Documente Academic

Documente Profesional

Documente Cultură

CEDA OnLine Leak Repair

Încărcat de

anwarhas050 evaluări0% au considerat acest document util (0 voturi)

176 vizualizări6 paginiCEDA Online Leak Repair

Drepturi de autor

© © All Rights Reserved

Formate disponibile

PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentCEDA Online Leak Repair

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

176 vizualizări6 paginiCEDA OnLine Leak Repair

Încărcat de

anwarhas05CEDA Online Leak Repair

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 6

SPECIALIZED SERVICES AND EQUIPMENT FOR INDUSTRY

On Line Leak Repair

On Site, On Stream Leak Repair Services

• Will stop virtually any type of chemical process leak, • In-house machine shop facility for custom fabrications

including toxins and process leaks. and stocked items (ie. Clamps and enclosures).

• Performed while your plant is in operation. • Ongoing sealant development for various products.

• Temperatures ranging from cryogenic to 930°C and • Supported by In-house Mechanical, Chemical and

pressures from vacuum to 42,000 kpa and greater. Petroleum Engineering.

• Nondestructive leak repair methods available on

request.

Wire & Peen Method on Heat Exchanges

2 ON LINE LEAK REPAIR

Wire & Peen Method on Flange

Valve Packing Repair on line or during turnarounds

Procedure No. CMS-0729-GB, Drill the Pilot Hole, but do not break thru. Tap the Pilot Hole.

Blow-back Prevention.

Thread standard Injection Fitting into pilot hole.

Thread 3-Way HPPG into back of Injection Fitting.

Thread Sealant Injection Fitting into HPPG.

Push 5/32” Break-Thru Bit to bottom of pilot hole.

Turn down HPPG Packing Compression Cap.

Build and maintain sealant injection pressure of

approximately line pressure plus 20%.

Drill through into valve packing area.

ON LINE LEAK REPAIR 3

4 ON LINE LEAK REPAIR

By combining highly skilled personnel with state of the art technology, CEDA offers

value-added solutions to your toughest problems.

Typical Applications Typical Liquids

Digester Leaks Alcohols Lubrication Oils

Dresser Coupling Leaks Animal Oils/Fats Methylene Chloride

Expansion Joint Leaks Beer Milk

Flange Leaks Brines Mineral Oils

Floating Tank Roof with Cracks Calcium Chloride Molasses

Chromic Acid Paints

Heat Exchanger Leaks

Citric Acid Potassium Carbonate

Leaks between Shaft and Sleeve

Condensate Refrigerants

Pin Hole Leaks

Crude Oils Seawater

Pressure Seal Valve Leaks

Contaminated Water Sewage

Pump Leaks

Deionized Water Sludges

Rotating and Equipment Leaks

Detergents Slurries

Ruptured Pipe Leaks Distilled Water Steam

Tower Tray Leaks Effluents Sulphuric Acid

Turbine Seal Cover Leaks Food Grade products Titanium Chloride

Union Leaks Fruit Juices Transformer Oils

Valve Bonnet Leaks Fuel Oils Vegetable Oils

Valve Packing Leaks Glycols Vinegar

Weld Leaks Hydrochloric Acid Water

Variety of Piping Materials and Conditions

Aluminum Brass Carbon Steel Cast Iron

Copper Fibre Glass Stainless Steel Outround

Horizontal Inclines Vertical

Partnership in Health and Safety Certification of Recognition – 24 Hour Service across North America

ON LINE LEAK REPAIR 5

CEDA Mechanical Services

On-Site Machining services has one of the largest inventory of Line Crimping services have successfully performed crimps on

portable machining equipment in North America with capabilities lines from 1/2” XS pipe through 4” schedule 80 pipe. CEDA has

in machining flange faces from 1” through to 120”, also heat developed a safe and effective way to crimp pipe by incorporating

exchangers, channel heads, tube sheets, flat and raised faces, ring “stop blocks”which allow for maximum crimping pressure without

grooves, lap joints, pump and motor bases, key-way cutting, pipe concern of shearing the pipe. Our ability to operate the line crimp

cutting and beveling, etc. equipment remotely has reduced the risk to personnel by ensuring

that technicians are kept at a safe distance from the crimp location.

On-Line Leak Repair services will stop or contain virtually any

type of chemical and/or process leaks on flanges, valve bonnets, Concrete Repair/Injection service includes concrete restoration,

valve packings, heat exchangers. Leaking components are repaired epoxy pressure injection, chemical water stop and joint sealing

without interrupting process operations.This is accomplished by injections and can be done above or below the water line in most

the application of process specific sealants, prefabricated cases. Some applications are as follows: basements, columns,

enclosures, or enclosures engineered to specific concrete tanks, cooling tower basins, floors, dams, tunnels, grain

components/pressure requirements at temperatures ranging from elevators, reservoirs, etc.

930°C. Engineering services for leak repairs are provided on an

around the clock basis with in-house personnel. On-Site Bolting and Joint Integrity services can provide you

with the most versatile hydraulic torquing and tensioning tools

Line Freezing services can be used for leak locating, hydrostatic currently on the market.These tools are extremely compact and

testing, isolation for valve change out, piping alterations and portable for studs ranging from 3/4” through 4”.

decommissioning piping on a variety of piping materials from 1/2”

through to 48”. The Gel Plug service can be used in conjunction CEDA Support Groups: Loss prevention and safety program,

with this service for the isolation of piping systems. mechanical and chemical engineering, shutdown planning, project

management, machine shop, fabrication facility, emergency

Gel Plug service can provide temporary valve isolation and is response department, technical sales, research, development and

also used for pipeline cleaning, the tractoring effect of the gel qualified management.

caused by the laminar flow tends to entrap solid particles within

the gel.Types of gel plugs that are available; water, hydrocarbon

and methanol.

Hot Tapping services provide a safe and cost effective method of

making tie-ins to on-line piping, tanks and vessels. CEDA provides

customized solutions and highly trained personnel to complete

your hot tapping requirements in the safest possible manner.

PRINTED IN CANADA

S-ar putea să vă placă și

- Asset Integrity Management A Complete Guide - 2020 EditionDe la EverandAsset Integrity Management A Complete Guide - 2020 EditionÎncă nu există evaluări

- Unique Online Leak Repair TechniquesDocument8 paginiUnique Online Leak Repair TechniquesMario Alfredo MunafóÎncă nu există evaluări

- Furmanite Leak and Safety Valve Onsite Services PDFDocument11 paginiFurmanite Leak and Safety Valve Onsite Services PDFJessica ButlerÎncă nu există evaluări

- PCD001 Flexible Hose ManualDocument18 paginiPCD001 Flexible Hose ManualJohnHynes100% (1)

- PipeDocument47 paginiPipemohanÎncă nu există evaluări

- D BB Pipeline Isolation PaperDocument24 paginiD BB Pipeline Isolation Paperhadi137Încă nu există evaluări

- Pressure Vessel Inspection PDF FreeDocument44 paginiPressure Vessel Inspection PDF FreemabroukÎncă nu există evaluări

- Introduction To Valves - Only The Basics - Valves Are Mechanical Devices That Controls The Flow and Pressure Within A System or ProcessDocument6 paginiIntroduction To Valves - Only The Basics - Valves Are Mechanical Devices That Controls The Flow and Pressure Within A System or Processamit100% (1)

- Swagelok High Pressure FittingsDocument8 paginiSwagelok High Pressure FittingsSyahirul AlimÎncă nu există evaluări

- U BundleDocument16 paginiU BundleWael ElAriny100% (1)

- Floating Head Heat Exchanger MaintenanceDocument15 paginiFloating Head Heat Exchanger MaintenanceSriKakarlapudi100% (2)

- Pipeline Leak Repair Solutions for Corrosion, Damage and TheftsDocument6 paginiPipeline Leak Repair Solutions for Corrosion, Damage and TheftsGhufran Ahmed BalaÎncă nu există evaluări

- Collar Bolts: in Shell and Tube Heat ExchangersDocument2 paginiCollar Bolts: in Shell and Tube Heat ExchangersMahdi HocineÎncă nu există evaluări

- Types of GasketsDocument7 paginiTypes of GasketsPoncho RmzÎncă nu există evaluări

- Nesl Training ManualDocument91 paginiNesl Training ManualSOUMYA DEEP CHATTERJEEÎncă nu există evaluări

- Ineos Com 19 Dera Fabrication Guide Bro 135 Web 1Document76 paginiIneos Com 19 Dera Fabrication Guide Bro 135 Web 1shafeeqm3086Încă nu există evaluări

- PipingDocument102 paginiPipingArt James0% (1)

- Valves Guide: Types, Parts, Standards & SpecificationsDocument141 paginiValves Guide: Types, Parts, Standards & SpecificationsrichardÎncă nu există evaluări

- Flangemanagementpresentation 160911122834Document83 paginiFlangemanagementpresentation 160911122834Yusuf Alfathony100% (2)

- Spiral Wound GasketsDocument7 paginiSpiral Wound GasketsYap HSÎncă nu există evaluări

- Heat Exchanger Maintenance: Can We Afford to WaitDocument7 paginiHeat Exchanger Maintenance: Can We Afford to WaitBill ChambersÎncă nu există evaluări

- Module 5 Pipeline Repairs PDFDocument129 paginiModule 5 Pipeline Repairs PDFElias Jurado Teixeira100% (2)

- Manual Torque WrenchDocument2 paginiManual Torque WrenchVipul ShahÎncă nu există evaluări

- Garlock Metal - Gaskets TorqueDocument48 paginiGarlock Metal - Gaskets TorqueakenathorÎncă nu există evaluări

- Mechanical Seal Failures ExplainedDocument30 paginiMechanical Seal Failures ExplainedTg TarroÎncă nu există evaluări

- Joint Integrity Procedure - GQP-ENG-014Document32 paginiJoint Integrity Procedure - GQP-ENG-014mohd as shahiddin jafriÎncă nu există evaluări

- Prevent Leaks in Heat ExchangersDocument7 paginiPrevent Leaks in Heat ExchangersNirmal SubudhiÎncă nu există evaluări

- Lessons Learned - Piping MaterialsDocument19 paginiLessons Learned - Piping MaterialsBrian MayÎncă nu există evaluări

- Pipeline PigsDocument7 paginiPipeline PigsnadÎncă nu există evaluări

- Bp-On Stream Leak Repairs of Piping ComponentsDocument54 paginiBp-On Stream Leak Repairs of Piping ComponentsAlberto Fernando Leon ArismendyÎncă nu există evaluări

- Hydrotest Blind PDFDocument9 paginiHydrotest Blind PDFManu Jojo100% (1)

- Ball Valve Overhaul ProcedureDocument7 paginiBall Valve Overhaul Procedurerocket789Încă nu există evaluări

- Types of Flanges-Definition of FlangesDocument4 paginiTypes of Flanges-Definition of FlangesindikumaÎncă nu există evaluări

- Torquing ManualDocument17 paginiTorquing ManualZool HilmiÎncă nu există evaluări

- ABSA - Pressure Piping Fabrication Requirement & QC Seminar - Selected PagesDocument69 paginiABSA - Pressure Piping Fabrication Requirement & QC Seminar - Selected PagesBhaiJan59100% (4)

- Inspection of Static & Rotating Equipment InstallationDocument3 paginiInspection of Static & Rotating Equipment InstallationNaiyer KarimiÎncă nu există evaluări

- Steam Trap Inspection Guide PDFDocument8 paginiSteam Trap Inspection Guide PDFchanayire100% (1)

- Presentation - Pipe HandlingDocument21 paginiPresentation - Pipe HandlingAsheesh TripathiÎncă nu există evaluări

- Double Block and Bleed ValveDocument16 paginiDouble Block and Bleed ValveBa Jun Thối100% (1)

- Smooth Finish FlangesDocument4 paginiSmooth Finish FlangessanoopvkÎncă nu există evaluări

- Floating Head Heat Exchanger Maintenance GuideDocument15 paginiFloating Head Heat Exchanger Maintenance GuideASWIN.MTÎncă nu există evaluări

- Catalogue of ProductsDocument96 paginiCatalogue of Productssf wÎncă nu există evaluări

- Mersen Process Technologies ProviderDocument6 paginiMersen Process Technologies ProviderIbhar Santos MumentheyÎncă nu există evaluări

- ASME Temporary Repairs 101410-1Document41 paginiASME Temporary Repairs 101410-1khanz88_rulz1039Încă nu există evaluări

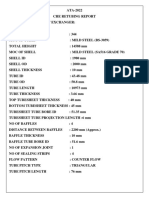

- CHE Retubing ReportDocument29 paginiCHE Retubing ReportRajesh KtrÎncă nu există evaluări

- CH 02 Piping and Pipeline MaintenanceDocument30 paginiCH 02 Piping and Pipeline MaintenanceAmbar Nurul AnsariÎncă nu există evaluări

- LT Pipeline Ball ValvesDocument19 paginiLT Pipeline Ball ValvessiswoutÎncă nu există evaluări

- Cci Valve 100DSVDocument8 paginiCci Valve 100DSVyg89Încă nu există evaluări

- Pipeline Support1Document18 paginiPipeline Support1Mohamed RishaÎncă nu există evaluări

- GRLC Grayloc Installation Maintenance Bulletin Rev JDocument4 paginiGRLC Grayloc Installation Maintenance Bulletin Rev JlsgmzÎncă nu există evaluări

- PiggingDocument5 paginiPiggingDendi AriyonoÎncă nu există evaluări

- Bolting BinderDocument30 paginiBolting BinderDeni DeniÎncă nu există evaluări

- Repairs of Piping Components PDFDocument54 paginiRepairs of Piping Components PDFIshtiaqueÎncă nu există evaluări

- BAF-ball Valves Rev 1 PDFDocument40 paginiBAF-ball Valves Rev 1 PDFJack ChavanÎncă nu există evaluări

- Flange Management Procedure IFUDocument32 paginiFlange Management Procedure IFUMarvan Audy Buriko100% (1)

- Metal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryDe la EverandMetal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryÎncă nu există evaluări

- Troubleshooting Rotating Machinery: Including Centrifugal Pumps and Compressors, Reciprocating Pumps and Compressors, Fans, Steam Turbines, Electric Motors, and MoreDe la EverandTroubleshooting Rotating Machinery: Including Centrifugal Pumps and Compressors, Reciprocating Pumps and Compressors, Fans, Steam Turbines, Electric Motors, and MoreÎncă nu există evaluări

- FRP Catalogue PDFDocument134 paginiFRP Catalogue PDFAnonymous EKxXjqyVHÎncă nu există evaluări

- Insurance ActDocument115 paginiInsurance ActAzizi JaisÎncă nu există evaluări

- Tube BundleDocument6 paginiTube Bundleanwarhas05Încă nu există evaluări

- Riser ClampsDocument2 paginiRiser Clampsanwarhas05Încă nu există evaluări

- MIT Preventive MaintenanceDocument20 paginiMIT Preventive MaintenanceDexron3Încă nu există evaluări

- RCM PDFDocument46 paginiRCM PDFanwarhas05Încă nu există evaluări

- Post Weld Heat Treatment Procedure: Doc Ref: Isb/PwhtDocument13 paginiPost Weld Heat Treatment Procedure: Doc Ref: Isb/PwhtMahtemeselasie Tesfamariam Hailu100% (4)

- Handbook-Riser-Design - Clamps PDFDocument46 paginiHandbook-Riser-Design - Clamps PDFanwarhas050% (1)

- Injection Safety PresentationDocument20 paginiInjection Safety Presentationanwarhas05100% (1)

- Cameron H2 ChokeDocument64 paginiCameron H2 Chokeanwarhas05Încă nu există evaluări

- Exova TestingDocument13 paginiExova Testinganwarhas05Încă nu există evaluări

- AcidRain and Its EffectDocument29 paginiAcidRain and Its EffectDarya MemonÎncă nu există evaluări

- Technical Manual Adjustable Choke MANUAL006-1 PDFDocument51 paginiTechnical Manual Adjustable Choke MANUAL006-1 PDFanwarhas05Încă nu există evaluări

- Chapter 20Document22 paginiChapter 20AlÎncă nu există evaluări

- New - Reinforcement of NozzleDocument31 paginiNew - Reinforcement of NozzleChagar HarshpalÎncă nu există evaluări

- Sr Mgr Whitney Grande on Safety Programs Life-CycleDocument9 paginiSr Mgr Whitney Grande on Safety Programs Life-Cycleanwarhas05Încă nu există evaluări

- HE Tube Plug SizeDocument5 paginiHE Tube Plug Sizeanwarhas05Încă nu există evaluări

- Steam TableDocument12 paginiSteam Tableanwarhas05Încă nu există evaluări

- Steam TableDocument12 paginiSteam Tableanwarhas05Încă nu există evaluări

- UserGuide - 510 - 570 - 653 PDFDocument25 paginiUserGuide - 510 - 570 - 653 PDFMurugananthamParamasivamÎncă nu există evaluări

- Ultrasonic Inspection Velocity TableDocument2 paginiUltrasonic Inspection Velocity Tableanwarhas05100% (1)

- Piping Field Inspection ChecklistDocument2 paginiPiping Field Inspection Checklistanwarhas0583% (6)

- BWG Chart: Wire Gauge Sizes in Inches and MillimetersDocument1 paginăBWG Chart: Wire Gauge Sizes in Inches and Millimetersanwarhas05Încă nu există evaluări

- Steam TableDocument12 paginiSteam Tableanwarhas05Încă nu există evaluări

- Presentation Duxvalves B.VDocument25 paginiPresentation Duxvalves B.Vanwarhas05Încă nu există evaluări

- CWI Responsibilities and AWS StandardsDocument3 paginiCWI Responsibilities and AWS Standardsanwarhas05Încă nu există evaluări

- OFFSHORE REPAIRS: In-situ solutions ensure fast turnaround for splash zonesDocument4 paginiOFFSHORE REPAIRS: In-situ solutions ensure fast turnaround for splash zonesanwarhas05Încă nu există evaluări

- Guide For Insepction For Installed Fired HeatersDocument35 paginiGuide For Insepction For Installed Fired HeatersColoLatino100% (7)

- HE Tube Plug SizeDocument5 paginiHE Tube Plug Sizeanwarhas05Încă nu există evaluări

- Siwes Report For PetroleumDocument53 paginiSiwes Report For PetroleumDavid Akomolafe100% (3)

- Namira Afralita Azahra - 2B - Jurnal KAODocument7 paginiNamira Afralita Azahra - 2B - Jurnal KAOLita NamiraÎncă nu există evaluări

- Oil RefineringDocument4 paginiOil RefineringmritunjayÎncă nu există evaluări

- Presented at The Students Technical Symposium & Exhibition Held at Obafemi Awolowo University, Ile Ife On The 22 of February, 2019Document46 paginiPresented at The Students Technical Symposium & Exhibition Held at Obafemi Awolowo University, Ile Ife On The 22 of February, 2019Osisiogu UkachiÎncă nu există evaluări

- About The AuthorDocument2 paginiAbout The AuthorRichardÎncă nu există evaluări

- Major Resources and Globalization in the Philippines and CanadaDocument2 paginiMajor Resources and Globalization in the Philippines and CanadaJoseph ObchigueÎncă nu există evaluări

- List of Petrol Pump HP GurgaonDocument46 paginiList of Petrol Pump HP GurgaonNext Vision HomeÎncă nu există evaluări

- Land Grab Drivers Signal Emerging Extractive Bioeconomy RegimeDocument19 paginiLand Grab Drivers Signal Emerging Extractive Bioeconomy RegimeWen Yang SongÎncă nu există evaluări

- You and The Program - Ebook ExcerptDocument8 paginiYou and The Program - Ebook ExcerptShmuel Ben-bassatÎncă nu există evaluări

- Invest in Pakistan (2019)Document10 paginiInvest in Pakistan (2019)Cornhill StrategyÎncă nu există evaluări

- Planner Responsibility by Plant V3Document12 paginiPlanner Responsibility by Plant V3Nida ZaidiÎncă nu există evaluări

- Engineering Encyclopedia: Oil Industry OverviewDocument8 paginiEngineering Encyclopedia: Oil Industry OverviewCobra_007Încă nu există evaluări

- Why Brent Crude Oil Price Is Higher Than WTIDocument4 paginiWhy Brent Crude Oil Price Is Higher Than WTIVerrsha TollasariyaÎncă nu există evaluări

- Contact Details and Experience SummaryDocument3 paginiContact Details and Experience Summaryeng20072007Încă nu există evaluări

- SPE-194652-MS Maximizing A Mature Field Value by Combining Polymer Flooding, Well Interventions, and Infill DrillingDocument21 paginiSPE-194652-MS Maximizing A Mature Field Value by Combining Polymer Flooding, Well Interventions, and Infill DrillingRidwan Al-KhandiÎncă nu există evaluări

- Exercise 8Document2 paginiExercise 8NurfauziyahÎncă nu există evaluări

- HADocument64 paginiHAlpczyfansÎncă nu există evaluări

- 05 Trip Sheet - IPM - QuartzDocument7 pagini05 Trip Sheet - IPM - QuartzRebarÎncă nu există evaluări

- NPTEL PHASE - II - Petroleum Refinery EngineeringDocument4 paginiNPTEL PHASE - II - Petroleum Refinery EngineeringRakeshKumarÎncă nu există evaluări

- Malaysia Country Report Chapter SummaryDocument22 paginiMalaysia Country Report Chapter SummaryIzuan OthmanÎncă nu există evaluări

- Proper disposal of used oil ordinanceDocument4 paginiProper disposal of used oil ordinanceAlbert CongÎncă nu există evaluări

- Competitive Strategy1Document10 paginiCompetitive Strategy1K DÎncă nu există evaluări

- Marketing-Strategy-For-Lubricants-Among-Fleet-Owner-Segment-1-1024 (20 Files Merged)Document20 paginiMarketing-Strategy-For-Lubricants-Among-Fleet-Owner-Segment-1-1024 (20 Files Merged)Haleema SadiaÎncă nu există evaluări

- Water InjectionDocument11 paginiWater InjectionWaqas SaleemÎncă nu există evaluări

- 1 - Introduction of EOR LecturesDocument22 pagini1 - Introduction of EOR LecturesPipit IrfaniÎncă nu există evaluări

- Natural Gas Engineering: PETR5350/6350Document42 paginiNatural Gas Engineering: PETR5350/6350rickÎncă nu există evaluări

- Properties of Petroleum ProductsDocument30 paginiProperties of Petroleum ProductsBharath KumarÎncă nu există evaluări

- Clasification Torbanite and Cannel Coal IDocument22 paginiClasification Torbanite and Cannel Coal IJulian De Bedout OrdoñezÎncă nu există evaluări

- Department of Petrochemical Engineering College of Technical Engineering University of Polytechnic-DuhokDocument4 paginiDepartment of Petrochemical Engineering College of Technical Engineering University of Polytechnic-DuhokWalid AdnanÎncă nu există evaluări

- Academic Question Paper Test 15Document23 paginiAcademic Question Paper Test 15Rohan Prajapati67% (3)