Documente Academic

Documente Profesional

Documente Cultură

ACCEL-DFI Instructions 6a Digital Ignition Dfi 75606

Încărcat de

Ilango PanneerselvanDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

ACCEL-DFI Instructions 6a Digital Ignition Dfi 75606

Încărcat de

Ilango PanneerselvanDrepturi de autor:

Formate disponibile

FORM 1522D REV.

12/07

INSTALLATION INSTRUCTIONS

ACCEL/DFI 6A Electronic Ignition Control

Module for Distributor Equipped Engines

PART NO. 75606

PARTS INCLUDED:

1 Ignition Control Module 5 1/4" Male Disconnects

4 #10 Sheet Metal Screws 5 1/4" Female Disconnects

2 Wire Ties 1 Rubber Grommet

2 Ring Terminals, Insulated 2 Cable Clamps

1 1-amp/100 volt Diode 1 Magnetic Pickup Extension

2 1/4" Tab Terminals

GENERAL INFORMATION

BATTERY ROUTING

This Ignition Control Module operates on any negative ground, 12 volt Wires should be routed away from sharp edges, moving objects, and heat

electrical system with a distributor. It will also work with 16 volt batteries sources. Wires that are next to each other in the engine’s firing order

and can withstand a momentary spike of 24 volts in case of jump starts. should be separated. For example, in a Chevy V8 with a firing order of

This system delivers full voltage with a supply of 10-18 volts, and 1-8-4-3-6-5-7-2, the #5 and #7 cylinders are positioned next to each

operates with a supply voltage as low as 8 volts. If your application other on the engine as well as in the firing order. Voltage from the #5

does not use an alternator, allow at least 15 amp/hour for every half wire could jump to the #7 wire. This could cause detonation and engine

hour of operation. If you crank the engine with the same battery or other damage. For added protection against cross-fire, ACCEL offers PRO

accessories, such as an electric fuel or water pump, increase the SLEEVE (P/N170071). Pro Sleeve is a glass woven, silicone coated

amp/hour rating. protective sleeve that slides over your plug wires. It also helps reduce

damage from heat and sharp objects.

COILS

For optimum performance with your Ignition Control Module, use a

matching coil such as ACCEL/DFI 6A E-core coil P/N 75607 or Mallory’s MISCELLANEOUS INFORMATION

PROMASTER® Coil P/N 29440 or 30440. Mallory’s PROMASTER® Coil P/N

29625 or 30625 can also be used, as well as most stock coils or after- SEALING

market coils designed as stock replacements. Do not attempt to seal the Ignition Control Module. All of the circuits

receive a conformal coating of sealant that protects the electronics from

NOTE: Do not use Mallory’s PROMASTER® Coil P/N 28880. moisture. Sealing the Ignition will not allow any moisture that seeps in

through the grommets to drain and may result in corrosion.

TACHOMETERS

The yellow wire on the Ignition Control Module provides a trigger signal WELDING

for tachometers, shift lights, or other add-on RPM activated devices. This To avoid any damage to the Ignition Control Module when welding on the

wire produces a 12 volts square wave signal with a 20% duty cycle. vehicle, disconnect the positive (red) and negative (black) power cables of

Some vehicles with factory tachometers may require a tach adapter to the Ignition Control Module. It is also a good idea to disconnect the

work with the Ignition Control Module. If your GM vehicle uses an inline tachometer ground wire as well.

filter, it may cause the tach to drop to zero on acceleration. If this occurs,

bypass the filter. For more information on tachometers, see pages 3 & 4. DISTRIBUTOR CAP AND ROTOR

We recommend installing a new distributor cap and rotor when installing

SPARK PLUGS the Ignition Control Module. Be sure the cap is clean inside and out,

Using the correct spark plug and heat range is important for optimum especially the terminals and rotor tip. On vehicles with smaller caps, it is

performance. Because there are so many variables to consider, we possible for the air inside the cap to become electrically charged causing

suggest starting with your engine manufacturer’s spark plug recommen- crossfire which can result in misfire. You can prevent this by drilling a

dation. From there, you can experiment with small changes in plug gap couple of vent holes in the cap. Drill the holes between terminals at rotor

and heat range to obtain the best performance from your engine. Use height, facing away from the intake. If needed, place a small piece of

the chart at right as a starting point. We also recommend non-resistor screen over the holes to act as a filter.

spark plugs.

DIAGNOSTIC LED

SPARK PLUG WIRES On the end panel of the Ignition Control Module there is a small hole.

High quality, spiral wound wire and proper routing are essential to the Behind this hole is a red LED indicator. This serves two purposes:

operation of the Ignition Control Module. This type of wire provides a when you first turn on the ignition switch, the LED will flash rapidly

good path for the spark to follow while minimizing electromagnetic 3 times. This indicates that the ignition system has power, and that the

interference (EMI). microprocessor is running properly. In addition, the LED will flash when

NOTE: Do not use solid core spark plug wires with this Ignition Control. receiving a proper trigger signal from the vehicle. If, after a normal

ACCEL/DFI TECHNICAL SUPPORT 248.380.2780 www.accel-dfi.com 1

power-up, the LED doesn’t flash when cranking the engine, you TRIGGER WIRES

should check your triggering circuit for problems. If the LED flashes Either of two circuits will trigger the Ignition Control Module: a points

when the engine is cranked, but there is still no spark, the problem lies circuit (dark blue) or a magnetic pickup circuit (violet and green wires).

somewhere else. NOTE: The two circuits will never be used together.

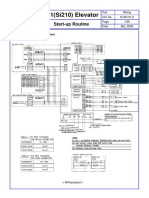

CYLINDER SELECTION Dark Blue Connects to the ACCEL/DFI EST (Dk.Blue wire/pin

Your Ignition comes from the factory set up for 8 cylinder operation. If H of 8 pin ignition connector) or to points, electronic

you want to use this ignition with a 4 or 6 cylinder engine, you must first ignition amplifier output or to the green wire of most

remove the four screws that hold the endplate with the LED hole. Once timing accessories. When this wire is used, the

the endplate is removed, you’ll see the end of the circuit board. Look for magnetic pickup connector is not used.

the two-section switch. To select 4 cylinder mode, move the switch Violet/Green These wires are routed together in one harness to

marked "1" to the "ON" position. To select 6 cylinder mode, move the form the magnetic pickup connector. The connector

switch marked "2" to the "ON" position. If both switches are "OFF", or plugs directly into most aftermarket distributors or

both are "ON", the ignition will run in the 8 cylinder mode. See Figure 1. crank trigger. It will also connect to factory magnetic

pickups or other aftermarket pickups. The violet wire

MOUNTING is positive (+) and the green is negative (–). When

The Ignition Control Module can be mounted in any position. If you mount these wires are used, the dark blue wire is not used.

it in the engine compartment, keep it away from moving objects and heat Consult the chart that shows the polarity of other

sources. Do not mount the unit in a closed area, such as the glovebox. common magnetic pickups

When you find a suitable location to mount the unit, make sure all wires Yellow Connects to the tachometer.

of the ignition reach their connections. Hold the ignition in place and

mark the location of the mounting holes. Use a 1/8" drill bit to drill the

holes. Use the supplied self-tapping screws to mount the box. ROUTING WIRES

Route all wires away from heat sources, sharp edges, and moving

objects. Route the trigger wires separate from the other wires and spark

WIRING plug wires. If possible, route them along a ground plane, such as the

WIRE LENGTH block or firewall, which creates an electrical shield. The magnetic pickup

All of the wires of the Ignition Control Module may be shortened as long wires should be routed separately and twisted together to help reduce

as quality connectors are used or soldered in place. To lengthen the extraneous interference. For best results use Shielded Ground Cable.

wires, use one size larger gauge wire (12 gauge for power leads, 16 WARNING: The Ignition Control Module is a capacitive discharge ignition.

gauge for all others). Use the proper connectors to terminate all wires. High voltage is present at the coil primary terminals. Do not touch these

All connections must be soldered and sealed. terminals or connect test equipment to them.

GROUNDS

A poor ground connection can cause many frustrating problems. When

a wire is specified to go to ground, connect it to the chassis. Always

connect a ground strap between the engine and chassis. Connect any

ground wires to a clean, paint-free metal surface.

BALLAST RESISTOR FIGURE 1

If your vehicle has a ballast resistor in line with the coil wiring, it is not

necessary to bypass it. This is because the Ignition Control Module

receives its main power directly from the battery.

WIRE FUNCTIONS

DIAGNOSTIC

LED

Power Leads

The two heavy gauge wires (14 gauge) that

deliver battery voltage to the ignition:

Heavy Red Connects directly to

the battery positive (+)

terminal or to a positive

battery junction. It could also

be connected to the positive

side of the starter solenoid.

NOTE: Never connect this

wire to the alternator. LABELS FOR

"CYLINDER SELECT"

Heavy Black Connects to frame or chassis ON CIRCUIT BOARD

ground.

Trigger and Coil Leads

Red/White Connects to a switched 12 volt source, such as

the ignition key.

Red Connects to the positive (+) terminal of the coil.

NOTE: This is the only wire that makes electrical

(Shielded) contact with the coil positive (+) terminal.

Small Black Connects to the negative (–) terminal of the coil.

NOTE: This is the only wire that makes electrical

contact with the coil positive (–) terminal.

2 www.accel-dfi.com ACCEL/DFI TECHNICAL SUPPORT 248.380.2780

INOPERATIVE TACHOMETERS

COMMON COLORS FOR MAG PICKUP WIRES If your tachometer fails to operate with the 6A installed, you may need a

Distributor Mag +(Crk +) Mag –(Crk -) Mallory tach adapter. Before purchasing a tach adapter, try connecting

Mallory Crank Trigger Purple Green your tachometer trigger wire to the yellow wire of the 6A Ignition Control

Mallory Billet Competition Module. This output produces a 12 volt, square wave. If the tach still

Distributor, Series does not operate, you will need a tach adapter. Two different tach

Nos. 81 and 84 Orange Purple adapters are available:

Mallory Comp® 9000 Series PN 29078 If you are using the magnetic pickup connector (green and

Nos. 96-99 Orange Purple violet wires) to trigger the 6A, you will need this adapter.

Mallory Harness P/N 29040 Red Black PN 29074 If your tach was triggered from the coil negative terminal

(voltage trigger) and you are suing the dark blue wire to

MSD distributor’s Orange/Black Violet/Black trigger the 6A, you will need this adapter

MSD Crank Trigger Orange/Black Violet/Black

BALLAST RESISTOR

Ford Orange Purple

If you have a current trigger tach (originally connected to coil (+)

Accel 46/48000 Series Orange/Black Violet/Black positive) and use the dark blue wire of the Ignition for triggering, you can

Accel 51/61000 Series Red Black purchase a Chrysler Dual Ballast Resistor (1973-76 applications). Wire

Chrysler Orange/White Black it as shown in Figure 3.

ENGINE RUN-ON

PRESTART CHECKLIST If your engine continues to run even when the ignition is turned off, you

are experiencing engine run-on. Usually, older vehicles with an external

• The only wires connected to the coil terminals should be the shielded voltage regulator are susceptible to this condition. Because the Ignition

red connected to coil positive (+) and black connected to coil negative (–). Control Module receives power directly from the battery, it does not

• The small red/white wire is connected to a switched 12 volt source, require much current to keep the unit energized. If you are experiencing

such as the ignition key. run-on, it is due to a small amount of voltage going through the charging

• Power leads are connected directly to the battery positive and lamp indicator and feeding the small red/white wire (even if the key is

negative terminals. turned off).

• If you’re not using an alternator, the battery should be connected

and fully charged.

• The engine MUST be equipped with at least one ground strap to

the chassis.

THEFT DETERRENT

The Ignition Control Module provides an easy way to install a theft FIGURE 2

deterrent kill switch. See Figure 2. USING THE MAGNETIC

USING MAGNETIC

PICKUP WIRE TO

PICKUP TO TRIGGER

TRIGGER

MAGNETIC PICKUP TRIGGER THE HYFIRE

THE ACCEL/DFI

®

VIA6A

When using the Mag. pickup to trigger the Ignition Control Module, install DARK BLUE BLACK

WHITE BLACK

a switch across the dark blue (points) wire to ground. When the white HYFIRE® VIA

FROMACCEL/DFI

FROM 6A

wire is grounded, the vehicle will crank but will not start.

WHITE WIRE TRIGGER

When using the dark blue wire to trigger the Ignition Control Module, DARK BLUE

install a switch to the purple (Mag. +) wire and the other side to ground. USING

USING THE DARK

WHITEBLUE

When the purple (Mag. +) wire is grounded, the vehicle will crank but WIRE

WIRE TO TRIGGER

TRIGGER

will not start. PURPLE

THE HYFIRE

THE ®

ACCEL/DFI

VIA6A

CONNECTS TO

PURPLE BLACK

TROUBLESHOOTING MAGNETIC PICKUP

This section offers several tests and checks you can perform to ensure

GREEN

proper installation and operation of the 6A Ignition Control Module. If

you experience a problem with your 6A, first check for proper installation

and poor connections. You can eliminate many problems by checking

these items. If you have any questions concerning your 6A Ignition

Control Module contact the ACCEL/DFI Technical Service Department

at 248-380-2780, Monday through Friday, 8:00 am to 5:00 pm

Eastern time.

12 VOLT FIGURE 3

TACH ADAPTERS IGNITION SWITCH

If your tachometer does not operate correctly, you probably need a FROM POINTS OR

tach adapter such as those made by Mallory. Consult the Tachometer RED/WHITE

SMALL RED AMPLIFIER

FROM ACCEL/DFI

FROM 6A

HYFIRE® VIA

Compatibility List for common tachometers and compatible tach

WHITEBLUE

DARK WIRE WIRE

FROM

adapters. ® VIA

HYFIREACCEL/DFI

FROM 6A

CHRYSLER DUAL

BALLAST RESISTOR

ACCEL/DFI TECHNICAL SUPPORT 248.380.2780 www.accel-dfi.com 3

GM 1973-83 WITH DELCOTRON ALTERNATORS

GM Delcotron alternators use an internal voltage regulator. Install the

TACHOMETER COMPATIBILITY LIST

diode inline on the smallest wire exiting the alternator (see Figure 5). Aftermarket White Wire Magnetic Trigger

It is usually a brown wire. Tachometer Trigger Connector

Autogage Mallory 29074 Mallory 29078

Most other applications: To eliminate run-on, place a resistor in-line

to the small red/white wire to keep voltage from leaking into the Ignition Autometer — —

Control Module. Ford Motorsport — —

Moroso — —

MISSES AND INTERMITTENT PROBLEMS

Stewart Mallory 29074 Mallory 29078

Experience has shown that if your engine is misfiring or hesitating at

higher RPM, it is usually not an ignition problem. Most common causes S.W. & Bi Torx — —

include a coil or plug wire failure, arcing from the cap or boot plug to Sun Mallory 29074 Mallory 29078

ground or spark ionization inside the cap. Perform the following checks: VDO Mallory 8910 Mallory 29078

• Inspect the plug wires at the cap and at the spark plug for a tight AMC (Jeep) Mallory 29074 Mallory 29078

connection. Visually inspect for cuts, abrasions, or burns. Chrysler Mallory 29074 Mallory 29078

• Inspect the primary coil wire connections. Because the Ignition Control Ford (Before 1976) Mallory 29074 Mallory 29078

Module receives a direct 12 volt source from the battery, there will not Ford (After 1976) Mallory 29074 Mallory 29078

be any voltage at the coil positive (+) terminal, even with the key GM Bypass in-line Bypass in-line

turned on. WARNING: During cranking, or while the engine is running, filter filter

very high voltage will be present and no test equipment should be

Imports Mallory 29074 Mallory 29078

connected. WARNING: Do not touch the coil terminals during cranking

or while the engine is running.

• Make sure that the battery is fully charged and the connections

are clean and tight. If you are not running an alternator, this is an

imperative check. If the battery voltage drops below 10 volts during Early Ford and GM: To solve the run-on problem, a diode is supplied

a race, the Ignition Control Module output voltage will drop. with the Ignition Control. By installing this diode in-line of the wire that

goes to the charging indicator, the voltage is blocked from entering the

• Is the engine running lean? Inspect the spark plugs and the entire Ignition Control Module. Figure 4 shows the proper diode installation for

fuel system. early Ford and GM vehicles.

• Check all wiring connections for corrosion or damage. Remember NOTE: Diodes are used to allow voltage to flow only one way. Make sure

to use proper connections followed by soldering, then seal the the diode is installed facing the proper direction, as shown in Figure 4.

connections completely. Ford: Install the diode inline to the wire going to the #1 terminal.

GM: Install the diode inline to the wire going to the #4 terminal.

FIGURE 6

FIGURE 4

FOR FORD VEHICLES FOR EARLY GM VEHICLES

ATTACH DIODE TO ATTACH DIODE TO DARK

WHITE

#1 TERMINAL #4 TERMINAL BLUE

WIRE

TO CHARGING LIGHT

1A-100V DIODE SPLICE HERE

TO GROUND

CHECKING FOR SPARK

If Triggering the Ignition with the Dark Blue Wire: (See Figure 6)

1. Make sure the ignition switch is in the "OFF" position.

2. Remove the coil wire from the distributor cap and set the terminal

approximately 1/4" from ground.

3. Disconnect the Ignition Control Module white wire from the

distributor’s points or ignition amplifier.

4. Turn the ignition to the "ON" position. Do not crank the engine.

DELCOTRON SPLICE HERE FIGURE 5

ALTERNATOR

5. Tap the dark blue wire to ground several times. Each time you pull

TO CHARGING LIGHT the wire from ground, a spark should jump from the coil wire to

ground. If spark is present, the ignition is working properly. If there is

no spark, skip to Step 6 on next page.

1A-100V DIODE

4 www.accel-dfi.com ACCEL/DFI TECHNICAL SUPPORT 248.380.2780

If Triggering With the Magnetic Pickup: (See Figure 7) the key is in the ON position. If 12 volts is not present, find

1. Make sure the ignition switch is in the OFF position. another switched 12 volts source and repeat the test.

2. Remove the coil wire from the distributor cap and set the terminal D. If, after following the test procedures and inspecting all of the

approximately 1/4" from ground. wiring, there is still no spark, the Ignition Control Module is in

need of repair. See the Warranty and Service section for

3. Disconnect the Ignition Control Module magnetic pickup wires from information.

the distributor.

4. Turn the ignition to the ON position. Do not crank the engine.

5. With a small jumper wire, short the Ignition Control Module green and FIGURE 7

violet magnetic pickup wires together. Each time you break this short,

a spark should jump from the coil wire to ground. If spark is present,

the ignition is working properly. If there is no spark skip to Step 6

below.

6. If there is no spark.

A. Inspect all of the wiring.

B. Substitute another coil and repeat the test. If there is now spark,

GREEN

the coil is at fault.

C. If there is still no spark, check to make sure there is 12 volts on JUMPER WIRE

the small red/white wire from the Ignition Control Module when VIOLET

ACCEL/DFI TECHNICAL SUPPORT 248.380.2780 www.accel-dfi.com 5

Installing the ACCEL/DFI 6A with a Points/Amplifier Installing the ACCEL/DFI 6A with a Magnetic

Style Ignition or ACCEL/DFI GEN 7 Pickup Distributor or Crank Trigger

IGNITION KEY TO 12 VOLTS

IGNITION KEY TO 12 VOLTS

RED/WHITE

Originally connected to coil (+) RED/WHITE

ORIGINAL COIL (+)

BLACK (LARGER)

TO BATTERY NEG (-)

BLACK (LARGE 14 GA)

TO BATTERY NEG (-)

FIGURE 8 RED (LARGER) RED (LARGE 14 GA)

TO BATTERY POS (+) TO BATTERY POS (+)

DARK BLUE

FIGURE 9 NOT USED

Original

Originalcoil

coilwire

wire from

from points

points

or DARK BLUE

orelectronic

electronicignition

ignition amplifier.

amplifier

To GEN 7 dr. blue (est) wire.

PART

PARTNo.

No.6852

75606

PART No. 6852

PART No. 75606 ®

ACCEL/DFI 6A R

® H

ACYCFEILR/D

EF6I A

6A R

ELECTRONIC IGNITION CONTROL MODULE

ELECTRONIC IGNITION CONTROL MODULE

GREEN

FROM MAG PICK-UP DIST

OR CRANK TRIGGER

MAGNETIC PICK-UP

PURPLE

(NOT USED)

YELLOW

TO TACHOMETER

YELLOW

TO TACHOMETER

RED

RED

COIL

COIL

BLACK (SHIELDED CABLE)

BLACK (SHIELDED CABLE)

SHIELD DRAIN

SHIELD DRAIN

IGNITION KEY TO 12 VOLTS

RED/WHITE

RED

GREEN DARK BLUE

BROWN

CONNECT WIRES AT

FIGURE 10 THESE POINTS

TO ENGINE

GROUND

Installing the ACCEL/DFI 6A with a PART

PARTNo.

No. 75606

6852

Mallory UNILITE® or Magnetic ®

ACCEL/DFI 6A R

Breakerless Distributor ELECTRONIC IGNITION CONTROL MODULE

PURPLE

NOT USED

GREEN

RED (LARGE 14 GA)

TO BATTERY POS (+)

BLACK (LARGE 14 GA)

TO BATTERY NEG (-)

YELLOW

TO TACHOMETER

RED

COIL

BLACK (SHIELDED CABLE)

SHIELD DRAIN

6 www.accel-dfi.com ACCEL/DFI TECHNICAL SUPPORT 248.380.2780

IGNITION KEY TO 12 VOLTS

ORIGINAL COIL (+) RED/WHITE

PURPLE

GREEN

RED (LARGE 14 GA)

TO BATTERY POS (+)

BLACK (LARGE 14 GA)

TO BATTERY NEG (-)

FIGURE 11

PART No.

PART No.6852

75606 Installing the ACCEL/DFI 6A with a

®

H

ACYCF

ELIR

/DE

FI66A

A R

Mallory 81-84 Series Distributor

(2-Wire Magnetic Pickup)

ELECTRONIC IGNITION CONTROL MODULE

DARK BLUE

NOT USED

YELLOW

TO TACHOMETER

RED

COIL

BLACK (SHIELDED CABLE)

SHIELD DRAIN

PURPLE

Installing the ACCEL/DFI 6A with a

GREEN

Dual Connector Coil HEI System

RED (LARGE 14 GA) PART OF MALLORY HEI

TO BATTERY POS (+) KIT P/N 29008 (NOT

INCLUDED)

BLACK (LARGE 14 GA)

TO BATTERY NEG (-) FIGURE 12

YELLOW RED PINK

TO IGNITION SWITCH

TO TACHOMETER

RED/WHITE RED PINK

FROM DISTRIBUTOR

DARK BLUE WHITE

CONNECT FACTORY TACH HERE

BLACK WHITE

(SHIELDED CABLE) WHITE (NOT USED) PINK (NOT USED)

RED PINK WHITE

FI 66A

A

ELECTRONIC IGNITION CONTROL MODULE

SHIELD DRAIN

SPLICE WIRES AT THESE LOCATIONS

ACYCF

H /DE

EILR R

PART No. 75606

6852

®

PART

ACCEL/DFI TECHNICAL SUPPORT 248.380.2780 www.accel-dfi.com 7

There are three different large cap HEI distributors. To identify which

of the following diagrams fit your specific application, remove the

distributor cap and rotor and locate the ignition module at the base

of the distributor. Count the number of terminals on both ends of the

4-Pin Module 5-Pin Module

module and follow the corresponding diagram. GM used 4, 5, and

7-pin modules in these distributors.

NOTE: Some 5-pin modules may experience a hesitation or stall on FIGURE 13

deceleration. If this occurs, contact the ACCEL/DFI Technical Service

Department for the required bolt-in diode to correct the problem. 7-Pin Module

RED (LARGE 14 GA) PURPLE

TO BATTERY POS (+) PART OF MALLORY HEI KIT

P/N 29008 (NOT INCLUDED)

WHITE

PART

PART No.

No. 6852

75606 PURPLE

®

H

ACYCF

ELI/RDE

FI 6A

A

ELECTRONIC IGNITION CONTROL MODULE

R

GREEN GREEN

GREEN

TO ENGINE

GROUND

BLACK (LARGE 14 GA)

TO BATTERY NEG (-)

YELLOW

TO TACHOMETER

BLACK (TO C+)

DARK BLUE

NOT USED

WHITE JUMPER RED/WHITE RED (TO B+)

SHIELDED CABLE

PART OF MALLORY HEI KIT

P/N 29008 (NOT INCLUDED)

SHIELD DRAIN

FIGURE 14

KEY CONNECTOR

Installing the ACCEL/DFI 6A with an HEI

HEAVY RED OR PINK WIRE FROM CAR 4-Pin Module (Magnetic Pickup Trigger)

WIRING HARNESS

RED (LARGE 14 GA) RED/WHITE RED JUMPER

TO BATTERY POS (+)

PART OF MALLORY

HEI KIT P/N 29008

DARK BLUE WHITE JUMPER (NOT INCLUDED)

PART PART OF MALLORY HEI KIT

PARTNo.

No.6852

75606

P/N 29008 (NOT INCLUDED)

®

ACCEL/DFI 6A R

ELECTRONIC IGNITION CONTROL MODULE

BLACK (LARGE 14 GA)

TO BATTERY NEG (–)

GREEN HEAVY PINK OR RED FROM

NOT USED VEHICLE WIRE HARNESS

PURPLE

TO TACH

YELLOW

TO TACHOMETER

TO ENGINE

GROUND

FIGURE 15

Installing the ACCEL/DFI 6A

with an HEI 5-Pin BLACK (TO C+)

or 7-Pin Module

RED (TO B+)

(Amplifier Trigger)

SHIELDED CABLE PART OF MALLORY

HEI KIT P/N 29008

SHIELD DRAIN (NOT INCLUDED)

8 www.accel-dfi.com ACCEL/DFI TECHNICAL SUPPORT 248.380.2780

HEAVY PINK, ORANGE, OR RED WIRE

PINK

FROM DISTRIBUTOR

BROWN

GREEN

MAGNETIC PICKUP

NOT USED

PURPLE

NOT USED (TAPE END) RED

PART No. JUMPER

PART No.6852

75606 WHITE JUMPER

DARK BLUE

®

ACCEL/DFI 6A R

ELECTRONIC IGNITION CONTROL MODULE RED/WHITE

PART OF MALLORY

HEI KIT P/N 29008

(NOT INCLUDED)

RED (LARGE 14 GA) BLACK RED (SHIELDED CABLE)

TO BATTERY POS (+) (SMALL

18 GA)

BLACK (LARGE 14 GA)

TO BATTERY NEG (-) SHIELD DRAIN

FIGURE 16

Installing the ACCEL/DFI 6A with an

External 4-Terminal Coil (Single

Connector)

RED

GREEN

RED/WHITE

DARK BLUE

BLACK (LARGE 14GA)

TO BATTERY NEG (-)

PART

PART No.

No. 75606

6852

®

ACCEL/DFI 6A R

FIGURE 17

ELECTRONIC IGNITION CONTROL MODULE

Installing the ACCEL/DFI 6A with

a Ford Duraspark using the

Dark Blue Wire Trigger

TO BATTERY POS (+)

RED (LARGE 14GA)

PURPLE

MAGNETIC PICK-UP

(NOT USED)

GREEN

YELLOW

TO TACHOMETER

RED

SHIELDED CABLE

COIL

BLACK

SHIELD DRAIN

ACCEL/DFI TECHNICAL SUPPORT 248.380.2780 www.accel-dfi.com 9

WHITE

PART OF MALLORY

RED HEI KIT P/N 29008

(NOT INCLUDED)

INSULATE UNUSED

ENDS OF JUMPERS

RED (LARGE 14GA)

TO BATTERY POS (+)

RED (SMALL 18GA)

BLACK (LARGE 14GA)

TO BATTERY NEG (-)

WHITE

PART

PART No. 75606

No. 6852 FIGURE 18

®

H

ACYCF

EILR

/DEFI6A

6A R

Installing the ACCEL/DFI 6A

with a Ford TFI

ELECTRONIC IGNITION CONTROL MODULE

(Without Harness)

YELLOW

TO TACHOMETER

SHIELD

DRAIN

BLACK (SHIELDED CABLE)

RED

PURPLE

MAGNETIC PICK-UP

(NOT USED)

GREEN

FIGURE 19

Installing the ACCEL/DFI 6A

with a Ford TFI

(With Harness)

ADAPTER/HARNESS P/N 29062

DARK BLUE GREEN

(NOT INCLUDED)

RED/WHITE RED

PART No.

No. 6852

75606 BLACK BLACK

®

H

ACYCF

EILR

/DE

FI66A

A R

ELECTRONIC IGNITION CONTROL MODULE

RED YELLOW

SHIELD DRAIN

SHIELDED CABLE

YELLOW

TO TACHOMETER YELLOW BLACK RED GREEN

BLACK (LARGE 14 GA)

TO BATTERY NEG (-)

FACTORY HARNESS PLUG

RED (LARGE 14 GA)

TO BATTERY POS (+) (ORIGINALLY CONNECTED

TO THE COIL)

PURPLE

MAGNETIC PICK-UP

(NOT USED)

GREEN

10 www.accel-dfi.com ACCEL/DFI TECHNICAL SUPPORT 248.380.2780

SPLICE

CHRYSLER

BLACK MODULE

ORANGE

GREEN VIOLET

PURPLE

6 FT EXTENSION CABLE

CUT ONE END AND

SPLICE AS SHOWN GREEN

FROM RED/WHITE

ORIGINAL COIL

FIGURE 20

PART

Installing the ACCEL/DFI 6A with a

PARTNo.

No.6852

75606

Chrysler Electronic Ignition using

®

H

ACYCF

EILR

/DE

FI66A

A R

a Magnetic Pickup Trigger

ELECTRONIC IGNITION CONTROL MODULE

DARK BLUE

NOT USED

YELLOW

TO TACHOMETER

RED (LARGE 14 GA)

TO BATTERY POS (+)

BLACK (LARGE 14 GA)

TO BATTERY NEG (-)

RED

SHIELDED CABLE

COIL

BLACK

SHIELD IGNITION TO 12 VOLTS ORIGINAL COIL (+)

DRAIN

GREEN/ORANGE RED/WHITE

BLACK/GRAY DARK BLUE

FROM POINTS OR

ELECTRONIC IGNITION

ORIGINAL COIL (-)

PART

PART No.

No. 6852

75606

FIGURE 21 ®

ACCEL/DFI 6A R

Installing the ACCEL/DFI 6A with a Late ELECTRONIC IGNITION CONTROL MODULE

Model Dodge (with 2-Pin Connector)

YELLOW

TO TACHOMETER

RED (LARGE 14 GA)

TO BATTERY POS (+)

BLACK (LARGE 14 GA)

TO BATTERY NEG (-)

GREEN

MAGNETIC PICKUP

NOT USED

PURPLE

GREEN/ORANGE RED

BLACK/GRAY OR GRAY BLACK (SHIELDED CABLE)

SHIELD DRAIN

ACCEL/DFI TECHNICAL SUPPORT 248.380.2780 www.accel-dfi.com 11

ORIGINAL COIL (+) WIRE

AMPLIFIER SPLICE HERE

RED/WHITE

FIGURE 22

Installing the ACCEL/DFI 6A with

a Typical Import Application

TO IGNITION

SWITCH

ORIGINAL COIL (-)

TERMINAL FROM (+) RED

AMPLIFIER

SHIELD

DRAIN SHIELDED CABLE

SPLICE HERE

(-) BLACK

DARK BLUE

PART No.

No.6852

75606

®

H

ACYCF

EILR

/DE

FI66A

A R

ELECTRONIC IGNITION CONTROL MODULE

YELLOW

TO TACHOMETER

RED (LARGE 14 GA)

TO BATTERY POS (+)

BLACK (LARGE 14 GA)

TO BATTERY NEG (-)

GREEN

MAGNETIC PICKUP

NOT USED

PURPLE

PRESTOLITE PERFORMANCE ACCEL/DFI FORM 1522D

29387 LORIE LANE, WIXOM, MI 48393 REV. 12/07

TECHNICAL SUPPORT 248.380.2780 FAX 248.380.4906 Made in U.S.A.

Printed in U.S.A.

12 www.accel-dfi.com ACCEL/DFI TECHNICAL SUPPORT 248.380.2780

S-ar putea să vă placă și

- 003-004 Overhead Set: General InformationDocument16 pagini003-004 Overhead Set: General InformationIgoen YandriÎncă nu există evaluări

- Catalogue Produits OnanDocument6 paginiCatalogue Produits OnanJohn LarsonÎncă nu există evaluări

- Installation Instructions For DC and AC Electric Rewind ReelsDocument4 paginiInstallation Instructions For DC and AC Electric Rewind ReelsGinoGuanÎncă nu există evaluări

- Why Does My Engine Start But Then Stop - AxleAddict - A Community of Car Lovers, Enthusiasts, and Mechanics Sharing Our Auto AdviceDocument28 paginiWhy Does My Engine Start But Then Stop - AxleAddict - A Community of Car Lovers, Enthusiasts, and Mechanics Sharing Our Auto AdvicegrafpapÎncă nu există evaluări

- 2010 Ginn Motor Company HHR Atlanta GADocument8 pagini2010 Ginn Motor Company HHR Atlanta GAatlantachevroletÎncă nu există evaluări

- Transmission and Transfer Case: Manual Transmission - G56 - Service InformationDocument68 paginiTransmission and Transfer Case: Manual Transmission - G56 - Service InformationRyanÎncă nu există evaluări

- HDS7 ManualDocument132 paginiHDS7 ManualTed G.Încă nu există evaluări

- 63 Fuller RTF 11608 Transmission Service ManualDocument106 pagini63 Fuller RTF 11608 Transmission Service ManualEmanuel SepulvedaÎncă nu există evaluări

- V8 Tpi Speed SensorsDocument18 paginiV8 Tpi Speed SensorsRay Ray RayÎncă nu există evaluări

- Heavy-Duty Diagnostic: Product CatalogDocument12 paginiHeavy-Duty Diagnostic: Product CatalogMartin CasillasÎncă nu există evaluări

- VW MK4 TDI 205 F ThermostatDocument3 paginiVW MK4 TDI 205 F ThermostatDavid NeiferdÎncă nu există evaluări

- ETCS-I (Electronic Throttle Control System-Intelligent)Document9 paginiETCS-I (Electronic Throttle Control System-Intelligent)ShzllÎncă nu există evaluări

- Automotive Aftermarket: Adhesive and Sealants GuideDocument48 paginiAutomotive Aftermarket: Adhesive and Sealants GuideFrancis MartinezÎncă nu există evaluări

- ACDelco TechConnect Sept Oct 2014 NewsletterDocument8 paginiACDelco TechConnect Sept Oct 2014 NewsletterBenjamin DoverÎncă nu există evaluări

- John Deere Z225 EZTrak Mower (North American Version) Service Repair Manual (Tm1477)Document15 paginiJohn Deere Z225 EZTrak Mower (North American Version) Service Repair Manual (Tm1477)zhuangfuqian31Încă nu există evaluări

- Onan RV Troubleshooting GuideDocument17 paginiOnan RV Troubleshooting GuideBruce EgglestonÎncă nu există evaluări

- User's Guide: Group G Controller For Automatic & Non-Automatic Transfer SwitchesDocument40 paginiUser's Guide: Group G Controller For Automatic & Non-Automatic Transfer Switchesangel aguilarÎncă nu există evaluări

- Illustrated Parts List: 13500 Starting WattsDocument6 paginiIllustrated Parts List: 13500 Starting WattsTeresa ArguelloÎncă nu există evaluări

- 05 TitanDocument344 pagini05 TitanDavid ChalkerÎncă nu există evaluări

- Peterbuilt Model - 220 - Body - Builder - Manual - 2017Document85 paginiPeterbuilt Model - 220 - Body - Builder - Manual - 2017Raj ChoudharyÎncă nu există evaluări

- ADESystem Jeep SecurityDocument20 paginiADESystem Jeep SecuritycrankyhoboÎncă nu există evaluări

- 2019 GMC Sierra Limited Denali Owners ManualDocument493 pagini2019 GMC Sierra Limited Denali Owners ManualJhon MechanicÎncă nu există evaluări

- Aprilia 3-Phase Recharging System DiagnosisDocument15 paginiAprilia 3-Phase Recharging System DiagnosisManuallesÎncă nu există evaluări

- The Charging System Has Three Main Components: The Alternator, The Voltage Regulator, and The BatteriesDocument20 paginiThe Charging System Has Three Main Components: The Alternator, The Voltage Regulator, and The BatteriesMae CherryÎncă nu există evaluări

- 220VDC80AHChargerswithDCDB PDFDocument20 pagini220VDC80AHChargerswithDCDB PDFbinodeÎncă nu există evaluări

- RXV2065 HTR6295Document163 paginiRXV2065 HTR6295Milan JovićÎncă nu există evaluări

- BOSSDocument99 paginiBOSScamohunter71Încă nu există evaluări

- MARK ELITE SERIES CHIRP OM EN 988-10812-003 W PDFDocument64 paginiMARK ELITE SERIES CHIRP OM EN 988-10812-003 W PDFAlexandre VecaÎncă nu există evaluări

- CT Calculationas For 33kV SwitchgearDocument5 paginiCT Calculationas For 33kV Switchgearjm.mankavil6230Încă nu există evaluări

- Briggs and Stratton Vanguard Engine Manual 272144 - WatermarkedDocument191 paginiBriggs and Stratton Vanguard Engine Manual 272144 - Watermarkedlucian stoianofÎncă nu există evaluări

- Peterbilt Essentials Module3 SleepersDocument6 paginiPeterbilt Essentials Module3 SleepersLuis Reinaldo Ramirez ContrerasÎncă nu există evaluări

- Wiring & Connection1Document29 paginiWiring & Connection1AUNG100% (2)

- PCB Power Driver & Power Transistor CrownDocument6 paginiPCB Power Driver & Power Transistor CrownYetrox89% (84)

- Electrical Interview QuestionsDocument26 paginiElectrical Interview Questionsprathikgala2324234Încă nu există evaluări

- Nema MG1Document670 paginiNema MG1Juan Abdón Sepúlveda Garrido100% (2)

- Solenoide lb7Document1 paginăSolenoide lb7Anonymous 5tkF5bFwOÎncă nu există evaluări

- Single Phase P11000 (Yanmar)Document2 paginiSingle Phase P11000 (Yanmar)gigo_dreamÎncă nu există evaluări

- Operation and Installation ManualDocument105 paginiOperation and Installation ManualNAVEDTRA12204Încă nu există evaluări

- Mitsubishi Eclipse Spyder 3.0LDocument97 paginiMitsubishi Eclipse Spyder 3.0LrobertoÎncă nu există evaluări

- 2 g4 1.9L ALH Autom TrsDocument13 pagini2 g4 1.9L ALH Autom TrsDan Paşca100% (1)

- Acura TSX 2004 Manual and Power Steering, Steering Column, Gear and LinkageDocument144 paginiAcura TSX 2004 Manual and Power Steering, Steering Column, Gear and Linkagejorge antonio guillenÎncă nu există evaluări

- Intermittent Transmission Clutch Shudder Dps6 Automatic Transmission And/Or Transmission Fluid Leak TSB 14-0047Document6 paginiIntermittent Transmission Clutch Shudder Dps6 Automatic Transmission And/Or Transmission Fluid Leak TSB 14-0047peter064Încă nu există evaluări

- Direct Injection (Current) PDFDocument7 paginiDirect Injection (Current) PDFToni JuanÎncă nu există evaluări

- 2011 Mad PogDocument81 pagini2011 Mad PogBruno Pilieci100% (1)

- CatalogoDocument64 paginiCatalogoomarantonioÎncă nu există evaluări

- Accu Turn Manual 8944 Lathe W Parts ListDocument38 paginiAccu Turn Manual 8944 Lathe W Parts ListJohnfromFresno100% (1)

- TG Series: Power Take-OffDocument24 paginiTG Series: Power Take-OffJose Daniel RiveirosÎncă nu există evaluări

- 6-55 Hydraulic Equipment Pump & Adapting PartsDocument4 pagini6-55 Hydraulic Equipment Pump & Adapting PartsPaull SalasÎncă nu există evaluări

- Tecumseh Transaxle Service Information p2333Document124 paginiTecumseh Transaxle Service Information p2333Wayne Anstey100% (1)

- Ford Motorcraft CarburationDocument40 paginiFord Motorcraft CarburationjohnvandurenÎncă nu există evaluări

- Heavy-Duty Diagnostic: Product CatalogDocument12 paginiHeavy-Duty Diagnostic: Product CatalogSonthi MooljindaÎncă nu există evaluări

- The Theory Behind The Engine BrakeDocument3 paginiThe Theory Behind The Engine BrakeJoseGarzaÎncă nu există evaluări

- Alpha LPW LPWS LPWX Engines Operators HandbookDocument48 paginiAlpha LPW LPWS LPWX Engines Operators Handbookchristiam tevesÎncă nu există evaluări

- Generator - Onan NHM Operators ManualDocument31 paginiGenerator - Onan NHM Operators Manualbugman58Încă nu există evaluări

- mm38 PDFDocument32 paginimm38 PDFDieselkÎncă nu există evaluări

- CVT C Transmission TransaxleDocument240 paginiCVT C Transmission TransaxleFX WamalaÎncă nu există evaluări

- Volt Sandy BlogsDocument9 paginiVolt Sandy BlogskrivasscribdÎncă nu există evaluări

- Programming The PowertrainDocument10 paginiProgramming The PowertrainMiller Andres ArocaÎncă nu există evaluări

- Zenith Carburetor Adjustment Procedure 14992Document1 paginăZenith Carburetor Adjustment Procedure 14992ChevronelleÎncă nu există evaluări

- LX279 With 48C Deck: Lawn Tractor 48" Convertible DeckDocument1 paginăLX279 With 48C Deck: Lawn Tractor 48" Convertible DeckManuel Fernandez Mora0% (1)

- Otc Detroit Diesel Flyer 5 PDFDocument2 paginiOtc Detroit Diesel Flyer 5 PDFIsmael TrejoÎncă nu există evaluări

- 31 Series Trouble ShootingDocument4 pagini31 Series Trouble ShootingrburtonshawÎncă nu există evaluări

- VW - DSG Component AgungDocument4 paginiVW - DSG Component AgungAgung PurnamaÎncă nu există evaluări

- 6.2 Twin TurboDocument10 pagini6.2 Twin TurboDave MilnerÎncă nu există evaluări

- Fruitland Vacuum Pump: Operation and Maintenance ManualDocument48 paginiFruitland Vacuum Pump: Operation and Maintenance ManualALEXÎncă nu există evaluări

- Motorcycle, Solo (Harley-Davidson Model WLA)De la EverandMotorcycle, Solo (Harley-Davidson Model WLA)Încă nu există evaluări

- Com - Com: Solid State Protective RelaysDocument23 paginiCom - Com: Solid State Protective Relaysshehroz baigÎncă nu există evaluări

- 22FD4P2N113Document2 pagini22FD4P2N113alejandro diazÎncă nu există evaluări

- CanCom Connector Chart 2018Document13 paginiCanCom Connector Chart 2018Derick100% (1)

- Dave Lawton PWM Kit Instructions 1Document9 paginiDave Lawton PWM Kit Instructions 1Eric BlairÎncă nu există evaluări

- Basics, Maintenance, and Diagnostics 38Document1 paginăBasics, Maintenance, and Diagnostics 38imcoolmailme2Încă nu există evaluări

- Siemens MAC15NDocument4 paginiSiemens MAC15NTas KayÎncă nu există evaluări

- Enchufe de Conexion SobrellenadoDocument2 paginiEnchufe de Conexion SobrellenadoJose MorenoÎncă nu există evaluări

- An Improved Method For Protection of Three Phase Induction Motor Using ArduinoDocument6 paginiAn Improved Method For Protection of Three Phase Induction Motor Using Arduinowondi BETÎncă nu există evaluări

- SFH619A: Vishay SemiconductorsDocument10 paginiSFH619A: Vishay SemiconductorsKh Nazmul Ahmed RemonÎncă nu există evaluări

- Navweps 16-45-637 TB 11 6625 274 12/1Document100 paginiNavweps 16-45-637 TB 11 6625 274 12/1amoratorÎncă nu există evaluări

- Igbt & Sic Gate Driver Fundamentals: Enabling The World To Do More With Less PowerDocument35 paginiIgbt & Sic Gate Driver Fundamentals: Enabling The World To Do More With Less Powersuper_facaÎncă nu există evaluări

- Transformers Study Material PDFDocument6 paginiTransformers Study Material PDFMurugeswariÎncă nu există evaluări

- 4Document5 pagini4durgendraÎncă nu există evaluări

- 314 Actuator Manual (Inactive)Document32 pagini314 Actuator Manual (Inactive)abduallah muhammadÎncă nu există evaluări

- XW2R - To PLC - Bro - EN - 201303Document20 paginiXW2R - To PLC - Bro - EN - 201303Faccturas IMAÎncă nu există evaluări

- List of Electrical Pending Works 21042020Document9 paginiList of Electrical Pending Works 21042020Sanjib Banerjee0% (1)

- Epson Aculaser Cx16nfDocument26 paginiEpson Aculaser Cx16nffefotroncitoÎncă nu există evaluări

- 3RT60251BB40 Datasheet enDocument6 pagini3RT60251BB40 Datasheet enSanjaya FernandoÎncă nu există evaluări

- Science5 - Periodical Test Quarter 3Document3 paginiScience5 - Periodical Test Quarter 3Honeylou PadayaoÎncă nu există evaluări

- Compact Fluorecent LampDocument11 paginiCompact Fluorecent LampKathleen Jhoren ReglosÎncă nu există evaluări

- Gallien-Krueger 700RB (Volume 2) Service ManualDocument23 paginiGallien-Krueger 700RB (Volume 2) Service ManualMaximiliano VanegasÎncă nu există evaluări

- 2006 D6CA Engine Control (ETC) System Schematic DiagramsDocument1 pagină2006 D6CA Engine Control (ETC) System Schematic DiagramsDavid GallegosÎncă nu există evaluări

- Backstepping Control of Wind Energy System With Multilevel InverterDocument6 paginiBackstepping Control of Wind Energy System With Multilevel InvertermahaÎncă nu există evaluări