Documente Academic

Documente Profesional

Documente Cultură

Iqwq FT LSPDS 00 032003 - 0a PDF

Încărcat de

hapinefeTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Iqwq FT LSPDS 00 032003 - 0a PDF

Încărcat de

hapinefeDrepturi de autor:

Formate disponibile

FLUOR. EJf(onMobil.

WEST QURNA I SPECIFICATION-UPSTREAM PIPING

CLASSIFICATION LINE CLASS 150

ISSUED FOR ISSUED

APPROVAL (IFA) AS-BUILT (IAB)

ISSUED FOR ISSUED FOR

CONSTRUCTION (IFC) BID (IFB)

ISSUED FOR ISSUED FOR

FABRICATION (IFFAB) FEED (IFF)

WEST QURNA I

SPECIFICA TION-

ISSUED FOR ISSUED FOR

INFORMATION (IFI) DESIGN (IFD)

UPSTREAM PIPING CLASSIFICATION - LINE CLASS 150

OO-COMMON OVERALL-ALL

ISSUED FOR AREAS

ISSUED FOR

PROCUREMENT (IFP) HAZOP (IFH)

IQW Q-FTISSUED

-LSPDS-OO-032003

FOR ISSUED FOR

PURCHASE (IFPUR) USE (IFU)

(Based upon ExxonMobil GP 03-20-03, Version 2.4.0, dated October 2009)

ISSUED FOR REVIEW ISSUED FOR

AND COMMENT (IFR) VOID (IFV)

01-Oct-2012

Rev n!::otQ Description By Lead Mgr Client

ISSUED FOR REVIEW AND COMMENT

(IMPLEMENTED CLIENT COMMENTS OF

15 MARCH 2011)

REPLACES IQWQ-FTH-LSPDS-00-032003-

A 1C, IQWQ-FTH-LSPDS-00-032003-A1E,

C 18-Apr-2011 RAG DJC JTP

IQWQ-FTH-LSPDS-00-032003-A3B, IQWQ-

FTH-LSPDS-00-032003-A6E, IQWQ-FTH-

LSPDS-OO-032003-A6H, IQWQ-FTH-LSPDS-

00-032003-A61, AND IQWQ-FTH-LSPDS-OO-

032003-A11

0 02-Jun-2011 ISSUED FOR USE RAG DJC JTP

~ ~'!!)

OA 26-Sep-2012 ISSUED FOR REVIEW AND COMMENT CK

/"\ ; /

,~.~~ "-- l'..

26-Sep-2012, Rev. OA IQWQ-FT-LSPDS-OO-032003

Page 1 of 73

WEST QURNA I SPECIFICATION-UPSTREAM PIPING

CLASSIFICATION LINE CLASS 150

REVISION LOG

REVISION 0A:

1. All notes shown in all caps.

2. Page 16, Deleted ENP Ball Valves

3. Page 16, Seq. 40 – Added Note VB7

4. Page 16, Seq. 70 – Changed Item Name to BALSWS and Abbreviated Description from PE x SE

to SW x SE.

5. Page 16, Deleted Small Bore Forges Swing Check

6. Page 16, Seq. 210 – Added Note VC5

7. Page 16, Seq. 220 – Added Note VC5

8. Page 16, Seq. 230 – Added Note VC7

9. Page 16, Seq. 340 – Change Size for Gear Operation, Triple Offset, Removed Redundancy

10. Page 16, Seq. 390 – Added Small Bore Forged Full Port Valve

11. Page 16, Seq. 440 – Added GO for Gear Operation in Description

12. Page 17, Seq. 540 – Deleted Note 051

13. Page 17, Seq. 990-1010 – Added Note FD3

14. Page 18, Seq. 1040 – Added Note FD3

15. Page 18, Seq. 1180 – Added Note 051

16. Page 18, Seq. 1250 – Added Note 051

17. Page 18, Deleted Threaded Swage Nipples

18. Page 18, Seq. 1350-1370 – Gaskets, Eliminated Redundancy

19. Page 18, Seq. 1350 – Added Note GF3

20. Page 18, Seq. 1470 – Added Note MS9

21. Page 19, Seq. 1510 – Added Class 150 Paddle Blind

22. Page 19, Seq. 1520 – Added Note NE1

23. Page 19, Seq. 1670 – Added Correct Spec Requirement

24. Page 19, Seq. 1680 – Added Correct Spec Requirement

25. Page 20, Adjusted Branch Table

26. Page 20, Note B Revised With Correct Document Number

27. Page 21, Seq. 40 – Added Note VB7

28. Page 21, Seq. 50-80 – Deleted ENP Ball Valves

29. Page 21, Seq. 80 -- Changed Item Name to BALSWS and Abbreviated Description from PE x SE

to SW x SE.

30. Page 21, Seq. 100 – Added 300 Class Ball Valve NPS 2-6

31. Page 21, Deleted Small Bore Forged Swing Check

32. Page 21, Seq. 220 – Adjusted Check Valve To Horizontal and Vertical Operation

33. Page 21, Seq. 230 – Added Note VC5

34. Page 21, Seq. 240 – Added Note VC5

35. Page 21, Seq. 250 – Added Note VC7

36. Page 21, Seq. 360 – Change Size for Gear Operation, Triple Offset

37. Page 21, Seq. 410 – Added Small Bore Forged Full Port Valve

38. Page 21, Seq. 460 – Added GO for Gear Operation In Description

39. Page 22, Seq. 630-680 – Added Class 9000 Socket Weld Fittings To Match XXS Pipe

40. Page 22, Seq. 760-860 – Added Class 6000 Socket Weld Fittings To Match SCH 160 Pipe

41. Page 22, Seq. 980-990 – Added Note UK3

42. Page 22, Seq. 991-1010 – Added Two Schedule Elbolets With Note UK4

26-Sep-2012, Rev. 0A IQWQ-FT-LSPDS-00-032003

Page 2 of 73

WEST QURNA I SPECIFICATION-UPSTREAM PIPING

CLASSIFICATION LINE CLASS 150

43. Page 23, Seq. 1011-1012 – Added Two Schedule Latrolet

44. Page 23, Seq. 1260-1270 – Grouped Class 150 Flanges Together

45. Page 23, Seq. 1330-1380 – Grouped Class 300 Flanges Together, Added Notes FD3, and UK9

46. Page 24, Seq. 1590 – Adjusted Sch. 160 Nipple Size Range And Added Note 051

47. Page 24, Seq. 1660 – Adjusted Sch. 160 Nipple Size Range And Added Note 051

48. Page 24, Deleted Concentric SCH 160 TBE, TSE Swages

49. Page 24, Deleted Concentric XXS TSE Swage

50. Page 24, Seq. 1710 – Change Size Range Of Swage

51. Page 24, Seq. 1720 -1722 – Added Conc., Ecc. XS Swages

52. Page 24, Seq. 1730 – Change Size Range Of Swage

53. Page 24, Seq. 1770 – Added Note GF3

54. Page 24, Deleted Small Size SW Graphite LS IR Gasket

55. Page 24, Seq. 1850 – Added Class 150 Insulating Gasket Kit

56. Page 24, Seq. 1860 – Added Class 300 Insulating Gasket Kit

57. Page 25, Seq. 1990 – Added Class 150 Paddle Blank

58. Page 25, Seq. 2000 – Added Class 300 Paddle Blank

59. Page 25, Seq. 2100-2130 – Added Miscellaneous Design Requested Components

60. Page 25, Seq. 2170-2190 – Added U/G Pipe

61. Page 25, Seq. 2300 – Added Correct Spec Requirement

62. Page 25, Seq. 2310 – Added Correct Spec Requirement

63. Page 26, Adjusted Branch Connection Table

64. Page 26, Note B Revised With Correct Document Number

65. Page 27-31, A1H New Line Class

66. Page 32-36, A1I New Line Class

67. Page 37, Removed ENP (Electro Nickel Plated) Ball Valves

68. Page 37, Removed Small Bore Swing Check Valve

69. Page 37, Seq. 130 – Adjusted Check Valve To Horizontal and Vertical Operation

70. Page 37, Seq. 140 – Adjust Size Range, Added Note VC5

71. Page 37, Seq. 260 – Adjusted Size Range

72. Page 37, Seq. 270 – Added 300# Gate Valve

73. Page 37, Seq. 282 – Added 5000# Needle Valve

74. Page 37, Seq. 330 – Adjusted Pipe Size Range

75. Page 37, Removed Threaded Elbolet, And Threaded Latrolet

76. Page 38, Seq. 500-570 – Increased Size Range Of Fittings

77. Page 38, Seq. 620 – Adjusted Flange Size Range

78. Page 38, Seq. 660 – Adjusted Flange Size Range

79. Page 38, Seq. 691 – Added Threaded 300# Orifice Flange

80. Page 38, Seq. 700 – Added 300# Orifice Flange

81. Page 38, Seq. 740-780 – Changed Schedule Of Nipples

82. Page 38, Seq. 800 – Added Note 130

83. Page 38, Seq. 820 - 880 – Changed Schedule Of Swages

84. Page 38, Seq. 930 - 980 – Removed Grafoil Tanged Ring Gasket, And Increased Size Range Of

Existing Gaskets

85. Page 38, Seq. 970 - 980 – Added Note 294

86. Page 39 Seq. 1110 – Added Paddle Blanks

87. Page 39, Seq. 1120 – Revised Size Range

88. Page 39, Seq. 1170 -1250 – Added Underground Material

89. Page 40, Branch Connection Table Adjusted To Show Threaded Connections

90. Page 40, Note B Revised With Correct Document Number

26-Sep-2012, Rev. 0A IQWQ-FT-LSPDS-00-032003

Page 3 of 73

WEST QURNA I SPECIFICATION-UPSTREAM PIPING

CLASSIFICATION LINE CLASS 150

91. Page 41, Seq. 60 – Added Note VB7

92. Page 41, Seq. 90 -- Changed Item Name to BALSWS and Abbreviated Description from PE x SE

to SW x SE.

93. Page 41, Seq. 110 – Added Class 300 Ball Valve NPS 2-6

94. Page 41, Removed Small Bore Swing Check Valve

95. Page 41, Seq. 240 – Adjusted Check Valve To Horizontal and Vertical Operation

96. Page 41, Seq. 250 – Added Note VC5

97. Page 41, Seq. 260 – Added Note VC5

98. Page 41, Seq. 270 – Added Note VC7

99. Page 41, Seq. 330-340 – Change Size Range Of Valves

100. Page 41, Seq. 340 – Change Size Range Of Valve

101. Page 41, Removed Triple Offset Butterfly Valve With Locking Device

102. Page 41, Seq. 380 – Added Gear Operation and Change Size Range of Valve

103. Page 41, Seq. 430 – Added Full Port Valve

104. Page 41, Seq. 460 – Change Size Range Of Valve

105. Page 41, Seq. 480 – Added Through-Conduit 150# Gate Valve

106. Page 41, Seq. 500 – Added 30” Gear Operated Valve

107. Page 42, Seq. 580 – Added NPS Calc Note

108. Page 42, Seq. 650 – Added ½” Wall DSAW Pipe

109. Page 42, Seq. 680 – Added NPS Calc Note

110. Page 42, Removed Class 9000 Socket Weld Union

111. Page 42, Removed Class 6000 Socket Weld Union

112. Page 42, Seq. 700-750 – Added Class 9000 Socket Weld Fittings for ½ - ½ To Match XXS Pipe

113. Page 42, Seq. 830-930 – Adjusted Class 6000 Socket Weld Fittings For ¾ - 1½ To Match SCH

160 Pipe

114. Page 42, Seq. 940 – Added Flat Sockolet

115. Page 43, Seq. 1050 – Added Two Schedule Weldolet

116. Page 43, Seq. 1170 – Added XS Latrolet

117. Page 43, Seq. 1180 – Adjusted Weldolet Size Range

118. Page 43, Seq. 1190 – Added Two Schedule Weldolet

119. Page 43, Seq. 1250 – Added Two Schedule Reducing Tee

120. Page 43, Seq. 1280 – Added Two Schedule Concentric Reducer

121. Page 43, Seq. 1300 – Added Two Schedule Eccentric Reducer

122. Page 43, Seq. 1310 – Added STD WT Weldolet

123. Page 43, Seq. 1320-1400 – Added ½” Wall Fittings to Match ½” Pipe

124. Page 43, Seq. 130 – Added NPS Calc Note

125. Page 43, Seq. 1460 – Added Class 150 Bore Flange

126. Page 43, Seq. 1500-1510 – Added WN Class 150 Series A, B ½” Bore Flange With Note E08

127. Page 44, Seq. 1530-1570 – Added Note FD3

128. Page 44, Seq. 1580-1600 – Added WN Class 300 Series A, B ½” Bore Flange With Note FD3,

E08

129. Page 44, Seq. 1640-1650 – Added Class 150 Series A, B ½” Blind With Note E08

130. Page 44, Seq. 1670 – Added Note FD3

131. Page 44, Seq. 1680-1700 – Added Class 300 Series A, B ½” Blind With Note FD3, E08

132. Page 44, Seq. 1970-1980 – Swage Nipples, Eliminated Redundancy

133. Page 44, Seq. 2010 – Added Eccentric Sch 160 Swage

134. Page 45, Seq. 2050 – Added Class 150 Grafoil Tanged Ring Gasket With Note GF3

135. Page 45, Seq. 2080-2090 – Added Class 150 Series A, B 304SS Sp. Wnd. Gasket With Note

FA2

26-Sep-2012, Rev. 0A IQWQ-FT-LSPDS-00-032003

Page 4 of 73

WEST QURNA I SPECIFICATION-UPSTREAM PIPING

CLASSIFICATION LINE CLASS 150

136. Page 45, Seq. 2130-2140 – Added Class 300 Series A, B 304SS Sp. Wnd. Gasket With Note

FA2

137. Page 45 – Removed General Class 150 304SS Sp. Wnd. Gasket

138. Page 45, Seq. 2160 – Added Class 150 Insulating Gasket And Gas Kit With Note 294

139. Page 45, Seq. 2170 – Added Class 300 Insulating Gasket And Gas Kit With Note 294

140. Page 45, Seq. 2260 – Changed Strainer Size Range

141. Page 45, Seq. 2270 – Added 150# Y Strainer

142. Page 45, Seq. 2280 – Added Note MS9

143. Page 45, Seq. 2320 – Added Class 150 Blank Paddle

144. Page 45, Seq. 2330 – Added Note NE1

145. Page 45, Seq. 2380 – Added Class 150 Blank Paddle Series A With Note E08

146. Page 45, Seq. 2390 – Added Class 150 Spacer Paddle Series A With Note E08

147. Page 45, Seq. 2400 – Added Class 150 Blank Paddle Series B With Note E08

148. Page 45, Seq. 2410 – Added Class 150 Spacer Paddle Series B With Note E08

149. Page 45, Seq. 2430-2512 – Added U/G Pipe

150. Page 46, Removed Reinforcing Weld For Stub-In

151. Page 46, Removed Reinforcing Pad

152. Page 46, Seq. 2610-2620 – Added Construction Specification Details

153. Page 47, Note B Revised With Correct Document Number

154. Page 47, Added Note C And Chart Reference

155. Page 48, Seq. 40 – Added Note VB7

156. Page 48, Deleted Class 600 Ball Valves

157. Page 48, Seq. 70,90 – Adjusted Size Range Of Class 1500 Valves

158. Page 48, Seq. 90 -- Changed Item Name to BALSWS and Abbreviated Description from PE x SE

to SW x SE.

159. Page 48, Deleted Horizontal Swing Check Valves

160. Page 48, Seq. 210 – Adjusted Size range, added note 027

161. Page 48, Deleted Class 800 Piston Check Valve

162. Page 48, Seq. 220-230 – Added Note VC5

163. Page 48, Seq. 240 – Added Note VC7

164. Page 48, Seq. 280 – Adjusted Size Range of Class 1500 Globe Valve

165. Page 48, Deleted Class 800 Globe Valve

166. Page 48, Deleted Class 150 Butterfly Valve With Locking Device

167. Page 48, Seq. 340 – Adjusted Size Range Of Gear Operated Butterfly Valve

168. Page 48, Seq. 380 – Adjusted Size Range Of NACE Gate Valve

169. Page 48, Seq. 390 – Added Class 1500 Threaded NACE Gate Valve

170. Page 48, Seq. 400 – Adjusted Size Range Of NACE Gate Valve

171. Page 48, Deleted Class 800 Gate Valve

172. Page 48, Seq. 520 – Adjusted Size Range SCH 160 Pipe

173. Page 49, Deleted SCH 120 Pipe

174. Page 49, Seq. 570-620 – Class 6000 Fittings Changed to Class 9000

175. Page 49, Deleted Class 6000 Union

176. Page 49, Seq. 670 – Class 6000 Sockolet Changed To Class 9000

177. Page 49, Seq. 700-800 – Adjusted All SCH 160 Fitting Sizes

178. Page 49, Seq. 810 – Added Two Schedule Elbolet With Note UK4

179. Page 49, Deleted All SCH 120 Fittings

180. Page 49, Deleted SCH 120 Flange

181. Page 49, Seq. 940 – Weld Neck Flange Changed To Socket Weld

182. Page 49, Seq. 950 – Adjusted Class 150 SCH 160 Bore Flange Size

26-Sep-2012, Rev. 0A IQWQ-FT-LSPDS-00-032003

Page 5 of 73

WEST QURNA I SPECIFICATION-UPSTREAM PIPING

CLASSIFICATION LINE CLASS 150

183. Page 49, Seq. 980 – Added Note FD3

184. Page 49, Seq. 990 – Adjusted Class 300 SCH 160 Bore Flange Size And Added Note FD3 And

UK9

185. Page 49, Seq. 1010 – Added Note FD3

186. Page 50, Seq. 1040 – Added Note FD3

187. Page 50, Deleted All SCH 120 Bore Flanges

188. Page 50, Seq. 1080 – Adjusted SCH 160 Bore Orifice Flange Size

189. Page 50 Deleted SCH 120 Bore Orifice Flange

190. Page 50, Deleted Threaded Swage Nipples

191. Page 50, Seq. 1250 – Added Eccentric XXS BBE Swage

192. Page 50, Seq. 1290 – Added Class 150 Grafoil Tanged Ring Gasket With Note GF3

193. Page 50, Seq. 1320 – Adjusted Class 300 Gasket Size

194. Page 50, Deleted Class 150 Low Stress SS Spiral Wound Gasket

195. Page 50, Seq. 1400 – Adjusted to Class 1500 And Size Range

196. Page 50, Seq. 1410 – Adjusted Size Range And Added Note MS9

197. Page 50, Seq. 1450 – Added Class 150 Blank Paddle

198. Page 50, Seq. 1460 – Added Note NE1

199. Page 51, Deleted Reinforcing Weld

200. Page 51, Deleted Reinforcing Pad

201. Page 51, Seq. 1610-1620 – Added Correct Spec Requirement

202. Page 52, Adjusted Branch Connection Table

203. Page 52, Note B Revised With Correct Document Number

204. Page 53, Seq. 40 – Added Note VB7

205. Page 53, Seq. 90 -- Changed Item Name to BALSWS and Abbreviated Description from PE x SE

to SW x SE.

206. Page 53, Deleted Class 1500 Swing Check Valve

207. Page 53, Seq. 210 – Adjusted Check Valve To Horizontal and Vertical Operation

208. Page 53, Seq. 220-230 – Added Note VC5

209. Page 53, Seq. 240 – Added Note VC7

210. Page 53, Deleted Class 150 Butterfly Valve With Locking Device

211. Page 53, Seq. 340 – Adjusted Size Range Of Gear Operated Butterfly Valve

212. Page 53, Seq. 510 – Adjusted XXS Pipe Size

213. Page 54, Deleted SCH 160 Pipe

214. Page 54, Deleted Class 6000 Union

215. Page 54, Seq. 570-610 – Adjusted Class 6000 Fittings to Class 9000

216. Page 54, Seq. 660 – Adjusted Class 6000 Sockolet to Class 9000

217. Page 54, Deleted SCH 160 Fittings

218. Page 54, Seq. 690-780 – Adjusted Size Ranges of XXS Fittings

219. Page 54, Seq. 800 – Adjusted Size Range Of Duel Schedule Weldolet

220. Page 54, Seq. 860 – Adjusted Duel Schedule Reducing Tee Low Size Range

221. Page 54, Seq. 880 – Added SCH 120 Concentric Reducer

222. Page 54, Seq. 900 – Added SCH 120 Eccentric Reducer

223. Page 55, Seq. 1050 – Adjusted Flange Connection Type to Socket Weld

224. Page 55, Seq. 1060 – Adjusted Size Range of Class 150 Flange

225. Page 55, Deleted Class 150 SCH 160 Bore Flange

226. Page 55, Seq. 1100 – Added Note FD3

227. Page 55, Seq. 1110 – Adjusted Size Range, Added Note FD3

228. Page 55, Seq. 1120-1130 – Added Note FD3

229. Page 55, Deleted Class 300 SCH 160 Bore Flange

26-Sep-2012, Rev. 0A IQWQ-FT-LSPDS-00-032003

Page 6 of 73

WEST QURNA I SPECIFICATION-UPSTREAM PIPING

CLASSIFICATION LINE CLASS 150

230. Page 55, Seq. 1160 – Added Note FD3

231. Page 55, Seq. 1200 – Adjusted Size Range Of Orifice Flange

232. Page 55, Deleted SCH 160 Bore Orifice Flange

233. Page 55, Deleted TOE Concentric Swage

234. Page 55, Seq. 1440 – Added XXS Eccentric Swage

235. Page 55, Seq. 1480 – Added Class 150 Grafoil Tanged Ring Gasket With Note GF3

236. Page 55, Deleted Class 150 Low Stress Gasket

237. Page 55, Seq. 1510 – Consolidated Class 300 SS Spiral Wound Gasket

238. Page 55, Seq. 1590 – Adjusted Class 600 Y Strainer to Class 1500

239. Page 56, Seq. 1600 – Adjusted Size Range, Added Note MS9

240. Page 56, Seq. 1640 – Added Class 150 Blank Paddle

241. Page 56, Seq. 1650 – Added Note NE1

242. Page 56, Deleted Reinforcing Weld

243. Page 56, Deleted Reinforcing Pad

244. Page 56, Seq. 1800-1810 – Added Construction Specification Details

245. Page 57, Adjusted Branch Connection Table

246. Page 57, Note B Revised With Correct Document Number

247. Page 58 - 62, Modified Construction Parameters to 1 ½ And Smaller Socket Weld, 2 And Larger

Butt Weld

248. Page 58 - 62, Material Changed To 316/316L SS

249. Page 58 - 62, Design Under Specification ASME B16.5 MG 2.2

250. Page 58, Seq. 40 – Added Note VB7

251. Page 58, Seq. 50 -- Changed Item Name to BALSWS and Abbreviated Description from PE x SE

to SW x SE.

252. Page 58, Seq. 50-60 – Adjusted Ball Valve Material To 316/316L SS

253. Page 58, Seq. 70 – Adjusted Ball Valve To Be Fire Safe

254. Page 58, Deleted Class 800 Swing Check Valve

255. Page 58, Seq. 190 – Adjusted Class 800 Piston Check Valve To Horizontal And Vertical

Operation

256. Page 58, Seq. 200-210 – Added Note VC5

257. Page 58, Seq. 220 – Added Note VC7

258. Page 58, Deleted Class 150 Butterfly Valve With Locking Device

259. Page 58, Seq. 320 – Adjusted Lower Size Range And Added GO For Gear Operation

260. Page 58, Seq. 370 – Increased Size Range to 2

261. Page 58, Seq. 420 – Valve Material Changed To 316/316L SS

262. Page 59, Deleted Sch 80S Pipe

263. Page 59, Deleted Class 3000 Union

264. Page 59, Seq. 1090 – Adjusted Socket Weld Flange To Class 150

265. Page 60, Seq. 1140-1170 – Added Note FD3

266. Page 60, Seq. 1200 – Added Note FD3

267. Page 60, Seq. 1300-1320 – Added Note 051

268. Page 60, Seq. 1340 – Adjusted Nipple To Threaded One End

269. Page 60, Seq. 1370-1390 – Added Note 051

270. Page 60, Deleted Sch 160 Swage Nipples

271. Page 60, Seq. 1480-1500 – Adjusted Large End Sizes To Max 3

272. Page 60, Deleted Sch 40S Threaded Single End Swage

273. Page 60, Seq. 1540 – Adjusted Large End Sizes To Max 3

274. Page 61, Seq. 1550 – Adjusted Small And Large End Sizes

275. Page 61, Seq. 1580 – Added Class 150 Grafoil Tanged Ring Gasket With Note GF3

26-Sep-2012, Rev. 0A IQWQ-FT-LSPDS-00-032003

Page 7 of 73

WEST QURNA I SPECIFICATION-UPSTREAM PIPING

CLASSIFICATION LINE CLASS 150

276. Page 61, Seq. 1590 – Adjusted Gasket For Low Stress Operation

277. Page 61, Seq. 1680 – Adjusted Y Strainer Sizes

278. Page 61, Seq. 1690 – Adjusted Strainer Sizes, Added Note MS9

279. Page 61, Seq. 1721 – Added Class 150 Blank Paddle

280. Page 61, Seq. 1730 – Added Note NE1

281. Page 61, Deleted Reinforcing Weld

282. Page 61, Deleted Reinforcing Pad

283. Page 61, Seq. 1900-1910 – Added Construction Specification Details

284. Page 62, Pressure Temperature Table And Chart Adjusted

285. Page 62, Adjusted Branch Connection Table

286. Page 62, Note B Revised With Correct Document Number

287. Page 63-65, New Line Class A11A-P

288. Page 66-70, New Line Class A18A

26-Sep-2012, Rev. 0A IQWQ-FT-LSPDS-00-032003

Page 8 of 73

WEST QURNA I SPECIFICATION-UPSTREAM PIPING

CLASSIFICATION LINE CLASS 150

SCOPE

1) This Project Engineering Specification contains the Line Class 150 tables that accompany

IQWQ-FT-LSPDS-00-030101. Additional valve information is contained in IQWQ-FT-LSPDS-

00 032010.

2) This Project Engineering Specification shall apply to all onshore and offshore facility piping

that is governed by ASME B31.3. Final decision on applicability of the marine piping

specification shall be agreed upon between the project/affiliate and the governing body.

26-Sep-2012, Rev. 0A IQWQ-FT-LSPDS-00-032003

Page 9 of 73

WEST QURNA I SPECIFICATION-UPSTREAM PIPING

CLASSIFICATION LINE CLASS 150

TABLE OF CONTENTS

REVISION LOG................................................................................................................................2

1.0 REQUIRED REFERENCES ............................................................................................. 11

1.1 Project Engineering Specifications ................................................................. 11

1.2 API–American Petroleum Institute .................................................................. 11

1.3 ASME–American Society of Mechanical Engineers ...................................... 11

1.4 ASTM–American Society for Testing and Materials ...................................... 12

1.5 BSI – British Standards Institution .................................................................. 13

1.6 MSS–Manufacturers Standardization Society................................................ 13

1.7 Other References............................................................................................... 14

2.0 LINE CLASSIFICATION SHEETS................................................................................... 15

2.1 Class 150: Carbon Steel – A1C ........................................................................ 16

2.2 Class 150: Carbon Steel – A1E ........................................................................ 21

2.3 Class 150: Carbon Steel – A1H ........................................................................ 27

2.4 Class 150: Carbon Steel: A1I............................................................................ 32

2.5 Class 150: Galvanized Steel – A3B.................................................................. 37

2.6 Class 150: Carbon Steel – A6E ........................................................................ 41

2.7 Class 150: Carbon Steel – A6H ........................................................................ 48

2.8 Class 150: Carbon Steel – A6I.......................................................................... 53

2.9 Class 150: Carbon Steel – A11A ...................................................................... 58

2.10 Class 150: Stainless Steel – A11A-P .............................................................. 63

2.11 Class 150: Duplex Steel – A18A....................................................................... 66

3.0 KEY SHEET FOR CLASS 150 LINE CLASSIFICATIONS ............................................. 71

ATTACHMENT: PURPOSE CODE DEFINITIONS ..................................................................... 73

26-Sep-2012, Rev. 0A IQWQ-FT-LSPDS-00-032003

Page 10 of 73

WEST QURNA I SPECIFICATION-UPSTREAM PIPING

CLASSIFICATION LINE CLASS 150

1.0 REQUIRED REFERENCES

1) This Section lists the Project Engineering Specifications, codes, standards, and publications

that shall be used with this document. Unless otherwise specified herein, use the latest

edition.

2) The text of the numbered "Notes" referenced in the classification sheets is found in Appendix

E of IQWQ-FT-LSPDS-00-030101. A dagger (†) is used to identify such notes in this Project

Engineering Specification.

1.1 Project Engineering Specifications

IQWQ-FT-LSPDS-00-030101 Upstream Piping Component Selection and System Design

IQWQ-FT-LSPDS-00-031902 Upstream Piping Fabrication, Erection, Inspection, Testing,

and Cleaning

IQWQ-FT-LSPDS-00-032010 Upstream Piping Classifications - Valve Indices and

Descriptions

1.2 API–American Petroleum Institute

API SPEC 5L Specification for Line Pipe

API SPEC 6D Specification for Pipeline Valves

API STD 594 Check Valves: Flanged, Lug, Wafer and Butt-welding

API STD 600 Bolted Bonnet Steel Gate Valves for Petroleum and Natural Gas Industries

API STD 602 Steel Gate, Globe and Check Valves for Sizes DN 100 and Smaller for the

Petroleum and Natural Gas Industries

API STD 609 Butterfly Valves: Double Flanged, Lug- and Wafer-Type

1.3 ASME–American Society of Mechanical Engineers

ASME B16.5 Pipe Flanges and Flanged Fittings NPS 1/2 Through NPS 24

Metric/Inch Standard

ASME B16.9 Factory-Made Wrought Buttwelding Fittings

ASME B16.11 Forged Fittings, Socket-Welding and Threaded

ASME B16.20 Metallic Gaskets for Pipe Flanges Ring-Joint, Spiral-Wound, and

Jacketed

ASME B16.21 Nonmetallic Flat Gaskets for Pipe Flanges

ASME B16.24 Cast Copper Alloy Pipe Flanges and Flanged Fittings Classes 150,

300, 600, 900, 1500, and 2500

ASME B16.34 Valves - Flanged, Threaded, and Welding End

26-Sep-2012, Rev. 0A IQWQ-FT-LSPDS-00-032003

Page 11 of 73

WEST QURNA I SPECIFICATION-UPSTREAM PIPING

CLASSIFICATION LINE CLASS 150

ASME B16.36 Orifice Flanges

ASME B16.47 Large Diameter Steel Flanges NPS 26 Through NPS 60 Metric/Inch

Standard

ASME B18.2.1 Square and Hex Bolts and Screws (Inch Series)

ASME B18.2.2 Square and Hex Nuts (Inch Series)

ASME B31.1 Power Piping

ASME B31.3 Process Piping

ASME B36.10M Welded and Seamless Wrought Steel Pipe

ASME B36.19M Stainless Steel Pipe

ASME SEC VIII D1 BPVC Section VIII - Rules for Construction of Pressure Vessels -

Division 1

1.4 ASTM–American Society for Testing and Materials

ASTM A 53/A 53M Standard Specification for Pipe, Steel, Black and Hot-Dipped, Zinc-

Coated, Welded and Seamless

ASTM A 105/A 105M Standard Specification for Carbon Steel Forgings for Piping

Applications

ASTM A 106/A 106M Standard Specification for Seamless Carbon Steel Pipe for High-

Temperature Service

ASTM A 182/A 182M Standard Specification for Forged or Rolled Alloy and Stainless

Steel Pipe Flanges, Forged Fittings, and Valves and Parts for High-

Temperature Service

ASTM A 193/A 193M Standard Specification for Alloy-Steel and Stainless Steel Bolting

Materials for High Temperature or High Pressure Service and Other

Special Purpose Applications

ASTM A 194/A 194M Standard Specification for Carbon and Alloy Steel Nuts for Bolts for

High Pressure or High Temperature Service, or Both

ASTM A 216/A 216M Standard Specification for Steel Castings, Carbon, Suitable for

Fusion Welding, for High-Temperature Service

ASTM A 234/A 234M Standard Specification for Piping Fittings of Wrought Carbon Steel

and Alloy Steel for Moderate and High Temperature Service

ASTM A 312/A 312M Standard Specification for Seamless, Welded, and Heavily Cold

Worked Austenitic Stainless Steel Pipes

ASTM A 320/A 320M Standard Specification for Alloy-Steel and Stainless Steel Bolting

Materials for Low-Temperature Service

ASTM A 333/A 333M Standard Specification for Seamless and Welded Steel Pipe for

Low-Temperature Service

26-Sep-2012, Rev. 0A IQWQ-FT-LSPDS-00-032003

Page 12 of 73

WEST QURNA I SPECIFICATION-UPSTREAM PIPING

CLASSIFICATION LINE CLASS 150

ASTM A 350/A 350M Standard Specification for Carbon and Low-Alloy Steel Forgings,

Requiring Notch Toughness Testing for Piping Components

ASTM A 351/A 351M Standard Specification for Castings, Austenitic, for Pressure-

Containing Parts

ASTM A 352/A 352M Standard Specification for Steel Castings, Ferritic and Martensitic,

for Pressure-Containing Parts, Suitable for Low-Temperature

Service

ASTM A 358/A 358M Standard Specification for Electric-Fusion-Welded Austenitic

Chromium-Nickel Stainless Steel Pipe for High-Temperature Service

and General Applications

ASTM A 403/A 403M Standard Specification for Wrought Austenitic Stainless Steel Piping

Fittings

ASTM A 420/A 420M Standard Specification for Piping Fittings of Wrought Carbon Steel

and Alloy Steel for Low-Temperature Service

ASTM A 671 Standard Specification for Electric-Fusion-Welded Steel Pipe for

Atmospheric and Lower Temperatures

ASTM B 148 Standard Specification for Aluminum-Bronze Sand Castings

ASTM B 150/B 150M Standard Specification for Aluminum Bronze Rod, Bar, and Shapes

ASTM B 151/B 151M Standard Specification for Copper-Nickel-Zinc Alloy (Nickel Silver)

and Copper-Nickel Rod and Bar

ASTM B 171/B 171M Standard Specification for Copper-Alloy Plate and Sheet for

Pressure Vessels, Condensers, and Heat Exchangers

ASTM B 466/B 466M Standard Specification for Seamless Copper-Nickel Pipe and Tube

ASTM B 467 Standard Specification for Welded Copper-Nickel Pipe

1.5 BSI – British Standards Institution

BSI BS 5154 Copper Alloy Globe, Globe Stop and Check, Check and Gate Valves

BSI BS EN 1982 Copper and Copper Alloys - Ingots and Castings

1.6 MSS–Manufacturers Standardization Society

MSS SP-43 Wrought and Fabricated Butt-Welding Fittings for Low Pressure, Corrosion

Resistant Applications

MSS SP-80 Bronze Gate, Globe, Angle, and Check Valves

26-Sep-2012, Rev. 0A IQWQ-FT-LSPDS-00-032003

Page 13 of 73

WEST QURNA I SPECIFICATION-UPSTREAM PIPING

CLASSIFICATION LINE CLASS 150

MSS SP-97 Integrally Reinforced Forged Branch Outlet Fittings - Socket Welding,

Threaded and Buttwelding Ends

1.7 Other References

DNV Det Norske Veritas appropriate standards and specifications.

26-Sep-2012, Rev. 0A IQWQ-FT-LSPDS-00-032003

Page 14 of 73

WEST QURNA I SPECIFICATION-UPSTREAM PIPING

CLASSIFICATION LINE CLASS 150

2.0 LINE CLASSIFICATION SHEETS

The text of the numbered "Notes" referenced in the classification sheets is found in Appendix E of

IQWQ-FT-LSPDS-00-030101. A dagger (†) is used to identify such notes in this Project

Engineering Specification.

26-Sep-2012, Rev. 0A IQWQ-FT-LSPDS-00-032003

Page 15 of 73

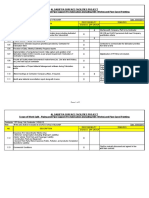

SEQ REV NOTE ITEM ITEM CODE SIZE RANGE / DESCRIPTION REFERENCE / NOTES

NO. NO. NAME SMALL END SIZES LARGE END SIZES

10

20 ***** VALVES ***** 08 FULL PORT VALVES SHALL BE USED WHEN

30 INDICATED ON P&ID.

40 0A VB7 ***** BALL VALVES ***** 025 SWING OR DUAL PLATE CHECK VALVES

50 SHALL BE DESIGNED FOR INSTALLATION IN

60 BALPE DBAA5(L) 1/2 - 1 1/2 BALL 600# PBE STL, FS HNDL OP THE HORIZONTAL OR VERTICAL UPFLOW

70 0A BALSWS DBAA7(L) 1/2 - 1 1/2 BALL 600# SW X SE STL, FS HNDL OP POSITIONS.

80 Ball V BBAA0 1 - 1 1/2 BALL 300# RF STL, RP, FS, 316 TRIM 027 PISTON TYPE CHECK VALVES IN SIZES NPS 1

90 Ball V ABAA0 2-6 BALL 150# RF STL, RP, FS. 316 TRIM 1/2 AND SMALLER SHALL BE DESIGNED

100 BALFLG ABAA0(GO) BALL 150# RF STL, RP, FS. 316 TRIM GO (WITH SPRINGS) FOR INSTALLATION IN THE

8 - 24

HORIZONTAL OR UPWARD FLOW POSITIONS.

110 BALFLG ABFA0 2-4 BALL 150# RF STL, FP, FS, 316 TRIM

051 NPS 1 AND SMALLER FERRITIC PIPE NIPPLES

120 BALFLG ABFA0(GO) 6 - 24 BALL 150# RF STL, FP, FS, 316 TRIM GO

BETWEEN EQUIPMENT AND THE FIRST

130 BALFLG ABAA0(DI) 2-6 BALL 150# RF STL, RP, DI, FS, 316 TRIM BLOCK VALVE, OR BETWEEN A HEADER AND

140 BALFLG ABAA0(DI)-(GO) 8 - 24 BALL 150# RF STL, RP, DI, FS, 316 TRIM GO FIRST BLOCK VALVE, SHALL HAVE A

150 BALFLG ABFA0(DI) 2-4 BALL 150# RF STL, FP, DI, FS, 316 TRIM MINIMUM THICKNESS OF SCHEDULE 160.

160 BALFLG ABFA0(DI)-(GO) 6 - 24 BALL 150# RF STL, FP, DI, FS, 316 TRIM GO FOR THESE NIPPLES IN NONFERRITIC

170 PIPING, THE MINIMUM THICKNESS SHALL BE

180 025 ***** CHECK VALVES ***** SCHEDULE 80 (SOCKET WELDED) AND 160

(THREADED).

190

200 0A 027 CHESW YCNA5 CHECK 800# SW STL, PISTON, F6/STEL SEAT H&V 101 USE SWAGES IN THREADED PIPING

3/4 - 1 1/2 SYSTEMS WHERE SMALL END DOES NOT

210 0A VC5 CHELUG ACYA0 2 - 24 CHECK 150# RF STL, LUG DRILLED THRU EXCEED NPS 1½ AND LARGE END DOES NOT

220 0A VC5 CHEFLG ACAA0 1 - 24 CHECK 150# RF STL, F6/STEL SEAT EXCEED NPS 3. THE END PREPARATION IS

230 0A VC7 CHEFLG ACFA0 1 - 24 CHECK 150# RF STL, FP, F6/STEL SEAT TO BE IN ACCORDANCE WITH THE

240 APPROPRIATE LINE CLASS.

250 ***** GLOBE VALVES ***** 144 ONLY TO BE USED AT ORIFICE TAPS AS

260 INDICATED ON THE P&IDS.

270 GLOSW YTAA5 3/4 - 1 1/2 GLOBE 800# SW STL, F6/STEL SEAT FD3 USE CLASS 300 FLANGES ONLY WHERE

280 GLOFLG BTAA0 1 - 1 1/2 GLOBE 300# RF STL, F6/STEL SEAT REQUIRED.

290 GLOFLG ATAA0 2-8 GLOBE 150# RF STL, F6/STEL SEAT GF3 USE WITH CLASS 150 SOCKETWELD

300 GLOFLG ATAA0(GO) GLOBE 150# RF STL, F6/STEL SEAT GO FLANGES.

10 - 10

310 MS9 THESE STRAINERS ARE FOR STARTUP USE

ONLY AND SHALL BE REMOVED PRIOR TO

320 ***** BUTTERFLY VALVES *****

TURNOVER.

330

340 0A BTFFGO AFAA0(GO) 3 - 24 BUTTERFLY TRIPLE 150# RF STL GO ISO

350

360 ***** GATE VALVES ***** SERVICE

370 GENERAL PROCESS, GLYCOL/TEG,

380 GATSW YGAA5 1/2 - 1 1/2 GATE 800# SW STL, F6/STEL SEATS HYDROCARBONS, CHEMICALS, PRODUCED WATER,

390 0A 08 GATSW YGFA5 1/2 - 1 1/2 GATE 800# SW STL, F6/STEL SEATS FP OPEN AND CLOSED DRAINS.

400 GATSCR YGAA6 1/2 - 1 1/2 GATE 800# SCRD STL, F6/STEL SEATS

DESIGN: ASME B16.5 MG 1.1

410 GATFLG BGAA0 1 - 1 1/2 GATE 300# RF STL, F6/STEL SEATS CODE: ASME B31.3

420 GATSWS YGAA7 1/2 - 1 1/2 GATE 800# SW/SCRD STL, F6/STEL SEATS

430 GATFLG AGAA0 1 - 12 GATE 150# RF STL, F6/STEL SEATS

440 0A GATFLG AGAA0(GO) 14 - 24 GATE 150# RF STL, F6/STEL SEATS GO

450

460 MATERIAL: CARBON STEEL

470 ***** INSTRUMENT BLOCK VALVE ***** FLANGE RATING: 150 RF

480 TEMPERATURE RANGE: -5 / 205 °C

490 144 BALPSC DBAA17(L)-(DI) 1/2 - 1/2 BALL 600# PE X FNPT STL, DI, RP, FS, LEVER OP

COMMENT:

500 BALPSC ABAA10(DI) 2-2 BALL 150# RF X FNPT STL, DI, RP, FS, LEVER OP

Iraq West Qurna I Project CONSTRUCTION Iraq West Qurna I Project

Fluor Transworld Services, Inc. 1 1/2" & SMALLER - SOCKETWELD

CORR. ALLOW. DATE BY REV SHEET PA CLASS

2" & LARGER - BUTTWELD

W3QR

1.5 MM 02JUN11 RAP 0A 1 OF 4 5 A1C

Southern Iraq

26-Sep-2012, Rev. 0A IQWQ-FT-LSPDS-00-032003

Page 16 of 73

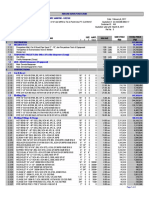

SEQ REV NOTE ITEM ITEM CODE SIZE RANGE / DESCRIPTION REFERENCE / NOTES

NO. NO. NAME SMALL END SIZES LARGE END SIZES

510 NE1 TO BE USED WITH CLASS 300 VALVES ONLY.

520 ***** PIPE ***** VB7 BALL VALVE TAGS TO BE USED AS

530 INDICATED ON THE P&IDs.

540 0A PIPBAR 5356033 1/2 - 1 1/2 PIPE XS SMLS STL A106-B VC5 PREFERRED TYPE CHECK VALVE IN

550 PIPBAR 5356033 2-2 PIPE XS SMLS STL A106-B GENERAL SERVICES IS A RETAINERLESS

560 Piping 5356030 3 - 24 PIPE STD WT SMLS STL A106-B DUAL-PLATE STYLE CHECK VALVE, PER API

570 STANDARD 594, EXCEPT IN LINES THAT WILL

580 ***** FITTINGS ***** REQUIRE PIGGING.

590 VC7 TO BE USED IN LINES THAT WILL REQUIRE

PIGGING

600 ELLSW 5478105EM 1/2 - 1 1/2 ELL 90 DEG 3000# SW STL A105 NORM

610 45LSW 5478106EM 1/2 - 1 1/2 ELL 45 DEG 3000# SW STL A105 NORM

620 TEESW 5478107EM 1/2 - 1 1/2 TEE 3000# SW STL A105 NORM

630 TERSW 5478127EM 1/2 - 1 TEE RED 3000# SW STL A105 NORM 3/4 - 1 1/2

640 CAPSW 5478108EM 1/2 - 1 1/2 CAP 3000# SW STL A105 NORM

650 COUFSW 5478109EM 1/2 - 1 1/2 COUPLING 3000# SW STL A105 NORM

660 PLGSCR 5490670 1/2 - 1 1/2 PLUG HEX HEAD SCRD STL A105

670 CAPSCR 5490566EM 1/2 - 1/2 CAP 6000# SCRD STL A105 NORM

680 CAPSCR 5490267EM 3/4 - 1 1/2 CAP 3000# SCRD STL A105 NORM

690 PLGSW 5478115EM 1/2 - 1 1/2 PLUG ROUND HEAD SW STL A105 NORM

700

710 SOLLET 5532671EM 1/2 - 1 1/2 SOCKOLET 3000# STL A105 NORM 2 - 24

720 TOLLET 5514691EM 1/2 - 1/2 THREDOLET 6000# STL A105 NORM 2 - 24

730 TOLLET 5514671EM 3/4 - 1 1/2 THREDOLET 3000# STL A105 NORM 2 - 24

740

750 ELLBW 5374276 2-2 ELL 90 DEG LR XS STL A234 WPB

760 45LBW 5374282 2-2 ELL 45 DEG XS STL A234 WPB

770 TEEBW 5374285 2-2 TEE XS STL A234 WPB

780 TERBW 5374135 2-2 TEE RED STD X XS STL A234 WPB 3-4

790 CAPBW 5374286 2-2 CAP XS STL A234 WPB

800 REDCBW 5374137 2-2 REDUCER CONC STD X XS STL A234 WPB 3-4

810 REDEBW 5374138 2-2 REDUCER ECC STD X XS STL A234 WPB 3-4

820 WOLLET 5504207EM 2-2 WELDOLET STD WT X XS STL A105 NORM 6 - 24

830

840 ELLBW 5374114 3 - 24 ELL 90 DEG LR STD WT STL A234 WPB

850 45LBW 5374120 3 - 24 ELL 45 DEG STD WT STL A234 WPB

860 TEEBW 5374123 3 - 24 TEE STD WT STL A234 WPB SERVICE

870 Reduci 5374122 3 - 20 TEE RED STD WT STL A234 WPB 4 - 24 GENERAL PROCESS, GLYCOL/TEG,

880 CAPBW 5374124 3 - 24 CAP STD WT STL A234 WPB HYDROCARBONS, CHEMICALS, PRODUCED WATER,

890 REDCBW 5374125 3 - 20 REDUCER CONC STD WT STL A234 WPB 4 - 24 OPEN AND CLOSED DRAINS.

900 REDEBW 5374126 3 - 20 REDUCER ECC STD WT STL A234 WPB 4 - 24

DESIGN: ASME B16.5 MG 1.1

910 WOLLET 5504203EM 3 - 16 WELDOLET STD WT STL A105 NORM 8 - 24

CODE: ASME B31.3

920

930 ***** PIPE FLANGES *****

940

950 SWFRF 5601738EM 1/2 - 1 1/2 FLG SW 150# RF STL XS BORE A105 NORM

960 WNKRF 5554405EM 2-2 FLG WN 150# RF STL XS BORE A105 NORM MATERIAL: CARBON STEEL

970 WNKRF 5554402EM 3 - 24 FLG WN 150# RF STL STD BORE A105 NORM FLANGE RATING: 150 RF

980 TEMPERATURE RANGE: -5 / 205 °C

990 0A FD3 SWFRF 5601798EM 1/2 - 1 1/2 FLG SW 300# RF STL XS BORE A105 NORM

COMMENT:

1000 0A FD3 WNKRF 5554638EM 2-2 FLG WN 300# RF STL XS BORE A105 NORM

Iraq West Qurna I Project CONSTRUCTION Iraq West Qurna I Project

Fluor Transworld Services, Inc. 1 1/2" & SMALLER - SOCKETWELD

CORR. ALLOW. DATE BY REV SHEET PA CLASS

2" & LARGER - BUTTWELD

W3QR

1.5 MM 02JUN11 RAP 0A 2 OF 4 5 A1C

Southern Iraq

26-Sep-2012, Rev. 0A IQWQ-FT-LSPDS-00-032003

Page 17 of 73

SEQ REV NOTE ITEM ITEM CODE SIZE RANGE / DESCRIPTION REFERENCE / NOTES

NO. NO. NAME SMALL END SIZES LARGE END SIZES

1010 0A FD3 WNKRF 5554635EM 3 - 24 FLG WN 300# RF STL STD BORE A105 NORM

1020

1030 BLFRF 5615476EM 1/2 - 24 FLG BLIND 150# RF STL A105 NORM

1040 0A FD3 BLFRF 5615497EM 1/2 - 24 FLG BLIND 300# RF STL A105 NORM

1050

1060 ***** ORIFICE FLANGES *****

1070

1080 ORIRF 5622523EM 2-2 WN ORIF SET 300# RF STL XS BORE A105 NORM

1090 ORIRF 5622520EM 3 - 24 WN ORIF SET 300# RF STL STD BORE A105 NORM

1100

1110 ***** PIPE NIPPLES *****

1120

1130 NIPTBE 5539171 1/2 - 1/2 NIPPLE XXS STL A106-B TBE 75 MM (3") LONG

1140 NIPTBE 5539131 3/4 - 1 1/2 NIPPLE SCH 160 STL A106-B TBE 75 MM (3") LONG

1150 NIPTOE 5539181 1/2 - 1/2 NIPPLE XXS STL A106-B TOE 75 M (3") LONG

1160 NIPTOE 5539141 3/4 - 1 1/2 NIPPLE SCH 160 STL A106-B TOE 75 MM (3") LONG

1170 NIPPBE 5539111 1/2 - 1 1/2 NIPPLE XS STL A106-B PBE 75 MM (3") LONG

1180 0A 051 NIPPBE 5539151 1/2 - 1 NIPPLE SCH 160 STL A106-B PBE 75 MM (3") LONG

1190

1200 NIPTBE 5539173 1/2 - 1/2 NIPPLE XXS STL A106-B TBE 150 MM (6") LONG

1210 NIPTBE 5539133 3/4 - 1 1/2 NIPPLE SCH 160 STL A106-B TBE 150 MM (6") LONG

1220 NIPTOE 5539183 1/2 - 1/2 NIPPLE XXS STL A106-B TOE 150 MM (6") LONG

1230 NIPTOE 5539143 3/4 - 1 1/2 NIPPLE SCH 160 STL A106-B TOE 150 MM (6") LONG

1240 NIPPBE 5539113 1/2 - 1 1/2 NIPPLE XS STL A106-B PBE 150 MM (6") LONG

1250 0A 051 NIPPBE 5539153 1/2 - 1 NIPPLE SCH 160 STL A106-B PBE 150 MM (6") LONG

1260

1270 101 ***** SWAGE NIPPLES *****

1280

1290 SWACBE 5543611 1/2 - 1 1/2 SWAGE CONC XS STL A234 WPB BBE 3/4 - 3

1300

1310 SWAEBE 5548701 1/2 - 1 1/2 SWAGE ECC XS STL A234 WPB BBE 3/4 - 3

1320

1330 ***** GASKETS *****

1340

1350 0A GF3 GASFR 5668831 1/2 - 1 1/2 GASKET 150# GRAFOIL TANG RING 1/16" THK

1351 0A GASFRS 5672129 2 - 24 GASKET 150# 304SS SP WND GRAPHITE LS IR SERVICE

1360 GENERAL PROCESS, GLYCOL/TEG,

1370 0A GASFRS 5672150 1/2 - 24 GASKET 300# 304SS SP WND GRAPHITE IR HYDROCARBONS, CHEMICALS, PRODUCED WATER,

1380 OPEN AND CLOSED DRAINS.

1400 ***** BOLTING *****

DESIGN: ASME B16.5 MG 1.1

1410

CODE: ASME B31.3

1420 BOLS 5675648EM 1/4 - 99 STUD-BOLT A193 GR B7 W/A194 GR 2H NUTS CTD

1430

1440 ***** TEMPORARY STRAINERS *****

1450

1460 STRWYE 5762126 1/2 - 1 1/2 Y-STRAINER 600# SW STL 304 SCR .033 PERF MATERIAL: CARBON STEEL

1470 0A MS9 STRCON 5762575 2 - 24 STRAINER 150# RF/FF STL CONICAL FLANGE RATING: 150 RF

1480 TEMPERATURE RANGE: -5 / 205 °C

1490 ***** LINE BLANKS *****

COMMENT:

1500

Iraq West Qurna I Project CONSTRUCTION Iraq West Qurna I Project

Fluor Transworld Services, Inc. 1 1/2" & SMALLER - SOCKETWELD

CORR. ALLOW. DATE BY REV SHEET PA CLASS

2" & LARGER - BUTTWELD

W3QR

1.5 MM 02JUN11 RAP 0A 3 OF 4 5 A1C

Southern Iraq

26-Sep-2012, Rev. 0A IQWQ-FT-LSPDS-00-032003

Page 18 of 73

SEQ REV NOTE ITEM ITEM CODE SIZE RANGE / DESCRIPTION REFERENCE / NOTES

NO. NO. NAME SMALL END SIZES LARGE END SIZES

1510 0A SPEDIS 5749852 1/2 - 1 1/2 BLANK PADDLE 150# RF STL

1520 0A NE1 SPEDIS 5749854 1 - 1 1/2 BLANK PADDLE 300# RF STL

1530 Specta 5749496 2 - 14 FIGURE 8 BLANK 150# RF STL

1540

1550 Paddle 5749852 16 - 24 BLANK PADDLE 150# RF STL

1560 Paddle 5750153 16 - 24 SPACER PADDLE 150# RF STL

1570

1580 ***** BRANCHES *****

1590

1600 USE BRANCH TABLE

1610

1620 ***** CONSTRUCTION DETAILS *****

1630

1640 SEAL WELDING ----------- REQUIRED

1650 PIPE BENDS ----------- NONE

1660 THREAD SEALANT ------ KEY GRAPHITE PASTE

1670 0A PWHT ----------- PER IQWQ-FT-LTTDS-00-0004

1680 0A NDE ----------- PER IQWQ-FT-LTTDS-00-0004

1690

1700

1710 FOR VENTS/DRAINS, SAMPLE, PIPING/INSTRUMENT

1720 CONNECTIONS, REFER TO MODULES IN

1730 IQWQ-FT-LSSTD-00-0007

SERVICE

GENERAL PROCESS, GLYCOL/TEG,

HYDROCARBONS, CHEMICALS, PRODUCED WATER,

OPEN AND CLOSED DRAINS.

DESIGN: ASME B16.5 MG 1.1

CODE: ASME B31.3

MATERIAL: CARBON STEEL

FLANGE RATING: 150 RF

TEMPERATURE RANGE: -5 / 205 °C

COMMENT:

Iraq West Qurna I Project CONSTRUCTION Iraq West Qurna I Project

Fluor Transworld Services, Inc. 1 1/2" & SMALLER - SOCKETWELD

CORR. ALLOW. DATE BY REV SHEET PA CLASS

2" & LARGER - BUTTWELD

W3QR

1.5 MM 02JUN11 RAP 0A 4 OF 4 5 A1C

Southern Iraq

26-Sep-2012, Rev. 0A IQWQ-FT-LSPDS-00-032003

Page 19 of 73

-

Iraq West Qurna I Project Contract: W3QR

Southern Iraq Fluor Transworld Services, Inc.

LINE CLASS: A1C

LEGEND : ANGLE: 90°

REV: 0A

A = Sockolet®

RT = Reducing Tee (B.W. for 2" and larger,

S.W. for 1-1/2" and smaller) Pressure - Temperature

T = Tee (B.W. for 2" and larger, Ratings

S.W. for 1-1/2" and smaller) T (°C) P (kg/cm2)

W = Weldolet® -5 20.0

38 20.0

24 T 50 19.6

20 RT T 100 18.0

18 RT RT T 150 16.1

16 W RT RT T 200 14.1

14 W W RT RT T 205 13.9

BRANCH SIZE - NPS

12 W W W RT RT T

10 W W W W RT RT T

8 W W W W W RT RT T

6 W W W W W W RT RT T

4 W W W W W W W RT RT T

3 W W W W W W W W RT RT T

2 W W W W W W W W W RT RT T

1-1/2 A A A A A A A A A A A A T

1 A A A A A A A A A A A A RT T

3/4 A A A A A A A A A A A A RT RT T

1/2 A A A A A A A A A A A A RT RT RT T

24 20 18 16 14 12 10 8 6 4 3 2 1-1/2 1 3/4 1/2

HEADER SIZE - NPS

Note:

a. Where additional reinforcing is required for mechanical strength, use reinforcement as indicated on the piping drawing.

b. For 45° branch connections see IQWQ-FT-LSPDS-00-030101.

0A

A1C

25.0

20.0

Pressure (kg/cm^2)

15.0

10.0

5.0

0.0

38

50

-5

100

150

200

205

Temperature (°C)

26-Sep-2012, Rev. 0A IQWQ-FT-LSPDS-00-032003

Page 20 of 73

SEQ REV NOTE ITEM ITEM CODE SIZE RANGE / DESCRIPTION REFERENCE / NOTES

NO. NO. NAME SMALL END SIZES LARGE END SIZES

10 08 FULL PORT VALVES SHALL BE USED WHEN

20 ***** VALVES ***** INDICATED ON P&ID.

30 025 SWING OR DUAL PLATE CHECK VALVES

40 0A VB7 ***** BALL VALVES ***** SHALL BE DESIGNED FOR INSTALLATION IN

50 THE HORIZONTAL OR VERTICAL UPFLOW

60 BALPE DBAA5(L) 1/2 - 1 1/2 BALL 600# PBE STL, FS HNDL OP POSITIONS.

70 BALSCR DBAA6(L) 1/2 - 1 1/2 BALL 600# SCRD STL, 316 TR HNDL OP FS 027 PISTON TYPE CHECK VALVES IN SIZES NPS 1

1/2 AND SMALLER SHALL BE DESIGNED

80 0A BALSWS DBAA7(L) 1/2 - 1 1/2 BALL 600# SW X SE STL, FS HNDL OP

(WITH SPRINGS) FOR INSTALLATION IN THE

90 BALFLG BBAA0 1 - 1 1/2 BALL 300# RF STL, RP, FS, 316 TRIM HORIZONTAL OR UPWARD FLOW POSITIONS.

100 0A BALFLG BBAA0 2-6 BALL 300# RF STL, RP, FS, 316 TRIM

051 NPS 1 AND SMALLER FERRITIC PIPE NIPPLES

110 BALFLG ABAA0 2-6 BALL 150# RF STL, RP, FS. 316 TRIM BETWEEN EQUIPMENT AND THE FIRST

120 BALFLG ABAA0(GO) 8 - 24 BALL 150# RF STL, RP, FS. 316 TRIM GO BLOCK VALVE, OR BETWEEN A HEADER AND

130 BALFLG ABFA0 2-4 BALL 150# RF STL, FP, FS, 316 TRIM FIRST BLOCK VALVE, SHALL HAVE A

140 BALFLG ABFA0(GO) 6 - 24 BALL 150# RF STL, FP, FS, 316 TRIM GO MINIMUM THICKNESS OF SCHEDULE 160.

150 BALFLG ABAA0(DI) 2-6 BALL 150# RF STL, RP, DI, FS, 316 TRIM FOR THESE NIPPLES IN NONFERRITIC

160 BALFLG ABAA0(DI)-(GO) BALL 150# RF STL, RP, DI, FS, 316 TRIM GO PIPING, THE MINIMUM THICKNESS SHALL BE

8 - 24

SCHEDULE 80 (SOCKET WELDED) AND 160

170 BALFLG ABFA0(DI) 2-4 BALL 150# RF STL, FP, DI, FS, 316 TRIM (THREADED).

180 BALFLG ABFA0(DI)-(GO) 6 - 24 BALL 150# RF STL, FP, DI, FS, 316 TRIM GO

101 USE SWAGES IN THREADED PIPING

190 SYSTEMS WHERE SMALL END DOES NOT

200 025 ***** CHECK VALVES ***** EXCEED NPS 1½ AND LARGE END DOES NOT

210 EXCEED NPS 3. THE END PREPARATION IS

220 0A 027 CHESW YCNA5 3/4 - 1 1/2 CHECK 800# SW STL, PISTON, F6/STEL SEAT H&V TO BE IN ACCORDANCE WITH THE

230 0A VC5 CHELUG ACYA0 2 - 24 CHECK 150# RF STL, LUG DRILLED THRU APPROPRIATE LINE CLASS.

240 0A VC5 CHEFLG ACAA0 1 - 24 CHECK 150# RF STL, F6/STEL SEAT 144 ONLY TO BE USED AT ORIFICE TAPS AS

250 0A VC7 CHEFLG ACFA0 1 - 24 CHECK 150# RF STL, FP, F6/STEL SEAT INDICATED ON THE P&IDS.

260 294 UNDERGROUND PIPING SHALL BE ISOLATED

FROM ABOVEGROUND PIPING WITH

270 ***** GLOBE VALVES *****

INSULATING GASKET KIT, USE THIS ITEM TO

280 ISOLATE.

290 GLOSW YTAA5 3/4 - 1 1/2 GLOBE 800# SW STL, F6/STEL SEAT

DT3 IT IS NOT RECOMMENDED TO USE THIS ITEM

300 GLOFLG BTAA0 1 - 1 1/2 GLOBE 300# RF STL, F6/STEL SEAT IN CONDITIONS OVER 107 DEGREES CELCIUS

310 GLOFLG ATAA0 2-8 GLOBE 150# RF STL, F6/STEL SEAT DT4 IT IS NOT RECOMMENDED TO USE THIS ITEM

320 GLOFLG ATAA0(GO) 10 - 10 GLOBE 150# RF STL, F6/STEL SEAT GO IN CONDITIONS OVER 121 DEGREES CELCIUS

330

340 ***** BUTTERFLY VALVES *****

350

360 0A BTFFGO AFAA0(GO) BUTTERFLY TRIPLE 150# RF STL GO ISO SERVICE

3 - 24

370 GENERAL PROCESS, GLYCOL/TEG,

380 ***** GATE VALVES ***** HYDROCARBONS, CHEMICALS, PRODUCED WATER,

390 OPEN AND CLOSED DRAINS.

400 GATSW YGAA5 1/2 - 1 1/2 GATE 800# SW STL, F6/STEL SEATS

DESIGN: ASME B16.5 MG 1.1

410 0A 08 GATSW YGFA5 1/2 - 1 1/2 GATE 800# SW STL, F6/STEL SEATS FP CODE: ASME B31.3

420 GATSCR YGAA6 1/2 - 1 1/2 GATE 800# SCRD STL, F6/STEL SEATS

421 GATSWS YGFA7 3/4 - 1 1/2 GATE 800# SW/SCRD STL, F6/STEL FULL PORT BONNEY H-11

430 GATFLG BGAA0 1-3 GATE 300# RF STL, F6/STEL SEATS

440 GATSWS YGAA7 1/2 - 1 1/2 GATE 800# SW/SCRD STL, F6/STEL SEATS

450 GATFLG AGAA0 1 - 12 GATE 150# RF STL, F6/STEL SEATS MATERIAL: CARBON STEEL

460 0A GATFLG AGAA0(GO) 14 - 24 GATE 150# RF STL, F6/STEL SEATS GO FLANGE RATING: 150 RF

470 TEMPERATURE RANGE: -5 / 205 °C

480 ***** INSTRUMENT BLOCK VALVES ******

COMMENT:

490

Iraq West Qurna I Project CONSTRUCTION Iraq West Qurna I Project

Fluor Transworld Services, Inc. 1 1/2" & SMALLER - SOCKETWELD

CORR. ALLOW. DATE BY REV SHEET PA CLASS

2" & LARGER - BUTTWELD

W3QR

3 MM 02JUN11 RAP 0A 1 OF 5 5 A1E

Southern Iraq

26-Sep-2012, Rev. 0A IQWQ-FT-LSPDS-00-032003

Page 21 of 73

SEQ REV NOTE ITEM ITEM CODE SIZE RANGE / DESCRIPTION REFERENCE / NOTES

NO. NO. NAME SMALL END SIZES LARGE END SIZES

500 144 BALPSC DBAA17(L)-(DI) 1/2 - 1/2 BALL 600# PE X FNPT STL, DI, RP, FS, LEVER OP FD3 USE CLASS 300 FLANGES ONLY WHERE

510 BALPSC ABAA10(DI) 2-2 BALL 150# RF X FNPT STL, DI, RP, FS, LEVER OP REQUIRED.

520 GF3 USE WITH CLASS 150 SOCKETWELD

530 ***** PIPE ***** FLANGES.

540 MS9 THESE STRAINERS ARE FOR STARTUP USE

550 PIPBAR 5356038 1/2 - 1/2 PIPE XXS SMLS STL A106-B ONLY AND SHALL BE REMOVED PRIOR TO

560 PIPBAR 5356037 PIPE SCH 160 SMLS STL A106-B TURNOVER.

3/4 - 1 1/2

570 PIPBAR 5356037 2-2 PIPE SCH 160 SMLS STL A106-B NE1 TO BE USED WITH CLASS 300 VALVES ONLY.

580 PIPBAR 5356033 3-6 PIPE XS SMLS STL A106-B UK3 USE 2" SCH 160 WELDOLET AND CLASS 300

590 Piping 5356030 8 - 24 PIPE STD WT SMLS STL A106-B WELD NECK FLANGE SCH 160 BORE FOR

TEMPERATURE INSTRUMENT CONNECTIONS.

600

610 ***** FITTINGS ***** UK4 USE 2" SCH 160 ELBOLET AND CLASS 300

WELD NECK FLANGE SCH 160 BORE FOR

620 TEMPERATURE INSTRUMENT CONNECTIONS.

630 0A ELLSW 5478501EM 1/2 - 1/2 ELL 90 DEG 9000# SW STL A105 NORM

UK9 USE 2" SCH 160 CLASS 300 WELD NECK

640 0A 45LSW 5478502EM 1/2 - 1/2 ELL 45 DEG 9000# SW STL A105 NORM FLANGE WITH OLET FOR TEMPERATURE

650 0A TEESW 5478503EM 1/2 - 1/2 TEE 9000# SW STL A105 NORM CONNECTIONS.

660 0A TERSW 5478504EM 1/2 - 1/2 TEE RED 9000# SW STL A105 NORM 3/4 - 1 1/2 VB7 BALL VALVE TAGS TO BE USED AS

670 0A CAPSW 5478506EM 1/2 - 1/2 CAP 9000# SW STL A105 NORM INDICATED ON THE P&IDs.

680 0A COUFSW 5478507EM 1/2 - 1/2 COUPLING 9000# SW STL A105 NORM VC5 PREFERRED TYPE CHECK VALVE IN

690 PLGSCR 5490670 1/2 - 1/2 PLUG HEX HEAD SCRD STL A105 GENERAL SERVICES IS A RETAINERLESS

700 CAPSCR 5490566EM 1/2 - 1/2 CAP 6000# SCRD STL A105 NORM DUAL-PLATE STYLE CHECK VALVE, PER API

710 PLGSW 5478115EM 1/2 - 1/2 PLUG ROUND HEAD SW STL A105 NORM STANDARD 594, EXCEPT IN LINES THAT WILL

REQUIRE PIGGING.

720

730 0A SOLLET 5532840EM 1/2 - 1/2 SOCKOLET 9000# STL A105 NORM 2 - 24 VC7 TO BE USED IN LINES THAT WILL REQUIRE

PIGGING

740 TOLLET 5514691EM 1/2 - 1/2 THREDOLET 6000# STL A105 NORM 2 - 24

750

760 0A ELLSW 5478301EM 3/4 - 1 1/2 ELL 90 DEG 6000# SW STL A105 NORM

770 0A 45LSW 5478302EM 3/4 - 1 1/2 ELL 45 DEG 6000# SW STL A105 NORM

780 0A TEESW 5478303EM 3/4 - 1 1/2 TEE 6000# SW STL A105 NORM

790 0A TERSW 5478312EM 3/4 - 1 TEE RED 6000# SW STL A105 NORM 1 - 1 1/2

800 0A CAPSW 5478304EM 3/4 - 1 1/2 CAP 6000# SW STL A105 NORM

810 0A COUFSW 5478305EM 3/4 - 1 1/2 COUPLING 6000# SW STL A105 NORM

820 PLGSCR 5490670 3/4 - 1 1/2 PLUG HEX HEAD SCRD STL A105

830 0A CAPSCR 5490566EM 3/4 - 1 1/2 CAP 6000# SCRD STL A105 NORM

840 PLGSW 5478115EM 3/4 - 1 1/2 PLUG ROUND HEAD SW STL A105 NORM

850 SERVICE

860 0A SOLLET 5532831EM 3/4 - 1 1/2 SOCKOLET 6000# STL A105 NORM 2 - 24 GENERAL PROCESS, GLYCOL/TEG,

870 TOLLET 5514671EM 3/4 - 1 1/2 THREDOLET 3000# STL A105 NORM 2 - 24 HYDROCARBONS, CHEMICALS, PRODUCED WATER,

880 OPEN AND CLOSED DRAINS.

910 ELLBW 5374492 2-2 ELL 90 DEG LR SCH 160 STL A234 WPB

DESIGN: ASME B16.5 MG 1.1

920 45LBW 5374498 2-2 ELL 45 DEG SCH 160 STL A234 WPB

CODE: ASME B31.3

930 TEEBW 5374501 2-2 TEE SCH 160 STL A234 WPB

940 TERBW 5374299 2-2 TEE RED XS X 160 STL A234 WPB 3-4

950 CAPBW 5374502 2-2 CAP SCH 160 STL A234 WPB

960 REDCBW 5374303 2-2 REDUCER CONC XS X SCH 160 STL A234 WPB 3-4

970 REDEBW 5374304 2-2 REDUCER ECC XS X SCH 160 STL A234 WPB 3-4 MATERIAL: CARBON STEEL

980 UK3 WOLLET 5504361EM 2-2 WELDOLET XS X SCH 160 STL A105 NORM 6-6 FLANGE RATING: 150 RF

990 UK3 WOLLET 5504218EM 2-2 WELDOLET STD WT X SCH 160 STL A105 NORM 8 - 24 TEMPERATURE RANGE: -5 / 205 °C

991 UK4 EOTBW 5516696EM 2-2 ELBOLET XS X SCH 160 STL A105 NORM 6-6

COMMENT:

1010 0A UK4 EOTBW 5516697EM 2-2 ELBOLET STD WT X SCH 160 STL A105 NORM 8 - 24

Iraq West Qurna I Project CONSTRUCTION Iraq West Qurna I Project

Fluor Transworld Services, Inc. 1 1/2" & SMALLER - SOCKETWELD

CORR. ALLOW. DATE BY REV SHEET PA CLASS

2" & LARGER - BUTTWELD

W3QR

3 MM 02JUN11 RAP 0A 2 OF 5 5 A1E

Southern Iraq

26-Sep-2012, Rev. 0A IQWQ-FT-LSPDS-00-032003

Page 22 of 73

SEQ REV NOTE ITEM ITEM CODE SIZE RANGE / DESCRIPTION REFERENCE / NOTES

NO. NO. NAME SMALL END SIZES LARGE END SIZES

1011 0A LOTBW 5524693EM 2-2 LATROLET XS X SCH 160 STL A105 NORM 6-6

1012 0A LOTBW 5524694EM 2-2 LATROLET STD WT X SCH 160 STL A105 NORM 8 - 24

1020

1030 ELLBW 5374276 3-6 ELL 90 DEG LR XS STL A234 WPB

1040 45LBW 5374282 3-6 ELL 45 DEG XS STL A234 WPB

1050 TEEBW 5374285 3-6 TEE XS STL A234 WPB

1060 TERBW 5374284 3-4 TEE RED XS STL A234 WPB 4-6

1070 TERBW 5374135 4-6 TEE RED STD X XS STL A234 WPB 8 - 10

1080 CAPBW 5374286 3-6 CAP XS STL A234 WPB

1090 REDCBW 5374287 3-4 REDUCER CONC XS STL A234 WPB 4-6

1100 REDCBW 5374137 4-6 REDUCER CONC STD X XS STL A234 WPB 8 - 14

1110 REDEBW 5374288 3-4 REDUCER ECC XS STL A234 WPB 4-6

1120 REDEBW 5374138 4-6 REDUCER ECC STD X XS STL A234 WPB 8 - 14

1130 WOLLET 5504207EM 3-6 WELDOLET STD WT X XS STL A105 NORM 8 - 24

1140

1150 ELLBW 5374114 8 - 24 ELL 90 DEG LR STD WT STL A234 WPB

1160 45LBW 5374120 8 - 24 ELL 45 DEG STD WT STL A234 WPB

1170 TEEBW 5374123 8 - 24 TEE STD WT STL A234 WPB

1180 TERBW 5374122 8 - 20 TEE RED STD WT STL A234 WPB 10 - 24

1190 CAPBW 5374124 8 - 24 CAP STD WT STL A234 WPB

1200 REDCBW 5374125 8 - 20 REDUCER CONC STD WT STL A234 WPB 10 - 24

1210 REDEBW 5374126 8 - 20 REDUCER ECC STD WT STL A234 WPB 10 - 24

1220 WOLLET 5504203EM 8 - 16 WELDOLET STD WT STL A105 NORM 14 - 24

1230

1240 ***** PIPE FLANGES *****

1250

1260 0A SWFRF 5601750EM 1/2 - 1/2 FLG SW 150# RF STL XXS BORE A105 NORM

1270 0A SWFRF 5601747EM 3/4 - 1 1/2 FLG SW 150# RF STL 160 BORE A105 NORM

1280 WNKRF 5554409EM 2-2 FLG WN 150# RF STL 160 BORE A105 NORM

1290 WNKRF 5554405EM 3-6 FLG WN 150# RF STL XS BORE A105 NORM

1300 WNKRF 5554402EM 8 - 24 FLG WN 150# RF STL STD BORE A105 NORM

1310 SWFRF 5601750EM 1/2 - 1/2 FLG SW 150# RF STL XXS BORE A105 NORM

1311 SWFRF 5601747EM 3/4 - 1 1/2 FLG SW 150# RF STL 160 BORE A105 NORM

1312

1330 0A FD3 SWFRF 5601799EM 1/2 - 1/2 FLG SW 300# RF STL XXS BORE A105 NORM

1340 0A FD3 SWFRF 5601800EM 3/4 - 1 1/2 FLG SW 300# RF STL 160 BORE A105 NORM SERVICE

1350 0A FD3 WNKRF 5554642EM 2-2 FLG WN 300# RF STL 160 BORE A105 NORM GENERAL PROCESS, GLYCOL/TEG,

1360 0A UK9 HYDROCARBONS, CHEMICALS, PRODUCED WATER,

1370 0A FD3 WNKRF 5554638EM 3-6 FLG WN 300# RF STL XS BORE A105 NORM OPEN AND CLOSED DRAINS.

1380 0A FD3 WNKRF 5554635EM 8 - 24 FLG WN 300# RF STL STD BORE A105 NORM

DESIGN: ASME B16.5 MG 1.1

1390

CODE: ASME B31.3

1400 BLFRF 5615476EM 1/2 - 1 1/2 FLG BLIND 150# RF STL A105 NORM

1410 BLFRF 5615476EM 2 - 24 FLG BLIND 150# RF STL A105 NORM

1420

1430 BLFRF 5615497EM 1/2 - 1 1/2 FLG BLIND 300# RF STL A105 NORM

1440 BLFRF 5615497EM 2 - 24 FLG BLIND 300# RF STL A105 NORM MATERIAL: CARBON STEEL

1450 FLANGE RATING: 150 RF

1460 ***** ORIFICE FLANGES ***** TEMPERATURE RANGE: -5 / 205 °C

1470

COMMENT:

1480 ORIRF 5622527EM 2-2 WN ORIF SET 300# RF STL 160 BORE A105 NORM

Iraq West Qurna I Project CONSTRUCTION Iraq West Qurna I Project

Fluor Transworld Services, Inc. 1 1/2" & SMALLER - SOCKETWELD

CORR. ALLOW. DATE BY REV SHEET PA CLASS

2" & LARGER - BUTTWELD

W3QR

3 MM 02JUN11 RAP 0A 3 OF 5 5 A1E

Southern Iraq

26-Sep-2012, Rev. 0A IQWQ-FT-LSPDS-00-032003

Page 23 of 73

SEQ REV NOTE ITEM ITEM CODE SIZE RANGE / DESCRIPTION REFERENCE / NOTES

NO. NO. NAME SMALL END SIZES LARGE END SIZES

1490 ORIRF 5622523EM 3-6 WN ORIF SET 300# RF STL XS BORE A105 NORM

1500 ORIRF 5622520EM 8 - 24 WN ORIF SET 300# RF STL STD BORE A105 NORM

1510

1520 ***** PIPE NIPPLES *****

1530

1540 NIPTBE 5539171 1/2 - 1/2 NIPPLE XXS STL A106-B TBE 75 MM (3") LONG

1550 NIPTBE 5539131 3/4 - 1 1/2 NIPPLE SCH 160 STL A106-B TBE 75 MM (3") LONG

1560 NIPTOE 5539181 1/2 - 1/2 NIPPLE XXS STL A106-B TOE 75 M (3") LONG

1570 NIPTOE 5539141 3/4 - 1 1/2 NIPPLE SCH 160 STL A106-B TOE 75 MM (3") LONG

1580 NIPPBE 5539191 1/2 - 1/2 NIPPLE XXS STL A106-B PBE 75 MM (3") LONG

1590 0A 051 NIPPBE 5539151 3/4 - 1 NIPPLE SCH 160 STL A106-B PBE 75 MM (3") LONG

1600

1610 NIPTBE 5539173 1/2 - 1/2 NIPPLE XXS STL A106-B TBE 150 MM (6") LONG

1620 NIPTBE 5539133 3/4 - 1 1/2 NIPPLE SCH 160 STL A106-B TBE 150 MM (6") LONG

1630 NIPTOE 5539183 1/2 - 1/2 NIPPLE XXS STL A106-B TOE 150 MM (6") LONG

1640 NIPTOE 5539143 3/4 - 1 1/2 NIPPLE SCH 160 STL A106-B TOE 150 MM (6") LONG

1650 NIPPBE 5539193 1/2 - 1/2 NIPPLE XXS STL A106-B PBE 150 MM (6") LONG

1660 0A 051 NIPPBE 5539153 3/4 - 1 NIPPLE SCH 160 STL A106-B PBE 150 MM (6") LONG

1670

1680 101 ***** SWAGE NIPPLES *****

1690

1700 SWACBE 5543711 1/2 - 1/2 SWAGE CONC XXS STL A234 WPB BBE 3/4 - 2

1710 0A SWACBE 5543661 3/4 - 1 1/2 SWAGE CONC SCH 160 STL A234 WPB BBE 1-3

1720 0A SWACTS 5543591 3/4 - 2 SWAGE CONC XS STL A234 WPB TSE 1 1/2 - 4

1721

1722 0A SWAETS 5548681 3/4 - 2 SWAGE ECC XS STL A234 WPB TSE 1 1/2 - 4

1730 0A SWAEBE 5548751 3/4 - 1 1/2 SWAGE ECC SCH 160 STL A234 WPB BBE 1-3

1740

1750 ***** GASKETS *****

1760

1770 0A GF3 GASFR 5668831 1/2 - 1 1/2 GASKET 150# GRAFOIL TANG RING 1/16" THK

1790 GASFRS 5672129 2 - 24 GASKET 150# 304SS SP WND GRAPHITE LS IR

1800

1810 GASFRS 5672150 1/2 - 1 1/2 GASKET 300# 304SS SP WND GRAPHITE IR

1820 GASFRS 5672150 2 - 24 GASKET 300# 304SS SP WND GRAPHITE IR

1830 SERVICE

1850 0A 294 GASRJ 5674548EM 2 - 12 GASKET 150# INSULATING GASKET AND GAS KIT FS GENERAL PROCESS, GLYCOL/TEG,

1860 0A 294 GASRJ 5674549EM 2 - 12 GASKET 300# INSULATING GASKET AND GAS KIT FS HYDROCARBONS, CHEMICALS, PRODUCED WATER,

1870 OPEN AND CLOSED DRAINS.

1880 ***** BOLTING *****

DESIGN: ASME B16.5 MG 1.1

1890

CODE: ASME B31.3

1900 BOLS 5675648EM 1/4 - 99 STUD-BOLT A193 GR B7 W/A194 GR 2H NUTS CTD

1910

1920 ***** TEMPORARY STRAINERS *****

1930

1940 STRWYE 5762126 1/2 - 1 1/2 Y-STRAINER 600# SW STL 304 SCR .033 PERF MATERIAL: CARBON STEEL

1950 MS9 STRCON 5762575 2 - 24 STRAINER 150# RF/FF STL CONICAL FLANGE RATING: 150 RF

1960 TEMPERATURE RANGE: -5 / 205 °C

1970 ***** LINE BLANKS *****

COMMENT:

1980

Iraq West Qurna I Project CONSTRUCTION Iraq West Qurna I Project

Fluor Transworld Services, Inc. 1 1/2" & SMALLER - SOCKETWELD

CORR. ALLOW. DATE BY REV SHEET PA CLASS

2" & LARGER - BUTTWELD

W3QR

3 MM 02JUN11 RAP 0A 4 OF 5 5 A1E

Southern Iraq

26-Sep-2012, Rev. 0A IQWQ-FT-LSPDS-00-032003

Page 24 of 73

SEQ REV NOTE ITEM ITEM CODE SIZE RANGE / DESCRIPTION REFERENCE / NOTES

NO. NO. NAME SMALL END SIZES LARGE END SIZES

1990 0A SPEDIS 5749852 1/2 - 1 1/2 BLANK PADDLE 150# RF STL

2000 0A NE1 SPEDIS 5749854 1 - 1 1/2 BLANK PADDLE 300# RF STL

2010 Specta 5749496 2 - 14 FIGURE 8 BLANK 150# RF STL

2020

2030 Paddle 5749852 16 - 24 BLANK PADDLE 150# RF STL

2040 Paddle 5750153 16 - 24 SPACER PADDLE 150# RF STL

2050

2060 ***** MISCELLANEOUS ITEMS *****

2070

2080 WNKRF 5555104 8-8 FLG WN 600# RF STL STD BORE A105

2090 GASFRS 5672196 8-8 GASKET 600# 304SS SP WND GRAPHITE IR

2100 0A STRWYE 5763052 2-4 Y-STRAINER 150# RF STL, 304 SCR .033PERF MUELLER 781

2110 0A SPEBLD 5749497 2-6 FIGURE 8 BLANK 300# RF STL

2120 0A LOTBW 5524693EM 2-2 LATROLET XS X SCH 160 STL A105 NORM 6-6

2130 0A LOTBW 5524694EM 2-2 LATROLET STD WT X SCH 160 STL A105 NORM 8 - 24

2140

2150 0A ***** UNDERGROUND CONSTRUCTION *****

2160

2170 0A 294 PIPBAR 5356547EM 2-2 PIPE SCH 160 SMLS STL A106-B 3LPE

2180 0A 294 PIPBAR 5356543EM 3-6 PIPE XS SMLS STL A106-B 3LPE

2190 0A 294 PIPBAR 5356540EM 8 - 12 PIPE STD WT SMLS STL A106-B 3LPE

2200 DT3 SPACAS 5810100EM 2 - 12 CASING SPACER HDPE MODEL KP POLY SPACER

2201 DT4 LINSEL 5810200EM 3 - 10 LINK SEAL MODULAR SEAL EPDM (BLACK) MODEL C

2202

2210 ***** BRANCHES *****

2220

2230 USE BRANCH TABLE

2240

2250 ***** CONSTRUCTION DETAILS *****

2260

2270 SEAL WELDING ----------- REQUIRED

2280 PIPE BENDS ----------- NONE

2290 THREAD SEALANT ------ KEY GRAPHITE PASTE

2300 0A PWHT ----------- PER IQWQ-FT-LTTDS-00-0004

2310 0A NDE ----------- PER IQWQ-FT-LTTDS-00-0004

2320 SERVICE

2330 GENERAL PROCESS, GLYCOL/TEG,

2340 FOR VENTS/DRAINS, SAMPLE, PIPING/INSTRUMENT HYDROCARBONS, CHEMICALS, PRODUCED WATER,

2350 CONNECTIONS, REFER TO MODULES IN OPEN AND CLOSED DRAINS.

2360 IQWQ-FT-LSSTD-00-0007

DESIGN: ASME B16.5 MG 1.1

2370

CODE: ASME B31.3

MATERIAL: CARBON STEEL

FLANGE RATING: 150 RF

TEMPERATURE RANGE: -5 / 205 °C

COMMENT:

Iraq West Qurna I Project CONSTRUCTION Iraq West Qurna I Project

Fluor Transworld Services, Inc. 1 1/2" & SMALLER - SOCKETWELD

CORR. ALLOW. DATE BY REV SHEET PA CLASS

2" & LARGER - BUTTWELD

W3QR

3 MM 02JUN11 RAP 0A 5 OF 5 5 A1E

Southern Iraq

26-Sep-2012, Rev. 0A IQWQ-FT-LSPDS-00-032003

Page 25 of 73

-

Iraq West Qurna I Project Contract: W3QR

Southern Iraq Fluor Transworld Services, Inc.

LINE CLASS: A1E

LEGEND : ANGLE: 90°

REV: 0A

A = Sockolet®

RT = Reducing Tee (B.W. for 2" and larger,

S.W. for 1-1/2" and smaller) Pressure - Temperature

T = Tee (B.W. for 2" and larger, Ratings

S.W. for 1-1/2" and smaller) T (°C) P (kg/cm2)

W = Weldolet® -5 20.0

38 20.0

24 T 50 19.6

20 RT T 100 18.0

18 RT RT T 150 16.1

16 W RT RT T 200 14.1

14 W W RT RT T 205 13.9

BRANCH SIZE - NPS

12 W W W RT RT T

10 W W W W RT RT T

8 W W W W W RT RT T

6 W W W W W W RT RT T

4 W W W W W W W RT RT T

3 W W W W W W W W RT RT T

2 W W W W W W W W W RT RT T

1-1/2 A A A A A A A A A A A A T

1 A A A A A A A A A A A A RT T

3/4 A A A A A A A A A A A A RT RT T

1/2 A A A A A A A A A A A A RT RT RT T

24 20 18 16 14 12 10 8 6 4 3 2 1-1/2 1 3/4 1/2

HEADER SIZE - NPS

Note:

a. Where additional reinforcing is required for mechanical strength, use reinforcement as indicated on the piping drawing.

b. For 45° branch connections see IQWQ-FT-LSPDS-00-030101.

0A

A1E

25.0

20.0

Pressure (kg/cm^2)

15.0

10.0

5.0

0.0

38

50

-5

100

150

200

205

Temperature (°C)

26-Sep-2012, Rev. 0A IQWQ-FT-LSPDS-00-032003

Page 26 of 73

SEQ REV NOTE ITEM ITEM CODE SIZE RANGE / DESCRIPTION REFERENCE / NOTES

NO. NO. NAME SMALL END SIZES LARGE END SIZES

10 025 SWING OR DUAL PLATE CHECK VALVES

20 ***** VALVES ***** SHALL BE DESIGNED FOR INSTALLATION IN

30 THE HORIZONTAL OR VERTICAL UPFLOW

40 VB7 ***** BALL VALVES ***** POSITIONS.

50 027 PISTON TYPE CHECK VALVES IN SIZES NPS 1

70 BALSWS DBAA7(L) 3/4 - 1 1/2 BALL 600# SW X SE STL, FS HNDL OP 1/2 AND SMALLER SHALL BE DESIGNED

(WITH SPRINGS) FOR INSTALLATION IN THE

80 BALFLG BBAA0 1 - 1 1/2 BALL 300# RF STL, RP, FS, 316 TRIM

HORIZONTAL OR UPWARD FLOW POSITIONS.

90 BALFLG ABAA0 2-6 BALL 150# RF STL, RP, FS. 316 TRIM

101 USE SWAGES IN THREADED PIPING

100 BALFLG ABAA0(GO) 8 - 24 BALL 150# RF STL, RP, FS. 316 TRIM GO SYSTEMS WHERE SMALL END DOES NOT

110 BALFLG ABFA0 2-4 BALL 150# RF STL, FP, FS, 316 TRIM EXCEED NPS 1½ AND LARGE END DOES NOT

120 BALFLG ABFA0(GO) 6 - 24 BALL 150# RF STL, FP, FS, 316 TRIM GO EXCEED NPS 3. THE END PREPARATION IS

130 BALFLG ABAA0(DI) 2-6 BALL 150# RF STL, RP, DI, FS, 316 TRIM TO BE IN ACCORDANCE WITH THE

140 BALFLG ABAA0(DI)-(GO) 8 - 24 BALL 150# RF STL, RP, DI, FS, 316 TRIM GO APPROPRIATE LINE CLASS.

150 BALFLG ABFA0(DI) 2-4 BALL 150# RF STL, FP, DI, FS, 316 TRIM FD3 USE CLASS 300 FLANGES ONLY WHERE

160 BALFLG ABFA0(DI)-(GO) 6 - 24 BALL 150# RF STL, FP, DI, FS, 316 TRIM GO REQUIRED.

170 GF3 USE WITH CLASS 150 SOCKETWELD

180 025 ***** CHECK VALVES ***** FLANGES.

190 MS9 THESE STRAINERS ARE FOR STARTUP USE

ONLY AND SHALL BE REMOVED PRIOR TO

200 027 CHESW FCNA5 3/4 - 1 1/2 CHECK 1500# SW STL, PISTON, F6/STEL SEAT H&V

TURNOVER.

201 CHESW YCNA5 3/4 - 1 1/2 CHECK 800# SW STL, PISTON, F6/STEL SEAT H&V

NE1 TO BE USED WITH CLASS 300 VALVES ONLY.

210 VC5 CHELUG ACYA0 2 - 24 CHECK 150# RF STL, LUG DRILLED THRU

220 VC5 CHEFLG ACAA0 CHECK 150# RF STL, F6/STEL SEAT UK3 USE 2" SCH 160 WELDOLET AND CLASS 300

1 - 24

WELD NECK FLANGE SCH 160 BORE FOR

230 VC7 CHEFLG ACFA0 1 - 24 CHECK 150# RF STL, FP, F6/STEL SEAT TEMPERATURE INSTRUMENT CONNECTIONS.

240

UK4 USE 2" SCH 160 ELBOLET AND CLASS 300

250 ***** GLOBE VALVES ***** WELD NECK FLANGE SCH 160 BORE FOR

260 TEMPERATURE INSTRUMENT CONNECTIONS.

270 GLOSW FTAA5 3/4 - 1 1/2 GLOBE 1500# SW STL, F6/STEL SEAT UK9 USE 2" SCH 160 CLASS 300 WELD NECK

280 GLOFLG BTAA0 1 - 1 1/2 GLOBE 300# RF STL, F6/STEL SEAT FLANGE WITH OLET FOR TEMPERATURE

290 GLOFLG ATAA0 2-8 GLOBE 150# RF STL, F6/STEL SEAT CONNECTIONS.

300 GLOFLG ATAA0(GO) 10 - 12 GLOBE 150# RF STL, F6/STEL SEAT GO VB7 BALL VALVE TAGS TO BE USED AS

310 INDICATED ON THE P&IDs.

320 ***** BUTTERFLY VALVES *****

330

340 BTFFGO AFAA0(GO) 3 - 24 BUTTERFLY TRIPLE 150# RF STL GO ISO

350

360 ***** GATE VALVES ***** SERVICE

370 GENERAL PROCESS, GLYCOL/TEG,

380 GATSW FGAA5 3/4 - 1 1/2 GATE 1500# SW STL, F6/STEL SEATS BB HYDROCARBONS, CHEMICALS, UTILITY WATER,

390 GATSCR FGAA6 3/4 - 1 1/2 GATE 1500# SCRD STL, F6/STEL SEATS OPEN AND CLOSED DRAINS.

400 GATSWS FGAA7 3/4 - 1 1/2 GATE 1500# SW/SCRD STL, F6/STEL BB

DESIGN: ASME B16.5 MG 1.1

401 GATSW YGAA5 3/4 - 1 1/2 GATE 800# SW STL, F6/STEL SEATS CODE: ASME B31.3

402 GATSWS YGAA7 1/2 - 1 1/2 GATE 800# SW/SCRD STL, F6/STEL SEATS

430 GATFLG BGAA0 1 - 1 1/2 GATE 300# RF STL, F6/STEL SEATS

440 GATFLG AGAA0 1 - 12 GATE 150# RF STL, F6/STEL SEATS

450 GATFLG AGAA0(GO) 14 - 24 GATE 150# RF STL, F6/STEL SEATS GO

460 MATERIAL: CARBON STEEL

470 ***** INSTRUMENT BLOCK VALVES ****** FLANGE RATING: 150 RF

480 TEMPERATURE RANGE: -5 / 205 °C

490 BALPSC ABAA10(DI) 2-2 BALL 150# RF X FNPT STL, DI, RP, FS, LEVER OP

COMMENT:

500

Iraq West Qurna I Project CONSTRUCTION Iraq West Qurna I Project

Fluor Transworld Services, Inc. 1 1/2" & SMALLER - SOCKETWELD

CORR. ALLOW. DATE BY REV SHEET PA CLASS

2" & LARGER - BUTTWELD

W3QR

5 MM 17FEB12 MVP 0A 1 OF 4 5 A1H

Southern Iraq

26-Sep-2012, Rev. 0A IQWQ-FT-LSPDS-00-032003

Page 27 of 73

SEQ REV NOTE ITEM ITEM CODE SIZE RANGE / DESCRIPTION REFERENCE / NOTES

NO. NO. NAME SMALL END SIZES LARGE END SIZES

501 VC5 PREFERRED TYPE CHECK VALVE IN

502 GENERAL SERVICES IS A RETAINERLESS

510 ***** PIPE ***** DUAL-PLATE STYLE CHECK VALVE, PER API

520 STANDARD 594, EXCEPT IN LINES THAT WILL

REQUIRE PIGGING.

530 PIPBAR 5356038 3/4 - 1 1/2 PIPE XXS SMLS STL A106-B

540 PIPBAR 5356037 PIPE SCH 160 SMLS STL A106-B VC7 TO BE USED IN LINES THAT WILL REQUIRE

2-4

PIGGING

570 PIPBAR 5356033 6 - 24 PIPE XS SMLS STL A106-B

580

590 ***** FITTINGS *****

600

610 ELLSW 5478501EM 3/4 - 1 1/2 ELL 90 DEG 9000# SW STL A105 NORM

620 45LSW 5478502EM 3/4 - 1 1/2 ELL 45 DEG 9000# SW STL A105 NORM

630 TEESW 5478503EM 3/4 - 1 1/2 TEE 9000# SW STL A105 NORM

640 TERSW 5478504EM 3/4 - 1 TEE RED 9000# SW STL A105 NORM 1 - 1 1/2

650 CAPSW 5478506EM 3/4 - 1 1/2 CAP 9000# SW STL A105 NORM

660 COUFSW 5478507EM 3/4 - 1 1/2 COUPLING 9000# SW STL A105 NORM

670 PLGSCR 5490670 3/4 - 1 1/2 PLUG HEX HEAD SCRD STL A105

680 CAPSCR 5490566EM 3/4 - 1 1/2 CAP 6000# SCRD STL A105 NORM

690 PLGSW 5478115EM 3/4 - 1 1/2 PLUG ROUND HEAD SW STL A105 NORM

700

710 SOLLET 5532840EM 3/4 - 1 1/2 SOCKOLET 9000# STL A105 NORM 2 - 24

720 TOLLET 5514691EM 3/4 - 1 1/2 THREDOLET 6000# STL A105 NORM 2 - 24

730

760 ELLBW 5374492 2-4 ELL 90 DEG LR SCH 160 STL A234 WPB

770 45LBW 5374498 2-4 ELL 45 DEG SCH 160 STL A234 WPB

780 TEEBW 5374501 2-4 TEE SCH 160 STL A234 WPB

790 TERBW 5374500 2-3 TEE RED SCH 160 STL A234 WPB 3-4

800 TERBW 5374299 3-4 TEE RED XS X 160 STL A234 WPB 6-8

810 CAPBW 5374502 2-4 CAP SCH 160 STL A234 WPB

820 REDCBW 5374503 2-3 REDUCER CONC SCH 160 STL A234 WPB 3-4

830 REDCBW 5374303 3-4 REDUCER CONC XS X SCH 160 STL A234 WPB 6 - 10

840 REDEBW 5374504 2-3 REDUCER ECC SCH 160 STL A234 WPB 3-4

850 REDEBW 5374304 3-4 REDUCER ECC XS X SCH 160 STL A234 WPB 6 - 10

860 UK3 WOLLET 5504361EM 2-4 WELDOLET XS X SCH 160 STL A105 NORM 6 - 24

890 UK4 EOTBW 5516696EM 2-2 ELBOLET XS X SCH 160 STL A105 NORM 6 - 24

920 SERVICE

930 ELLBW 5374276 6 - 24 ELL 90 DEG LR XS STL A234 WPB GENERAL PROCESS, GLYCOL/TEG,

940 45LBW 5374282 6 - 24 ELL 45 DEG XS STL A234 WPB HYDROCARBONS, CHEMICALS, UTILITY WATER,

950 TEEBW 5374285 6 - 24 TEE XS STL A234 WPB OPEN AND CLOSED DRAINS.

960 TERBW 5374284 6 - 20 TEE RED XS STL A234 WPB 8 - 24

DESIGN: ASME B16.5 MG 1.1

980 CAPBW 5374286 6 - 24 CAP XS STL A234 WPB

CODE: ASME B31.3

990 REDCBW 5374287 6 - 20 REDUCER CONC XS STL A234 WPB 8 - 24

1050 REDEBW 5374288 6 - 20 REDUCER ECC XS STL A234 WPB 8 - 24

1080 WOLLET 5504359EM 6 - 16 WELDOLET XS STL A105 NORM 12 - 24

1110

1230 MATERIAL: CARBON STEEL

1231 FLANGE RATING: 150 RF

1232 TEMPERATURE RANGE: -5 / 205 °C

1320 ***** PIPE FLANGES *****

COMMENT:

1330

Iraq West Qurna I Project CONSTRUCTION Iraq West Qurna I Project

Fluor Transworld Services, Inc. 1 1/2" & SMALLER - SOCKETWELD

CORR. ALLOW. DATE BY REV SHEET PA CLASS

2" & LARGER - BUTTWELD

W3QR

5 MM 17FEB12 MVP 0A 2 OF 4 5 A1H

Southern Iraq

26-Sep-2012, Rev. 0A IQWQ-FT-LSPDS-00-032003

Page 28 of 73

SEQ REV NOTE ITEM ITEM CODE SIZE RANGE / DESCRIPTION REFERENCE / NOTES

NO. NO. NAME SMALL END SIZES LARGE END SIZES

1350 SWFRF 5601750EM 3/4 - 1 1/2 FLG SW 150# RF STL XXS BORE A105 NORM

1360 WNKRF 5554409EM 2-4 FLG WN 150# RF STL 160 BORE A105 NORM

1370 WNKRF 5554405EM 6 - 24 FLG WN 150# RF STL XS BORE A105 NORM

1400

1410 FD3 SWFRF 5601799EM 3/4 - 1 1/2 FLG SW 300# RF STL XXS BORE A105 NORM

1420 FD3 WNKRF 5554642EM 2-4 FLG WN 300# RF STL 160 BORE A105 NORM

1430 UK9

1440 FD3 WNKRF 5554638EM 6 - 24 FLG WN 300# RF STL XS BORE A105 NORM

1470

1480 BLFRF 5615476EM 3/4 - 24 FLG BLIND 150# RF STL A105 NORM

1490 FD3 BLFRF 5615497EM 3/4 - 24 FLG BLIND 300# RF STL A105 NORM

1500

1520 ***** ORIFICE FLANGES *****

1530

1540 ORIRF 5622527EM 2-4 WN ORIF SET 300# RF STL 160 BORE A105 NORM

1550 ORIRF 5622523EM 6 - 24 WN ORIF SET 300# RF STL XS BORE A105 NORM

1580

1590 ***** PIPE NIPPLES *****

1600

1610 NIPTBE 5539171 3/4 - 1 1/2 NIPPLE XXS STL A106-B TBE 75 MM (3") LONG

1620 NIPTOE 5539181 3/4 - 1 1/2 NIPPLE XXS STL A106-B TOE 75 M (3") LONG

1630 NIPPBE 5539191 3/4 - 1 1/2 NIPPLE XXS STL A106-B PBE 75 MM (3") LONG

1650

1660 NIPTBE 5539173 3/4 - 1 1/2 NIPPLE XXS STL A106-B TBE 150 MM (6") LONG

1670 NIPTOE 5539183 3/4 - 1 1/2 NIPPLE XXS STL A106-B TOE 150 MM (6") LONG

1680 NIPPBE 5539193 3/4 - 1 1/2 NIPPLE XXS STL A106-B PBE 150 MM (6") LONG

1690

1700 101 ***** SWAGE NIPPLES *****

1710

1720 SWACBE 5543711 3/4 - 1 1/2 SWAGE CONC XXS STL A234 WPB BBE 1-3

1740

1750 SWAEBE 5548801 3/4 - 1 1/2 SWAGE ECC XXS STL A234 WPB BBE 1-3

1760

1770 ***** GASKETS *****

1780

1790 GF3 GASFR 5668831 3/4 - 1 1/2 GASKET 150# GRAFOIL TANG RING 1/16" THK SERVICE

1810 GASFRS 5672129 2 - 24 GASKET 150# 304SS SP WND GRAPHITE LS IR GENERAL PROCESS, GLYCOL/TEG,

1820 HYDROCARBONS, CHEMICALS, UTILITY WATER,

1830 GASFRS 5672150 3/4 - 1 1/2 GASKET 300# 304SS SP WND GRAPHITE IR OPEN AND CLOSED DRAINS.

1840 GASFRS 5672150 2 - 24 GASKET 300# 304SS SP WND GRAPHITE IR

DESIGN: ASME B16.5 MG 1.1

1850

CODE: ASME B31.3

1870 ***** BOLTING *****

1880

1890 BOLS 5675648EM 1/4 - 99 STUD-BOLT A193 GR B7 W/A194 GR 2H NUTS CTD

1900

1901 MATERIAL: CARBON STEEL

1910 ***** TEMPORARY STRAINERS ***** FLANGE RATING: 150 RF

1920 TEMPERATURE RANGE: -5 / 205 °C

1930 STRWYE 5762350 3/4 - 1 1/2 Y-STRAINER 1500# SW STL 316 SCR .033 PERF

COMMENT:

1940 MS9 STRCON 5762575 2 - 24 STRAINER 150# RF/FF STL CONICAL

Iraq West Qurna I Project CONSTRUCTION Iraq West Qurna I Project

Fluor Transworld Services, Inc. 1 1/2" & SMALLER - SOCKETWELD

CORR. ALLOW. DATE BY REV SHEET PA CLASS

2" & LARGER - BUTTWELD

W3QR

5 MM 17FEB12 MVP 0A 3 OF 4 5 A1H

Southern Iraq

26-Sep-2012, Rev. 0A IQWQ-FT-LSPDS-00-032003

Page 29 of 73

SEQ REV NOTE ITEM ITEM CODE SIZE RANGE / DESCRIPTION REFERENCE / NOTES

NO. NO. NAME SMALL END SIZES LARGE END SIZES

1950

1960 ***** LINE BLANKS *****

1970

1980 SPEDIS 5749852 1/2 - 1 1/2 BLANK PADDLE 150# RF STL

1990 NE1 SPEDIS 5749854 3/4 - 1 1/2 BLANK PADDLE 300# RF STL

2000 Specta 5749496 2 - 14 FIGURE 8 BLANK 150# RF STL

2010

2020 Paddle 5749852 16 - 24 BLANK PADDLE 150# RF STL

2030 Paddle 5750153 16 - 24 SPACER PADDLE 150# RF STL

2040

2050 ***** BRANCHES *****

2060

2070 USE BRANCH TABLE

2080

2090 ***** CONSTRUCTION DETAILS *****

2100

2110 SEAL WELDING ----------- REQUIRED

2120 PIPE BENDS ----------- NONE

2130 THREAD SEALANT ------ KEY GRAPHITE PASTE

2140 PWHT ----------- PER IQWQ-FT-LTTDS-00-0004

2150 NDE ----------- PER IQWQ-FT-LTTDS-00-0004

2160

2170

2180 FOR VENTS/DRAINS, SAMPLE, PIPING/INSTRUMENT

2190 CONNECTIONS, REFER TO MODULES IN

2200 IQWQ-FT-LSSTD-00-0007

SERVICE

GENERAL PROCESS, GLYCOL/TEG,

HYDROCARBONS, CHEMICALS, UTILITY WATER,

OPEN AND CLOSED DRAINS.

DESIGN: ASME B16.5 MG 1.1

CODE: ASME B31.3

MATERIAL: CARBON STEEL

FLANGE RATING: 150 RF

TEMPERATURE RANGE: -5 / 205 °C

COMMENT:

Iraq West Qurna I Project CONSTRUCTION Iraq West Qurna I Project

Fluor Transworld Services, Inc. 1 1/2" & SMALLER - SOCKETWELD

CORR. ALLOW. DATE BY REV SHEET PA CLASS

2" & LARGER - BUTTWELD

W3QR

5 MM 17FEB12 MVP 0A 4 OF 4 5 A1H

Southern Iraq

26-Sep-2012, Rev. 0A IQWQ-FT-LSPDS-00-032003

Page 30 of 73

-

Iraq West Qurna I Project Contract: W3QR

Southern Iraq Fluor Transworld Services, Inc.

LINE CLASS: A1H

LEGEND : ANGLE: 90°

REV: 0A

A = Sockolet®

RT = Reducing Tee (B.W. for 2" and larger,

S.W. for 1-1/2" and smaller) Pressure - Temperature

T = Tee (B.W. for 2" and larger, Ratings

S.W. for 1-1/2" and smaller) T (°C) P (kg/cm2)

W = Weldolet® -5 20.0

38 20.0

24 T 50 19.6

20 RT T 100 18.0