday01Încă nu există evaluări

- Drill Machine - ChecklistDocument1 paginăDrill Machine - ChecklistarkonamtfplÎncă nu există evaluări

- Daily Checklist For DGDocument2 paginiDaily Checklist For DG7Days Facility ManagementÎncă nu există evaluări

- Saudi Aramco Inspection Checklist: Flow - Positive Displacement Meter - Material Receiving SAIC-J-6108 1-Oct-05 InstDocument3 paginiSaudi Aramco Inspection Checklist: Flow - Positive Displacement Meter - Material Receiving SAIC-J-6108 1-Oct-05 InstAdel KlkÎncă nu există evaluări

- Checklist Compressor - SAMPLEDocument1 paginăChecklist Compressor - SAMPLESUKhan100% (1)

- Ire Alarm System Pre-Test and Acceptance Test ChecklistDocument2 paginiIre Alarm System Pre-Test and Acceptance Test ChecklisthÎncă nu există evaluări

- Generator Start Up Checklist 1 0Document2 paginiGenerator Start Up Checklist 1 0quynh_nguyen017724Încă nu există evaluări

- Powder Coating ProcedureDocument1 paginăPowder Coating Procedurenastyn-1Încă nu există evaluări

- Sop For HydrotestDocument3 paginiSop For HydrotestShyam QCÎncă nu există evaluări

- Fire Alarm Panel Check ListDocument1 paginăFire Alarm Panel Check Listfairoos aliÎncă nu există evaluări

- PPM Task Sheet - MPGSDocument4 paginiPPM Task Sheet - MPGSJacobÎncă nu există evaluări

- Daily Machine Check List - Drill TapDocument2 paginiDaily Machine Check List - Drill Tapshailendra5508110Încă nu există evaluări

- 3.3.9 Air Compressor Maintenance LogDocument1 pagină3.3.9 Air Compressor Maintenance Logkhrayzie bhoneÎncă nu există evaluări

- Advanced Oilfield Technology Company LLC: Work ProcedureDocument6 paginiAdvanced Oilfield Technology Company LLC: Work ProcedureAhmed M. AbdelazizÎncă nu există evaluări

- Cutting Machine Check Sheet: Machine Set No.: Department: Contractor Name: Last Inspection Date: Inspection DateDocument1 paginăCutting Machine Check Sheet: Machine Set No.: Department: Contractor Name: Last Inspection Date: Inspection Datepartha100% (1)

- Check List For Mobile Air CompressorDocument1 paginăCheck List For Mobile Air CompressorSaravanan JambunathanÎncă nu există evaluări

- Stacker Preventive Maintenance Weekly: Clean and InspectDocument1 paginăStacker Preventive Maintenance Weekly: Clean and InspectFabio Gonzalez100% (1)

- Rock Breaker Self ChecklistDocument1 paginăRock Breaker Self ChecklistNair R RakeshÎncă nu există evaluări

- Bearing Housing Assembly Procedure EXTERNALDocument10 paginiBearing Housing Assembly Procedure EXTERNALAlejandroZegarraÎncă nu există evaluări

- Template-Post Shutdown ReportDocument3 paginiTemplate-Post Shutdown Reportarief bayuÎncă nu există evaluări

- E 001B1 MotorDocument2 paginiE 001B1 MotorBhihi RajaÎncă nu există evaluări

- Itr Ew 01a - EngDocument2 paginiItr Ew 01a - Engwassim nasriÎncă nu există evaluări

- Sop Welder TigDocument2 paginiSop Welder TigShahid Raza100% (1)

- 318-Welding Machine Inspection Report Monthly Rev 000Document1 pagină318-Welding Machine Inspection Report Monthly Rev 000francisÎncă nu există evaluări

- Lockout/tagout Inspection FormDocument2 paginiLockout/tagout Inspection Formerofik72Încă nu există evaluări

- Compressor ChecklistDocument5 paginiCompressor ChecklistJuanPabloAlvarezÎncă nu există evaluări

- PUMP Testing SheetDocument3 paginiPUMP Testing SheetAlan Tan Y RÎncă nu există evaluări

- Sop OPOP Eng 007 - Operating Diesel Bowsers and TanksDocument8 paginiSop OPOP Eng 007 - Operating Diesel Bowsers and Tankscontrax8100% (1)

- STD-QD-011D Visual Inspection Checklist PipingDocument4 paginiSTD-QD-011D Visual Inspection Checklist PipingtayyabÎncă nu există evaluări

- Commissioning Procedures For ConveyorsDocument2 paginiCommissioning Procedures For ConveyorsNur KhamidÎncă nu există evaluări

- 13-OM-QC-PL-MS-06 - MS FIXED TUBE TYPE EXCHANGER'S INSPECTION & CLEANING (Rev.00)Document7 pagini13-OM-QC-PL-MS-06 - MS FIXED TUBE TYPE EXCHANGER'S INSPECTION & CLEANING (Rev.00)SANDEEP100% (1)

- Electrical Pump & Motor Inspection ChecklistDocument1 paginăElectrical Pump & Motor Inspection ChecklistJIJESH GOKULDASÎncă nu există evaluări

- Eil Permit For Energy Isolation & De-IsolationDocument1 paginăEil Permit For Energy Isolation & De-IsolationAvesh ChauahanÎncă nu există evaluări

- Sop Hydraulic Punch and ShearDocument1 paginăSop Hydraulic Punch and ShearBorislav VulićÎncă nu există evaluări

- JSA - Main Turbine Lub Oil Pumps - OHDocument2 paginiJSA - Main Turbine Lub Oil Pumps - OHShubham Gupta0% (1)

- 23-022 Installation Procedures ValvesDocument6 pagini23-022 Installation Procedures ValvesAli Khalid QureshiÎncă nu există evaluări

- Form 10 For Lifting Tools and Tackles Like Crane Chain Pully Block Hoist Sling Belt EtcDocument1 paginăForm 10 For Lifting Tools and Tackles Like Crane Chain Pully Block Hoist Sling Belt EtcHEMANT RAMJI100% (1)

- 1E-Motors Inspection ChecklistDocument1 pagină1E-Motors Inspection ChecklistAnonymous iiUUgwÎncă nu există evaluări

- 26 - Welding Machine ChecklistDocument1 pagină26 - Welding Machine ChecklistZeeshan AbbasiÎncă nu există evaluări

- PETI ChecklistDocument1 paginăPETI Checklistwan nazeriÎncă nu există evaluări

- Generator Set Pre-Start-Up ChecklistDocument2 paginiGenerator Set Pre-Start-Up Checklist4685752Încă nu există evaluări

- Form 11Document8 paginiForm 11Chandrasekhar Sonar100% (1)

- ACHE - Installation, Erection, Start Up & Commissioning Check ListDocument2 paginiACHE - Installation, Erection, Start Up & Commissioning Check Listrahim_335162856100% (1)

- Daily Plant Inspection ChecklistDocument2 paginiDaily Plant Inspection ChecklistMuthu KumarÎncă nu există evaluări

- Daily Plant Inspection ChecklistDocument1 paginăDaily Plant Inspection Checklist8460272421Încă nu există evaluări

- Daily Plant Inspection ChecklistDocument1 paginăDaily Plant Inspection Checklistemilyarcher281991Încă nu există evaluări

- Zoom Boom Daily Inspection ChecklistDocument1 paginăZoom Boom Daily Inspection ChecklistAbdejelil ChokriÎncă nu există evaluări

- SWP-SF010A - 11 Daily Boom - Scissor Insp Rev ADocument2 paginiSWP-SF010A - 11 Daily Boom - Scissor Insp Rev ACliffordÎncă nu există evaluări

- Problem For Setting 4. Bush Damage: 1. M CP#03 Delivery Cylinder Piston Damage 2. Hydraulic Boom Pump ProblemDocument1 paginăProblem For Setting 4. Bush Damage: 1. M CP#03 Delivery Cylinder Piston Damage 2. Hydraulic Boom Pump ProblemFeroz GullÎncă nu există evaluări

- Valve Clearance Should Be Adjusted When The Engine Is Cool (Below 140 F or 60 C)Document2 paginiValve Clearance Should Be Adjusted When The Engine Is Cool (Below 140 F or 60 C)Feroz GullÎncă nu există evaluări

- Work Shop RepairDocument7 paginiWork Shop RepairFeroz GullÎncă nu există evaluări

- Detail of Tyre Brust/ Damage at Mr. Waqas's Site Date Gate Pass # TM# Tire DamgeDocument2 paginiDetail of Tyre Brust/ Damage at Mr. Waqas's Site Date Gate Pass # TM# Tire DamgeFeroz GullÎncă nu există evaluări

- Satisfactory Note Nov 2019Document5 paginiSatisfactory Note Nov 2019Feroz GullÎncă nu există evaluări

- USDP Shehzore02Document39 paginiUSDP Shehzore02Feroz GullÎncă nu există evaluări

- cp#03Document2 paginicp#03Feroz GullÎncă nu există evaluări

- Long Break Down DetailsDocument2 paginiLong Break Down DetailsFeroz GullÎncă nu există evaluări

- Over Time 02Document2 paginiOver Time 02Feroz GullÎncă nu există evaluări

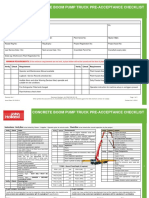

- JH FRM Pae 001 28 Concrete Boom Pump Truck Plant Pre Acceptance ChecklistDocument2 paginiJH FRM Pae 001 28 Concrete Boom Pump Truck Plant Pre Acceptance ChecklistFeroz Gull100% (1)

- Tire Burstage ReportDocument2 paginiTire Burstage ReportFeroz GullÎncă nu există evaluări

- Tyre ReportDocument10 paginiTyre ReportFeroz GullÎncă nu există evaluări

- Plant, Machinery & Equipment Breakdown ReportDocument2 paginiPlant, Machinery & Equipment Breakdown ReportFeroz Gull100% (3)

- Lucky Paragon Readymix LTD Daily Issuance Summary Store DepartmentDocument8 paginiLucky Paragon Readymix LTD Daily Issuance Summary Store DepartmentFeroz GullÎncă nu există evaluări

- Problem For Setting 4. Bush Damage: 1. M CP#03 Delivery Cylinder Piston Damage 2. Hydraulic Boom Pump ProblemDocument1 paginăProblem For Setting 4. Bush Damage: 1. M CP#03 Delivery Cylinder Piston Damage 2. Hydraulic Boom Pump ProblemFeroz GullÎncă nu există evaluări

- Plant, Machinery & Equipment Breakdown ReportDocument2 paginiPlant, Machinery & Equipment Breakdown ReportFeroz GullÎncă nu există evaluări

- Over Time SheetDocument4 paginiOver Time SheetFeroz GullÎncă nu există evaluări

- Plant, Machinery & Equipment Breakdown ReportDocument2 paginiPlant, Machinery & Equipment Breakdown ReportFeroz GullÎncă nu există evaluări

- Plant, Machinery & Equipment Breakdown ReportDocument2 paginiPlant, Machinery & Equipment Breakdown ReportFeroz Gull100% (1)

- Over Time SheetDocument4 paginiOver Time SheetFeroz GullÎncă nu există evaluări

- Problem For Setting 4. Bush Damage: 1. M CP#03 Delivery Cylinder Piston Damage 2. Hydraulic Boom Pump ProblemDocument1 paginăProblem For Setting 4. Bush Damage: 1. M CP#03 Delivery Cylinder Piston Damage 2. Hydraulic Boom Pump ProblemFeroz GullÎncă nu există evaluări

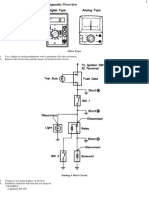

- Reading ABS CodesDocument3 paginiReading ABS CodesJoao SilvaÎncă nu există evaluări

- 3TNE84Document43 pagini3TNE84Indo BinaDiesel100% (2)

- Chapt1 - Classification & ParametersDocument94 paginiChapt1 - Classification & ParameterspeterÎncă nu există evaluări

- 16-01 Present Perfect Car Vocabulary, Transportation Conversation, Listening and ActivitiesDocument156 pagini16-01 Present Perfect Car Vocabulary, Transportation Conversation, Listening and ActivitiesTeacher GabiÎncă nu există evaluări

- Subaru Justy L3-1.2 2wd Carb Repair PDFDocument557 paginiSubaru Justy L3-1.2 2wd Carb Repair PDFThezoharKabbalahÎncă nu există evaluări

- Maintenance of Railway TrackDocument39 paginiMaintenance of Railway TrackvennillaÎncă nu există evaluări

- Chapter 4 5 6 - Highway Safety Manual - 1st Edition - 2010Document135 paginiChapter 4 5 6 - Highway Safety Manual - 1st Edition - 2010miradhilaa100% (1)

- DOT Road Closure ReportDocument7 paginiDOT Road Closure ReportJeff MorrisÎncă nu există evaluări

- 101 Introduction To Safe Driving EnglishDocument42 pagini101 Introduction To Safe Driving EnglishDevang TailorÎncă nu există evaluări

- BMW N47D20 EngineDocument4 paginiBMW N47D20 EngineCallum Smith100% (3)

- Yamaha 135Document399 paginiYamaha 135John Francis CerezoÎncă nu există evaluări

- Diesel DiagnosticsDocument22 paginiDiesel DiagnosticsCesarÎncă nu există evaluări

- Fires in Vehicle-FIVE 2012 PDFDocument324 paginiFires in Vehicle-FIVE 2012 PDFmomoÎncă nu există evaluări

- Rorty Locost IRSAssemblyDocument45 paginiRorty Locost IRSAssemblyjeepnjay7502100% (1)

- Combination Meter: D1 (A), D2 (B)Document10 paginiCombination Meter: D1 (A), D2 (B)PeterÎncă nu există evaluări

- Reading-Comprehension Teacher British Innovation in TransportdocDocument4 paginiReading-Comprehension Teacher British Innovation in TransportdocAngel Angeleri-priftis.Încă nu există evaluări

- Paris Connections: Charles de Gaulle AirportDocument8 paginiParis Connections: Charles de Gaulle AirportmittentenÎncă nu există evaluări

- Minimum Standards For P.D 975 & B.P 220Document5 paginiMinimum Standards For P.D 975 & B.P 220coneyquÎncă nu există evaluări

- Repor 2 PDFDocument344 paginiRepor 2 PDFHanna TbÎncă nu există evaluări

- BPW VB-axles Specs. EngDocument4 paginiBPW VB-axles Specs. EngakangucaiÎncă nu există evaluări

- GTR R35 FSU-Front SuspensionDocument21 paginiGTR R35 FSU-Front Suspensiondinodyno100% (1)

- Morth CircularDocument5 paginiMorth Circularshiva5059Încă nu există evaluări

- Picanto Automatic Transaxle System.Document2 paginiPicanto Automatic Transaxle System.Esquisof100% (1)

- XGD 435 Bus - 02 - Braking System Assembly Quality Inspection Report - 03.06.2022Document5 paginiXGD 435 Bus - 02 - Braking System Assembly Quality Inspection Report - 03.06.2022MASEDE JOBÎncă nu există evaluări

- PSB-221 Worker Hit by A Reversing VehicleDocument1 paginăPSB-221 Worker Hit by A Reversing Vehiclejayand_netÎncă nu există evaluări

- Great Wall Parts CatalogueDocument6 paginiGreat Wall Parts CatalogueВенци Александров100% (1)

- ZLJ5455V3.5 Spare Parts CatalogDocument268 paginiZLJ5455V3.5 Spare Parts CatalogDemerson Tavares0% (1)

- Paver Finisher: Engine Technical SpecsDocument2 paginiPaver Finisher: Engine Technical SpecszlÎncă nu există evaluări

- A Technical Seminar On: Suspension SystemDocument24 paginiA Technical Seminar On: Suspension SystemRanjan suvarnaÎncă nu există evaluări