Documente Academic

Documente Profesional

Documente Cultură

Minimizing Reheat Guide

Încărcat de

Boey HeDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Minimizing Reheat Guide

Încărcat de

Boey HeDrepturi de autor:

Formate disponibile

2018 Building Performance Analysis Conference and

SimBuild co-organized by ASHRAE and IBPSA-USA

Chicago, IL

September 26-28, 2018

DEHUMIDIFICATION STRATEGIES AND THEIR APPLICABILITY BASED ON

CLIMATE AND BUILDING TYPOLOGY

Jagan Pillai, P.E., BEMP and Rushil Desai

Atelier Ten, New York, NY

ABSTRACT Traditionally, moisture removal is achieved by passing

air over a chilled coil (water, glycol, or refrigerant) and

Dehumidification is a highly energy intensive process, cooling it below its dew point temperature so the air

especially in humid climates and for building typologies releases moisture by condensing on the coil surface. This

that require strict space humidity setpoints. Sub-cooling is an energy intensive process (cooling 1 lb of water by

of air to condense out moisture using chilled water or 1°F requires about 1 Btu of energy, while condensing 1

refrigerant is the most common method for lb of water vapor to water requires about 1,000 Btu). This

dehumidifying. Alternative strategies such as desiccant sub-cooling, in many instances, is then followed by re-

wheel, dual wheel and wrap around coils could more heating the air up to the desired supply temperature.

energy efficiently be used for certain climate zones and Depending on the specifics of the project, strategies such

project types. Using energy models and results from a as desiccant dehumidification, dual wheel systems, wrap

customized Excel-based tool, this paper evaluates around coils, and decoupling of sensible and latent loads,

applicability of each dehumidification strategy based on may show benefit in terms of annual energy use and

the local climate and building typology. reduced system size. To understand the applicability of

INTRODUCTION these strategies, their effectiveness was studied by

varying two key parameters: climate and building

Moisture indoors affects occupant comfort, the lifespan program type. Multiple energy models and a spreadsheet

of building materials, and the operational effectiveness tool developed by the authors, were used to perform the

of program types that handle hygroscopic materials. In analysis. Based on the results from this analysis, this

certain cases, the selection of mechanical equipment paper discusses the benefits and limitations of several

with thermally active surfaces also requires controlled such dehumidification strategies and provides

space moisture levels to avoid the risk of surface recommendations for early phase design considerations.

condensation. Therefore, the ability to maintain strict

humidity levels within a desired range by removing DESCRIPTION OF STRATEGIES

moisture from supply air is a critical aspect of air The following dehumidification strategies, that have

conditioning system design. shown notable energy savings on existing projects, have

The load on the cooling coil associated with removal of been evaluated against a base case of a Dedicated

moisture that results from occupants, outside air Outdoor Air System (DOAS) with an enthalpy wheel,

(infiltration, ventilation air), and other processes which chilled water cooling coil, and heating hot water reheat.

generate moisture, is called latent load. Space latent • Desiccant dehumidification

loads typically contribute to about 20-30% of the total

building cooling load. Sensible Heat Ratio (SHR) is used • Dual wheel system

as a metric to design mechanical cooling equipment. A • Wrap-around coil

lower SHR corresponds to high latent gains and vice • Tiered cooling (chilled water for sensible

versa. cooling, direct expansion for latent cooling)

𝑆𝑒𝑛𝑠𝑖𝑏𝑙𝑒 𝐿𝑜𝑎𝑑 This section discusses the operating principles behind

𝑆𝐻𝑅 = 𝑆𝑒𝑛𝑠𝑖𝑏𝑙𝑒 𝐿𝑜𝑎𝑑 + 𝐿𝑎𝑡𝑒𝑛𝑡 𝐿𝑜𝑎𝑑 (1)

each aforementioned strategy and highlights the

differences in how each dehumidifies outside air.

© 2018 ASHRAE (www.ashrae.org) and IBPSA-USA (www.ibpsa.us). 759

For personal use only. Additional reproduction, distribution, or transmission in either print or digital form is not permitted without

ASHRAE or IBPSA-USA's prior written permission.

Chilled Water Cooling and Dehumidification 3); pre-cooled air then blows through a desiccant

The most common process for dehumidification is to use dehumidification wheel where it goes through an

a chilled water cooling coil. Figure 1 shows the system isenthalpic process (3-4). During this process the

schematic and psychrometric chart showing the cooling moisture content of the air reduces and increases

and dehumidification process. temperature. The high temperature air then passes over a

post-cooling coil to cool it down to the required supply

Outdoor air, after exchanging energy with exhaust air (1-

air temperature (4-5). This process, if optimized, can

2) passes over the cooling coil to cool the air down to the

have a lower cooling load compared to the base case.

required leaving air humidity ratio (2-3) and then is

reheated to the required supply air temperature (3-4). Desiccant dehumidification systems have the capability

to dry the air to any desired humidity level, which is an

Desiccant Dehumidification advantage for certain applications. The limitation of this

In this process, a desiccant is used to remove moisture system is the need for high grade heat (about 180°F) to

from air. Figure 2 shows the schematic and the regenerate the desiccant. Thus, the best fit for this system

psychrometric process for a desiccant dehumidification is if the space needs to be maintained at a low (<50%)

system with an active desiccant wheel. Outside air, after relative humidity or if there is a source of waste heat

passing through an enthalpy recovery wheel (1-2), passes available to regenerate the desiccant.

over a pre-cooling coil to reduce the air temperature (2-

Figure 1 Chilled water cooling/dehumidification: Schematic & Psychrometric chart

Figure 2 Desiccant dehumidification: Schematic & Psychrometric chart

Dual Wheel System with Cooling Coil Exhaust air first passes through the sensible wheel (4’-

3’) where it transfers heat to the supply air (3-4) to heat

In this process, an additional, sensible heat recovery

it to the desired temperature. This cooler exhaust air then

wheel is introduced after the cooling coil to provide free

passes through the enthalpy recovery wheel to exchange

reheat (refer to Figure 3).

© 2018 ASHRAE (www.ashrae.org) and IBPSA-USA (www.ibpsa.us). 760

For personal use only. Additional reproduction, distribution, or transmission in either print or digital form is not permitted without

ASHRAE or IBPSA-USA's prior written permission.

energy with incoming outside air (1-2). The outside air In this process, outside air, after passing through the

then passes over the cooling coil for cooling and enthalpy recovery wheel (1-2), goes over the first

dehumidification (2-3). sensible coil, which reduces the air temperature (2-3);

Similar to the base case, this method relies on cooling the air passes through the cooling coil (3-4) for

coils for dehumidification but has the advantages of dehumidification and cooling. Then the air passes over a

reduced coil load and free reheat. second sensible coil (4-5) to heat it to the desired supply

air temperature. The first and second sensible coils are

Wrap Around Coil with Cooling Coil connected and transfer heat from air before the cooling

This strategy employs a wrap around coil in addition to coil to the air after the cooling coil. This helps reduce the

the cooling coil to make the process more energy cooling load on the primary cooling coil and provides

efficient (see Figure 4). free reheat.

Figure 3 Dual wheel: Schematic & Psychrometric chart

Figure 4 Wrap-around coil: Schematic & Psychrometric chart

Tiered Cooling System (Direct Expansion + CHW) tiered cooling approach decouples the latent

(dehumidification) and sensible cooling loads by using

The level of dehumidification through cooling and

direct refrigerant expansion (DX) for latent cooling at the

condensation is heavily dependent on the temperature of

DOAS, and the chilled water system is designed and

the cooling coil. In chilled water system design, the low

operated at a higher temperature (50-55°F), thus

coil temperatures required for this process dictate the

achieving building sensible cooling (60-70% of total

design chilled water temperature (42-44°F). Designing

cooling load) more efficiently compared to a low

and operating chillers at low temperatures increases the

temperature chilled water system.

chiller lift and reduces the efficiency of the chiller. The

© 2018 ASHRAE (www.ashrae.org) and IBPSA-USA (www.ibpsa.us). 761

For personal use only. Additional reproduction, distribution, or transmission in either print or digital form is not permitted without

ASHRAE or IBPSA-USA's prior written permission.

An advantage of DX dehumidification, as compared to • Climate Zone: 4A (Mixed - Humid), 1A (Very

chilled water dehumidification, is better humidity hot - humid), 3C (Marine)

control. However, the disadvantage is lower efficiency. • Sensible Heat Ratio: 0.60, 0.80

• Space Relative Humidity: 50%, 60%

Modeling Assumptions

This analysis includes a 250,000 ft2 office building with

typical occupancy and ventilation requirements. To

reduce the number of variables and avoid

overcomplications in the analysis, the base assumption

for all test cases is that the building is served by

decoupled systems i.e. a Dedicated Outdoor Air System

(DOAS) provides ventilation air and latent cooling, and

fan coil units meet space sensible cooling loads. The

study assumes the DOAS supplies close to room neutral

(65°F) ventilation air directly to the space. On-site water-

Figure 5 Psychrometric chart showing the cooling cooled chillers with ASHRAE 90.1-2013 prescribed

process for each strategy and their corresponding minimum efficiencies provide on-site chilled water.

cooling load. All strategies show cooling load reduction Analysis Tools

compared to the base case. (1-Base case, 2-Desiccant Multiple energy model runs, using DOE-2.2 eQuest

dehumidification, 3-Dual wheel, 4-Wrap around coil) v3.65 were created, to extract hourly load profiles for the

ventilation air flow rate and latent loads, based on

METHODOLOGY

different sensible heat ratios. These profiles serve as

An air conditioning system’s latent load is based on inputs to a spreadsheet-based tool developed to analyze

outdoor air (infiltration and ventilation air) and humidity all the dehumidification strategies discussed in this

gains from occupants and other internal processes. The paper. Other inputs to the tool include hourly outside air

other factor in latent load calculations is the indoor conditions, space temperature and humidity set-points,

relative humidity set-point. and DOAS supply air conditions.

𝑄𝑙𝑎𝑡𝑒𝑛𝑡 = 4840 x 𝐶𝐹𝑀 x (𝑊1 − 𝑊2 ) (2) Using principles of heat and mass transfer,

psychrometrics, and appropriate sequences of operation,

𝑄𝑙𝑎𝑡𝑒𝑛𝑡 : 𝑆𝑝𝑎𝑐𝑒 𝑙𝑎𝑡𝑒𝑛𝑡 𝑙𝑜𝑎𝑑 (𝐵𝑡𝑢/ℎ)

the tool calculates cooling, heating, and fan energies for

𝐶𝐹𝑀: 𝐴𝑖𝑟 𝑓𝑙𝑜𝑤 𝑖𝑛 𝑐𝑢𝑏𝑖𝑐 𝑓𝑒𝑒𝑡 𝑝𝑒𝑟 𝑚𝑖𝑛𝑢𝑡𝑒 each system configuration on an hourly basis for an

𝑊1 : 𝐻𝑢𝑚𝑖𝑑𝑖𝑡𝑦 𝑟𝑎𝑡𝑖𝑜 𝑜𝑓 𝑟𝑒𝑡𝑢𝑟𝑛 𝑎𝑖𝑟 (lbw/lba) entire year. Benefits of using the tool are: the tool

𝑊2 : 𝐻𝑢𝑚𝑖𝑑𝑖𝑡𝑦 𝑟𝑎𝑡𝑖𝑜 𝑜𝑓 𝑠𝑢𝑝𝑝𝑙𝑦 𝑎𝑖𝑟 (lbw/lba) enables a side-by-side comparison of the annual energy

performance associated with all the strategies; it helps

Analysis parameters optimize controls for each strategy. This tool has been

For this study, the factors contributing to latent loads successfully used on several real-world projects as a

were translated to the following parameters: design tool and for annual energy estimation.

• Climate Zone (as an indicator for outdoor air Visualization of Results

humidity) Figure 6 shows the whole building annual energy use of

• Sensible Heat Ratio (as an indicator for space a typical office building with decoupled HVAC system

latent loads) in Climate Zone 4A. The whole building energy use has

been characterized by end use to identify the major

• Space Relative Humidity (as an indicator of

energy drivers in the building. The only energy end uses

design conditions)

affected by the dehumidification strategy chosen are

The combination of sensible heat ratio and the space DOAS cooling, reheat, and fan energies.

relative humidity can be used as an indicator of building

Strategies such as desiccant dehumidification and DX

typology. The study focuses on HVAC energy savings

dehumidification do not need chilled water to meet the

and peak cooling load reductions that result from the

latent loads, thus enabling the building chilled water loop

following permutations and combinations of the above

to only have to meet the space sensible loads. By

parameters:

implementing this strategy, the chilled water system can

be designed and operated at a higher chilled water

© 2018 ASHRAE (www.ashrae.org) and IBPSA-USA (www.ibpsa.us). 762

For personal use only. Additional reproduction, distribution, or transmission in either print or digital form is not permitted without

ASHRAE or IBPSA-USA's prior written permission.

temperature. This would significantly improve chiller the dual wheel system and the wrap around coil provide

performance and hence, affect the sensible cooling the greatest energy savings. This is because, in a very hot

energy required for space conditioning. Thus, building and humid climate, sub-cooling air for dehumidification

sensible cooling energy is also accounted for as an end is required for a significant number of hours. A dual

use affected by dehumidification strategy selection. wheel or wrap around coil can efficiently extract heat

from incoming and exhaust air to reduce the cooling load

on the coil and provide free reheat for the supply air.

The desiccant dehumidification process also shows

notable reduction in cooling energy compared to the base

case. But, this process requires significant heating

energy to regenerate the desiccant. Thus, this strategy

can be implemented only if a renewable source of

heat/waste heat is available on-site.

The DX dehumidification strategy shows a significant

penalty in all cases due to the hot and humid climate.

This is because, latent cooling is a large component of

the overall cooling load. Using a less efficient DX unit

compared to water-cooled chillers, significantly

increases the DOAS cooling energy. Also, the operation

of a high temperature chilled water loop for building

sensible cooling has limited impact on chiller efficiency

improvement and there is no free-cooling potential from

Figure 6 Whole building annual energy end use the use of a water-side economizer.

characterization for a typical office building in a

mixed-humid climate As seen in Figure 7, implementation of strategies such as

desiccant dehumidification, dual wheel, and wrap

The results and discussion are based on the impact of around coil, also help in reducing the DOAS peak

dehumidification strategy on these selected energy end cooling load. Most of these strategies show about 20%

uses. All results are presented in terms of HVAC source reduction in peak cooling load.

energy, since it normalizes the electricity and gas

Climate Zone 4A (Mixed-Humid)

consumption, thus acting as a suitable metric for

comparison. US average source-to-site ratios of 3.34 and Figure 8 shows the annual HVAC source energy

1.047 were used for electricity and natural gas, comparison for the various dehumidification strategies

respectively. (Architecture 2030, 2012; Energy Star) tested at different relative humidity and sensible heat

ratio combinations for Climate Zone 4A.

RESULTS & DISCUSSION

In a mixed-humid climate, analysis shows that the total

The results are arranged in a matrix format with two source energy consumed by a desiccant

varying parameters - sensible heat ratios (SHR) and dehumidification system can be lower than the base case

maximum space relative humidity (RH) set-points, scenario. This is because, in addition to reduction in

tested for each of the three climate zones of concern. DOAS cooling energy, running the building chilled

In all DX dehumidification cases, hot gas by-pass water loop for sensible cooling only at a higher chilled

provides reheat, therefore it is considered free and not water temperature provides significant improvement in

depicted on the graphs. For the base case and desiccant the chiller plant performance.

dehumidification strategies, reheat/regeneration heating

is provided by on-site boilers operating at ASHRAE Similar to the results from desiccant dehumidification,

90.1-2013 minimum efficiency. DX dehumidification also provides significant savings

compared to the base case. This is also because of the

Climate Zone 1A (Hot-Humid) improved plant efficiency.

Figure 7 shows the annual HVAC source energy The strategies including dual wheel and wrap around coil

comparison for the dehumidification strategies tested at provide savings only for conditions requiring strict space

different relative humidity and sensible heat ratio relative humidity control. Savings from these approaches

combinations for Climate Zone 1A. are higher at lower SHR i.e. higher space latent gains.

The results indicate that for any combination of the

maximum indoor relative humidity (Max RH) and SHR,

© 2018 ASHRAE (www.ashrae.org) and IBPSA-USA (www.ibpsa.us). 763

For personal use only. Additional reproduction, distribution, or transmission in either print or digital form is not permitted without

ASHRAE or IBPSA-USA's prior written permission.

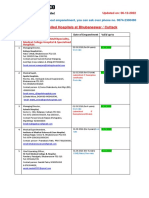

DOAS COOLING BLDG SENSIBLE COOLING DOAS FANS DOAS REHEAT/REGEN DOAS PEAK COOLING LOAD

Max RH - 50% SHR - 0.8 Max RH - 60% SHR - 0.8

14000 350

HVAC SOURCE ENERGY (MMBT U)

14000 350

HVAC SOURCE ENERGY (MMBT U)

DOAS PEAK COOLING LOAD (TONS)

DOAS PEAK COOLING LOAD (TONS)

14000 -4% 16% 17% -6% -6% 5% 5% -9%

HVAC SOURCE ENERGY (MMBT U)

12000 300 12000 300

7% 9% 10% 10%

10000 12000 250 10000 250

8000 200 8000 200

10000

6000 150 6000 150

8000

4000 100 4000 100

2000 6000 50 2000 50

0 4000 0 0 0

CHW COIL DESICCANT DUAL WRAP DIRECT CHW COIL DESICCANT DUAL WRAP DIRECT

ONLY WHEEL WHEEL AROUND COIL EXPANSION ONLY WHEEL WHEEL AROUND COIL EXPANSION

2000

Max RH - 50% SHR - 0.6 Max RH - 60% SHR - 0.6

14000 350 14000 350

HVAC SOURCE ENERGY (MMBT U)

HVAC SOURCE ENERGY (MMBT U)

DOAS PEAK COOLING LOAD (TONS)

0

DOAS PEAK COOLING LOAD (TONS)

-1% 20% 21% -4% -4% 6% 6% -8%

12000 CHW COIL ONLY DESICCANT

300 WHEEL 12000 DUAL WRAP AROUND COIL 300 DIRECT EXPANSION

WHEEL

10000 250 10000 250

8000 200 8000 200

6000 150 6000 150

4000 100 4000 100

2000 50 2000 50

0 0 0 0

CHW COIL DESICCANT DUAL WRAP DIRECT CHW COIL DESICCANT DUAL WRAP DIRECT

ONLY WHEEL WHEEL AROUND COIL EXPANSION ONLY WHEEL WHEEL AROUND COIL EXPANSION

Figure 7 Annual HVAC source energy comparison across all strategies for Climate Zone 1A (Very hot-humid)

Max RH - 50% SHR - 0.8 Max RH - 60% SHR - 0.8

14000 350 14000 350

HVAC SOURCE ENERGY (MMBT U)

HVAC SOURCE ENERGY (MMBT U)

DOAS PEAK COOLING LOAD (TONS)

DOAS PEAK COOLING LOAD (TONS)

11% 5% 6% 10% 11% 0% 0% 12%

12000 300 12000 300

10000 250 10000 250

8000 200 8000 200

6000 150 6000 150

4000 100 4000 100

2000 50 2000 50

0 0 0 0

CHW COIL DESICCANT DUAL WRAP DIRECT CHW COIL DESICCANT DUAL WRAP DIRECT

ONLY WHEEL WHEEL AROUND COIL EXPANSION ONLY WHEEL WHEEL AROUND COIL EXPANSION

Max RH - 50% SHR - 0.6 Max RH - 60% SHR - 0.6

14000 350 14000 350

HVAC SOURCE ENERGY (MMBT U)

HVAC SOURCE ENERGY (MMBT U)

DOAS PEAK COOLING LOAD (TONS)

DOAS PEAK COOLING LOAD (TONS)

7% 9% 10% 10% 12% 1% 1% 12%

12000 300 12000 300

10000 250 10000 250

8000 200 8000 200

6000 150 6000 150

4000 100 4000 100

2000 50 2000 50

0 0 0 0

CHW COIL DESICCANT DUAL WRAP DIRECT CHW COIL DESICCANT DUAL WRAP DIRECT

ONLY WHEEL WHEEL AROUND COIL EXPANSION ONLY WHEEL WHEEL AROUND COIL EXPANSION

Figure 8 Annual HVAC source energy comparison across all strategies for Climate Zone 4A (Mixed-humid)

© 2018 ASHRAE (www.ashrae.org) and IBPSA-USA (www.ibpsa.us). 764

For personal use only. Additional reproduction, distribution, or transmission in either print or digital form is not permitted without

ASHRAE or IBPSA-USA's prior written permission.

Max RH - 50% SHR - 0.8 Max RH - 60% SHR - 0.8

14000 350 14000 350

HVAC SOURCE ENERGY (MMBT U)

HVAC SOURCE ENERGY (MMBT U)

DOAS PEAK COOLING LOAD (TONS)

DOAS PEAK COOLING LOAD (TONS)

3% 1% 1% 8% 3% -3% -3% 9%

12000 300 12000 300

10000 250 10000 250

8000 200 8000 200

6000 150 6000 150

4000 100 4000 100

2000 50 2000 50

0 0 0 0

CHW COIL DESICCANT DUAL WRAP DIRECT CHW COIL DESICCANT DUAL WRAP DIRECT

ONLY WHEEL WHEEL AROUND COIL EXPANSION ONLY WHEEL WHEEL AROUND COIL EXPANSION

Max RH - 50% SHR - 0.6 Max RH - 60% SHR - 0.6

14000 350 14000 350

HVAC SOURCE ENERGY (MMBT U)

HVAC SOURCE ENERGY (MMBT U)

DOAS PEAK COOLING LOAD (TONS)

DOAS PEAK COOLING LOAD (TONS)

2% 3% 3% 7% 2% -3% -3% 9%

12000 300 12000 300

10000 250 10000 250

8000 200 8000 200

6000 150 6000 150

4000 100 4000 100

2000 50 2000 50

0 0 0 0

CHW COIL DESICCANT DUAL WRAP DIRECT CHW COIL DESICCANT DUAL WRAP DIRECT

ONLY WHEEL WHEEL AROUND COIL EXPANSION ONLY WHEEL WHEEL AROUND COIL EXPANSION

Figure 9 Annual HVAC source energy comparison across all strategies for Climate Zone 3C (Marine)

Similar to the hot-humid climate, use of desiccant This becomes a limitation on the coil moisture removal

dehumidification, dual wheel, or a wrap around coil capacity. Assuming a typical chilled water supply

provides potential reductions in the peak cooling load. temperature of 42-44°F, the minimum supply air

humidity ratio that can be achieved is about 0.0075-

Climate Zone 3C (Marine) 0.008 lbw/lba. Using desiccant or DX based

Figure 9 shows the annual HVAC source energy dehumidification strategies, a further reduction in the

comparison for the various dehumidification strategies supply air humidity ratio can be achieved. Table 1

tested at different relative humidity and sensible heat discusses DOAS sizing comparing the base case and

ratio combinations for Climate Zone 3C. desiccant dehumidification strategies.

In this climate, the energy consumed by the DOAS for Table 1 DOAS sizing comparison for two different

cooling and dehumidification is significantly lower dehumidification strategies

compared to the other two Climate zones. For a relaxed Building Area 250,000 ft2

space relative humidity set-point, the energy Number of Occupants 1,250

consumption at the DOAS is almost negligible. Ventilation air per ASHRAE 62.1 30,000 cfm

Since the DOAS cooling load is small, a tiered approach Occupant Latent Load 250,000 Btu

by incorporating a DX unit for latent conditioning at the Infiltration Latent Load 38,000 Btu

DOAS and operating the chilled water loop at a higher Total Latent Load 288,000 Btu

temperature for sensible cooling provides significant Space Humidity Ratio (75°F, 50%RH) 0.0092 lbw/lba

energy savings across all relative humidity and sensible

heat ratio scenarios. Sizing Parameters Base Case Desiccant

Dehumidification

Dehumidification strategies show limited DOAS peak

Allowable minimum 0.008 0.005

cooling load reduction for the strict 50% RH and 0.6

humidity ratio

SHR scenario, but a negligible reduction in peak DOAS

Airflow to meet latent 49,600 cfm 14,200 cfm

cooling load in all other scenarios.

load (equation 2)

DOAS Sizing Benefits DOAS Size 49,600 cfm 30,000 cfm

In case of a decoupled system configuration, dedicated

outdoor air systems are sized to meet the higher of

ventilation air flow rate or the air flow required to meet

the space latent gains. While using the base case for

latent cooling, the minimum air temperature that can be

achieved is a function of the chilled water temperature.

© 2018 ASHRAE (www.ashrae.org) and IBPSA-USA (www.ibpsa.us). 765

For personal use only. Additional reproduction, distribution, or transmission in either print or digital form is not permitted without

ASHRAE or IBPSA-USA's prior written permission.

CONCLUSION 6. For the warm-marine climate (Figure 11c), mild

Figure 10 presents an early design phase decision chart outside air conditions reduce the energy consumed

summarizing optimal strategy selection across variations for cooling and dehumidification significantly.

of the key parameters (climate, space relative humidity, Therefore, most dehumidification strategies show

sensible heat ratio). The following are the key negligible energy benefit. Using a tiered approach in

observations from this study: this climate can help improve the chiller plant

efficiency, thus providing overall building energy

1. The selection of a particular dehumidification

use reduction.

strategy is most dependent on the climate, followed

by the space humidity setpoint, followed by the 7. Wrap around coils and dual wheels only provide

sensible heat ratio (SHR). This is because SHR savings when sub-cooling and reheat is required for

deviates significantly from the design SHR on an dehumidification. They provide the most benefit in

hourly basis during actual operation. hot-humid climates.

2. In buildings with chilled water cooling, the 8. Desiccant dehumidification, dual wheel and wrap

minimum supply air humidity ratio is dictated by the around coil all provide peak cooling load reduction

chilled water temperature. This may impact DOAS in addition to energy savings.

sizing under certain design conditions. Also, based

REFERENCES

on real project data, if not designed correctly, this

may affect the ability of the system to maintain ASHRAE 90.1-2013, “Energy Standard for Buildings

desired space relative humidity. Except Low-Rise Residential Buildings”

3. For hot and humid climates (Figure 11a), dual ASHRAE Handbook: Fundamentals. Inch-pound ed.

wheel/wrap-around coil based approaches are the Atlanta, Ga.: ASHRAE, 2013

most relevant since buildings in such a climate are ASHRAE Handbook: HVAC Systems and Equipment

not designed for heating and the primary benefit of Inch-pound ed. Atlanta, Ga.: ASHRAE, 2012

these strategies is that they eliminate reheat entirely. Architecture 2030, 2012: 2030 Challenge Targets: U.S.

4. For mixed-humid climates (Figure 11b), at stricter National Medians. August 2012.

humidity setpoints, desiccant dehumidification is http://www.architecture2030.org/files/2030_Challe

more applicable. If there is a source of waste heat nge_Targets_National.pdf

available, desiccant dehumidification provides the EPA’s Energy Star Source-Site Calculator Ratios. U.S.

highest energy savings potential. Environmental Protection Agency.

5. In a mixed-humid climate, it is always energy http://www.energystar.gov/ia/business/evaluate_pe

efficient to use the tiered approach with direct rformance/site_source.pdf

expansion/desiccant for latent conditioning and high

temperature chilled water for sensible conditioning.

(a) (b) (c)

Figure 10 Dehumidification strategy early design decision matrix

© 2018 ASHRAE (www.ashrae.org) and IBPSA-USA (www.ibpsa.us). 766

For personal use only. Additional reproduction, distribution, or transmission in either print or digital form is not permitted without

ASHRAE or IBPSA-USA's prior written permission.

S-ar putea să vă placă și

- Harolds Real Analysis Cheat Sheet 2022Document54 paginiHarolds Real Analysis Cheat Sheet 2022Boey HeÎncă nu există evaluări

- Installed Batteries: Computer Name System Product Name Bios Os Build Platform Role Connected Standby Report TimeDocument3 paginiInstalled Batteries: Computer Name System Product Name Bios Os Build Platform Role Connected Standby Report TimeBoey HeÎncă nu există evaluări

- Installed Batteries: Computer Name System Product Name Bios Os Build Platform Role Connected Standby Report TimeDocument3 paginiInstalled Batteries: Computer Name System Product Name Bios Os Build Platform Role Connected Standby Report TimeBoey HeÎncă nu există evaluări

- Appendix (7) Structural Loading of Fire Engine On AccesswayDocument2 paginiAppendix (7) Structural Loading of Fire Engine On AccesswayBoey HeÎncă nu există evaluări

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (345)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- ProbDocument10 paginiProbKashif JawaidÎncă nu există evaluări

- 2.1 DRH Literary Translation-An IntroductionDocument21 pagini2.1 DRH Literary Translation-An IntroductionHassane DarirÎncă nu există evaluări

- Sample Interview Questions For Planning EngineersDocument16 paginiSample Interview Questions For Planning EngineersPooja PawarÎncă nu există evaluări

- Garments Costing Sheet of LADIES Skinny DenimsDocument1 paginăGarments Costing Sheet of LADIES Skinny DenimsDebopriya SahaÎncă nu există evaluări

- The Serious Student of HistoryDocument5 paginiThe Serious Student of HistoryCrisanto King CortezÎncă nu există evaluări

- ATAL Selected FDPs AY 2023 24Document15 paginiATAL Selected FDPs AY 2023 24parthiban palanisamy100% (2)

- Reproduction in PlantsDocument12 paginiReproduction in PlantsAnand Philip PrasadÎncă nu există evaluări

- Empanelled Hospitals List Updated - 06-12-2022 - 1670482933145Document19 paginiEmpanelled Hospitals List Updated - 06-12-2022 - 1670482933145mechmaster4uÎncă nu există evaluări

- April 2021 BDA Case Study - GroupDocument4 paginiApril 2021 BDA Case Study - GroupTinashe Chirume1Încă nu există evaluări

- XU-CSG Cabinet Minutes of Meeting - April 4Document5 paginiXU-CSG Cabinet Minutes of Meeting - April 4Harold John LaborteÎncă nu există evaluări

- Interbond 2340UPC: Universal Pipe CoatingDocument4 paginiInterbond 2340UPC: Universal Pipe Coatingnoto.sugiartoÎncă nu există evaluări

- Annex To ED Decision 2013-015-RDocument18 paginiAnnex To ED Decision 2013-015-RBurse LeeÎncă nu există evaluări

- What Are Some of The Best Books On Computer ScienceDocument9 paginiWhat Are Some of The Best Books On Computer ScienceSarthak ShahÎncă nu există evaluări

- Learning TheoryDocument7 paginiLearning Theoryapi-568999633Încă nu există evaluări

- Zambia National FormularlyDocument188 paginiZambia National FormularlyAngetile Kasanga100% (1)

- Work Site Inspection Checklist 1Document13 paginiWork Site Inspection Checklist 1syed hassanÎncă nu există evaluări

- K MCQsDocument6 paginiK MCQsF ParikhÎncă nu există evaluări

- Module 2 TechnologyDocument20 paginiModule 2 Technologybenitez1Încă nu există evaluări

- Epistemology and OntologyDocument6 paginiEpistemology and OntologyPriyankaÎncă nu există evaluări

- GA Power Capsule For SBI Clerk Mains 2024 (Part-2)Document82 paginiGA Power Capsule For SBI Clerk Mains 2024 (Part-2)aa1904bbÎncă nu există evaluări

- Profibus Adapter Npba-02 Option/Sp Profibus Adapter Npba-02 Option/SpDocument3 paginiProfibus Adapter Npba-02 Option/Sp Profibus Adapter Npba-02 Option/Spmelad yousefÎncă nu există evaluări

- Ged 102 Mathematics in The Modern WorldDocument84 paginiGed 102 Mathematics in The Modern WorldKier FormelozaÎncă nu există evaluări

- Cpar ReviewerDocument6 paginiCpar ReviewerHana YeppeodaÎncă nu există evaluări

- 16 Personalities ResultsDocument9 pagini16 Personalities Resultsapi-605848036Încă nu există evaluări

- FDD Spindle Motor Driver: BA6477FSDocument12 paginiFDD Spindle Motor Driver: BA6477FSismyorulmazÎncă nu există evaluări

- Atlascopco XAHS 175 DD ASL Parts ListDocument141 paginiAtlascopco XAHS 175 DD ASL Parts ListMoataz SamiÎncă nu există evaluări

- Islamiyat ProjectDocument21 paginiIslamiyat ProjectSubhan Khan NiaziÎncă nu există evaluări

- Lecture 12 Health Management Information SystemDocument14 paginiLecture 12 Health Management Information SystemKamran SheikhÎncă nu există evaluări

- Icici PrudentialDocument52 paginiIcici PrudentialDeepak DevaniÎncă nu există evaluări

- Roland Fantom s88Document51 paginiRoland Fantom s88harryoliff2672100% (1)