Documente Academic

Documente Profesional

Documente Cultură

MIG Welding Speed Selection

Încărcat de

budakgemukDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

MIG Welding Speed Selection

Încărcat de

budakgemukDrepturi de autor:

Formate disponibile

Chapter 9: Understanding the ABCs of Mig Welding 145

Adjusting Mig Equipment to Suit

Your Mig Welding Project

A lot of variables come into play when you’re mig welding. You have to figure out

your electrode wire size, wire feed speed, voltage, and shielding gas type, and all

those factors have to jibe with the thickness of the metal you’re welding.

Table 9-2 helps you to figure out some of those details by listing the wire feed

speed (first number) and voltage (second number) recommended for each

parent metal thickness and wire size combo. Wire feed speed numbers are

in inches per minute, and voltage numbers are in volts. This table applies to

steel parent metals only.

For example, if you’re mig welding on a piece of metal that’s 3⁄16 inch thick and

you’re using a mig electrode wire size of .030 inch, you would want a wire

feed speed of 280 inches per minute and voltage of 19 volts if you were using

a shielding gas mixture of 75 percent argon 25 percent carbon dioxide. If your

shielding gas for that project was 100 percent carbon dioxide, you’d want to

keep your wire feed speed at 280 inches per minute but increase your voltage

to 20 volts.

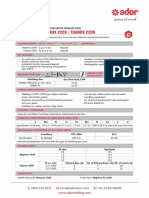

Table 9-2 Feed Speed and Voltage Settings for Common Mig Welds

Metal Thickness

3 1

Wire Gas Composition 22 20 18 16 14 12 10 ∕16 in. ∕4 in.

Size Gauge Gauge Gauge Gauge Gauge Gauge Gauge

.023 in. 75% argon, 25% CO2 70/18 120/15 140/16 190/16 260/17 330/18

100% CO2 n/a 120/18 140/19 190/19 260/20 330/20

.030 in. 75% argon, 25% CO2 80/15 90/16 130/16 180/17 230/18 280/19 330/19

100% CO2 80/18 90/19 130/19 180/20 230/21 280/22 330/21

.035 in. 75% argon, 25% CO2 90/16 120/16 160/16 200/17 240/18 280/18 320/19

100% CO2 90/19 120/19 160/19 200/20 240/21 280/20 320/22

.045 in. 75% argon, 25% CO2 80/16 100/16 120/17 140/18 160/19 180/19 200/20

100% CO2 80/19 100/19 120/20 140/21 160/22 180/22 200/23

15_455968-ch09.indd 14515_455968-ch09.indd 145 8/30/10 2:13 PM8/30/10 2:13 PM

S-ar putea să vă placă și

- Indian Institute of Welding Refresher Course Module on GMAW and FCAW ProcessesDocument47 paginiIndian Institute of Welding Refresher Course Module on GMAW and FCAW ProcessesdayalramÎncă nu există evaluări

- CSF-71T Technical Report EN - V2Document7 paginiCSF-71T Technical Report EN - V2Miroslav ThôngÎncă nu există evaluări

- Materials of Construction-ZeCor™Document4 paginiMaterials of Construction-ZeCor™Anonymous JWI6rqtÎncă nu există evaluări

- Er308l PDFDocument1 paginăEr308l PDFnargissuhailÎncă nu există evaluări

- Idalloy: C MN Si CR Mo V P S CuDocument1 paginăIdalloy: C MN Si CR Mo V P S CuiocephÎncă nu există evaluări

- Er308 PDFDocument1 paginăEr308 PDFKhedira Al JibrillÎncă nu există evaluări

- Effect of Shielding GasesDocument7 paginiEffect of Shielding GasesMayank SinglaÎncă nu există evaluări

- Gemphil Special Metals IncorporatedDocument5 paginiGemphil Special Metals IncorporatedMark Kenneth Chan BalicantaÎncă nu există evaluări

- CWC-BookletF1 10Document1 paginăCWC-BookletF1 10satnamÎncă nu există evaluări

- Eti Ohe 76 - 6 97 - PDFDocument16 paginiEti Ohe 76 - 6 97 - PDFCounter RoverÎncă nu există evaluări

- S-23804-Eng - 22 12 HTDocument2 paginiS-23804-Eng - 22 12 HTbiliboi5Încă nu există evaluări

- Inconel 82 (Austral-Wright)Document1 paginăInconel 82 (Austral-Wright)Claudia MmsÎncă nu există evaluări

- WPSAmerica Shielding Gases and Mechanical PropertiesDocument44 paginiWPSAmerica Shielding Gases and Mechanical PropertiessanjibkrjanaÎncă nu există evaluări

- COMPARISON OF TIG AND ACTIVATED TIG WELDINGDocument21 paginiCOMPARISON OF TIG AND ACTIVATED TIG WELDINGVishnu TejaÎncă nu există evaluări

- Coidan Graphite ElectrodesDocument9 paginiCoidan Graphite ElectrodesIrpan HerawanÎncă nu există evaluări

- Product Data Sheet OK Autrod 12.64: G 'Gas-Shielded Metal-Arc Welding'Document2 paginiProduct Data Sheet OK Autrod 12.64: G 'Gas-Shielded Metal-Arc Welding'Cem DufourÎncă nu există evaluări

- Nadia Hamzawy Mohamed - Nadia PaperDocument7 paginiNadia Hamzawy Mohamed - Nadia PaperchatgptuseregyptÎncă nu există evaluări

- Cswip Section 13 Mig Mag WeldingDocument23 paginiCswip Section 13 Mig Mag WeldingNsidibe Michael EtimÎncă nu există evaluări

- Cigweld-Deposited Rates PDFDocument7 paginiCigweld-Deposited Rates PDFNam_HitechÎncă nu există evaluări

- Spec - Ohe - Cat (Cu MG) 0120 (11 - 12 PDFDocument21 paginiSpec - Ohe - Cat (Cu MG) 0120 (11 - 12 PDFanuj sharmaÎncă nu există evaluări

- Welding Math and PhysicsDocument19 paginiWelding Math and PhysicsJose Cencič100% (1)

- (20834799 - Advances in Materials Science) A Study On The Effect of Different Activating Flux On a-TIG Welding Process of Incoloy 800HDocument12 pagini(20834799 - Advances in Materials Science) A Study On The Effect of Different Activating Flux On a-TIG Welding Process of Incoloy 800HARUN VÎncă nu există evaluări

- URB25Document4 paginiURB25malika_00Încă nu există evaluări

- Welding Rods InfoDocument9 paginiWelding Rods InfoSeju CherianÎncă nu există evaluări

- Welding Math (And Some Physics) : EchnologyDocument20 paginiWelding Math (And Some Physics) : EchnologyAdalberto MejiaÎncă nu există evaluări

- WPSAmerica Shielding Gases and Mechanical PropertiesDocument44 paginiWPSAmerica Shielding Gases and Mechanical PropertiesRameshBaskaranÎncă nu există evaluări

- Sandvik 254 SMO Datasheet for Seamless Tube and PipeDocument9 paginiSandvik 254 SMO Datasheet for Seamless Tube and PipeReadersmoÎncă nu există evaluări

- Handbook - Calculations0Document10 paginiHandbook - Calculations0paimpillyÎncă nu există evaluări

- ERNiCr 3Document1 paginăERNiCr 3Cemal NergizÎncă nu există evaluări

- SpecificationDocument27 paginiSpecificationMaddi vasuÎncă nu există evaluări

- Wascomat Flatwork Ironer Specifications IC5019 LF OC5021 R LF IC5025 R LF IC5028 R LF IC5032 R LFDocument2 paginiWascomat Flatwork Ironer Specifications IC5019 LF OC5021 R LF IC5025 R LF IC5028 R LF IC5032 R LFmairimsp2003Încă nu există evaluări

- Eliminating cracks in stainless steel TIG weldsDocument5 paginiEliminating cracks in stainless steel TIG weldsarjun prajapatiÎncă nu există evaluări

- Sandvik 2re10Document7 paginiSandvik 2re10himan_chongiÎncă nu există evaluări

- An Experimental Study On The Effect of Increased Pressure On MIG Welding ArcDocument6 paginiAn Experimental Study On The Effect of Increased Pressure On MIG Welding ArcSaket PatwaÎncă nu există evaluări

- Copper-Coated Solid Wire for Universal Welding ApplicationsDocument1 paginăCopper-Coated Solid Wire for Universal Welding ApplicationsInaamÎncă nu există evaluări

- Lecture 21: GTAG Welding: Fundamental of Welding Science and TechnologyDocument24 paginiLecture 21: GTAG Welding: Fundamental of Welding Science and TechnologyNavneet KumarÎncă nu există evaluări

- Basic Coated Electrode For Creep Resisting Steels: 1501 GR 622 To 1504 GR 622, BS 359 GR 622/640 1503 GR 660, 1504Gr 660Document1 paginăBasic Coated Electrode For Creep Resisting Steels: 1501 GR 622 To 1504 GR 622, BS 359 GR 622/640 1503 GR 660, 1504Gr 660mohamed AdelÎncă nu există evaluări

- Tech Data Sheet: Dual Shield T-115Document3 paginiTech Data Sheet: Dual Shield T-115carlosÎncă nu există evaluări

- CDA110 Specifaction SheetDocument5 paginiCDA110 Specifaction SheetGendakensÎncă nu există evaluări

- 9 III March 2021Document7 pagini9 III March 2021IJRASETPublicationsÎncă nu există evaluări

- Welding ConsumableDocument82 paginiWelding ConsumableAzmin BorkhanÎncă nu există evaluări

- Gas Tungsten Arc WeldingDocument2 paginiGas Tungsten Arc WeldingIGNACIO MADRINAN BORREROÎncă nu există evaluări

- 5 GtawDocument45 pagini5 GtawPutra Daha PratamaÎncă nu există evaluări

- Oman Cable Over Head Cable Spec 20-4Document34 paginiOman Cable Over Head Cable Spec 20-4harishpandyanÎncă nu există evaluări

- Optimization of Process Parameters of CO2 LasersDocument10 paginiOptimization of Process Parameters of CO2 LasersHassan HabibÎncă nu există evaluări

- 13 Mig & Mag WeldingDocument24 pagini13 Mig & Mag WeldingMohamed BencharifÎncă nu există evaluări

- MIGINOX 2209 / TIGINOX 2209: Gmaw / Gtaw Duplex Stainless SteelDocument1 paginăMIGINOX 2209 / TIGINOX 2209: Gmaw / Gtaw Duplex Stainless SteelV U P RaoÎncă nu există evaluări

- 2200226e Enquiry and PQR 1594289715Document5 pagini2200226e Enquiry and PQR 1594289715loganathanÎncă nu există evaluări

- JBC Classic Catalog - Engl2014Document20 paginiJBC Classic Catalog - Engl2014Scott ShafferÎncă nu există evaluări

- Welding 8Document3 paginiWelding 8রিপন মন্ডলÎncă nu există evaluări

- BS3468 Austenitic Cast Iron Material SpecificationsDocument2 paginiBS3468 Austenitic Cast Iron Material SpecificationsPanchoMiyamotoÎncă nu există evaluări

- DWG BrochureDocument4 paginiDWG BrochureMiguel BentoÎncă nu există evaluări

- TATA STEEL LTD., Wire Division Technical Delivery Conditions (TDC)Document2 paginiTATA STEEL LTD., Wire Division Technical Delivery Conditions (TDC)Mayank UkaniÎncă nu există evaluări

- Weld Like a Pro: Beginning to Advanced TechniquesDe la EverandWeld Like a Pro: Beginning to Advanced TechniquesEvaluare: 4.5 din 5 stele4.5/5 (6)

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsDe la EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsÎncă nu există evaluări

- Flux Cored Wire (FCW) : Typical Chemical Composition of All-Weld Metal (WT%) Product FeaturesDocument1 paginăFlux Cored Wire (FCW) : Typical Chemical Composition of All-Weld Metal (WT%) Product FeaturesbudakgemukÎncă nu există evaluări

- Frequently Asked Questions (FAQ) : WWW - Gamehero.myDocument2 paginiFrequently Asked Questions (FAQ) : WWW - Gamehero.mybudakgemukÎncă nu există evaluări

- SMK-241DT Digital Timer User ManualDocument2 paginiSMK-241DT Digital Timer User Manualbudakgemuk100% (1)

- REFERENCE DOCUMENTS AWS EL8 SAW Wire FLUX PDFDocument4 paginiREFERENCE DOCUMENTS AWS EL8 SAW Wire FLUX PDFIslam SahafayatÎncă nu există evaluări

- Traditional Machining Surface RoughnessDocument1 paginăTraditional Machining Surface RoughnessbudakgemukÎncă nu există evaluări

- Word Search AnimalDocument1 paginăWord Search AnimalbudakgemukÎncă nu există evaluări

- Welding Print Reading, 6th Edition Page 211Document1 paginăWelding Print Reading, 6th Edition Page 211budakgemukÎncă nu există evaluări

- Full Page PhotoDocument1 paginăFull Page PhotobudakgemukÎncă nu există evaluări

- Assignment ISOmetricDocument5 paginiAssignment ISOmetricbudakgemuk0% (1)

- Cross-Dock Assortment Arrangements: or Plant A Customer ADocument1 paginăCross-Dock Assortment Arrangements: or Plant A Customer AbudakgemukÎncă nu există evaluări

- Unifi FAQ Home PlanDocument18 paginiUnifi FAQ Home PlanbudakgemukÎncă nu există evaluări

- Word Search Animal PDFDocument1 paginăWord Search Animal PDFbudakgemukÎncă nu există evaluări

- Contoh Torque FizikDocument1 paginăContoh Torque FizikbudakgemukÎncă nu există evaluări

- Polarity Characteristics TigDocument1 paginăPolarity Characteristics TigbudakgemukÎncă nu există evaluări

- Consolidation Bulk ArrangementsDocument1 paginăConsolidation Bulk ArrangementsbudakgemukÎncă nu există evaluări

- Common Fraction, Decimal Fraction, and Millimeter ConversionsDocument1 paginăCommon Fraction, Decimal Fraction, and Millimeter ConversionsbudakgemukÎncă nu există evaluări

- MNP Offer FaqDocument5 paginiMNP Offer FaqbudakgemukÎncă nu există evaluări

- Master Chart of Welding and Joining Processes: AppendixDocument1 paginăMaster Chart of Welding and Joining Processes: AppendixbudakgemukÎncă nu există evaluări

- Chapter 11: Examining Plasma and Oxyfuel CuttingDocument1 paginăChapter 11: Examining Plasma and Oxyfuel CuttingbudakgemukÎncă nu există evaluări

- Welding Tools GuideDocument1 paginăWelding Tools GuidebudakgemukÎncă nu există evaluări

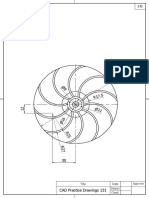

- CAD Practice Drawings Study GuideDocument4 paginiCAD Practice Drawings Study GuidebudakgemukÎncă nu există evaluări

- Cad Practice 2Document3 paginiCad Practice 2budakgemukÎncă nu există evaluări

- Projections and ViewsDocument6 paginiProjections and ViewsVincent VegaÎncă nu există evaluări

- Chap 26 Isometric DrawingDocument3 paginiChap 26 Isometric DrawingbudakgemukÎncă nu există evaluări

- Cad Practice 1Document3 paginiCad Practice 1budakgemukÎncă nu există evaluări

- FlowchartDocument1 paginăFlowchartbudakgemukÎncă nu există evaluări

- 10 - Chapter 5 PDFDocument10 pagini10 - Chapter 5 PDFAnonymous zsxsPPEÎncă nu există evaluări

- 01 Latihan Cuti Pertengahan Penggal Pertama 2013Document7 pagini01 Latihan Cuti Pertengahan Penggal Pertama 2013Azmaazniza AzanÎncă nu există evaluări

- Approx Material PropertiesDocument4 paginiApprox Material PropertiesbudakgemukÎncă nu există evaluări

- Grip-Engineering Info@grip - de Back: ASTM FixturesDocument26 paginiGrip-Engineering Info@grip - de Back: ASTM FixturesMehdi GouaderÎncă nu există evaluări

- Nov 06 Physics SL Paper 1Document17 paginiNov 06 Physics SL Paper 1Wojtek BłażejÎncă nu există evaluări

- Utilization of Red Mud As An Alternative Filler in Asphalt Mastic To Replace Naural Limestone PowderDocument11 paginiUtilization of Red Mud As An Alternative Filler in Asphalt Mastic To Replace Naural Limestone PowderRam VermaÎncă nu există evaluări

- Combined Loading of Rods 2 - Multiaxial Stress StateDocument13 paginiCombined Loading of Rods 2 - Multiaxial Stress StatePeet89Încă nu există evaluări

- Three Layer - Jones 1962Document16 paginiThree Layer - Jones 1962winengkuÎncă nu există evaluări

- Daily Ops ReportDocument2 paginiDaily Ops ReportMarlon Arrhases100% (1)

- Methods For Chemical Analysis of SoilsDocument102 paginiMethods For Chemical Analysis of SoilsMôi Trường Trung TâmÎncă nu există evaluări

- Potential Disadvantages of Catalysis: in General, It Is Greener To Use Catalysts Than To Not Use ThemDocument18 paginiPotential Disadvantages of Catalysis: in General, It Is Greener To Use Catalysts Than To Not Use ThemumarÎncă nu există evaluări

- CPC Liquid Cooling Catalog 11x17Document21 paginiCPC Liquid Cooling Catalog 11x17Benny S PutraÎncă nu există evaluări

- Rubber Modeling Using Uniaxial Test DataDocument12 paginiRubber Modeling Using Uniaxial Test DataMike RobertsonÎncă nu există evaluări

- WPS and PQR of GMAWDocument8 paginiWPS and PQR of GMAW魏利强Încă nu există evaluări

- PT Science 7 1stDocument3 paginiPT Science 7 1stSherene Frances BasilioÎncă nu există evaluări

- Amit Acharya 3Document19 paginiAmit Acharya 3Disha ChatterjeeÎncă nu există evaluări

- Assignments and Tutorials - Soil Mechanics - Spring NewDocument42 paginiAssignments and Tutorials - Soil Mechanics - Spring NewmanthanÎncă nu există evaluări

- Piping Support and FlexibilityDocument62 paginiPiping Support and FlexibilityAmr Metwally Anwar100% (5)

- Week 3 - Movement in & Out of Cells P4Document7 paginiWeek 3 - Movement in & Out of Cells P4aini.mohamat.zoomÎncă nu există evaluări

- Gas LiftDocument17 paginiGas LiftWenKhai LimÎncă nu există evaluări

- Jet Nozzles DUKDocument14 paginiJet Nozzles DUKKerx EndranoÎncă nu există evaluări

- 2 - LS-DYNA For SSI Oct 2010Document44 pagini2 - LS-DYNA For SSI Oct 2010naderi123Încă nu există evaluări

- Global Environmental Monitoring Index (GEMI)Document7 paginiGlobal Environmental Monitoring Index (GEMI)sergonzalezÎncă nu există evaluări

- Edgar Dutra Zanotto: Is Glass A Liquid or Is It Not? While Teaching MaterialsDocument4 paginiEdgar Dutra Zanotto: Is Glass A Liquid or Is It Not? While Teaching MaterialsValécia DantasÎncă nu există evaluări

- Journal BearingDocument7 paginiJournal BearingNur AfifahÎncă nu există evaluări

- Spotlight On... TurbulenceDocument46 paginiSpotlight On... TurbulenceHarshÎncă nu există evaluări

- MST326 202109Document8 paginiMST326 202109llynusÎncă nu există evaluări

- Physics Topical Test A - Book 2Document32 paginiPhysics Topical Test A - Book 2Jong.Gun.KimÎncă nu există evaluări

- Factors Affecting Evaporation PDFDocument2 paginiFactors Affecting Evaporation PDFLuis100% (3)

- Worksheet 6Document17 paginiWorksheet 6Sumair Khan MasoodÎncă nu există evaluări

- Core Lab PackscanDocument6 paginiCore Lab Packscanpromothes476Încă nu există evaluări

- Effects of Fines On Compaction Characteristics of Poorly Graded SandsDocument7 paginiEffects of Fines On Compaction Characteristics of Poorly Graded SandsJawad AbidiÎncă nu există evaluări

- Experiment Report 1 - Group 2 - Chemistry 40Document12 paginiExperiment Report 1 - Group 2 - Chemistry 40Daniella ChandraÎncă nu există evaluări