Documente Academic

Documente Profesional

Documente Cultură

RCC Section Drawing

Încărcat de

Shaikh ImranTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

RCC Section Drawing

Încărcat de

Shaikh ImranDrepturi de autor:

Formate disponibile

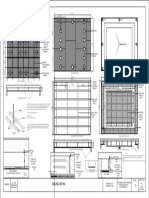

SCHEDULE OF BEAMS AT SECOND SLAB LEVEL 02 / 02

Sr. No. Beam Size Straight Straight Curt. Bar Extra Top Stirrups Stirrups

Group BxD Top Bar Bott. Bars Middle 0.6L Ends L/4 End zone L/4 Middle half

01 FB0 150 X 380 2 - 10 Dia 2 - 12 Dia --- --- 08 dia - 150 c/c 08 dia - 175 c/c

Min. Ld

02 FB1 150 X 380 2 - 10 Dia 2 - 12 Dia --- 1 - 12 Dia 08 dia - 150 c/c 08 dia - 200 c/c beyond column

Continue Extra tops at Internal

face

continous supports

03 FB2 150 X 380 2 - 12 Dia 2 - 12 Dia --- 1 - 12 Dia 08 dia - 150 c/c 08 dia - 200 c/c * Compulsary

Column links at

for All Top , Bottom & extra top column-beam junction

FB3 150 X 380 2 - 12 Dia 2 - 12 Dia 1 - 12 Dia 1 - 12 Dia 08 dia - 125 c/c 08 dia - 175 c/c end zone stirrups Remaining span

04 Extra Tops Bars

( upto L/4 ) stirrups upto L/4 400 mm are necessary

End Bent 400 mm

Min. 300mm

05 FB4 150 X 380 2 - 12 Dia 2 - 12 Dia 1 - 12 Dia 2 - 12 Dia 08 dia - 125 c/c 08 dia - 175 c/c

06 FB5 150 X 380 2 - 12 Dia 2 - 12 Dia 2 - 12 Dia --- 08 dia - 125 c/c 08 dia - 175 c/c

16mm dia

07 FB6 150 X 450 2 - 12 Dia 2 - 16 Dia --- 1 - 16 Dia 08 dia - 100 c/c 08 dia - 175 c/c Anchor Pin

50mm max Curtail Bar

first stirrup Position at Bottom middle 0.6L

08 FB7 230 X 380 2 - 16 Dia 3 - 16 Dia --- --- 08 dia - 150 c/c 08 dia - 150 c/c L=Length of Beam * IMPORTANT

09 FB8 230 X 380 3 - 12 Dia 3 - 12 Dia --- --- 08 dia - 150 c/c 08 dia - 150 c/c Column

50% Bottom bars are to be

Width/Depth Column

lapped at L/4 from support of column

(if Reqd.)

10 FB9 230 X 380 2 - 12 Dia 2 - 16 Dia 1 - 12 Dia 2 - 12 Dia 08 dia - 125 c/c 08 dia - 175 c/c

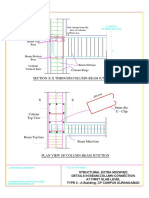

TYP. DETAILS OF LONGITUDINAL SECTION THROUGH BEAM.

11 FB10 230 X 450 2 - 16 Dia 3 - 16 Dia --- 3 - 16 Dia 08 dia - 100 c/c 08 dia - 150 c/c

12 FB11 230 X 450 2 - 16 Dia 3 - 16 Dia 1 - 16 Dia 3 - 16 Dia 08 dia - 100 c/c 08 dia - 150 c/c

13 FB12 230 X 530 3 - 16 Dia 3 - 16 Dia 2 - 16 Dia 3 - 16 Dia 08 dia - 100 c/c 08 dia - 125 c/c

Alt. bent up Steel continue from one span to other

14 FBR0 150 X 450 3 - 12 Dia 2 - 12 Dia --- --- 08 dia - 125 c/c 08 dia - 125 c/c

Alt. Bent up bars 0.3L1 0.3L2

15 FBR1 150 X 380 3 - 12 Dia 2 - 12 Dia --- --- 08 dia - 125 c/c 08 dia - 125 c/c

16 FBR2 150 X 380 4 - 16 Dia 2 - 12 Dia --- --- 08 dia - 125 c/c 08 dia - 125 c/c

17 FBR3 230 X 450 3 - 16 Dia 2 - 16 Dia --- --- 08 dia - 100 c/c 08 dia - 150 c/c

in cantilever portion in back beam portion 0.2L1 0.25L1 0.25L2

18 FBR4 230 X 450 4 - 16 Dia 2 - 16 Dia --- --- 08 dia - 100 c/c 08 dia - 150 c/c

in cantilever portion in back beam portion L1 L2

19 FBR5 230 X 450 5 - 16 Dia 3 - 16 Dia --- --- 08 dia - 100 c/c 08 dia - 100 c/c Slab Discontinuous end Slab continuous end

20 FBR6 230 X 380 3 - 16 Dia 2 - 12 Dia --- --- 08 dia - 125 c/c 08 dia - 125 c/c DETAILS OF BAR BENDING FOR SLABS

21 HB 200 X 125 2 - 10 Dia 2 - 12 Dia --- --- 08 dia - 175 c/c 08 dia - 175 c/c

22 HB1 200 X 125 2 - 12 Dia 2 - 12 Dia --- --- 08 dia - 150 c/c 08 dia - 150 c/c

DETAILS OF SLAB - AT SECOND SLAB LEVEL

Slab Thick Steel along Extra Top. Remark

Width (short) Length (long)

one way End bent 08 mm @ 125 c/c LEGENDS :

S1 125 08 mm @ 150 c/c 08 mm @ 150 c/c ---- plain jali Bent back Chimta

Min.300mm

S2 125 08 mm @ 100 c/c 08 mm @ 100 c/c ---- one way

300mm

plain jali

125 08 mm @ 175 c/c 08 mm @ 125 c/c 08 mm @ 250 c/c one way Beam As

S3 Slab at Beam Bottom

per schdule

125

S4 125 08 mm @ 175 c/c 08 mm @ 175 c/c 08 mm @ 300 c/c Two Way

S5 125 08 mm @ 150 c/c 08 mm @ 175 c/c 08 mm @ 300 c/c Two Way

CS 125 08 mm @ 150 c/c 08 mm @ 175 c/c Cantilever 08 mm @ 175 c/c TYPICAL STIRRUP

Bent back Chimta ---- SECTION A-B

SS1 150 08 mm @ 175 c/c 12 mm @ 150 c/c ---- Stairs / RING

Note :Alternate bent up of one span shall go to L/4 of other span.

> Provide extra tops at discontinuous ends.

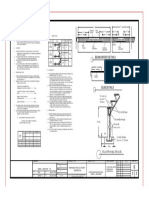

IMP NOTES :- 6. No concreting shall be done without seeking Structural Engineer's Structural Consultants

comment in writing.

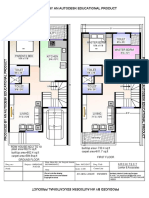

Client : NORTH Sheet Title :

1. All work shall be strictly executed as per the drawing. 7. Clear Cover to R/F bars shall be - Footing 50mm, Column 40mm ,Beams 30mm,

2. Structure designed for G+4 Including Future Provision (5 Slabs only). Slabs 20mm. Mr. S.A.G. Qureshi Sahab

if not found at site, foundations must be redesigned. 8. Developement/Lap length shall be used as 50 times dia of bar for beams , Structural Design Details Er. Shaikh Imran

3. Concrete Grade M20 and Steel Fe500 shall be used.

4. Fe500 grade Steel shall only be used if 14.5 % elongation is assured

Where bent used it shall be 42 times dia of bar.

9. Stripping time Shall be as per I.S.456-2000. N At SECOND slab level (DCE, M.E. Structure)

as per Codel Provisions. 10. False work/ Shuttering Stability, supervision is responsibility of contractor.

5. Concrete Mix design shall be followed. 11. Top bars are to be lapped at center of beam & Project Title : ( 02 of 02)

Reg.No. E-725/18

bottom bars at L/4 from column face (lap length =50xbar diameter).

12. Column bars lapping should be done at center of the column.

02 - Structural Schedule Aurangabad

13. If crush sand used for concreting work, it shall have proper mix design from lab. Proposed Apartment Building, & Detailing +91 88 55 866 787

14. Structural analysis & design is done for Gravity loadings only.

15. Any discrepancy shall be asked and discussed to Structural Engineer. At Beed Bypass, Aurangabad.

*** THIS DRAWING SHALL BE USED FOR SECOND SLAB LEVEL ONLY. Drawing No. 07-b Date : 13/02/2019 Revision No : 0

S-ar putea să vă placă și

- 7 SteelDocument6 pagini7 SteelIssaÎncă nu există evaluări

- Schedule of LoadsDocument2 paginiSchedule of LoadsDarwin PanÎncă nu există evaluări

- Review of Issue On Pavement EngineeringDocument8 paginiReview of Issue On Pavement EngineeringInahMisumiÎncă nu există evaluări

- GypsumffDocument10 paginiGypsumffSashwat GhaiÎncă nu există evaluări

- Bhutan GREEN Building Design Guidelines PDF For Website FIDocument123 paginiBhutan GREEN Building Design Guidelines PDF For Website FIGauravÎncă nu există evaluări

- Inaccessible and Impassable Roads and Alternative Surfacing Programme Narrative Report For January 2009Document29 paginiInaccessible and Impassable Roads and Alternative Surfacing Programme Narrative Report For January 2009ectransportÎncă nu există evaluări

- Field Testing of Bio-Engineering Techniques UsingDocument10 paginiField Testing of Bio-Engineering Techniques UsingEutiquio Rotaquio100% (1)

- Predicting Product PDFDocument12 paginiPredicting Product PDFStudy in an easy wayÎncă nu există evaluări

- 1B PPT Plumbing Roughing-InDocument80 pagini1B PPT Plumbing Roughing-InGail GenturalezÎncă nu există evaluări

- SOURCE Tech Spec SheetDocument2 paginiSOURCE Tech Spec Sheetqsa000Încă nu există evaluări

- Sound Absorbers Sheet 02Document1 paginăSound Absorbers Sheet 02Pooja JabadeÎncă nu există evaluări

- Strength of Materials ExamDocument1 paginăStrength of Materials ExamAndrew PortugalÎncă nu există evaluări

- Two Way Slab CalcsDocument2 paginiTwo Way Slab CalcsMarkÎncă nu există evaluări

- Group1 FinalDocument63 paginiGroup1 FinalArnav SinghÎncă nu există evaluări

- Application of Water Hyacinth INTRODUCTION SIPDocument1 paginăApplication of Water Hyacinth INTRODUCTION SIPKent Noreen ModanzaÎncă nu există evaluări

- Skill Acquisition CenterDocument1 paginăSkill Acquisition CenterSylvia OkaforÎncă nu există evaluări

- Ambler Boiler HouseDocument13 paginiAmbler Boiler HouseOmer MirzaÎncă nu există evaluări

- Chapter 1 Case StudyDocument4 paginiChapter 1 Case Studypuul124Încă nu există evaluări

- Assessment Report Format Sample For Old BuildingsDocument5 paginiAssessment Report Format Sample For Old BuildingsAndrew Araha0% (1)

- Multi-Storey Car Park Complex, Marina, LagosDocument12 paginiMulti-Storey Car Park Complex, Marina, LagosJusetine john gersaliaÎncă nu există evaluări

- PPTDocument24 paginiPPTupasnaÎncă nu există evaluări

- Wood & Wood DerivativesDocument8 paginiWood & Wood DerivativesPriya ManeÎncă nu există evaluări

- Griha Criteria No.32 Energy Audit and ValidationDocument13 paginiGriha Criteria No.32 Energy Audit and ValidationrichurichaÎncă nu există evaluări

- Bay SectionDocument1 paginăBay SectionMichelle AntonioÎncă nu există evaluări

- Construction Failure-Case StudyDocument7 paginiConstruction Failure-Case StudyMichaelJosephÎncă nu există evaluări

- Modified Type of Nyishi Typology, Bamboo Housing in Arunachal Pradesh.Document28 paginiModified Type of Nyishi Typology, Bamboo Housing in Arunachal Pradesh.Tana SumpiÎncă nu există evaluări

- CeilingConnex InstructionsDocument2 paginiCeilingConnex InstructionsRyan RusherÎncă nu există evaluări

- Formwork 150318073913 Conversion Gate01Document59 paginiFormwork 150318073913 Conversion Gate01Gurbaksh SinghÎncă nu există evaluări

- Ceiling DetailDocument1 paginăCeiling DetailDev SharmaÎncă nu există evaluări

- Building Design PDFDocument7 paginiBuilding Design PDFkbkwebsÎncă nu există evaluări

- Lec 2 - Types of Building Materials - Properties and UsesDocument23 paginiLec 2 - Types of Building Materials - Properties and UsesDoha anaÎncă nu există evaluări

- BERNAL, Comparative Analysis (ROMANESQUE FRENCH AND ITALIAN ARCHI)Document4 paginiBERNAL, Comparative Analysis (ROMANESQUE FRENCH AND ITALIAN ARCHI)Aidyl Kate BernalÎncă nu există evaluări

- Site Planning ProcessDocument53 paginiSite Planning ProcessKenet EnriquezÎncă nu există evaluări

- North Light Truss (Autosaved)Document13 paginiNorth Light Truss (Autosaved)Fidha SulfiÎncă nu există evaluări

- Office Case StudyDocument12 paginiOffice Case Studysonal guptaÎncă nu există evaluări

- Factor Affecting ArchitectureDocument7 paginiFactor Affecting Architectureswapnil aggarwal�Încă nu există evaluări

- Abts II - Architectuaral DetailsDocument3 paginiAbts II - Architectuaral DetailsSaurabh Parmar 28Încă nu există evaluări

- Introduction To StairsDocument13 paginiIntroduction To StairsShilpa BhargavaÎncă nu există evaluări

- False CeilingDocument6 paginiFalse CeilingCh. NarendraÎncă nu există evaluări

- ARCC Module 2 HandoutsDocument30 paginiARCC Module 2 HandoutsChelsieCabansagÎncă nu există evaluări

- Experimental Study On Bamboo Reinforced BeamDocument32 paginiExperimental Study On Bamboo Reinforced BeamPraveen RajÎncă nu există evaluări

- Canara Bank Estimate Boq PDFDocument23 paginiCanara Bank Estimate Boq PDFSai SrimanthÎncă nu există evaluări

- Unit 6 Defects of TimberDocument2 paginiUnit 6 Defects of TimberKrishnaSah0% (1)

- CASE STUDY On Primary School (National and International) 2nd Yr Jamia Millia IslamiaDocument15 paginiCASE STUDY On Primary School (National and International) 2nd Yr Jamia Millia IslamiaAnshal NaushadÎncă nu există evaluări

- Building Material Mid-ExamsDocument5 paginiBuilding Material Mid-ExamsArchitectural DesignÎncă nu există evaluări

- Literature StudyDocument21 paginiLiterature StudyCrisha Orozco GonzagaÎncă nu există evaluări

- Requirements of A Good PartitionDocument11 paginiRequirements of A Good PartitionShraddha Bahirat100% (1)

- Basement ProvisionsDocument193 paginiBasement ProvisionsAlexi ALfred H. TagoÎncă nu există evaluări

- INDMDocument12 paginiINDMRc RobesoÎncă nu există evaluări

- CasestudyDocument21 paginiCasestudyGunjan PataitÎncă nu există evaluări

- Design and Analysis of Multistoried Commercial Building (G+4) WithstaadDocument2 paginiDesign and Analysis of Multistoried Commercial Building (G+4) Withstaadinnovative technologiesÎncă nu există evaluări

- Pebble TypesDocument6 paginiPebble TypesTarun KumarÎncă nu există evaluări

- Taipei 101Document6 paginiTaipei 101Gabrielle LagadiaÎncă nu există evaluări

- Approval MaterialDocument1 paginăApproval MaterialDede NurcahyadiÎncă nu există evaluări

- Typical Floor Plan (3Bhk) : Project NameDocument1 paginăTypical Floor Plan (3Bhk) : Project NameAsif ChampÎncă nu există evaluări

- Tos 3: Unit 2B: Wooden Structures: ObjectivesDocument15 paginiTos 3: Unit 2B: Wooden Structures: ObjectivesAftab HawaldarÎncă nu există evaluări

- Pioneer A25fu20 53f 10 WooferDocument25 paginiPioneer A25fu20 53f 10 WooferblackestsheepÎncă nu există evaluări

- Acoustical Design: by Ar. Sarthak KauraDocument34 paginiAcoustical Design: by Ar. Sarthak KauraPaapu DeviÎncă nu există evaluări

- Schedule of Beams at Level - 4500: Ajay Kadam AssociatesDocument1 paginăSchedule of Beams at Level - 4500: Ajay Kadam AssociatesvinujohnpanickerÎncă nu există evaluări

- Beam/Girder Details: Structural NotesDocument1 paginăBeam/Girder Details: Structural NotesSylvestre UbaÎncă nu există evaluări

- Adobe Scan 16 Jun 2023Document4 paginiAdobe Scan 16 Jun 2023Shaikh ImranÎncă nu există evaluări

- Transaction Details 20230825113823Document1 paginăTransaction Details 20230825113823Shaikh ImranÎncă nu există evaluări

- r1 02 STR Col Fot Kaleem BhaiDocument1 paginăr1 02 STR Col Fot Kaleem BhaiShaikh ImranÎncă nu există evaluări

- Transaction Details 20230825113823Document1 paginăTransaction Details 20230825113823Shaikh ImranÎncă nu există evaluări

- Transaction Details 20230825113823Document1 paginăTransaction Details 20230825113823Shaikh ImranÎncă nu există evaluări

- 2nd Slab Extended PortionDocument1 pagină2nd Slab Extended PortionShaikh ImranÎncă nu există evaluări

- Col Fot Beam Calculations Affcons Office BuildingDocument47 paginiCol Fot Beam Calculations Affcons Office BuildingShaikh ImranÎncă nu există evaluări

- MIN STEEL IN FOOTINGS - Affcons Office BuildingDocument1 paginăMIN STEEL IN FOOTINGS - Affcons Office BuildingShaikh ImranÎncă nu există evaluări

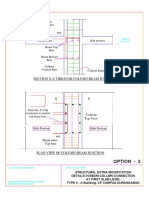

- Section X-X Through Column-Beam Junction: 8mm Dia. U-Clip at Junction To Anchor Top Beam BarsDocument1 paginăSection X-X Through Column-Beam Junction: 8mm Dia. U-Clip at Junction To Anchor Top Beam BarsShaikh ImranÎncă nu există evaluări

- Structural Layout of Column Footings (Foundation Plan) : C10 9"x15" C11 9"x15" C12 6"x15"Document1 paginăStructural Layout of Column Footings (Foundation Plan) : C10 9"x15" C11 9"x15" C12 6"x15"Shaikh ImranÎncă nu există evaluări

- Salik Bhai PlanDocument1 paginăSalik Bhai PlanShaikh ImranÎncă nu există evaluări

- 2nd Slab Extended PortionDocument1 pagină2nd Slab Extended PortionShaikh ImranÎncă nu există evaluări

- Section X-X Through Column-Beam Junction: 8mm Dia. U-Clip at Junction To Anchor Top Beam BarsDocument1 paginăSection X-X Through Column-Beam Junction: 8mm Dia. U-Clip at Junction To Anchor Top Beam BarsShaikh ImranÎncă nu există evaluări

- Schedule of Beams at First Slab Level: FB2 FB2 S1Document1 paginăSchedule of Beams at First Slab Level: FB2 FB2 S1Shaikh ImranÎncă nu există evaluări

- Resume - Siva Rami Reddy - Lead - Civil & Structural Engineer PDFDocument7 paginiResume - Siva Rami Reddy - Lead - Civil & Structural Engineer PDFShaikh ImranÎncă nu există evaluări

- (G+3F+2R Typical Floors+ Roof) 2. 3 Nos. (B+G+3P+36Typical+Roof)Document5 pagini(G+3F+2R Typical Floors+ Roof) 2. 3 Nos. (B+G+3P+36Typical+Roof)Shaikh ImranÎncă nu există evaluări

- (G+3F+2R Typical Floors+ Roof) 2. 3 Nos. (B+G+3P+36Typical+Roof)Document5 pagini(G+3F+2R Typical Floors+ Roof) 2. 3 Nos. (B+G+3P+36Typical+Roof)Shaikh ImranÎncă nu există evaluări

- Rule 1Document2 paginiRule 1Antonio Rojas SerranoÎncă nu există evaluări

- Ambadas Nagar-Model - PDF FINAL PLANDocument1 paginăAmbadas Nagar-Model - PDF FINAL PLANShaikh ImranÎncă nu există evaluări

- Resume - Mohd FaisalDocument2 paginiResume - Mohd FaisalShaikh ImranÎncă nu există evaluări

- Gamma PSDocument24 paginiGamma PSAluosh AluoshÎncă nu există evaluări

- Adnan Burneh - CV Update PDFDocument6 paginiAdnan Burneh - CV Update PDFShaikh ImranÎncă nu există evaluări

- Preparing Resume:: Why Resume Is Important?Document5 paginiPreparing Resume:: Why Resume Is Important?Easy StudyÎncă nu există evaluări

- 500 Concepts To Crack GATE3Document14 pagini500 Concepts To Crack GATE3Mohit RajaiÎncă nu există evaluări

- Force SystemDocument2 paginiForce SystemShaikh ImranÎncă nu există evaluări

- Amir Ebrahimi, MS, EIT: ExperienceDocument1 paginăAmir Ebrahimi, MS, EIT: ExperienceShaikh ImranÎncă nu există evaluări

- Comparison of Responses: Storey No.1 BeamsDocument25 paginiComparison of Responses: Storey No.1 BeamsShaikh ImranÎncă nu există evaluări

- Abstract Sheet For, Proposed Construction of Bhaktniwas, at Paithan, Dis AurangabadDocument51 paginiAbstract Sheet For, Proposed Construction of Bhaktniwas, at Paithan, Dis AurangabadShaikh ImranÎncă nu există evaluări

- Construction Details Cad Blocks: Footing Under A Eccentric Load 1Document5 paginiConstruction Details Cad Blocks: Footing Under A Eccentric Load 1Shaikh ImranÎncă nu există evaluări

- Regarding Shoe Footins: Structural Engineering Forum of India (Sefi)Document7 paginiRegarding Shoe Footins: Structural Engineering Forum of India (Sefi)Shaikh ImranÎncă nu există evaluări

- Top 10 IKEA ChairsDocument21 paginiTop 10 IKEA ChairsErin CunninghamÎncă nu există evaluări

- Archaeology and Epigraphy at Tayma (Saudi Arabia)Document14 paginiArchaeology and Epigraphy at Tayma (Saudi Arabia)binsaeed100% (1)

- MEP Planning ManualDocument197 paginiMEP Planning Manualsmshaidr50% (2)

- What Is Stud WeldingDocument4 paginiWhat Is Stud WeldingMithun MuraleedharanÎncă nu există evaluări

- Civil Engineering Interview Questions and Answers - Part 3 PDFDocument2 paginiCivil Engineering Interview Questions and Answers - Part 3 PDFSiva2sankarÎncă nu există evaluări

- Niche Lifts Brochure Passenger 01Document8 paginiNiche Lifts Brochure Passenger 01xavierjeffÎncă nu există evaluări

- D 1501 Service Manual: DevelopDocument229 paginiD 1501 Service Manual: DevelopJoel RodriguesÎncă nu există evaluări

- Feeder Protection and Control REF620: Application ManualDocument132 paginiFeeder Protection and Control REF620: Application ManualHugo Hernandez JuarezÎncă nu există evaluări

- Remote Procedure Call IntroDocument4 paginiRemote Procedure Call IntrooparikokoÎncă nu există evaluări

- Mohenjo-Daro PicturesDocument32 paginiMohenjo-Daro PicturesIzhaŕ ĶẳsìÎncă nu există evaluări

- TOGAF 8 Certification For PractitionersDocument101 paginiTOGAF 8 Certification For PractitionersMbaStudent56Încă nu există evaluări

- Modular Construction From Projects To Products Full Report NEWDocument34 paginiModular Construction From Projects To Products Full Report NEWmathew simonÎncă nu există evaluări

- Spatial Expressions of Local Identity in The Times of Rapid Globalisation PaperDocument8 paginiSpatial Expressions of Local Identity in The Times of Rapid Globalisation Paperarh_mmilicaÎncă nu există evaluări

- Eberspaecher Manual EasyStarRplus enDocument28 paginiEberspaecher Manual EasyStarRplus enAlin BardosÎncă nu există evaluări

- 1Document451 pagini1Guadalupe SmithÎncă nu există evaluări

- 8 Final Birpur Branch Bank of Baroda - ModelDocument1 pagină8 Final Birpur Branch Bank of Baroda - ModelOtgonbayar AmarbuyanÎncă nu există evaluări

- Fountain Design GuideDocument19 paginiFountain Design Guideinfo66567% (3)

- The Meaning of Insula in Roman Residential TerminologyDocument39 paginiThe Meaning of Insula in Roman Residential TerminologyMaria Ruiz SánchezÎncă nu există evaluări

- BREEAM Assessing Health and Wellbeing in BuildingsDocument16 paginiBREEAM Assessing Health and Wellbeing in BuildingspcastrorÎncă nu există evaluări

- Balcony Glass Partition Calculation - JBRSDocument63 paginiBalcony Glass Partition Calculation - JBRSahsan khan100% (1)

- Material SpecificationDocument3 paginiMaterial SpecificationRobert M. Longo, AIAÎncă nu există evaluări

- Script For Man Made Wonders of The WorldDocument10 paginiScript For Man Made Wonders of The WorldsadatbafÎncă nu există evaluări

- Nmap Cheat SheetDocument18 paginiNmap Cheat SheetJesse VazquezÎncă nu există evaluări

- Program A DownloadDocument227 paginiProgram A DownloaddifreneÎncă nu există evaluări

- Homplex Cooper Catalogue PDFDocument13 paginiHomplex Cooper Catalogue PDFTudor_PanainteÎncă nu există evaluări

- Inter-Process Communication in Linux PDFDocument25 paginiInter-Process Communication in Linux PDFVÎncă nu există evaluări

- Alfred H. Barr-De StijlDocument9 paginiAlfred H. Barr-De StijlŽeljkaÎncă nu există evaluări

- ExteriorScape Product GuideDocument28 paginiExteriorScape Product GuideWorld Outdoor EmporiumÎncă nu există evaluări

- China Harbour Method Statement - Installation of Marker BuoysDocument9 paginiChina Harbour Method Statement - Installation of Marker BuoysSeaworks Company100% (3)

- M1319Document42 paginiM1319Kiran KharadeÎncă nu există evaluări