Documente Academic

Documente Profesional

Documente Cultură

Anchor Bolt Emdedded Length-BP-2

Încărcat de

Narasimha AkkammagariDescriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Anchor Bolt Emdedded Length-BP-2

Încărcat de

Narasimha AkkammagariDrepturi de autor:

Formate disponibile

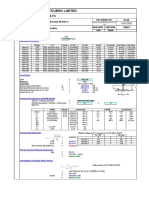

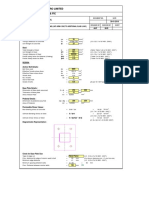

STAAD OUTPUT REACTIONS Paste Staad max min Reactions in Cell A8 Tensile stre

Shear stress(X dir)

Shear stress( Shear stress Checks Stress

Horizontal VerticalHorizontalMoment in bolt - 'ft' in bolt - 'fs' in bolt - 'fs' in bolt - 'fs'Combinedincreament

Node L/C Fx kN Fy kN Fz kN Mx kN-mMy kN-mMz kN-m (N/mm2) (N/mm2) (N/mm2) (N/mm2) stresses Factor

Max Fx 42 255 (1.5DL+1.5WL+Z(S)) 87.388 625.59 -95.814 0 0 0 0.00 61.52 67.45 91.29 - 1.000

Min Fx 41 251 (1.5DL+1.5WL+X(S)) -86.958 623.9 -95.79 0 0 0 0.00 61.22 67.43 91.08 - 1.000

Max Fy 42 255 (1.5DL+1.5WL+Z(S)) 87.388 625.59 -95.814 0 0 0 0.00 61.52 67.45 91.29 - 1.000

Min Fy 41244 (1.2DL+1.2LL+0.53CL2+1.2WL+Z(P))52.88 -81.704 -136.39 0 0 0 57.52 37.23 96.02 102.98 0.088 1.000

Max Fz 59 252 (1.5DL+1.5WL+X(P)) -77.289 562.67 170.77 0 0 0 0.00 54.41 120.22 131.96 - 1.000

Min Fz 42 256 (1.5DL+1.5WL+Z(P)) 81.661 580.47 -170.78 0 0 0 0.00 57.49 120.23 133.26 - 1.000

Max Mx 41 201 (1.5DL+1.5LL+1.05CL1) -5.842 171.49 -1.493 0 0 0 0.00 4.11 1.05 4.24 - 1.000

Min Mx 41 201 (1.5DL+1.5LL+1.05CL1) -5.842 171.49 -1.493 0 0 0 0.00 4.11 1.05 4.24 - 1.000

Max My 41 201 (1.5DL+1.5LL+1.05CL1) -5.842 171.49 -1.493 0 0 0 0.00 4.11 1.05 4.24 - 1.000

Min My 41 201 (1.5DL+1.5LL+1.05CL1) -5.842 171.49 -1.493 0 0 0 0.00 4.11 1.05 4.24 - 1.000

Max Mz 41 201 (1.5DL+1.5LL+1.05CL1) -5.842 171.49 -1.493 0 0 0 0.00 4.11 1.05 4.24 - 1.000

Min Mz 41 201 (1.5DL+1.5LL+1.05CL1) -5.842 171.49 -1.493 0 0 0 0.00 4.11 1.05 4.24 - 1.000

DESIGN CALCULATIONS REFERENCES /

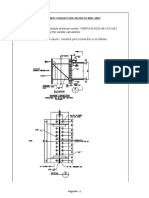

ANCHOR BOLT-EMBEDDED LENGTH REMARKS

Nodes:

ANCHOR BOLT BP-2 LOCATION:SITARAMA LIS PACKAGE-V

CONFIGURATION OF BOLTS

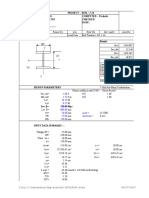

Dia. of Bolt (Designed For Tension) f = 24 mm

Total No of Bolts N = 4 No's

Net area of Bolts on one side As2 = 1420.50253425 mm2

Total net area of the bolts = 1420.50253425 mm2

DESIGN CALCULATIONS REFERENCES /

ANCHOR BOLT-EMBEDDED LENGTH REMARKS

CONCRETE

Characteristic compressive strength Fck = 30 N/mm2

Design bond stress in tension, = 1.5 Cl.26.2.1.1 of IS: 456 - 2000

Allowable Bending stress in concrete scbc = 10 N/mm2 Table 21 of IS: 456

Modulur ratio m = 8 Cl.B-2.1.2 of IS:456

Allowable Bearing stress in concrete 0.6Fck = 18 N/mm 2

Cl.7.4.1 of IS: 800 - 2007

BOLTS:

Grade of bolt = Gr.8.8

Allowable Tension capacity of bolt pt = 576.00 N/mm2 Cl. 10.3.5 of IS:800 - 2007

Allowable Shear capacity of bolt ps = 369.50 N/mm2 Cl. 10.3.3 of IS:800 - 2007

Factor for Combined shear and tension = 1.00 Cl. 10.3.5 of IS: 800 - 2007

( (Fs/Ps)2 + (Ft/Pt)2 < 1.00 )

STEEL:

Yield Strength of Steel (Max) = 250 N/mm2

Design strength of steel in Bearing pyp = 227.272727273 N/mm2

Design strength of steel, in Bending pyb 227.272727273 N/mm2 Cl.5.4.3 of IS:800

Modulus of elasticity of Concrete Ec = 25000 N/mm 2 Cl.6.2.3.1 of IS: 456

Modulus of elasticity of Steel Es = 200000 N/mm2 Cl.1.3 of IS:800

DESIGN OF 24 DIA. ANCHOR BOLT

Yield stress of Steel fy = 250 N/mm2 Anchor

BOLTS: bolt

Grade of the bolt = Gr.8.8

Maximum Tensile stress in bolt due to loads ft = 57.52 N/mm2 Ferrule L1

Maximum Shear stress in bolt due to loads = 57.49 N/mm2

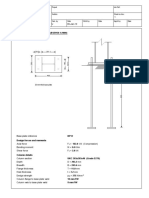

Size of Bolt provided f = 24.00 mm

Total Embedded length of the BOLT L = 740 mm L2

Length of the pocket, L1 L1 190 mm

Embedded length of the bolt below pocket, L2 L2 = 550 mm

Head plate

CONCRETE:

Characteristic compressive strength of concrete, f Fck = 30 N/mm2 Elevation

Permissible concrete bearing pressure 0.6Fck = 18 N/mm2

Permissible Stress in Bond, t bd = 1.5 N/mm2

DESIGN

Plan of Head

Check for tension Plate

Net area of the Bolt As = 355.13 mm2

Maximum Tension in the bolt due to external loads P=Pt x As = 20.43 kN

Allowable Tension in the bolt = 818.21 kN Satisfactory

Check for shear

Maximum shear in the bolt due to external loads = 20.42 kN

Allowable Shear in the bolt = 524.88 kN Satisfactory

Tension transferred by bond through bolt, T 1

T1 = L x tbd x p x f) = 83.69 kN Satisfactory

Size of the Anchor bolt head plate, b = 80 mm

Thickness of head plate, t = 12 mm

b) Tension to be carried by anchor bolt head plate,T 2 = 0.00 kN

Net area of th plate transferring force by bearing = 5948 mm2

= ( b*b - p*(f)2/4 )

Average bearing pressure on the concrete, fc = 0.00 N/mm2

<18.00 N/mm2 Satisfactory

c) Design of Head plate:

Maximum BM per mm width of plate = fc*(b/2-f/2) /2

2

= 0.0 N.mm

Plate modulus- Zp = 1*t /6 2

= 24.00 mm3

Moment capacity of plate, Mc = (pyp*Zp)/1.1 = 5454.54545455 N.mm

= >0 N.mm Satisfactory

Check of Head Plate Bending between Stiffeners:

Maximum BM in Head Plate between stiffeners = 0 N.mm Satisfactory

d) Design of stiffener plate of head plate

Height of the stiffener plate, h = 50 mm

Thickness of stiffener plate, ts = 8 mm

Length of stiffener plate = 0.5*b*sqrt(2) = 56.57 mm

Load on each stiffener plate = T2/4 = 0.00 kN

Cantilever BM in the stiffener = 0.00 kN.m

Plate modulus- Zp = ts*h2/6 = 3333.33333333 mm3

Moment capacity of plate, Mc = (pyp*Zp)/1.1 = 0.76 kN.m

= >0.00 kN.m Satisfactory

S-ar putea să vă placă și

- The Western and Eastern Concepts of SelfDocument3 paginiThe Western and Eastern Concepts of SelfTakumi Shawn Hinata100% (3)

- Splice ConnectionUC 254X254X73Document1 paginăSplice ConnectionUC 254X254X73PavanGuptaÎncă nu există evaluări

- HPE 3PAR StoreServ 20000 Storage Service and Upgrade Guide Service EditionDocument282 paginiHPE 3PAR StoreServ 20000 Storage Service and Upgrade Guide Service Editionben boltÎncă nu există evaluări

- Nissan 720 L4-2.0-Z20 1983-86 Manual PDFDocument641 paginiNissan 720 L4-2.0-Z20 1983-86 Manual PDFEduardo Ariel JuarezÎncă nu există evaluări

- R.R. Rojo and Associates: Anchor Bolt Design The Anchor Rod Design Is AdequateDocument10 paginiR.R. Rojo and Associates: Anchor Bolt Design The Anchor Rod Design Is AdequateMarkÎncă nu există evaluări

- Advance Connection Design - 1Document298 paginiAdvance Connection Design - 1amitkumar8946Încă nu există evaluări

- Beam Column - IS 800Document2 paginiBeam Column - IS 800parishith0% (1)

- 1 - Wind Load CalculationsDocument54 pagini1 - Wind Load CalculationsMASOOD MIYANÎncă nu există evaluări

- Connection ScheduleDocument192 paginiConnection ScheduleNikitaBhattaraiAcharyaÎncă nu există evaluări

- 2 & 4 Column Combined Footing DesignDocument31 pagini2 & 4 Column Combined Footing DesignAamir SuhailÎncă nu există evaluări

- Design of Moment Connection (Welded Type) : Beam Properties: ISB 113.5x113.5x4.5 Column Properties: ISMC 200Document10 paginiDesign of Moment Connection (Welded Type) : Beam Properties: ISB 113.5x113.5x4.5 Column Properties: ISMC 200Rajib MaharjanÎncă nu există evaluări

- Welded ConnectionDocument37 paginiWelded ConnectionRajib MaharjanÎncă nu există evaluări

- Dynamic Analysis and Design of UG WATER TANK TWOWAYDocument35 paginiDynamic Analysis and Design of UG WATER TANK TWOWAYsaiÎncă nu există evaluări

- Connection Design-VijayDocument278 paginiConnection Design-VijayPrabhumk07Încă nu există evaluări

- Bracing V1Document6 paginiBracing V1Shawkat Ali KhanÎncă nu există evaluări

- Welded Moment Connection PDFDocument22 paginiWelded Moment Connection PDFRajasekar MeghanadhÎncă nu există evaluări

- Rigid Connection DesignDocument215 paginiRigid Connection DesignUmer AziqÎncă nu există evaluări

- Design As Per IS 800-2007 (Jindal) (20131011)Document11 paginiDesign As Per IS 800-2007 (Jindal) (20131011)Pruthviraj JuniÎncă nu există evaluări

- Beam Design - 1 6mm Thick 14tk FlangeDocument7 paginiBeam Design - 1 6mm Thick 14tk Flangevrajan1988Încă nu există evaluări

- b2b SpliceDocument21 paginib2b SplicePrasad Dayalamoorthy DÎncă nu există evaluări

- Column Properties:-: Due To UplitDocument2 paginiColumn Properties:-: Due To UplitRohit SinghÎncă nu există evaluări

- DG Consulting EngineersDocument8 paginiDG Consulting EngineersThakshayani SellavelÎncă nu există evaluări

- Warehouse-Base Plate CalculationDocument20 paginiWarehouse-Base Plate CalculationVikram GaikwadÎncă nu există evaluări

- Beam To Beam Bolted Moment End Plate Connection - Sample Calculation (As 4100)Document4 paginiBeam To Beam Bolted Moment End Plate Connection - Sample Calculation (As 4100)Tiam MarapeÎncă nu există evaluări

- Design of Welded Splice Connection (DET.-D-04) : From Staad OutputDocument10 paginiDesign of Welded Splice Connection (DET.-D-04) : From Staad Outputvikas WaghmareÎncă nu există evaluări

- Final Design of Angle Members For 4leged Single Angle TowersDocument65 paginiFinal Design of Angle Members For 4leged Single Angle Towersks_raghuveerÎncă nu există evaluări

- Wind Load-Seismic CalculationsDocument23 paginiWind Load-Seismic CalculationsabbasamuÎncă nu există evaluări

- Conventional-Shed IS800-2007Document369 paginiConventional-Shed IS800-2007jatinÎncă nu există evaluări

- X B BC y F FC Z B C y W WC Z C BC: Designed By: Sheet No: Date: Rev No: Checked By: Revised By: Date: DateDocument123 paginiX B BC y F FC Z B C y W WC Z C BC: Designed By: Sheet No: Date: Rev No: Checked By: Revised By: Date: DateAsaru DeenÎncă nu există evaluări

- Ridge Connection Design RSP-1.Document121 paginiRidge Connection Design RSP-1.Asaru DeenÎncă nu există evaluări

- Steel Section Capacity Check For BeamDocument3 paginiSteel Section Capacity Check For BeamChirag JoshiÎncă nu există evaluări

- Embeddedplate With StudsDocument78 paginiEmbeddedplate With StudsAkhil VNÎncă nu există evaluări

- Beam-Column Moment ConnectionDocument10 paginiBeam-Column Moment Connectionrammohan100% (3)

- Input Data: Subject: Base Plate ConnectionDocument5 paginiInput Data: Subject: Base Plate ConnectionSambhav PoddarÎncă nu există evaluări

- Pinned Base (I-Section) : Design CapacitiesDocument8 paginiPinned Base (I-Section) : Design CapacitiesAwais HameedÎncă nu există evaluări

- Base Plate p1Document128 paginiBase Plate p1Pranav PrabhakarÎncă nu există evaluări

- FinPlate Type Cleat ConnectionDocument81 paginiFinPlate Type Cleat ConnectionRajveer SinghÎncă nu există evaluări

- Design Calculation of Security Building at Allipuram: L&T ConstructionDocument33 paginiDesign Calculation of Security Building at Allipuram: L&T Constructionjuliyet strucÎncă nu există evaluări

- Design of Column Using Channel (Front)Document8 paginiDesign of Column Using Channel (Front)Nitesh SinghÎncă nu există evaluări

- Portal FrameDocument42 paginiPortal Framesurendra_pangaÎncă nu există evaluări

- Steel-Angle Bracing Design-1Document12 paginiSteel-Angle Bracing Design-1rohitbhagat005Încă nu există evaluări

- Builtup SectionDocument4 paginiBuiltup SectionSuhas MangaloreÎncă nu există evaluări

- Column Is800Document4 paginiColumn Is800rammohanÎncă nu există evaluări

- Design of Bolted Gusset Base OF COLUMN (FOR HEAVELY LOADED COLUMS)Document5 paginiDesign of Bolted Gusset Base OF COLUMN (FOR HEAVELY LOADED COLUMS)Uttam Raj SutraveÎncă nu există evaluări

- BP2Document3 paginiBP2insane88Încă nu există evaluări

- Design of Base Plate LKP Arm 4-F-30.01.2018Document5 paginiDesign of Base Plate LKP Arm 4-F-30.01.2018HarikrishnaÎncă nu există evaluări

- Base Plate Design Fixed BaseDocument3 paginiBase Plate Design Fixed BaseDass MÎncă nu există evaluări

- Shiva Infra Solutions Pvt. LTD.: Quote Request / Work Order Form Page 1 of 2Document3 paginiShiva Infra Solutions Pvt. LTD.: Quote Request / Work Order Form Page 1 of 2Naveen RohiraÎncă nu există evaluări

- Base Plate1Document6 paginiBase Plate1jobees7850Încă nu există evaluări

- PS43-07,08, 132-18 - Base Plate and Anchor Bolt DesignDocument64 paginiPS43-07,08, 132-18 - Base Plate and Anchor Bolt DesignSiva baalanÎncă nu există evaluări

- Insert Plate DesignDocument24 paginiInsert Plate Designabhi arote100% (1)

- HILTI ANALYSIS Based On Tensile and Shear (Hitungan Manual Sendiri)Document3 paginiHILTI ANALYSIS Based On Tensile and Shear (Hitungan Manual Sendiri)inti lestariÎncă nu există evaluări

- FROM IS 875-Part 3Document2 paginiFROM IS 875-Part 3Santosh Bapu100% (1)

- Base Plate - Silo Supporting R1Document10 paginiBase Plate - Silo Supporting R1soumi bhattacharyaÎncă nu există evaluări

- Base Plate Design Is 800 2007Document147 paginiBase Plate Design Is 800 2007pandian100% (1)

- Water Tank Design - B-300mmDocument59 paginiWater Tank Design - B-300mmrachana0% (1)

- Combined Footing DesignDocument1 paginăCombined Footing Designbalaji gmscÎncă nu există evaluări

- Design of Base PlateDocument14 paginiDesign of Base PlateSunidhi ItagiÎncă nu există evaluări

- Design of Base Plate and Anchor BoltDocument7 paginiDesign of Base Plate and Anchor BoltsavsagarÎncă nu există evaluări

- Base Plate DesignDocument14 paginiBase Plate Designsoumi bhattacharyaÎncă nu există evaluări

- Insert Plate Design - LugsDocument8 paginiInsert Plate Design - Lugsnavneet3bawaÎncă nu există evaluări

- BS5400 R.C Design With Crack WidthDocument9 paginiBS5400 R.C Design With Crack WidthWangTF100% (4)

- Design of Bearing For Beam B21: y X CK CKDocument7 paginiDesign of Bearing For Beam B21: y X CK CKMahadev D. BhandareÎncă nu există evaluări

- Bitsat Paper 5Document19 paginiBitsat Paper 5pranka5240100% (1)

- Commercial Kitchen Fire InvestigationsDocument6 paginiCommercial Kitchen Fire InvestigationsBen ConnonÎncă nu există evaluări

- Onitsuka Tiger PDFDocument67 paginiOnitsuka Tiger PDFAhmad Bilal MawardiÎncă nu există evaluări

- 11 - Morphology AlgorithmsDocument60 pagini11 - Morphology AlgorithmsFahad MattooÎncă nu există evaluări

- Sandvik Saf 31803 Tube and Pipe, Seamless: DatasheetDocument9 paginiSandvik Saf 31803 Tube and Pipe, Seamless: DatasheetPaul NeedhamÎncă nu există evaluări

- Fo Transfer ProcedureDocument8 paginiFo Transfer ProcedureadityasahayÎncă nu există evaluări

- EMV Card Reader Upgrade Kit Instructions - 05162016Document6 paginiEMV Card Reader Upgrade Kit Instructions - 05162016Shashi K KumarÎncă nu există evaluări

- Farmhouse Style Plans - Farm & CountryDocument6 paginiFarmhouse Style Plans - Farm & Countryhanif azriÎncă nu există evaluări

- 3TRIGODocument5 pagini3TRIGOCielo Pabilan ObemioÎncă nu există evaluări

- Neuropsychological Performance in Neurofibromatosis Type 1: Original ArticleDocument5 paginiNeuropsychological Performance in Neurofibromatosis Type 1: Original ArticleRaquel DuarteÎncă nu există evaluări

- Hydraulics Course FileDocument81 paginiHydraulics Course FileSwarna LathaÎncă nu există evaluări

- Biochem Acids and Bases Lab ReportDocument4 paginiBiochem Acids and Bases Lab ReportShaina MabborangÎncă nu există evaluări

- Syllabus (402050B) Finite Element Analysis (Elective IV)Document3 paginiSyllabus (402050B) Finite Element Analysis (Elective IV)shekhusatavÎncă nu există evaluări

- Manual de Electronica HardbookDocument970 paginiManual de Electronica HardbookninoferÎncă nu există evaluări

- Sample Dewa Inspection CommentsDocument2 paginiSample Dewa Inspection Commentsrmtaqui100% (1)

- DoomsdayDocument29 paginiDoomsdayAsmita RoyÎncă nu există evaluări

- Qa/Qc Mechanical Monthly Progress Report For June 2015: Area/System Description Status RemarksDocument1 paginăQa/Qc Mechanical Monthly Progress Report For June 2015: Area/System Description Status RemarksRen SalazarÎncă nu există evaluări

- Setting Times of ConcreteDocument3 paginiSetting Times of ConcreteP DhanunjayaÎncă nu există evaluări

- The Common Reader-Virginia WoolfDocument216 paginiThe Common Reader-Virginia WoolfRusudan VardiashviliÎncă nu există evaluări

- Chapter 5 TEstDocument18 paginiChapter 5 TEstJeanneau StadegaardÎncă nu există evaluări

- Air System Sizing Summary For NIVEL PB - Zona 1Document1 paginăAir System Sizing Summary For NIVEL PB - Zona 1Roger PandoÎncă nu există evaluări

- Tyba S4 Syntax PDFDocument107 paginiTyba S4 Syntax PDFIndahÎncă nu există evaluări

- 02-09-18 SR - IZ Jee-Adv 2011-P1 PTA-03 Q PDFDocument31 pagini02-09-18 SR - IZ Jee-Adv 2011-P1 PTA-03 Q PDFswarupÎncă nu există evaluări

- Water Chemistry - An Introduction To The Chemistry of Natural and Engineered Aquatic Systems-Páginas-483-492Document10 paginiWater Chemistry - An Introduction To The Chemistry of Natural and Engineered Aquatic Systems-Páginas-483-492jhonier guevaraÎncă nu există evaluări

- API Casing Collapse CalcsDocument8 paginiAPI Casing Collapse CalcsJay SadÎncă nu există evaluări

- Product Specifications: MB3F-PSA4-19DEDocument2 paginiProduct Specifications: MB3F-PSA4-19DEВадим ЧеховскийÎncă nu există evaluări