Documente Academic

Documente Profesional

Documente Cultură

Jsa Lifting Procedure

Încărcat de

Mark Irwen GrebialdeDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Jsa Lifting Procedure

Încărcat de

Mark Irwen GrebialdeDrepturi de autor:

Formate disponibile

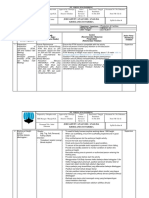

HSE-SAF-SFM-00-0018

Job Safety Analysis

Lifting, setting PC foundation and concreting Q-Chem I Pipe Rack Extension

Work Activity (Job): Date:

Work Team:

JSA Prepared by (Facilitator): ____________ JSA Location:

Critical Questions: Supervisor Approval:

Is a site visit to the job location required?

Is everyone ready and capable to work?

Has the potential for a spill or exposure been addressed?NA

Has the worst case been discussed?

Sequence of Basic Job Steps Potential Incidents or Hazards Ways to Eliminate or Reduce Potential Hazards

Equipment Delivery Uncertified operator Operators and drivers must have Qatar

Delivery of 45 toner crane. Miscommunication between driver and spotter. registered licensed.

Delivery of pc foundation. Heavy traffic during delivery. Traffic route determine to use road A and road

Delivery of truck mixer. Equipments unfit to travel. 5, used road pave only.

Delivery of pump car Road obstruction during delivery. Drivers must be familiar first the route and

Delivery of boom truck Drivers unaware of Q chem. 1 traffic rules. policies inside the compound.

Delivery of loader Possible damage of underground cable and fire water line Inform the Q chem. 1 Fire Safety Specialist

Delivery of plate compactor upon entering the project area. for any road blocked.

Delivery of Field Density Test apparatus. Equipment possible fire ignition. Provision of concrete/steel plate for

underground cable and fire water pipe

protection.

Provision of spotters to guide during delivery

of equipment.

Equipments should be checked before

delivery.

All equipment must have portable fire

extinguisher.

Job Safety Analysis Form Rev 1.0 - Sept 2005

1/9

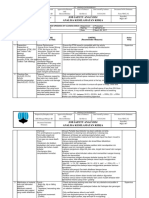

HSE-SAF-SFM-00-0018

Job Safety Analysis

Excavation : Error in establishing foundation corners. Foundation corners must be checked by

Clearing unnecessary materials. Inadequate excavation setback from the qualified surveyor.

Lay-out the foundation. foundation line. Detector scanning of the area to determine

Provide adequate setback. Overhead and under head obstruction during existing pipe lines.

Barricade the area. Track excavator movement. Provision of 250 mm thick R C concrete

Identify & mark existing pipe lines. Possible collapsed of foundation pit during pavement, for buried pipe protection, use as

Provide ingress/egress excavation thereby exposing buried existing pipe. access of tract excavator & other heavy

Provide warning sign. Miscommunication between operator and spotter. equipment for delivery of materials.

Paving with concrete the access of heavy Possible damage to the nearest existing pipeline Operator and spotter must be experience and

equipment where there are existing of the foundation pit. certified.

pipelines. No adequate safety ingress/egress in case of Undertake a trial excavation if necessary to

emergency. be sure no existing pipe line within the area.

No adequate barricade & warning sign. Excavation must have setback of 1000mm

No proper protection of existing buried pipe lines. from foundation outermost line to anticipate

cave-in.

Excavation pit must be slope outward at an

angle of repose from bottom edge to natural

ground level where no buried pipe lines exist.

Where buried pipe lines exist manual

excavation must be done using flat shovel.

Minimize excavation pit area for manual

excavation & provide shoring.

Spoiled materials must be filed nearby on

Job Safety Analysis Form Rev 1.0 - Sept 2005

2/9

HSE-SAF-SFM-00-0018

Job Safety Analysis

vacant area and covered by 3 micron thick

polyethylene sheets, to be used later as

backfill material.

Tool box meeting must be conducted before

excavation start.

Provide safe ingress/egress for foundation pit

beyond 1200mm depth & assign hole watch.

Compaction:

Water spraying to facilitate the Entry of water truck. Truck will not enter the work area. It will be parked at

compaction. the road, out side the barricaded area.

Follow buddy system and proper body ergonomics.

Compaction using light compact Possible back injury while laying the machine down in Use ropes to secure the machine and let it down

machine. the pit. slowly in the pit.

Formworks and concreting:

Workers exposed to heat/cold stress. Provide drinking water in designated location.

Possible skin peel -off when concreting due to Workers provided with coffee/tea during cold

Layout the lean concrete of chemicals composition of concrete. weather condition.

isolated footing & concreting. Possible skin scratch /bruises due to exposed Concrete workers provided with rubber

Formwork, rebar works & sharp nails & protruding object. gloves, apron, and gum boots during

concreting of footing over 3.0m x Workers exposed to noise pollution. concreting and basic PPE protection.

3.0 x 0.60 dimensions. All protruding object, unnecessary nails must

Concreting of elevated be removed immediately.

structures. All workers must be provided with air plug.

Backfilling spoiled materials Observe proper housekeeping for usable and

Job Safety Analysis Form Rev 1.0 - Sept 2005

3/9

HSE-SAF-SFM-00-0018

Job Safety Analysis

non-usable materials.

Provide garbage can for refuse materials.

Provide shelter for workers break time.

Lifting of pre cast foundation: Craned not properly anchor at a hard ground All riggers and operators must be certified.

surface. Provision of 25mm steel plate for

Setting of pc foundation to pc hole. Substandard/defective lifting equipments, underground cable protection.

shackles, and slings. Before lifting works starts there should be an

Overhead and under head obstruction during inspection of all lifting equipment and also

lifting. daily inspection must be done.

Possible collapsed of foundation pit during setting Lifting procedure/method of statement should

of pre cast foundation. be follow.

Possible damage of the nearest existing pipeline Critical lift permit should be secure for lifting a

of the foundation pit. high level risk.

Permits should be obtained from Q chem.1

and countersigned by logistics when at work

at in their respective area. Reflective vest

applied.

Tool box talk must be conducted to discuss

the procedure before lifting.

Crane must be 85% safe working load.

Crane must be anchor on a hard surface to

maintain stability and its level.

Pre lift dry run should be performed if there's

any critical lift.

Job Safety Analysis Form Rev 1.0 - Sept 2005

4/9

HSE-SAF-SFM-00-0018

Job Safety Analysis

Formworks and concreting:

Setting of anchor bolt Workers exposed to heat/cold stress. Enough drinking water must be provided

Installation of forms Possible skin peel -off when concreting due to Workers provided with coffee/tea during cold

Concreting of pedestal chemicals composition of concrete. weather condition.

Possible skin scratch /bruises due to exposed Concrete workers provided with rubber gloves

sharp nails. during concreting.

Workers exposed to noise pollution. All protruding unnecessary nails must be

removed immediately.

All workers must be provided with air plug.

Application of flex Crete:

Roughening of the Equipment possible fire ignition. (Generator) Equipments should be checked before

pedestals/foundations/girders using delivery.

grinder run by diesel generator.

Equipments should be checked before

starting daily.

All equipment must have portable fire

extinguisher.

Contact with hot surfaces.(Generator) Proper barricading.

Work crew exposed to the risk of falling small concrete Use face shield.

pieces piercing in the eyes or face or any part of the

Job Safety Analysis Form Rev 1.0 - Sept 2005

5/9

HSE-SAF-SFM-00-0018

Job Safety Analysis

body, or inhaling concrete dust while using the grinder. Use of disposable coveralls.

Leather gloves.

Dust mask.

Area will be barricaded.

Persons not related with the job will not be

Noisy area. allowed near by.

Use ear plugs.

Work crew exposed to the risk of coming in contact

with flex Crete while preparation and application.

Use rubber gloves, disposable coveralls, dust

mask and face shield.

Mixer will be switched off before removing

from the mixing container.

Follow buddy system, while handling.

Safety and Security Tools and equipments should be locked up or

Tools and Equipments removed at shift ends

Personnel Control Q-Chem. I security regulations to be followed

No cell phones allowed in the plant area

Q-Chem I traffic laws should be followed

No removal of items without gate pass

No smoking in the plant

Workers are only authorised to be job site

only.

Job Safety Analysis Form Rev 1.0 - Sept 2005

6/9

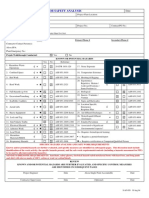

HSE-SAF-SFM-00-0018

Job Safety Analysis

Safety equipment required to do this job:

Hazard Specific Additional PPE Hazard Specific Additional PPE Other Considerations

Chemical Suit ___________________ Breathing Air __________________ Barricades ___________________

Disposable Coveralls ___________________ Respirator __________________ Fire Extinguisher ___________________

Protective Clothing _Long Sleeved______ Dust Mask __________________ MSDS ___________________

Special Gloves ___________________ Safety Harness __________________ Isolation ___________________

Fire-retardant clothing ___________________ Fall Arrest Device __________________ PTW ___________________

Rubber boots ___________________

Face shield ___Or Face Cover____

Job Safety Analysis Form Rev 1.0 - Sept 2005

7/9

HSE-SAF-SFM-00-0018

Job Safety Analysis

Job Safety Analysis Form (cont’d)

NOTE: These are in addition to the “Critical Questions” listed on the front of the JSA form.

Are you qualified to facilitate the JSA for this work?

Is the JSA Facilitator from the department responsible for completing the work?

Have you done this job before?

Have the right people participated in creating the JSA?

Did you conduct the JSA at the job location?

Has the JSA been reviewed by others who are knowledgeable about the work?

Has the JSA been reviewed and upgraded / revalidated at the work site for current conditions?

Have you included a step that includes a post-job critique and JSA upgrade for future use?

Have you communicated with others who might be affected by the work, e.g., Production?

Do you have the necessary resources to do the work, e.g., equipment, right tools, manpower, qualified people and proper PPE?

Do you need detailed work procedures or vendor technical information for this job?

Do you have all the necessary work permits to do the work?

Have you considered potential human-factors in the JSA, e.g., body position, noise, heat and cold?

Is now the right time to be doing the work?

Job Safety Analysis Form Rev 1.0 - Sept 2005

8/9

HSE-SAF-SFM-00-0018

Job Safety Analysis

Job Safety Analysis Form Rev 1.0 - Sept 2005

9/9

S-ar putea să vă placă și

- JSA ScaffoldingDocument2 paginiJSA ScaffoldingHrishikesh UnnikrishnanÎncă nu există evaluări

- Jsa ExcavatorDocument1 paginăJsa Excavatorbladeliger22Încă nu există evaluări

- Job Safety Analysis - Cone ErectionDocument7 paginiJob Safety Analysis - Cone ErectionMohammed MinhajÎncă nu există evaluări

- JSA-Manual Lifting of MaterialsDocument3 paginiJSA-Manual Lifting of Materialsfrancis_e_tan75% (4)

- Jsa For The Installation of I EamDocument5 paginiJsa For The Installation of I EamMohammed MinhajÎncă nu există evaluări

- JHA Blowing PressDocument5 paginiJHA Blowing PressLuqman OsmanÎncă nu există evaluări

- Refueling JSA 4 08 2019 Rev.03 Near WaterDocument9 paginiRefueling JSA 4 08 2019 Rev.03 Near Waterrisky indra antariÎncă nu există evaluări

- JSA Lifting OperationsDocument4 paginiJSA Lifting OperationsCristina Rican100% (1)

- JSA - Fire Proofing WorksDocument5 paginiJSA - Fire Proofing WorksAnis Uddin100% (3)

- Jsa For Lifting Crane 016Document6 paginiJsa For Lifting Crane 016kiran kumar100% (1)

- JSA For Cutting, Grinding and WeldingDocument4 paginiJSA For Cutting, Grinding and Weldingyc safety100% (3)

- JSA-010 Excavation SamplingDocument5 paginiJSA-010 Excavation SamplingMuhammadHaziqHaiqalÎncă nu există evaluări

- Crane JSADocument5 paginiCrane JSAPungky Tri WijayaÎncă nu există evaluări

- Health, Safety & Environmental Program Jsa (Job Safety Analysis)Document7 paginiHealth, Safety & Environmental Program Jsa (Job Safety Analysis)Osiobe Ewomazino50% (2)

- Jsa Working at HeightDocument4 paginiJsa Working at HeightDedy Kurniawan100% (1)

- JSA GC-5 Mobile ScaffoldingDocument6 paginiJSA GC-5 Mobile Scaffoldinggrande100% (2)

- 0 JsaDocument54 pagini0 JsaRavi AmarlapudiÎncă nu există evaluări

- DOD-JHA-040A (Rev-C) Night Shift WorkDocument9 paginiDOD-JHA-040A (Rev-C) Night Shift WorkMohammedÎncă nu există evaluări

- JSA WeldingDocument2 paginiJSA WeldingSigint Sides0% (3)

- JSA For Screeding With MeshDocument4 paginiJSA For Screeding With MeshMohammed Minhaj100% (1)

- Jsa For Work at HeightsDocument4 paginiJsa For Work at Heightsjithin shankar100% (1)

- Grounding System Jsa 2008Document4 paginiGrounding System Jsa 2008Aldrin100% (5)

- Jsa Tower CraneDocument4 paginiJsa Tower Craneputrasejahtra0% (2)

- JSA Template 2017-05-31 Cable Tray InstallationDocument19 paginiJSA Template 2017-05-31 Cable Tray InstallationJayvee Baradas ValdezÎncă nu există evaluări

- JSA G02 Lift Personnel in Scissor LiftDocument6 paginiJSA G02 Lift Personnel in Scissor Liftjokerseri100% (3)

- Lifting Operatio in Progress PDFDocument1 paginăLifting Operatio in Progress PDFsubhanmusadiq100% (1)

- Jsa-Jha For Using of Hand ToolsDocument2 paginiJsa-Jha For Using of Hand ToolsKamran Khan50% (2)

- JsaDocument39 paginiJsajithin shankar100% (3)

- 10 JSA Excavation, Lowering, Back FillingDocument8 pagini10 JSA Excavation, Lowering, Back FillingYosua SitumorangÎncă nu există evaluări

- JSA FOR Crane OperationDocument5 paginiJSA FOR Crane Operationwahyu nugrohoÎncă nu există evaluări

- JSA For Working at HeightDocument2 paginiJSA For Working at HeightXUE JIANÎncă nu există evaluări

- Jsa General HousekeepingDocument2 paginiJsa General HousekeepingHow Chin Engineering Sdn Bhd44% (9)

- Tower Crane Dismantling JSA HSE ProfessionalsDocument2 paginiTower Crane Dismantling JSA HSE ProfessionalsnabeelÎncă nu există evaluări

- Job Safety Analysis Sheet: Arc Welding, Cutting, GrindingDocument1 paginăJob Safety Analysis Sheet: Arc Welding, Cutting, GrindingalekyaÎncă nu există evaluări

- Jsa Welding Cutting and Grinding at Closing AreaDocument7 paginiJsa Welding Cutting and Grinding at Closing AreaDedy Kurniawan100% (2)

- JSA Working in Live AreasDocument1 paginăJSA Working in Live Areasyc safetyÎncă nu există evaluări

- JSA Lifting-Moving Heavy ObjectsDocument5 paginiJSA Lifting-Moving Heavy ObjectsYayan NantoÎncă nu există evaluări

- Rigging JSA RiggerDocument12 paginiRigging JSA RiggeraQiLGunawanÎncă nu există evaluări

- JSA LoadingDocument10 paginiJSA LoadingOcktri Bobet100% (3)

- ARK JSA 0 Rev 00 Crane LiftingDocument6 paginiARK JSA 0 Rev 00 Crane LiftingREMYAÎncă nu există evaluări

- Jsa Psa & GisDocument3 paginiJsa Psa & GisMohammed NouzalÎncă nu există evaluări

- SWMS Mobilisation of Blocks For MLT TEST RKDocument14 paginiSWMS Mobilisation of Blocks For MLT TEST RKrakeshkhanna78100% (1)

- JSA - Structural Steel Fabrication and Installation WorksDocument3 paginiJSA - Structural Steel Fabrication and Installation Workssakthi venkatÎncă nu există evaluări

- Chipping Work (Manually)Document1 paginăChipping Work (Manually)ChandruÎncă nu există evaluări

- Jsa SKDocument10 paginiJsa SKEngr Tahir UL Haq100% (2)

- Crane Jsa TGPDocument2 paginiCrane Jsa TGPSuryakant SurajÎncă nu există evaluări

- JSA For Dismantalling of PVC Pipe (5cm) by Acetylene Gas CuttingDocument4 paginiJSA For Dismantalling of PVC Pipe (5cm) by Acetylene Gas CuttingMohammed Minhaj100% (1)

- JSA ExcavationDocument6 paginiJSA Excavationkermech21607100% (1)

- JSA of Pipe Unloading.Document2 paginiJSA of Pipe Unloading.vijay kumar singh100% (1)

- Contoh JSA LiftingDocument1 paginăContoh JSA Liftingdimas100% (2)

- R1937-JSA-004 Job Safety Analysis For Pipe PullDocument3 paginiR1937-JSA-004 Job Safety Analysis For Pipe PullVineet AgrawalÎncă nu există evaluări

- 004 Piling JSADocument5 pagini004 Piling JSAmidozotyÎncă nu există evaluări

- SWMS Scaffold FixedDocument11 paginiSWMS Scaffold FixedEdha AliÎncă nu există evaluări

- SOP 10 - Safe Lifting Operations PDFDocument5 paginiSOP 10 - Safe Lifting Operations PDFMohammedJunaid100% (1)

- 972 99 100 (Mobile) : Job Safety AnalysisDocument8 pagini972 99 100 (Mobile) : Job Safety AnalysisSreeraj Reghunathan Nair VanmazhyÎncă nu există evaluări

- Lifting PlanDocument10 paginiLifting PlanEko Kurniawan100% (4)

- JSA-Site Survey and Downloading of Relay ConfigurationDocument4 paginiJSA-Site Survey and Downloading of Relay Configurationfrancis_e_tan100% (2)

- 3.jsa - Arc Welding-NDocument5 pagini3.jsa - Arc Welding-NVivek NaikÎncă nu există evaluări

- Norseman Directional Drilling Safe Work PracticeDocument6 paginiNorseman Directional Drilling Safe Work PracticeZYS ConstructionÎncă nu există evaluări

- Hydro Jetting and Sludge RemovalDocument18 paginiHydro Jetting and Sludge Removalmarvin100% (1)

- 0002 - 100 Work Permit SystemDocument6 pagini0002 - 100 Work Permit SystemOmar Santos90% (21)

- 0002 - 100 Work Permit SystemDocument6 pagini0002 - 100 Work Permit SystemOmar Santos90% (21)

- 0002 - 100 Work Permit SystemDocument6 pagini0002 - 100 Work Permit SystemOmar Santos90% (21)

- Method Statement - ASPHALT CONCRETE WORKS PDFDocument10 paginiMethod Statement - ASPHALT CONCRETE WORKS PDFTAHER AMMAR100% (6)

- Hardhat Blue Eagle 2016 2Document1 paginăHardhat Blue Eagle 2016 2Mark Irwen GrebialdeÎncă nu există evaluări

- Chemical - Reactions - Balancing - Equations by JSS Feb 2019Document34 paginiChemical - Reactions - Balancing - Equations by JSS Feb 2019Maria Alyssa MagallonÎncă nu există evaluări

- Aircraft Construction, Repair & Modification Mock Board Exam 10Document5 paginiAircraft Construction, Repair & Modification Mock Board Exam 10July TadeÎncă nu există evaluări

- The Punjab Factory RuleDocument313 paginiThe Punjab Factory Rulesafety_rliÎncă nu există evaluări

- ESB Networks Contractor Safety RegulationsDocument68 paginiESB Networks Contractor Safety RegulationsvhlactaotaoÎncă nu există evaluări

- Hoshin Policy Deployment TemplatesDocument8 paginiHoshin Policy Deployment Templatesjcruz909Încă nu există evaluări

- Important RCC Questions-Short and LongDocument15 paginiImportant RCC Questions-Short and LongmailjoelsamuelÎncă nu există evaluări

- HSE FRM 32 Final Incident ReportDocument6 paginiHSE FRM 32 Final Incident ReportDilshad aliÎncă nu există evaluări

- Mixed Grabar b2Document1 paginăMixed Grabar b2lynÎncă nu există evaluări

- Wireless Selection GuideDocument50 paginiWireless Selection GuideShailesh KshatriyaÎncă nu există evaluări

- Info - Iec61340-5-1 (Ed2 0 RLV) enDocument23 paginiInfo - Iec61340-5-1 (Ed2 0 RLV) enArhamÎncă nu există evaluări

- SZ 150.1 MergedDocument116 paginiSZ 150.1 MergedArif MamunÎncă nu există evaluări

- Positector Calibration ProcedureDocument6 paginiPositector Calibration ProcedureluigimasterÎncă nu există evaluări

- Differential Current-Based Fault Protection With Adaptive Threshold For Multip (Le PV Based DC MicrogridDocument13 paginiDifferential Current-Based Fault Protection With Adaptive Threshold For Multip (Le PV Based DC MicrogridANURAAGÎncă nu există evaluări

- Technical Delivery Condition of S500MCDocument4 paginiTechnical Delivery Condition of S500MCdcevipin100% (1)

- Lysaght SmartrussDocument2 paginiLysaght Smartrussiker880% (1)

- ELSAP11Document11 paginiELSAP11Angelo Sanchez Iafanti0% (1)

- Rashid Ch10 ImagesDocument47 paginiRashid Ch10 ImagesAtiq Ur RehmanÎncă nu există evaluări

- Conveyor Belt: Heavy Duty RubberDocument5 paginiConveyor Belt: Heavy Duty RubberHeidrahÎncă nu există evaluări

- Seismic Strengthening of Reinforced Concrete Columns With Straight Carbon Fibre Reinforced Polymer (CFRP) AnchorsDocument15 paginiSeismic Strengthening of Reinforced Concrete Columns With Straight Carbon Fibre Reinforced Polymer (CFRP) AnchorsKevin Paul Arca RojasÎncă nu există evaluări

- Aluminium - Copper AlloysDocument3 paginiAluminium - Copper AlloysRex RusselÎncă nu există evaluări

- Bucher LRV Hydraulic ValveDocument90 paginiBucher LRV Hydraulic Valvedean_lockey0% (1)

- SamplesDocument14 paginiSamplesSanjayÎncă nu există evaluări

- KMJT's Goldfarming GuideDocument36 paginiKMJT's Goldfarming GuideAnonymous oe4U3HCcÎncă nu există evaluări

- Need and Future of Electronics and Automation inDocument21 paginiNeed and Future of Electronics and Automation inAjay Kumar VermaÎncă nu există evaluări

- Relationship of EN 954-1 and IEC 61508 Standards PDFDocument2 paginiRelationship of EN 954-1 and IEC 61508 Standards PDFfitasmounirÎncă nu există evaluări

- KMH 432 - Estuzem - Week 8 - Part IIDocument26 paginiKMH 432 - Estuzem - Week 8 - Part IIGizem ÇetinerÎncă nu există evaluări

- Cooling Tower Fan#1 Breakdown/Maintenance Report: Site Name: Tata Metaliks Ltd. (1 X 10 MW CPP)Document4 paginiCooling Tower Fan#1 Breakdown/Maintenance Report: Site Name: Tata Metaliks Ltd. (1 X 10 MW CPP)amresh kumar tiwariÎncă nu există evaluări

- Drag of Conical Nose at Supersonic Speeds (Arthur Saw, EURECA 2013)Document2 paginiDrag of Conical Nose at Supersonic Speeds (Arthur Saw, EURECA 2013)Arthur Saw Sher-QenÎncă nu există evaluări

- Financial Auditor Job DescriptionDocument8 paginiFinancial Auditor Job Descriptionfinancemanagement702Încă nu există evaluări