Documente Academic

Documente Profesional

Documente Cultură

2297da800d139 001 A A3 (50) Cargo Functional Diagram

Încărcat de

iuliiulianTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

2297da800d139 001 A A3 (50) Cargo Functional Diagram

Încărcat de

iuliiulianDrepturi de autor:

Formate disponibile

450

APCPCWM_4828539:WP_0000045WP_0000045

000

0_

P

5W

040

00

0_

P

:W

395

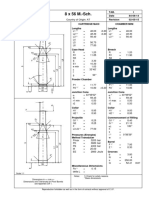

DWG No. : 2297DA800D139 ( PAGE 1 / 50 )

288

4_

M

W

C

P

C

P

A

1. THIS VESSEL TO BE DESIGNED/CONSTRUCTED IN ACCORDANCE WITH : 2

H. 2297 : 2

Det Norske Veritas (hereinafter called “DNV”) and registered by the symbols of : 9

+1A1, Tanker for Liquefied Gas, Ship type 2G (-163 C, 500 kg/m3, 0.35 bar), NAUTICUS (Newbuilding), PLUS, COAT-PSPC(B), E0##, 7

D

NAUT-OC, CLEAN, TMON, BIS, GAS FUELLED, BWM-T, OPP-F,RECYCLABLE, COMF-V(3)C(3).

F-AMC, ECA(SOX-A).

H. 2298 : A

8

Bureau Veritas (hereinafter called “BV”) with MOU

0

H. 2400/01 :

American Bureau of Shipping(hereinafter called “ABS”) with MOU

Flag : Malta 0

2. HANDLING CARGOES : Liquefied Natural Gas (LNG)

D

1

3. PRINCIPAL DIMENSIONS 3

- LENGTH O. A. : APP. 294.2 M

9

- LENGTH B. P. : 283.2 M

- BREADTH MLD : 44.0 M

- DEPTH MLD : 26.0 M

- DRAFT DESIGN : 11.5 M

C

- DRAFT SCANT. : 12.5 M

- FREEBOARD DECK : SUNKEN DECK

A

- FREEBOARD TYPE : “B” R

G

O

F

배포부서 부수

상선전장SYS설계1 1

U 기장SYS설계2 1

N 의장품질경영 1

C

의장1 선장 1

시운전(선장) 1

T 상선 CM 1

I

O

보 관

합 계 6

N This drawing or document is the property of Daewoo Shipbuilding & Marine Engineering Co., FOR WORKING

A Ltd., and must not be partially or wholly copied or used for any other purpose without prior

written permission of DSME.

FOR CONSTRUCTION

FOR REVISION

L 본 도면 및 기술자료는 대우조선해양의 재산으로서 사전 공식적인 허가없이 일부분이라도 제 자에게 유출을 금지함

( 3 )

A3:( 50 ) A4:( )

PROJECT No PROJECT

2297/98/2400/01 CARDIFF 159,800 M3 LNG CARRIER(DFDE)

D TITLE

I APPD BY SUNG HO, SHIN (

(TEL. : 055-680-4202)

2/27

A

G CHKD BY

CARGO FUNCTIONAL DIAGRAM

TAE IL, BAEK ( 2/27

(TEL. : 055-680-4210)

R

A DWG BY DOO BONG, KIM ( 2/27

M (M.P : 010-4603-8138) (TEL. : 055-680-4237)

DEPT

HULL PIPING DATE SCALE DWG No. REV No

A DESIGN PART 1 2012.02.27 NONE DA800D139 A

Printed by DSME 선장배관설계1 김두봉 2012- 02- 27 19:07

450

APCPCWM_4828539:WP_0000045WP_0000045

000

0_

P

5W

040

00

0_

P

:W

395

288

4_

DWG No. : 2297DA800D139 ( PAGE 2 / 50 )

M

W

C

P

C

P

A

PLAN HISTORY PLAN HISTORY

DATE REV No DESCRIPTION DWG CHKD APPD DATE REV No DESCRIPTION DWG CHKD APPD

2012. - SUBMITTED TO OWNER / CLASS(DNV) FOR APPROVAL D.B.KIM T.I.BAEK S.H.SHIN

02.27 A 김두봉) (백태일)

( (신성호)

- ISSUED FOR WORKING

Printed by DSME 선장배관설계1 김두봉 2012- 02- 27 19:07

450

APCPCWM_4828539:WP_0000045WP_0000045

000

0_

P

5W

040

00

0_

P

:W

395

288

4_

M

W

C

P

C

P

A

DWG No. : 2297DA800D139 ( PAGE 3 / 50 )

CONTENTS CONTENTS

NO. DESCRIPTION PAGE NO. DESCRIPTION PAGE

- SCHMATIC PIPING DIAGRAM FOR CARGO HANDLING SYSTEM 4 41 VACUUM PROCESS OF INSULATION SPACES 45

1 DRYING WITH BOTTOM FILLING AFTR DRY DOCK 5 42 N2 GAS FILLING OF THE INSULATION SPACES 46

2 DRYING WITH TOP FILLING AFTER DRY DOCK 6 43 PRESSURIZATION DURING NORMAL SERVICE 47

3 INERTING AFTER DRY DOCK 7 44 VACUUM PROCESS FOR CLEANSING SYSTEM BEFORE DRY DOCKING(TYP.) 48

4 DRYING AND INERTING USING LIQUID NITROGEN 8 45 PRESSURIZATION FOR CLEANSING SYSTEM BEFORE DRY DOCKING(TYP.) 49

5 GAS FILLING WITH VENTING(1ST STEP) 9 46 ONE(1) TANK VACUUM PROCESS OF THE INSULATION SPACES FOR INSPECTION 50

6 GAS FILLING WITH GAS RETURN TO SHORE(2ND STEP) 10

7 GAS FILLING WITH GCU BURNING 11

8 INITIAL COOLDOWN 12

9 LNG LOADING 13

10 FUEL GAS TO DFDE AND GCU (EXCESSIVE BOG) 14

11 FUEL GAS TO DFDE (NORMAL OPERATION) 15

12 FUEL GAS TO DFDE (DFDE LOAD CHANGE) 16

13 FUEL GAS TO DFDE AND GCU 17

14 FUEL GAS TO DFDE WITH F/VAPORIZER(LADEN VOYAGE) 18

15 FUEL GAS TO DFDE WITH F/VAPORIZER(USING STRIP. P/P, LADEN VOYAGE) 19

16 GCU BURNING DURING LADEN VOYAGE 20

17 LNG DISCHARGING WITH VAPOR RETURN FROM SHORE 21

18 LNG DISCHARGING WITHOUT VAPOR RETURN FROM SHORE 22

19 FUEL GAS TO DFDE WITH FORCING VAPORIZER(BALLAST VOYAGE) 23

20 FUEL GAS TO DFDE WITHOUT FORCING VAPORIZER(BALLAST VOYAGE) 24

21 GCU BURNING WITH FREE FLOW(BALLAST VOYAGE) 25

22 GCU BURNING (BALLAST VOYAGE) 26

23 COOLDOWN DURING BALLAST VOYAGE 27

24 CARGO TANK STRIPPING 28

25 WARMING UP WITH VENTING 29

26 WARMING UP WITH GAS BURNING 30

27 INERTING BEFORE DRY DOCK 31

28 INERTING WITH GCU BURNING BEFORE DRY DOCK 32

29 INERRTING WITH WARMING UP BEFORE DRY DOCK 33

30 AERATION WITH BOTTOM FILLING 34

31 AERATION WITH TOP FILLING 35

32 EMERGENCY CARGO TRANSFER 36

33 ONE(1) TANK WARMING UP(TYPICAL) 37

34 ONE(1) TANK INERTING(ALT.1 : TYPICAL) 38

35 ONE(1) TANK INERTING WITH WARMING UP (ALT. 2 : TYPICAL) 39

36 ONE(1) TANK AERATION(TYPICAL) 40

37 ONE(1) TANK DRYING AFTER INSPECTION(TYPICAL) 41

38 ONE(1) TANK INERTING AFTER INSPECTION(TYPICAL) 42

39 ONE(1) TANK GAS FILLING(TYPICAL) 43

40 ONE(1) TANK COOLDOWN(TYPICAL) 44

Printed by DSME 선장배관설계1 김두봉 2012- 02- 27 19:07

450

APCPCWM_4828539:WP_0000045WP_0000045

000

0_

P

5W

040

00

0_

P

:W

395

288

4_

DWG No. : 2297DA800D139 ( PAGE 4 / 50 )

M

W

C

P

C

P

A

SCHEMATIC PIPING DIAGRAM FOR CARGO HANDLING SYSTEM SYMBOL DESCRIPTION SYMBOL DESCRIPTION

REMOTE HYDRAULIC

200A (H/N 2297/89/2400/01 CARDIFF 159,800M3 LNG CARRIER) BUTTERFLY VALVE H

CONTROL

4 40 40 40

BUTTERFLY VALVE # REMOTE HYD. CONT.

* 40 H

0A0 0A 0A 0A (FLANGE TYPE) EM’CY SHUT DOWN

600A A0 25A H *

H

REMOTE HYD. CONT.

A

00 CG002

# # # # BALL VALVE THROTTLING

6

40

8L # 30

8L H

10

8

G H

20

8L H

10

8L

GLOBE VALVE AUTOMATIC CONTROL

H H

450A CG512

CG511

A

H C C C C C A

600A 70 MANUAL CONTROL /

088 8L 068 058 LIFT CHECK VALVE WITH FLAG INDICATOR/

A 500A NO.1 HD COMP. CG509 LC C LC LC WITH LIMIT SWITCH

FROM E/R CG516 A

40

CG527 600A HD

A H

500A CG515 H

600A A0 0A SWING CHECK VALVE REDUCER

CG520

HEATER

CG517 04

450A BLIND 500A NO.2 HD COMP. CG513 80A DUO PLATE CHECK VALVE SPECTACLE FLANGE

FLANGE 250A

VALVE

CG521 A A

SAFETY RELIEF VALVE SPOOL PIECE

A0 A

TO GCU #

H

250A

200A H

* 02 CG534

H 600A

R

E

V

RE

V

R

E

V

O

R

E

V STRAINER(Y-TYPE) STRAINER(CONICAL TYPE)

-O O

-X - O

-

CG636 *

A

70

4

G

CG538 CG536 200A

CG504 A

CG501

NO.1 LD COMP. A0

55

X

.

Q

I

.R

TS

X

.P

A

X

.

Q

IL M.SEP. MIST SEPERATOR IN-LINE MIXER

C L V

A 5 A A

A

05 A0

*CG406 92

5 00 35G A

2 A A0 A0 A0

06 07 CARGO HANLDING EQUIPMENT

TO D/F # 2C 00 07 01

H

A G

C H

7 EQUIPMENT Q TY CAPACITY TYPE

200A CG405 200A A NO.2 LD COMP. CG505

250A CENT., SUBM.,

H# A CG508

IN-LINE IN-LINE .P CARGO PUMP 8 1,850 m3/h ×160 mlc EL-MOTOR DRIVEN

CS504 ES CENT., SUBM.,

CG532

250A CG540 MIXER

250A MIXER TSI STRIPPING/STRAY PUMP 4 60 m3/h ×140 mlc EL-MOTOR DRIVEN

200A

H A A

CG415 FORCING VAP. VENT 80A

40A 250A N2 H M MAST A0 A FUEL GAS PUMP 2 12 m3/h ×110 mlc CENT., SUBM.,

040

CS528 CS529 40A EL-MOTOR DRIVEN

04

A

A

A 2 2 CENT.,HORIZONTAL

CS520

00 5G4

A0 HIGH DUTY COMPRESSOR 35,000 m3/h ×1.96 bar A EL-MOTOR DRIVEN

A

2 C 12 DRAIN

235 A0 80

7L

70

7L 067 057

50A

A

S5 POT H SC 07 01 LC LC

LOW DUTY COMPRESSOR 2 4,700 m3/h ×6.50 bar A CENT.,HORIZONTAL

# #

TO N2 SYS. C C C

A

H A

LNG. VAP. 0 FOR INSU.SPACE EL-MOTOR DRIVEN

CS501 CG530 400A 0

48PRESSURIZATION

25 25A

250A A

00 460 H

# 40

7L #

H

30

7L #

H

017

G H

20

7L H

017

LC LNG VAPORIZER 1 4,100 Kw SHELL & TUBE,

STEAM HEATED

2 GC C C C C SHELL & TUBE,

G

C 600A A0 A0 A0 25A A0 A0 A0 A0 FORCING VAPORIZER 1 810 Kw

04 04 04 04 04 55 07 STEAM HEATED

A

00 HD HEATER 1 3,700 Kw SHELL & TUBE,

10 6

20 A A0 20 036 30 STEAM HEATED

A0 6

6

G

C

00

3 06 6L

C A

56 CG605 G

C

0S

C H

* 10

0

G

NOTE.1 THE PIPE LINE BETWEEN FORCING VAPORIZER AND MIST SEPARATOR

G C SHALL BE ARRANGED IN A SLOPE AS FAR AS PRACTICABLE

5 C

300A GAS MAIIN 300A

200A

400A 600A VAPOR MAIN 500A

CS002 CG107

CL601

CS004

80A 80A STRIPPING/SPRAY MAIN 65A CS001

CS601

450A 600A LIQUID MAIN 450A 400A

CL107

CS603 01 41 01

CS415 * CS315 CL310 * 3S

C

3S

C CL210 * 2S

C CL110 *

A0 A

H H H H H H

CL410 CS408 CS404 CS308 CS304 04 CS208 CS108

CS416 4 CS316

A0 40A H * 144

SC

A0

4

A

00 A

00 A

05 40A H * A0

4

A0

02

A0

04

A0 40A

54 H *CS204 A0

4

A0

02

A0

04

A0 40A

54 * A

00 A

00 A

00 A

00 A

04

54 2 2

H

4 4 60 4 3 4

A

56

H

* *

H

5

40S

H

* *

H

5

30S

A0

4

*

H

5

20S

A0

4

CS104

1H

G

* 50

1

G

*

H

50

1S

C A C C C C C

200A 194 A 56 200A 193 A 200A A5 200A A5

SC 56 SC 56 6 6

064 20 063 20 6 20 6 20

A

00 A0 A0 LC A5 024 184 4 A

00 A

00 A

00 LC 02 183 3 A0 A0 A0 02L 022 2 A0 A0 A0 01L 021 1

3 03 04 50 6 SC SC 25A G

C 3 3 4 503

A

56 3SC SC 25A G

C 03 03 04 C5 SC 25A G

C 30 03 04 C5 SC

G

C 7025A

*

H

10

4L * *

H

20

4L H

4L

C

* *

H H 60 10

4

*

H

10

3L * *

H

20

3L H LC * *

H H 60 10

3

*

H

10

2L * *

H

20

2L H

02

LC *

H 60 10

2

*

H

10

1L * *

H

20

1L H

01

LC *

H 10

1

1S

C

061

C C 004

10

4S

71

4S

4S G C C 030 10

3S

71

3S

3S G C C 020 10

2S

2S G C C 010 10

1S G SC

C C LC C C LC C C LC C A

LC C C 70

4S A5 C C 70

3S

A5 C 70

2S

A5 C

25

C 2 C 2 C 2

A

00 A0 A

00 A

00 A0 A0 A0 00A

4 04 4 4 04 04 04 4

A 30 A 044 00A A A A

00 A0 A0 A0 A0 A0 041

A0

05 033 05 40 032 40 04 031 04

530 4L

C 3 LC 4 0

35 LC 3 3L 4 53 LC 53 2L 53 LC 53 LC

C C

FG P/P FG P/P

NO.4 CARGO TANK NO.3 CARGO TANK NO.2 CARGO TANK NO.1 CARGO TANK

Printed by DSME 선장배관설계1 김두봉 2012- 02- 27 19:07

450

APCPCWM_4828539:WP_0000045WP_0000045

000

0_

P

5W

040

00

0_

P

:W

395

288

4_

DWG No. : 2297DA800D139 ( PAGE 5 / 50 )

M

W

C

P

C

P

A

200A (H/N 2297/98/2400/01 CARDIFF 159,800M3 LNG CARRIER)

* 4 40 40 40 40

600A H

0A0 0A A0 25A 0A 0A AUXILIARIES INVOLVED INERT GAS GENERATOR(DRY AIR MODE)

A CG002 # # # -FLOW RATE : 16,000 M3/H

00 # 40 # 30 10 20 10

6 H 8L H 8L H 8

G H 8L H 8L

450A CG512

CG511

A

H C C C C C OPERATING DURATION LESS THAN 20 HOURS

600A 70

088 8L 068 058

A 500A NO.1 HD COMP. CG509 LC C LC LC

40

PERFORMANCE CRITERIA CARGO TANK DEW POINT : LOWER THAN -20℃

FROM E/R CG516 A

CG527 600A HD

A H

500A CG515 H

600A A0 0A

CG520

HEATER

CG517 04

450A BLIND 500A NO.2 HD COMP. CG513 80A FUNCTION :

FLANGE 250A NOTE

VALVE

CG521 A A

A0 A - REPLACE ATMOSPHERIC AIR BY DRY AIR

TO GCU #

H

250A

200A H

* 02 CG534

H 600A

R

E

V

RE

V

R

E

V

O

R

E

V

(CONDITON/CHECK POINT)

- DEW POINT OF DRY AIR IS LOWER THAN -45℃ FROM I.G.G.

-O O

-X - O

-

CG636 *

A

70

4

G

CG538 CG536 200A

CG504 A

CG501

NO.1 LD COMP. A0

55

X

.

Q

I

.R

TS

X

.P

A

X

.

Q

IL

C L V

A CHECK POINT :

A 5 05

A

A0

A

*CG406 92

5 00 35G A

2 A A0 A0 A0

06 07

TO D/F # 2C 00 07 01 - DEW POINT IN TANK BY SAMPLING AT TOP OF GAS DOME

H

A G

C H

7 AND SAMPLING LINES IN TANK

200A CG405 200A A NO.2 LD COMP. CG505

250A

H# CS504

A CG508

IN-LINE IN-LINE .P

ES

DRY AIR - OPERATING CONDITION OF I.G.G.

CG532 CG540 MIXER

250A MIXER TSI ATMOSPHERIC AIR

200A CG415

H A

FORCING VAP. 250A A

80A - MONITORING OF SAFETY DEVICE AND RELATED SENSORS

M VENT

40A 250A N2 H

MAST A0 A

040

CS528 CS529 40A 04

A

A

- TEMPERATURE OF SEA WATER AND ATMOSPHERE,

CS520 A 2

4 ATMOSPHERE PRESSURE

00 5G 12 DRAIN A0 A0 80 70 067 057

2 C 235

A

S5 POT H 07 7L 7L

50A

A

SC 01 LC LC

NECESSARY DEVICE :

# #

TO N2 SYS. C C C

A

H A

LNG. VAP. 0 FOR INSU.SPACE

CS501 CG530 400A 0

48PRESSURIZATION

25 25A

250A A

00 460 H

# 40

7L #

H

30

7L #

H

017

G H

20

7L H

017

LC - PORTABLE DEW POINT METER

2 GC C C C C

G

C 600A A0 A0 A0 25A A0 A0 A0 A0

04 04 04 04 04 55 07

A

00

16

20 A A0 20 036 30

A0

06 6

G

C

00

3 06 6L

C A

56 CG605 G

C

0S

C H

* 10

0

G

G C

5 C

300A GAS MAIIN 300A

200A

400A 600A VAPOR MAIN 500A

CS002 CG107

CL601

CS004

80A 80A STRIPPING/SPRAY MAIN 65A CS001

CS601

450A 600A LIQUID MAIN 450A 400A

CL107

CS603 01 41 01

CS415 * CS315 CL310 * 3S

C

3S

C CL210 * 2S

C CL110 *

A0 A

H H H H H H

CL410 CS408 CS404 CS308 CS304 04 CS208 CS108

CS416 4 CS316

A0 40A H * 144

SC

A0

4

A

00 A

00 A

05 40A H * A0

4

A0

02

A0

04

A0 40A

54 H *CS204 A0

4

A0

02

A0

04

A0 40A

54 * A

00 A

00 A

00 A

00 A

04

54 2 2

H

4 4 60 4 3 4

A

56

H

* *

H

5

40S

H

* *

H

5

30S

A0

4

*

H

5

20S

A0

4

CS104

1H

G

* 50

1

G

*

H

50

1S

C A C C C C C

200A 194 A 56 200A 193 A 200A A5 200A A5

SC 56 SC 56 6 6

064 20 063 20 6 20 6 20

A

00 A0 A0 LC A5 024 184 4 A

00 A

00 A

00 LC 02 183 3 A0 A0 A0 02L 022 2 A0 A0 A0 01L 021 1

3 03 04 50 6 SC SC 25A G

C 3 3 4 503

A

56 3SC SC 25A G

C 03 03 04 C5 SC 25A G

C 30 03 04 C5 SC

G

C 7025A

*

H

10

4L * *

H

20

4L H

4L

C

* *

H H 60 10

4

*

H

10

3L * *

H

20

3L H LC * *

H H 60 10

3

*

H

10

2L * *

H

20

2L H

02

LC *

H 60 10

2

*

H

10

1L * *

H

20

1L H

01

LC *

H 10

1

1S

C

061

C C 004

10

4S

71

4S

4S G C C 030 10

3S

71

3S

3S G C C 020 10

2S

2S G C C 010 10

1S G SC

C C LC C C LC C C LC C A

LC C C 70

4S A5 C C 70

3S

A5 C 70

2S

A5 C

25

C 2 C 2 C 2

A

00 A0 A

00 A

00 A0 A0 A0 00A

4 04 4 4 04 04 04 4

A 30 A 044 00A A A A

00 A0 A0 A0 A0 A0 041

A0

05 033 05 40 032 40 04 031 04

530 4L

C 3 LC 4 0

35 LC 3 3L 4 53 LC 53 2L 53 LC 53 LC

C C

FG P/P FG P/P

NO.4 CARGO TANK NO.3 CARGO TANK NO.2 CARGO TANK NO.1 CARGO TANK

Printed by DSME 선장배관설계1 김두봉 2012- 02- 27 19:07

450

APCPCWM_4828539:WP_0000045WP_0000045

000

0_

P

5W

040

00

0_

P

:W

395

288

4_

DWG No. : 2297DA800D139 ( PAGE 6 / 50 )

M

W

C

P

C

P

A

200A (H/N 2297/98/2400/01 AWILCO 155,900M3 LNG CARRIER)

* 40 40 40 40 40

600A H

0A 0A 0A 25A 0A 0A AUXILIARIES INVOLVED INERT GAS GENERATOR(DRY AIR MODE)

A

00 CG002

# # # #

#

-FLOW RATE : 16,000 M3/H

40 30 10 20 10

6 H 8L H 8L H 8

G H 8L H 8L

450A CG512

CG511

A

C C C C C

H

600A 80 70 OPERATING DURATION LESS THAN 20 HOURS

8L 068 058

A 500A NO.1 HD COMP. CG509 8L

C LC LC

C

FROM E/R CG516 A

40

CG527 600A HD

HEATER

A H

500A CG515 H

600A A0

04

0A PERFORMANCE CRITERIA CARGO TANK DEW POINT : LOWER THAN -20 ℃

CG520 CG517

450A BLIND 500A NO.2 HD COMP. CG513 80A

FLANGE 250A FUNCTION :

VALVE NOTE

CG521 A A

A A

# 200A 00 R - REPLACE ATMOSPHERIC AIR BY DRY AIR

CG534 R RE R

TO GCU H

250A H

* 2 H 600A E

V

-O

V

O

-X

E

V

O

-

E

V

O

-

(CONDITON/CHECK POINT)

℃

*

- DEW POINT OF DRY AIR IS LOWER THAN -45 FROM I.G.G.

CG636 70

4 CG538 CG536 200A CG501

NO.1 LD COMP. A0 X

. .R

X

.P X

.

A

G

C

CG504 A 55 Q

IL TS A

V

Q

IL

A 5 A A A

05 A0

*CG406 00 35G A0

CHECK POINT :

92 A0 A0

2

A

5 A 06 07

TO D/F # 2C 00 07 01

H

A G

C H

7 - DEW POINT IN TANK BY SAMPLING AT TOP OF GAS DOME

200A CG405 200A A NO.2 LD COMP. CG505

250A

AND SAMPLING LINES IN TANK

#

H

CS504

A CG508

IN-LINE IN-LINE .P

ES

DRY AIR

- OPERATING CONDITION OF I.G.G.

CG532 CG540 MIXER

200A CG415

H A

250A 250A MIXER TIS A ATMOSPHERIC AIR

FORCING VAP.

M VENT 80A - MONITORING OF SAFETY DEVICE AND RELATED SENSORS

40A CS528 CS529 250A N2 H

MAST A0 A0

40A 04 40

A

A

CS520 A 24 - TEMPERATURE OF SEA WATER AND ATMOSPHERE,

00 5G 12 DRAIN A0 A0 80 70 60 50 ATMOSPHERE PRESSURE

2 C 235

A

07 7L 7L 7L 7L

50A

A

S5C POT H SC 01

# #

TO N2 SYS. C C C C

A

H A

LNG. VAP. 00 FOR INSU.SPACE NECESSARY DEVICE :

CS501 CG530 400A 482PRESSURIZATION

25A

250A A

00 460

#

H

40

7L #

H

30

7L #

H

017

G H

20

7L H

10

7L

5 C C C C C - PORTABLE DEW POINT METER

G 2 GC A0 A0 A0 25A A0 A0 A A0

C 600A 04 04 04 04 550 07

A0 04

0 A 036

10 6

20 A0 20 30

A0 6

6

G

C 03 00

6

6L

C A

56 CG605 G

C

0S

C H

* 10

0

G

G C

5 C

200A 300A GAS MAIIN 300A

400A 600A VAPOR MAIN 500A

CS002 CG107

CL601

CS004

80A 80A STRIPPING/SPRAY MAIN 65A CS001

CS601

450A 600A LIQUID MAIN 450A 400A

CL107

CS603 01 41 01

CS415 * CS315 CL310 * 3S

C

3S

C CL210 * 2S

C CL110 *

A0 A

H H H H H H

CS416 CL410 CS408 CS404

4 CS316 CS308 CS304 04 CS208 CS108

A0 40A H * 144

SC

A0

4

A0

02

A

00 A

05 40A H * A

04 A0

02

A0

04

A0 40A

54 H *CS204 A0

4

A0

02

A0

04

A0 40A

54 * A

00 A

00 A

00 A

00 A

04

54 2

H

4 4 60 4 3 4

A

56

H

* *

H

5

40S

H

* *

H

5

30S

A0

4

*

H

5

20S

A0

4

CS104

1H

G

* 50

1

G

*

H

50

1S

C A C C C C C

200A 194 A 56 200A 193 A 200A A5 200A A5

SC 56 SC 56 6 6

064 20 063 20 6 20 6 20

A

00 A

00 A0 LC A5 024 184 4 A

00 A

00 A

00 LC 02 183 3 A0 A0 A0 02L 022 2 A0 A0 A0 01L 021 1

25A

3 3 04 50 6 SC SC 25A G

C 3 3 4 503 56A 3SC SC 25A G

C 03 03 04 C5 SC 25A G

C 03 03 04 C5 SC G

C 071

H* 10

4L * *

H

20

4L H

4L

C

* *

H H

064

10

4

*

H

10

3L * *

H

20

3L H LC * *

H H

063

10

3

*

H

10

2L * *

H

20

2L H

02

LC *

H

062

10

2

*

H

10

1L * *

H

20

1L H

01

LC *

H 10

1

SC

061

C C 004

10

4S

71

4S SC G C C 030 10

3S

71

3S SC G C C 020 10

2S SC G C C 010 10

1S G SC

C LC C LC C LC C A

LC C C 70

4S

A5 C C 70

3S

A

52 C 70

2S

A5 C 52

C 2 C C 2

A

00 A

00 A

00 A

00 A0 A0 A0 A0

4 4 4 4 04 04 04 40

A A A

00 A0 A0

040 A A0 A0

A 30 A A0 05A

40 033 40 032 40 031 40

05 4L 05 4L 05 LC

05 3L 4 53 LC 53 2L 04 LC 53 1L 04

3 C 3 C 3 3 C C 3 C

FG P/P FG P/P

NO.4 CARGO TANK NO.3 CARGO TANK NO.2 CARGO TANK NO.1 CARGO TANK

Printed by DSME 선장배관설계1 김두봉 2012- 02- 27 09:50

450

APCPCWM_4828539:WP_0000045WP_0000045

000

0_

P

5W

040

00

0_

P

:W

395

288

4_

DWG No. : 2297DA800D139 ( PAGE 7 / 50 )

M

W

C

P

C

P

A

200A (H/N 2297/98/2400/01 CARDIFF 159,800M3 LNG CARRIER)

* 40 40 40 40 40 AUXILIARIES INVOLVED

0A 0A 0A 0A

INERT GAS GENERATOR (INERT GAS MODE)

600A H

0A 25A

# # #

-FLOW RATE : 16,000 M3 /H

A

00 CG002

6 # 40

8L # 30

8L

10

8

20

8L

10

8L

G OPERATING DURATION

H H H H H

450A CG512

CG511

A

C C C C C LESS THAN 20 HOURS

600A

H

80 70

8L 068 058

500A NO.1 HD COMP. CG509 8L LC LC

℃

A

C C

FROM E/R CG516 A

40 PERFORMANCE CRITERIA CARGO TANK DEW POINT : LOWER THAN -40

CG527 600A HD

A H

500A CG515 H

600A A0 0A O2 CONTENT : LESS THAN 2% BY VOLUME

CG520

HEATER

CG517 04

450A BLIND 500A NO.2 HD COMP. CG513 80A

FLANGE 250A NOTE

VALVE FUNCTION :

CG521 A A

A A

(CONDITON/CHECK POINT)

TO GCU #

H

250A

200A H

* 00

2

CG534

H 600A

R

E

V

RE

V

R

E

V

O

R

E

V

- REPLACE DRY AIR BY INERT GAS

(DEW POINT OF INERT GAS IS LOWER THAN -45 ℃ FROM I.G.G.)

-O O

-X - O

-

CG636 *

A

70

4

G

CG538 CG536 200A

CG504 A

CG501

NO.1 LD COMP. A0

55

X

.

Q

IL

.R

TS

X

.P

A

X

.

Q

IL

C V

A 5 A A A

05 A0

CHECK POINT :

*CG406 92

5 00 35G A

2 A A0 A0 A0

06 07

TO D/F # 2C 00 07 01

H

A G

C H

- DEW POINT IN TANK BY SAMPLING AT TOP OF GAS DOME

7 AND SAMPLING LINES IN TANK.

200A CG405 200A A NO.2 LD COMP. CG505

250A

#

H

CS504

A CG508

IN-LINE IN-LINE .P

ES

- OPERATING CONDITION OF I.G.G.

MIXER

200A CG415

H A

FORCING VAP.

CG532

250A CG540 250A MIXER TIS A

80A

- MONITORING OF SAFETY DEVICE AND RELATED SENSORS

M VENT

40A CS528 CS529 250A N2 H

MAST A0 A0

40A 04 40

A

A - TEMPERATURE OF SEA WATER AND ATMOSPHERE,

CS520 A 24 ATMOSPHERE PRESSURE

00 5G 12 DRAIN A0 A0 80 70 60 50

2 C 235

A

07 7L 7L 7L 7L

50A

A

S5C POT H SC 01

# #

TO N2 SYS. C C C C

A

H A

LNG. VAP. 00 FOR INSU.SPACE

CG530 400A 250A # # # 10 NECESSARY DEVICE :

CS501 482PRESSURIZATION A

40

7L

30

7L 017 20

7L 7L

5

25A 00 460 H

C

H

C

H

G

C

H

C

H

C

G 2 GC A0 A0 A0 25A A0 A0 A A0 DRY AIR - PORTABLE DEW POINT METER, PORTABLE OXYGEN METER

C 600A 04 04 04 04 550 07

A0 04 INERT GAS

0 A 036

16

20 A0 20 30

A0

06 6

G

C 03 00

6

6L

C A

56 CG605 G

C

0S

C H

* 10

0

G

G C

5 C

200A 300A GAS MAIIN 300A

400A 600A VAPOR MAIN 500A

CS002 CG107

CL601

CS004

80A 80A STRIPPING/SPRAY MAIN 65A CS001

CS601

450A 600A LIQUID MAIN 450A 400A

CL107

CS603 01 41 01

CS415 * CS315 CL310 * 3S

C

3S

C CL210 * 2S

C CL110 *

A0 A

H H H H H H

CS416 CL410 CS408 CS404

4 CS316 CS308 CS304 04 CS208 CS108

A0 40A H * 144

SC

A0

4

A0

02

A

00 A

05 40A H * A

04 A0

02

A0

04

A0 40A

54 H *CS204 A0

4

A0

02

A0

04

A0 40A

54 * A

00 A

00 A

00 A

00 A

04

54 2

H

4 4 60 4 3 4

A

56

H

* *

H

5

40S

H

* *

H

5

30S

A0

4

*

H

5

20S

A0

4

CS104

1H

G

* 50

1

G

*

H

50

1S

C A C C C C C

200A 194 A 56 200A 193 A 200A A5 200A A5

SC 56 SC 56 6 6

064 20 063 20 6 20 6 20

A

00 A

00 A0 LC A5 024 184 4 A

00 A

00 A

00 LC 02 183 3 A0 A0 A0 02L 022 2 A0 A0 A0 01L 021 1

25A

3 3 04 50 6 SC SC 25A G

C 3 3 4 503 56A 3SC SC 25A G

C 03 03 04 C5 SC 25A G

C 03 03 04 C5 SC G

C 071

H* 10

4L * *

H

20

4L H

4L

C

* *

H H

064

10

4

*

H

10

3L * *

H

20

3L H LC * *

H H

063

10

3

*

H

10

2L * *

H

20

2L H

02

LC *

H

062

10

2

*

H

10

1L * *

H

20

1L H

01

LC *

H 10

1

SC

061

C C 004

10

4S

71

4S SC G C C 030 10

3S

71

3S SC G C C 020 10

2S SC G C C 010 10

1S G SC

C LC C LC C LC C A

LC C C 70

4S

A5 C C 70

3S

A

52 C 70

2S

A5 C 52

C 2 C C 2

A

00 A

00 A

00 A

00 A0 A0 A0 A0

4 4 4 4 04 04 04 40

A A A

00 A0 A0

040 A A0 A0

A 30 A A0 05A

40 033 40 032 40 031 40

05 4L 05 4L 05 LC

05 3L 4 53 LC 53 2L 04 LC 53 1L 04

3 C 3 C 3 3 C C 3 C

FG P/P FG P/P

NO.4 CARGO TANK NO.3 CARGO TANK NO.2 CARGO TANK NO.1 CARGO TANK

Printed by DSME 선장배관설계1 김두봉 2012- 02- 27 09:50

450

APCPCWM_4828539:WP_0000045WP_0000045

000

0_

P

5W

040

00

0_

P

:W

395

288

4_

DWG No. : 2297DA800D139 ( PAGE 8 / 50 )

M

W

C

P

C

P

A

200A (H/N 2297/98/2400/01 CARDIFF 159,800M3 LNG CARRIER)

* 40 40 40 40 40

600A H

0A 0A 0A 25A 0A 0A AUXILIARIES INVOLVED LNG VAPORIZER

A

00 CG002

# # # #

6 H

40

8L #

H

30

8L H

10

8

G H

20

8L H

10

8L

450A CG512

CG511

A

C C C C C OPERATING DURATION LESS THAN 24 HOURS

600A

H

80 70

8L 068 058

A 500A NO.1 HD COMP. CG509 8L

C LC LC

FROM E/R CG527 600A A H

500A

CG516

CG515

A

C

A0

40

0A PERFORMANCE CRITERIA CARGO TANK DEW POINT : LOWER THAN -40 ℃

600A

H

HD

CG520

HEATER

CG517 04 O2 CONTENT : LESS THAN 2% BY VOLUME

450A BLIND 500A NO.2 HD COMP. CG513 80A

FLANGE

VALVE

250A NOTE FUNCTION :

CG521 A A

A A

(CONDITON/CHECK POINT) - REPLACE ATMOSPHERIC AIR IN CARGO TANKS BY

TO GCU #

H

250A

200A H

* 00

2

CG534

H 600A

R

E

V

RE

V

R

E

V

O

R

E

V

EVAPORATED NITROGEN

-O O

-X - O

-

CG636 *

A

70

4

G

CG538 CG536 200A

CG504 A

CG501

NO.1 LD COMP. A0

55

X

.

Q

IL

.R

TS

X

.P

A

X

.

Q

IL CHECK POINT :

C V

A 5 A A A

05 A0

*CG406 92

5 00 35G A

2 A A0 A0 A0

06 07 - DEW POINT IN TANK BY SAMPLING AT TOP OF GAS DOME

TO D/F # 2C 00 07 01

H

A G

C H AND SAMPLING LINES IN TANK.

7

200A CG405 200A A NO.2 LD COMP. CG505

250A - OPERATING CONDITION OF LNG VAPORIZER

#

H

CS504

A CG508

IN-LINE IN-LINE .P

ES

MIXER

250A CG540

- MONITORING OF SAFETY DEVICE AND RELATED SENSORS

CG532 250A MIXER TIS

200A

H A A

CG415 FORCING VAP. VENT 80A

40A 250A N2 H M MAST A0 A0

CS528 CS529 40A

- TEMPERATURE OF SEA WATER AND ATMOSPHERE,

04 40

A

A

ATMOSPHERE PRESSURE

CS520 A 24

00 5G 12 DRAIN A0 A0 80 70 60 50

2 C 235

A

07 7L 7L 7L 7L

50A

A

S5C POT H SC 01

# #

TO N2 SYS. C C C C

A

H A LIQUID NITROGEN NECESSARY DEVICE :

LNG. VAP. 00 FOR INSU.SPACE

CS501 CG530 400A 482PRESSURIZATION

25A

250A A

00 460

#

H

40

7L #

H

30

7L #

H

017

G H

20

7L H

10

7L GASEOUS NITROGEN

- PORTABLE DEW POINT METER, PORTABLE OXYGEN METER

5 C C C C C

G 2 GC A0 A0 A0 25A A0 A0 A A0 ATMOSPHERIC AIR

C 600A 04 04 04 04 550 07

A0 04

0 A 036

16

20 A0 20 30

A0

06 6

G

C 03 00

6

6L

C A

56 CG605 G

C

0S

C H

* 10

0

G

G C

5 C

200A 300A GAS MAIIN 300A

400A 600A VAPOR MAIN 500A

CS002 CG107

CL601

CS004

80A 80A STRIPPING/SPRAY MAIN 65A CS001

CS601

450A 600A LIQUID MAIN 450A 400A

CL107

CS603 01 41 01

CS415 * CS315 CL310 * 3S

C

3S

C CL210 * 2S

C CL110 *

A0 A

H H H H H H

CS416 CL410 CS408 CS404

4 CS316 CS308 CS304 04 CS208 CS108

A0 40A H * 144

SC

A0

4

A0

02

A

00 A

05 40A H * A

04 A0

02

A0

04

A0 40A

54 H *CS204 A0

4

A0

02

A0

04

A0 40A

54 * A

00 A

00 A

00 A

00 A

04

54 2

H

4 4 60 4 3 4

A

56

H

* *

H

5

40S

H

* *

H

5

30S

A0

4

*

H

5

20S

A0

4

CS104

1H

G

* 50

1

G

*

H

50

1S

C A C C C C C

200A 194 A 56 200A 193 A 200A A5 200A A5

SC 56 SC 56 6 6

064 20 063 20 6 20 6 20

A

00 A

00 A0 LC A5 024 184 4 A

00 A

00 A

00 LC 02 183 3 A0 A0 A0 02L 022 2 A0 A0 A0 01L 021 1

25A

3 3 04 50 6 SC SC 25A G

C 3 3 4 503 56A 3SC SC 25A G

C 03 03 04 C5 SC 25A G

C 03 03 04 C5 SC G

C 071

H* 10

4L * *

H

20

4L H

4L

C

* *

H H

064

10

4

*

H

10

3L * *

H

20

3L H LC * *

H H

063

10

3

*

H

10

2L * *

H

20

2L H

02

LC *

H

062

10

2

*

H

10

1L * *

H

20

1L H

01

LC *

H 10

1

SC

061

C C 004

10

4S

71

4S SC G C C 030 10

3S

71

3S SC G C C 020 10

2S SC G C C 010 10

1S G SC

C LC C LC C LC C A

LC C C 70

4S

A5 C C 70

3S

A

52 C 70

2S

A5 C 52

C 2 C C 2

A

00 A

00 A

00 A

00 A0 A0 A0 A0

4 4 4 4 04 04 04 40

A A A

00 A0 A0

040 A A0 A0

A 30 A A0 05A

40 033 40 032 40 031 40

05 4L 05 4L 05 LC

05 3L 4 53 LC 53 2L 04 LC 53 1L 04

3 C 3 C 3 3 C C 3 C

FG P/P FG P/P

NO.4 CARGO TANK NO.3 CARGO TANK NO.2 CARGO TANK NO.1 CARGO TANK

Printed by DSME 선장배관설계1 김두봉 2012- 02- 27 09:50

450

APCPCWM_4828539:WP_0000045WP_0000045

000

0_

P

5W

040

00

0_

P

:W

395

288

4_

DWG No. : 2297DA800D139 ( PAGE 9 / 50 )

M

W

C

P

C

P

A

200A

40 40 40 40 (H/N 2297/98/2400/01 CARDIFF 159,800M3 LNG CARRIER)

600A H * 0A 0A

40

0A 25A 0A 0A

A

00 CG002

# # # # AUXILIARIES INVOLVED

6 H

40

8L #

H

30

8L H

10

8

G H

20

8L H

10

8L

LNG VAPORIZER

450A CG512

CG511

A

C C C C C

600A

H

80 70

8L 068 058 OPERATING DURATION

A 500A NO.1 HD COMP. CG509 8L

C LC LC

LESS THAN 10 HOURS

C

FROM E/R CG516 A

40

CG527 600A HD

A H

500A CG515 H

600A A0 0A

CG520

HEATER

CG517 04 PERFORMANCE CRITERIA

CH CONTENT : LESS THAN 5% BY VOLUME AT TOP OF FILLING LINE.

450A BLIND 500A NO.2 HD COMP. CG513 80A (TARGET VALUE TO BE REVISED ACC. TO TERMINAL REQUIREMENT)

FLANGE 250A

VALVE

CG521 A A

NOTE

FUNCTION :

A A

TO GCU #

H

250A

200A H

* 00

2

CG534

H 600A

R

E

V

RE

V

R

E

V

O

R

E

V

(CONDITON/CHECK POINT)

- REPLACE INERT GAS IN CARGO TANKS BY EVAPORATED

-O O

-X - O

-

*

NATURAL GAS

CG636 70

4 CG538 CG536 200A CG501

NO.1 LD COMP. A0 X

. .R

X

.P X

.

A

G

C

CG504 A 55 Q

IL TS A

V

Q

IL CHECK POINT :

A 5 A A A

05 A0

*CG406 92

5 00 35G A

2 A A0 A0 A0

06 07

TO D/F # 2C 07

- CH AND CO2 CONTENT IN TANK BY SAMPLING AT TOP OF GAS

H

A G

C H 00 01

7

DOME AND SAMPLING LINES IN TANK

200A CG405 200A A NO.2 LD COMP. CG505

250A

# CG508 - OPERATING CONDITION OF LNG VAPORIZER

H

A

IN-LINE IN-LINE .P

CS504 MIXER ES

200A CG415

H A

FORCING VAP.

CG532

250A CG540 250A MIXER TIS A

80A

- MONITORING OF SAFETY DEVICE AND RELATED SENSORS

M VENT

40A CS528 CS529 250A N2 H

MAST A0 A0

40A 04

- TEMPERATURE OF SEA WATER AND ATMOSPHERE, ATMOSPHERE

40

A

A

CS520 A 24 PRESSURE

00 5G 12 DRAIN A0 A0 80 70 60 50

2 C 235

A

07 7L 7L 7L 7L

50A

A

S5C POT H SC 01 - TEMP. & PRESS. : CARGO TANK, INSULATION SPACES, COFFERDAM

# #

TO N2 SYS. C C C C

A

H A

LNG. VAP. 00 FOR INSU.SPACE

CS501 CG530 400A 482PRESSURIZATION

25A

250A A

00 460

#

H

40

7L #

H

30

7L #

H

017

G H

20

7L H

10

7L NECESSARY DEVICE :

5 C C C C C

G 2 GC A0 A0 A0 25A A0 A0 A A0

C 600A 04 04 04 04 550 07

LNG -PORTABLE CO2 METER, PORTABLE CH OR CH4 METER

A0 04 WARM NATURAL GAS

0 A 036

*) THIS MODE IS ONLY APPLIED WHEN TERMINAL DO NOT ACCEPT

10 6

20 A0 20 30

A0 6

6

G

C 03 00

6

6L

C A

56 CG605 G

C

0S

C H

* 10

0

G

INERT GAS TO RECEIVE INERT GAS.

G C

OTHERWISE SEE ‘GAS FILLING WITH GAS RETURN TO SHORE’.

5 C

200A 300A GAS MAIIN 300A

400A 600A VAPOR MAIN 500A

CS002 CG107

CL601

CS004

80A 80A STRIPPING/SPRAY MAIN 65A CS001

CS601

450A 600A LIQUID MAIN 450A 400A

CL107

CS603 01 41 01

CS415 * CS315 CL310 * 3S

C

3S

C CL210 * 2S

C CL110 *

A0 A

H H H H H H

CS416 CL410 CS408 CS404

4 CS316 CS308 CS304 04 CS208 CS108

A0 40A H * 144

SC

A0

4

A0

02

A

00 A

05 40A H * A

04 A0

02

A0

04

A0 40A

54 H *CS204 A0

4

A0

02

A0

04

A0 40A

54 * A

00 A

00 A

00 A

00 A

04

54 2

H

4 4 60 4 3 4

A

56

H

* *

H

5

40S

H

* *

H

5

30S

A0

4

*

H

5

20S

A0

4

CS104

1H

G

* 50

1

G

*

H

50

1S

C A C C C C C

200A 194 A 56 200A 193 A 200A A5 200A A5

SC 56 SC 56 6 6

064 20 063 20 6 20 6 20

A

00 A

00 A0 LC A5 024 184 4 A

00 A

00 A

00 LC 02 183 3 A0 A0 A0 02L 022 2 A0 A0 A0 01L 021 1

25A

3 3 04 50 6 SC SC 25A G

C 3 3 4 503 56A 3SC SC 25A G

C 03 03 04 C5 SC 25A G

C 03 03 04 C5 SC G

C 071

H* 10

4L * *

H

20

4L H

4L

C

* *

H H

064

10

4

*

H

10

3L * *

H

20

3L H LC * *

H H

063

10

3

*

H

10

2L * *

H

20

2L H

02

LC *

H

062

10

2

*

H

10

1L * *

H

20

1L H

01

LC *

H 10

1

SC

061

C C 004

10

4S

71

4S SC G C C 030 10

3S

71

3S SC G C C 020 10

2S SC G C C 010 10

1S G SC

C LC C LC C LC C A

LC C C 70

4S

A5 C C 70

3S

A

52 C 70

2S

A5 C 52

C 2 C C 2

A

00 A

00 A

00 A

00 A0 A0 A0 A0

4 4 4 4 04 04 04 40

A A A

00 A0 A0

040 A A0 A0

A 30 A A0 05A

40 033 40 032 40 031 40

05 4L 05 4L 05 LC

05 3L 4 53 LC 53 2L 04 LC 53 1L 04

3 C 3 C 3 3 C C 3 C

FG P/P FG P/P

NO.4 CARGO TANK NO.3 CARGO TANK NO.2 CARGO TANK NO.1 CARGO TANK

Printed by DSME 선장배관설계1 김두봉 2012- 02- 27 09:50

450

APCPCWM_4828539:WP_0000045WP_0000045

000

0_

P

5W

040

00

0_

P

:W

395

288

4_

DWG No. : 2297DA800D139 ( PAGE 10 / 50 )

M

W

C

P

C

P

A

200A (H/N 2297/98/2400/01 CARDIFF 159,800M3 LNG CARRIER)

* 40 40 40 40 40

600A H

0A 0A 0A 25A 0A 0A AUXILIARIES INVOLVED LNG VAPORIZER, HIGH DUTY COMPRESSOR

A

00 CG002

# # # #

6

40

8L # 30

8L H

10

8

G

20

8L

10

8L

OPERATING DURATION

H H H H

450A CG512

CG511

A

C C C C C

LESS THAN 10 HOURS AFTER 1ST STEP COMPLETION. OR

600A

H

LESS THAN 20 HOURS IF ACCEPTED DELETION OF 1ST STEP

80 70

8L 068 058

A 500A NO.1 HD COMP. CG509 8L

C LC LC

C

FROM E/R 600A 500A

CG516 A

40 PERFORMANCE CRITERIA CO2 CONTENT : LESS THAN 1% BY VOLUME

CG527 HD

A H

CG515 H

600A A0 0A

CG520

HEATER

CG517 04

450A BLIND 500A NO.2 HD COMP. CG513 80A NOTE FUNCTION :

FLANGE 250A

VALVE

CG521 A A

A A (CONDITON/CHECK POINT) - REPLACE INERT GAS IN CARGO TANKS BY EVAPORATED NATURAL

TO GCU #

H

250A

200A H

* 00

2

CG534

H 600A

R

E

V

RE

V

R

E

V

O

R

E

V

GAS

-O O

-X - O

-

CG636 *

A

70

4

G

CG538 CG536 200A

CG504 A

CG501

NO.1 LD COMP. A0

55

X

.

Q

IL

.R

TS

X

.P

A

X

.

Q

IL

CHECK POINT :

C V

A

- CH AND CO2 CONTENT IN TANK BY SAMPLING AT TOP OF GAS

A 5 05

A

A0

A

*CG406 92 00 35G A0 A0 A0 DOME AND SAMPLING LINES IN TANK

2

A

5 A 06 07

TO D/F # 2C 00 07 01

H

A G

C H

7 - OPERATING CONDITION OF LNG VAPORIZER & VR COMPRESSOR

200A CG405 200A A NO.2 LD COMP. CG505

250A

#

H

CS504

A CG508

IN-LINE IN-LINE .P

ES

- MONITORING OF SAFETY DEVICE AND RELATED SENSORS

MIXER

200A CG415

H A

FORCING VAP.

CG532

250A CG540 250A MIXER TIS A

80A

- TEMPERATURE OF SEA WATER AND ATMOSPHERE, ATMOSPHERE

M VENT

40A CS528 CS529 250A N2 H

MAST A0 A0

PRESSURE

40A 04 40

A

A

CS520 A 24 - TEMP. & PRESS. : CARGO TANK, INSULATION SPACES, COFFERDAM

00 5G 12 DRAIN A0 A0 80 70 60 50

2 C 235

A

07 7L 7L 7L 7L

50A

A

S5C POT H SC 01 NECESSARY DEVICE :

# 20 #

TO N2 SYS. C C C C

A

H A

LNG. VAP. 00 FOR INSU.SPACE

CS501 CG530 400A 482PRESSURIZATION

25A

250A A

00 460

#

H

40

7L #

H

30

7L #

H

017

G H 7L H

10

7L - PORTABLE CO2 METER, PORTABLE CH OR CH4 METER

5 C C C C C

G 2 GC A0 A0 A0 25A A0 A0 A A0 LNG

C 600A 04 04 04 04 550 07

A0 04 WARM NATURAL GAS

0 A 036

16

20 A0 20 30

*

INERT GAS

06 6

G 03 00 6L

A G 0S 10

0

A0 G C 6 C 56 CG605 C C H

G

C

5 C

200A 300A GAS MAIIN 300A

400A 600A VAPOR MAIN 500A

CS002 CG107

CL601

CS004

80A 80A STRIPPING/SPRAY MAIN 65A CS001

CS601

450A 600A LIQUID MAIN 450A 400A

CL107

CS603 01 41 01

CS415 * CS315 CL310 * 3S

C

3S

C CL210 * 2S

C CL110 *

A0 A

H H H H H H

CS416 CL410 CS408 CS404

4 CS316 CS308 CS304 04 CS208 CS108

A0 40A H * 144

SC

A0

4

A0

02

A

00 A

05 40A H * A

04 A0

02

A0

04

A0 40A

54 H *CS204 A0

4

A0

02

A0

04

A0 40A

54 * A

00 A

00 A

00 A

00 A

04

54 2

H

4 4 60 4 3 4

A

56

H

* *

H

5

40S

H

* *

H

5

30S

A0

4

*

H

5

20S

A0

4

CS104

1H

G

* 50

1

G

*

H

50

1S

C A C C C C C

200A 194 A 56 200A 193 A 200A A5 200A A5

SC 56 SC 56 6 6

064 20 063 20 6 20 6 20

A

00 A

00 A0 LC A5 024 184 4 A

00 A

00 A

00 LC 02 183 3 A0 A0 A0 02L 022 2 A0 A0 A0 01L 021 1

25A

3 3 04 50 6 SC SC 25A G

C 3 3 4 503 56A 3SC SC 25A G

C 03 03 04 C5 SC 25A G

C 03 03 04 C5 SC G

C 071

H* 10

4L * *

H

20

4L H

4L

C

* *

H H

064

10

4

*

H

10

3L * *

H

20

3L H LC * *

H H

063

10

3

*

H

10

2L * *

H

20

2L H

02

LC *

H

062

10

2

*

H

10

1L * *

H

20

1L H

01

LC *

H 10

1

SC

061

C C 004

10

4S

71

4S SC G C C 030 10

3S

71

3S SC G C C 020 10

2S SC G C C 010 10

1S G SC

C LC C LC C LC C A

LC C C 70

4S

A5 C C 70

3S

A

52 C 70

2S

A5 C 52

C 2 C C 2

A

00 A

00 A

00 A

00 A0 A0 A0 A0

4 4 4 4 04 04 04 40

A A A

00 A0 A0

040 A A0 A0

A 30 A A0 05A

40 033 40 032 40 031 40

05 4L 05 4L 05 LC

05 3L 4 53 LC 53 2L 04 LC 53 1L 04

3 C 3 C 3 3 C C 3 C

FG P/P FG P/P

NO.4 CARGO TANK NO.3 CARGO TANK NO.2 CARGO TANK NO.1 CARGO TANK

Printed by DSME 선장배관설계1 김두봉 2012- 02- 27 09:50

450

APCPCWM_4828539:WP_0000045WP_0000045

000

0_

P

5W

040

00

0_

P

:W

395

288

4_

DWG No. : 2297DA800D139 ( PAGE 11 / 50 )

M

W

C

P

C

P

A

200A

(H/N 2297/98/2400/01 CARDIFF 159,800M3 LNG CARRIER)

* 40 40 40 40 40

600A H

0A 0A 0A 25A 0A 0A

A CG002 # # # AUXILIARIES INVOLVED

00 # 40 # 30 10 20 10

HD COMPRESSOR BY PASS LINE, HD HEATER, LNG VAPORIZER

6 H 8L H 8L H 8

G H 8L H 8L

450A CG512

CG511

A

C C C C C

600A

H

80 70

8L 068 058 OPERATING DURATION NO TIME LIMIT

A 500A NO.1 HD COMP. CG509 8L

C LC LC

C

FROM E/R CG516 A

40

CG527 600A HD

A H

500A CG515 H

600A A0 0A

CG520

HEATER

CG517 04 PERFORMANCE CRITERIA CO2 CONTENT : LESS THAN 1% BY VOLUME

450A BLIND 500A NO.2 HD COMP. CG513 80A

FLANGE 250A

VALVE

CG521 A A NOTE

FUNCTION :

A A

TO GCU #

H

250A

200A H

* 00

2

CG534

H 600A

R

E

V

RE

V

R

E

V

O

R

E

V (CONDITON/CHECK POINT)

-O O

-X - O

-

- REPLACE INERT GAS IN CARGO TANKS BY EVAPORATED NATURAL

CG636 *

A

70

4

G

CG538 CG536 200A

CG504 A

CG501

NO.1 LD COMP. A0

55

X

.

Q

IL

.R

TS

X

.P

A

X

.

Q

IL

GAS

C V

A 5 A A A

05 A0

CHECK POINT :

*CG406 92

5 00 35G A

2 A A0 A0 A0

06 07

TO D/F # 2C 00 07 01

H

A G

C H - CH AND CO2 CONTENT IN TANK BY SAMPLING AT TOP OF GAS

7 DOME AND SAMPLING LINES IN TANK

200A CG405 200A A NO.2 LD COMP. CG505

250A

#

H

CS504

A CG508

IN-LINE IN-LINE .P

ES

- OPERATING CONDITION OF LNG VAPORIZER & VR COMPRESSOR

CG532 CG540 MIXER

200A CG415

H A

250A 250A MIXER TIS A

FORCING VAP.

M VENT 80A - MONITORING OF SAFETY DEVICE AND RELATED SENSORS

40A CS528 CS529 250A N2 H

MAST A0 A0

40A 04 40

A

A

- TEMPERATURE OF SEA WATER AND ATMOSPHERE, ATMOSPHERE

CS520 A 24

00 5G 12 DRAIN A0 A0 80 70 60 50

PRESSURE

2 C 235

A

07 7L 7L 7L 7L

50A

A

S5C POT H SC 01

# #

TO N2 SYS. C C C C

A

H A - TEMP. & PRESS. : CARGO TANK, INSULATION SPACES, COFFERDAM

LNG. VAP. 00 FOR INSU.SPACE

CS501 CG530 400A 482PRESSURIZATION

25A

250A A

00 460

#

H

40

7L #

H

30

7L #

H

017

G H

20

7L H

10

7L NECESSARY DEVICE :

5 C C C C C LNG

G 2 GC A0 A0 A0 25A A0 A0 A A0

C 600A 04 04 04 04 550 07

04

WARM NATURAL GAS - PORTABLE CO2 METER, PORTABLE CH OR CH4 METER

A0

0 A 036

MIXED GAS(INERT GAS &

16

20 A0 20 30

A0

06 6

G

C 03 00

6

6L

C A

56 CG605 G

C

0S

C H

* 10

0

G

NATURAL GAS)

G C

5 C

200A 300A GAS MAIIN 300A

400A 600A VAPOR MAIN 500A

CS002 CG107

CL601

CS004

80A 80A STRIPPING/SPRAY MAIN 65A CS001

CS601

450A 600A LIQUID MAIN 450A 400A

CL107

CS603 01 41 01

CS415 * CS315 CL310 * 3S

C

3S

C CL210 * 2S

C CL110 *

A0 A

H H H H H H

CS416 CL410 CS408 CS404

4 CS316 CS308 CS304 04 CS208 CS108

A0 40A H * 144

SC

A0

4

A0

02

A

00 A

05 40A H * A

04 A0

02

A0

04

A0 40A

54 H *CS204 A0

4

A0

02

A0

04

A0 40A

54 * A

00 A

00 A

00 A

00 A

04

54 2

H

4 4 60 4 3 4

A

56

H

* *

H

5

40S

H

* *

H

5

30S

A0

4

*

H

5

20S

A0

4

CS104

1H

G

* 50

1

G

*

H

50

1S

C A C C C C C

200A 194 A 56 200A 193 A 200A A5 200A A5

SC 56 SC 56 6 6

064 20 063 20 6 20 6 20

A

00 A

00 A0 LC A5 024 184 4 A

00 A

00 A

00 LC 02 183 3 A0 A0 A0 02L 022 2 A0 A0 A0 01L 021 1

25A

3 3 04 50 6 SC SC 25A G

C 3 3 4 503 56A 3SC SC 25A G

C 03 03 04 C5 SC 25A G

C 03 03 04 C5 SC G

C 071

H* 10

4L * *

H

20

4L H

4L

C

* *

H H

064

10

4

*

H

10

3L * *

H

20

3L H LC * *

H H

063

10

3

*

H

10

2L * *

H

20

2L H

02

LC *

H

062

10

2

*

H

10

1L * *

H

20

1L H

01

LC *

H 10

1

SC

061

C C 004

10

4S

71

4S SC G C C 030 10

3S

71

3S SC G C C 020 10

2S SC G C C 010 10

1S G SC

C LC C LC C LC C A

LC C C 70

4S

A5 C C 70

3S

A

52 C 70

2S

A5 C 52

C 2 C C 2

A

00 A

00 A

00 A

00 A0 A0 A0 A0

4 4 4 4 04 04 04 40

A A A

00 A0 A0

040 A A0 A0

A 30 A A0 05A

40 033 40 032 40 031 40

05 4L 05 4L 05 LC

05 3L 4 53 LC 53 2L 04 LC 53 1L 04

3 C 3 C 3 3 C C 3 C

FG P/P FG P/P

NO.4 CARGO TANK NO.3 CARGO TANK NO.2 CARGO TANK NO.1 CARGO TANK

Printed by DSME 선장배관설계1 김두봉 2012- 02- 27 09:50

450

APCPCWM_4828539:WP_0000045WP_0000045

000

0_

P

5W

040

00

0_

P

:W

395

288

4_

DWG No. : 2297DA800D139 ( PAGE 12 / 50 )

M

W

C

P

C

P

A

200A

(H/N 2297/98/2400/01 CARDIFF 159,800M3 LNG CARRIER)

* 40 4 40 004 004

600A H

0A 0A0 0A 25A A A

A

00 CG002

# # # # AUXILIARIES INVOLVED HIGH DUTY COMPRESSORS

6 H

40

8L #

H

30

8L H

10

8

G H

20

8L H

10

8L

450A CG512

CG511

A

C C C C C

600A

H

80 70

8L 60 50 OPERATING DURATION LESS THAN 10 HOURS

A 500A NO.1 HD COMP. CG509 8L

C

8L 8L

C C C

FROM E/R CG516 A

40

CG527 600A A H

500A CG515

600A A0 0A

PERFORMANCE CRITERIA AVERAGE TEMPERATURE IN CARGO TANK : BELOWER THAN -130℃

H

HD

CG520

HEATER

CG517 04

450A BLIND 500A NO.2 HD COMP. CG513 80A

FLANGE 250A

VALVE

CG521 A A NOTE FUNCTION :

A A

TO GCU #

H

250A

200AH

* 00

2

CG534

H 600A

R

E

V

RE

V

R

E

V

O

R

E

V (CONDITON/CHECK POINT) - COOLING DOWN CARGO TANKS BY LNG SPRAYING IN ORDER TO :

1) AVOID THERMAL SHOCK ON HEAVY STRUCTURE SUCH AS PUMP

-O O

-X - -O

CG636 *

A

70

4

G

CG538 CG536200A

CG504 A

CG501

NO.1 LD COMP. A0

55

X

.

Q

IL

.R

TS

X

.P

A

X

.

Q

IL

TOWER AND EQUIPMENT.

2) LIMIT THE AMOUNT OF VAPOR DURING LNG LOADING.

C V

A 5 A A

A

05 A0

*CG406 92

5 00 35G A

2 A A0 A0 A0

06 07 CHECK POINT :

TO D/F # 2C 00 07 01

H

A G

C H

7 - OPERATING CONDITION OF HD COMPRESSORS.

200A CG405 200A A NO.2 LD COMP. CG505

250A

#

H

CS504

A CG508

IN-LINE IN-LINE .P

ES

- MONITORING OF SAFETY DEVICE AND RELATED SENSORS

CG532 CG540 MIXER

200A

H A

250A 250A MIXER TS - TEMPERATURE OF SEA WATER AND ATMOSPHERE, ATMOSPHERE

CG415 FORCING VAP. IM A

VENT 80A

40A CS528 CS529 250A N2 H

MAST A0 A0 PRESSURE

A

40A A

04 04

CS520 A 2

4 - TEMP. & PRESS. : CARGO TANK, INSULATION SPACES, COFFERDAM

00 5G 12 DRAIN A0 A0 80 70 067 057

2 C 32

A

5S POT H 07 7L 7L

50A

A

5S 01 LC LC

NECESSARY DEVICE :

# #

TO N2 SYS. C C C

A

H A

C

LNG. VAP. 0 FOR INSU.SPACE

CS501 CG530 400A 04 PRESSURIZATION

82 25A

250A A

00 406

#

H

40

7L #

H

30

7L #

H

10

7

G H

20

7L H

017

LC

LNG

- PORTABLE INSTRUMENT IS NOT REQUIRED

5

G 2 GC A

C

A0

C

A0 25A

C C

00A A0 A0 COLD NATURAL GAS

C 600A 040 04 04 00A 4 55 07 *) AVERAGE TEMPERATURE : GTT DEFINED THAT AVERAGE

A

00 4 TEMPERATURE SHOULD BE CALCULATED BY FOUR LOWER

A 30

16

20 A 20 30 TEMPERATURE SENSORS ALONG PUMP TOWER

A0

06 6

G

C

00

3

00

6

6L

C A

56 CG605

6

G

C

S0C *

H

10

0

G

G C

5 C

200A 300A GAS MAIIN 300A

400A 600A VAPOR MAIN 500A

CS002 CG107

CL601

CS004

80A 80A STRIPPING/SPRAY MAIN 65A CS001

CS601

450A 600A LIQUID MAIN 450A 400A

CL107

CS603 01 41 01

CS415 * CS315 CL310 * 3S

C

3S

C CL210 * 2S

C CL110 *

A0 A

H H H H H H

CS416 CL410 CS408 CS404

4 CS316 CS308 CS304 04 CS208 CS108

A 40A * 144 A0 A0 A

0 A

05 40A * A

04 A

00 A0 A0 40A *CS204 A0 00A A0 A0 40A * A0 A

00 A

00 A

0 A

04

540 4 02 40 04 54 4 04 54 04 40

H H H

S 2 2

H

3 2

* * 4 * * * *

A

56

H

C

H

5

04

SC

H

H

5

03

SC

A0

4 H

5

02

SC

A0

4

CS104

G

*

061 H 051

G H

50

S1C

91 A A 91 A A5 C C

200A 4S 5 56 200A 3S 5 200A 200A 56A

60 C6 20 60 C 6 20 6 6 20 60 20

A A

00 A0 4L

A5 204 81 4 A A

00 A

00 3LC 20 81 3 00A A0 A0 20L 20 2 A0 A 00A LC

1 20 1

00

3 3 04 C

6 SC 4S 25A G

C

00

3 3 4 053

A

56 3SC 3S 25A G

C 3 03 04 C5 2S 25A G

C 03 030 4 051 1S G

C 7025A

054

*

H

10

4L * *

H

20

4L H LC * *

H H

C

60 014 *

H

10

3L * *

H

20

3L H LC * *

H H

C

60 013 *

H

10

2L * *

H

20

2L H

02

LC *

H

C

60 012 *

H

10

1L * *

H

20

1L H LC *

H

C

011

1S

C 60

C C 00 10

4S

71

4S

4S G C C 003 10

3S

71

3S

3S G C C 002 10

2S

2S G C C 001 10

1S G 1S

4L C C LC C C LC C C LC C A C

C C 70 A C C 70 A

52 C 70 A5 C 52

C 4S

C 25 3S

C

2S

C 2

A

00 A

00 A

00 A

00 A0 A0 A0 A0

4 4 4 4 04 04 04 04

A0 00A A A0

A A A0 040 A0

A0 30 044 A 30 40 A0 30 40 A0 30 40

53 4L 05 LC

04 05 3L 05 3L 4 53 2L 53 2L 53 1L 53 1L 04

C 3 3 C 3 C C C C C

FG P/P FG P/P

NO.4 CARGO TANK NO.3 CARGO TANK NO.2 CARGO TANK NO.1 CARGO TANK

Printed by DSME 선장배관설계1 김두봉 2012- 02- 27 19:09

450

APCPCWM_4828539:WP_0000045WP_0000045

000

0_

P

5W

040

00

0_

P

:W

395

288

4_

DWG No. : 2297DA800D139 ( PAGE 13 / 50 )

M

W

C

P

C

P

A

200A

40 4 (H/N 2297/98/2400/01 CARDIFF 159,800M3 LNG CARRIER)

600A H * 0A 0A0

40

0A 25A 004 004

A A

A

00 CG002

# # # # AUXILIARIES INVOLVED HIGH DUTY COMPRESSORS

6 H

40

8L #

H

30

8L H

10

8

G H

20

8L H

10

8L

450A CG512

CG511

A

C C C C C

600A

H

80 70 60 50 OPERATING DURATION LESS THAN 12 HOURS EXCLUDING SLOW STARTING

A 500A NO.1 HD COMP. CG509 8L 8L 8L 8L AND TOPPING OFF

C C C C

FROM E/R CG516 A

40

CG527 600A HD

A H

500A CG515 H

600A A0 0A

CG520

HEATER

CG517 04 PERFORMANCE CRITERIA CARGO TANK FILLING : 98.0 % IN VOLUME

450A BLIND 500A NO.2 HD COMP. CG513 80A

FLANGE 250A

VALVE

CG521 A A NOTE FUNCTION :

A A

TO GCU #

H

250A

200AH

* 00

2

CG534

H 600A

R

E

V

RE

V

R

E

V

O

R

E

V (CONDITON/CHECK POINT) - LOADING LNG SUPPLIED FROM SHORE

-O O

-X - -O

CG636 * 70

4 CG538 CG536200A

CG504

CG501

NO.1 LD COMP. A0

55

X

.

Q

.R

X

.P X

.

Q

IL

G IL A CHECK POINT :

A

C

A TS V

A 5 A A

A

05 A0

*CG406 92

5 00 35G A

2 A A0 A0 A0

06 07 - OPERATING CONDITION OF HD COMPRESSORS.

TO D/F # 2C 00 07 01

H

A G

C H

7 - MONITORING OF SAFETY DEVICE AND RELATED SENSORS

200A CG405 200A A NO.2 LD COMP. CG505

250A

#

H

CS504

A CG508

IN-LINE IN-LINE .P

ES - TEMPERATURE OF SEA WATER AND ATMOSPHERE, ATMOSPHERE

CG532 CG540 MIXER

250A MIXER TS PRESSURE

200A CG415

H A

FORCING VAP. 250A IM A

80A

VENT

40A CS528 CS529 250A N2 H

MAST A0 A0 - TEMP. & PRESS. : CARGO TANK, INSULATION SPACES, COFFERDAM

A

40A A

04 04

CS520 A 2

00 5G4

A0 067 057

- CUSTODY TRANSFER SYSTEM

A

2 C 12 DRAIN 32 A0 80

7L

70

7L

50A

A 5S POT H 5S 07 01 LC LC

# # - DEBALLASTING CONDITION

TO N2 SYS. C C C

A

H A

C

LNG. VAP. 0 FOR INSU.SPACE

CS501 CG530 400A 04 PRESSURIZATION

82 25A

250A A

00 406

#

H

40

7L #

H

30

7L #

H

10

7

G H

20

7L H

017

LC

5 2 GC C C C C

G A A0 A0 25A 00A A0 A0 LNG NECESSARY DEVICE :

C 600A 040 04 04 00A 4 55 07

A

00 4 NATURAL GAS -PORTABLE OXYGEN DETECTOR, PORTABLE CH OR CH4 METER.

A 30

16

20 A 20 30

A0

06 6

G

C

00

3

00

6

6L

C A

56 CG605

6

G

C

S0C *

H

10

0

G

G C

5 C

200A 300A GAS MAIIN 300A

400A 600A VAPOR MAIN 500A

CS002 CG107

CL601

CS004

80A 80A STRIPPING/SPRAY MAIN 65A CS001

CS601

450A 600A LIQUID MAIN 450A 400A

CL107

CS603 01 41 01

CS415 * CS315 CL310 * 3S

C

3S

C CL210 * 2S

C CL110 *

A0 A

H H H H H H

CS416 CL410 CS408 CS404

4 CS316 CS308 CS304 04 CS208 CS108

A 40A * 144 A0 A0 A

0 A

05 40A * A

04 A

00 A0 A0 40A *CS204 A0 00A A0 A0 40A * A0 A

00 A

00 A

0 A

04

540 4 02 40 04 54 4 04 54 04 40

H H H

S 2 2

H

3 2

* * 4 * * * *

A

56

H

C

H

5

04

SC

H

H

5

03

SC

A0

4 H

5

02

SC

A0

4

CS104

G

*

061 H 051

G H

50

S1C

91 A A 91 A A5 C C

200A 4S 5 56 200A 3S 5 200A 200A 56A

60 C6 20 60 C 6 20 6 6 20 60 20

A A

00 A0 4L

A5 204 81 4 A A

00 A

00 3LC 20 81 3 00A A0 A0 20L 20 2 A0 A 00A LC

1 20 1

00

3 3 04 C

6 SC 4S 25A G

C

00

3 3 4 053

A

56 3SC 3S 25A G

C 3 03 04 C5 2S 25A G

C 03 030 4 051 1S G

C 7025A

054

*

H

10

4L * *

H

20

4L H LC * *

H H

C

60 014 *

H

10

3L * *

H

20

3L H LC * *

H H

C

60 013 *

H

10

2L * *

H

20

2L H

02

LC *

H

C

60 012 *

H

10

1L * *

H

20

1L H LC *

H

C

011

1S

C 60

C C 00 10

4S

71

4S

4S G C C 003 10

3S

71

3S

3S G C C 002 10

2S

2S G C C 001 10

1S G 1S

4L C C LC C C LC C C LC C A C

C C 70 A C C 70 A

52 C 70 A5 C 52

C 4S

C 25 3S

C

2S

C 2

A

00 A

00 A

00 A

00 A0 A0 A0 A0

4 4 4 4 04 04 04 04

A0 00A A A0

A A A0 040 A0

A0 30 044 A 30 40 A0 30 40 A0 30 40

53 4L 05 LC

04 05 3L 05 3L 4 53 2L 53 2L 53 1L 53 1L 04

C 3 3 C 3 C C C C C

FG P/P FG P/P

NO.4 CARGO TANK NO.3 CARGO TANK NO.2 CARGO TANK NO.1 CARGO TANK

Printed by DSME 선장배관설계1 김두봉 2012- 02- 27 19:09

450

APCPCWM_4828539:WP_0000045WP_0000045

000

0_

P

5W

040

00

0_

P

:W

395

288

4_

DWG No. : 2297DA800D139 ( PAGE 14 / 50 )

M

W

C

P

C

P

A

200A

(H/N 2297/98/2400/01 CARDIFF 159,800M3 LNG CARRIER)

* 40 4 40 004 004

600A 0A 0A0 0A 25A AUXILIARIES INVOLVED LOW DUTY COMPRESSORS, HD HEATER

H

A A

A

00 CG002

# # # # AFTER COOLER/NG HEATER

6 H

40

8L #

H

30

8L H

10

8

G H

20

8L H

10

8L

450A CG512

CG511

A

C C C C C

600A OPERATING DURATION -

H

80 70 60 50

A 500A NO.1 HD COMP. CG509 8L 8L 8L 8L

C C C C

FROM E/R CG516 A

40 MAINTAIN CARGO TANK PRESSURE

CG527 600A HD

A H

500A CG515 H

600A A0 0A PERFORMANCE CRITERIA APPLY TO FUEL GAS MODE ONLY

CG520

HEATER

CG517

500A NO.2 HD COMP.

04 GCU OPERATION TEMPERATURE : 0 - 100℃

450A BLIND CG513 80A

FLANGE 250A NOTE FUNCTION :

VALVE

CG521 A A

A A

(CONDITON/CHECK POINT) - BOIL OFF GAS BURNING AS FUEL IN DFDE & GCU

TO GCU #

H

250A

200AH

* 00

2

CG534

H 600A

R

E

V

RE

V

R

E

V

O

R

E

V

-O O

-X - -O

CG636 * 70 CG538 CG536200A CG501 A0 X

. .R

X

.P X

.

CHECK POINT :

4 CG504 NO.1 LD COMP. 55 Q Q

IL

A

G

C

A IL TS A

A

V - OPERATING CONDITION OF LD COMPRESSORS & HD HEATER

A 5 05

A

A0

A

*CG406 92

5 00 35G A

2 A A0 A0 A0

06 07 - MONITORING OF SAFETY DEVICE AND RELATED SENSORS.

TO D/F # 2C 00 07 01

H

A G

C H

7

200A CG405 200A NO.2 LD COMP. CG505 - TEMPERATURE OF SEA WATER AND ATMOSPHERE, ATMOSPHERE

250A

A

#

H

CS504

A CG508

IN-LINE IN-LINE .P

ES

PRESSURE

CG532 CG540 MIXER

200A

H A

250A 250A MIXER TS - TEMP. & PRESS. : CARGO TANK, INSULATION SPACES, COFFERDAM

CG415 FORCING VAP. IM A

VENT 80A

40A CS528 CS529 250A N2 H

MAST A0 A0

A

40A A

04 04

CS520 A 2

4 NECESSARY DEVICE :

00 5G 12 DRAIN A0 A0 80 70 067 057

2 C 32

A

5S POT H 07 7L 7L

50A

A

5S 01 LC LC -PORTABLE INSTRUMENT IS NOT REQUIRED

# # SEPARATOR DRAIN

TO N2 SYS. C C C

A

H A

C

LNG. VAP. 0 FOR INSU.SPACE

CS501 CG530 400A 04 PRESSURIZATION

82 25A

250A A

00 406

#

H

40

7L #

H

30

7L #

H

10

7

G H

20

7L H

017

LC

5 2 GC C C C C COLD NATURAL GAS

G A A0 A0 25A 00A A0 A0

C 600A 040 04 04 00A 4 55 07

A

00 4 WARM NATURAL GAS

A 30

16

20 A 20 30

A0

06 6

G

C

00

3

00

6

6L

C A

56 CG605

6

G

C

S0C *

H

10

0

G

WHEN LOAD CHANGE

G C

5 C

200A 300A GAS MAIIN 300A

400A 600A VAPOR MAIN 500A

CS002 CG107

CL601

CS004

80A 80A STRIPPING/SPRAY MAIN 65A CS001

CS601

450A 600A LIQUID MAIN 450A 400A

CL107

CS603 01 41 01

CS415 * CS315 CL310 * 3S

C

3S

C CL210 * 2S

C CL110 *

A0 A

H H H H H H

CS416 CL410 CS408 CS404

4 CS316 CS308 CS304 04 CS208 CS108

A 40A * 144 A0 A0 A

0 A

05 40A * A

04 A

00 A0 A0 40A *CS204 A0 00A A0 A0 40A * A0 A

00 A

00 A

0 A

04

540 4 02 40 04 54 4 04 54 04 40

H H H

S 2 2

H

3 2

* * 4 * * * *

A

56

H

C

H

5

04

SC

H

H

5

03

SC

A0

4 H

5

02

SC

A0

4

CS104

G

*

061 H 051

G H

50

S1C

91 A A 91 A A5 C C

200A 4S 5 56 200A 3S 5 200A 200A 56A

60 C6 20 60 C 6 20 6 6 20 60 20

A A

00 A0 4L

A5 204 81 4 A A

00 A

00 3LC 20 81 3 00A A0 A0 20L 20 2 A0 A 00A LC

1 20 1

00

3 3 04 C

6 SC 4S 25A G

C

00

3 3 4 053

A

56 3SC 3S 25A G

C 3 03 04 C5 2S 25A G

C 03 030 4 051 1S G

C 7025A

054

*

H

10

4L * *

H

20

4L H LC * *

H H

C

60 014 *

H

10

3L * *

H

20

3L H LC * *

H H

C

60 013 *

H

10

2L * *

H

20

2L H

02

LC *

H

C

60 012 *

H

10

1L * *

H

20

1L H LC *

H

C

011

1S

C 60

C C 00 10

4S

71

4S

4S G C C 003 10

3S

71

3S

3S G C C 002 10

2S

2S G C C 001 10

1S G 1S

4L C C LC C C LC C C LC C A C

C C 70 A C C 70 A

52 C 70 A5 C 52

C 4S

C 25 3S

C

2S

C 2

A

00 A

00 A

00 A

00 A0 A0 A0 A0

4 4 4 4 04 04 04 04

A0 00A A A0

A A A0 040 A0

A0 30 044 A 30 40 A0 30 40 A0 30 40

53 4L 05 LC

04 05 3L 05 3L 4 53 2L 53 2L 53 1L 53 1L 04

C 3 3 C 3 C C C C C

FG P/P FG P/P

NO.4 CARGO TANK NO.3 CARGO TANK NO.2 CARGO TANK NO.1 CARGO TANK

Printed by DSME 선장배관설계1 김두봉 2012- 02- 27 19:09

450

APCPCWM_4828539:WP_0000045WP_0000045

000

0_

P

5W

040

00

0_

P

:W

395

288

4_

DWG No. : 2297DA800D139 ( PAGE 15 / 50 )

M

W

C

P

C

P

A

200A

(H/N 2297/98/2400/01 CARDIFF 159,800M3 LNG CARRIER)

* 40 4 40 004 004

600A H

0A 0A0 0A 25A A A

A CG002 # # # AUXILIARIES INVOLVED LOW DUTY COMPRESSOR AND AFTER COOLER/NG HEATER

00 # 40

# 30 10 20 10

6 H 8L H 8L H 8

G H 8L H 8L

450A CG512

CG511

A

C C C C C

600A

H

80 70

8L 60 50 OPERATING DURATION -

A 500A NO.1 HD COMP. CG509 8L

C

8L 8L

C C C

FROM E/R CG516 A

40 MAINTAIN CARGO TANK PRESSURE BETWEEN PRESET PRESSURE

CG527 600A HD

A H

500A CG515 H

600A A0 0A PERFORMANCE CRITERIA RANGE (MAINTAIN CARGO TANK PRESSURE TO MIN. 5 kPa)

CG520

HEATER

CG517 04 APPLY TO FUEL GAS MODE OR DUEL FUEL MODE

450A BLIND 500A NO.2 HD COMP. CG513 80A

FLANGE 250A FUNCTION :

VALVE

CG521 A A NOTE

A A

- BOIL OFF GAS BURNING AS FUEL

TO GCU #

H

250A

200AH

* 00

2

CG534

H 600A

R

E

V

RE

V

R

E

V

O

R

E

V (CONDITON/CHECK POINT)

-O O

-X - -O CHECK POINT :

CG636 *

A

70

4

G

CG538 CG536200A

CG504

CG501

NO.1 LD COMP. A0

55

X

.

Q

IL

.R

TS

X

.P

A

X

.

Q

IL

- OPERATING CONDITION OF LD COMPRESSOR &

A

C V

A 5 A A

A

05 A0 AFTER COOLER/ NG HEATER

*CG406 92

5 00 35G A

2 A A0 A0 A0

06 07

TO D/F # 2C 00 07 01

A G

H C H

7 - MONITORING OF SAFETY DEVICE AND RELATED SENSORS.

200A CG405 200A A NO.2 LD COMP. CG505

250A

# A CG508

.P - TEMPERATURE OF SEA WATER AND ATMOSPHERE, ATMOSPHERE

H IN-LINE IN-LINE ES PRESSURE

CS504 CG540 MIXER

CG532 250A MIXER TS

200A CG415

H A

250A IM A

80A

40A

FORCING VAP. VENT - TEMP. & PRESS. : CARGO TANK, INSULATION SPACES, COFFERDAM

CS528 CS529 250A 40A N2 H

MAST A0 A0

04 04

A

A

CS520 A 2

4 NECESSARY DEVICE :

00 5G 12 DRAIN A0 A0 80 70 067 057

2 C 32

A

50A

A 5S POT H 5S 07 01 7L 7L LC LC LNG - PORTABLE INSTRUMENT IS NOT REQUIRED

# #

TO N2 SYS. C C C

A

H A

C

LNG. VAP. 0 FOR INSU.SPACE

CS501 CG530 400A 04 PRESSURIZATION

82 25A

250A A

00 406

#

H

40

7L #

H

30

7L #

H

10

7

G H

20

7L H

017

LC

SEPARATOR DRAIN *) VENTING MODE THROUGH GAS MAIN :

5 C C C C -IF FUEL DEMAND IN DFDE IS TOO LOW

G 2 GC A A0 A0 25A 00A A0 A0 COLD NATURAL GAS

C 600A 040 04 04 00A 4 55 07 -IF GCU IS NOT OPERATED

-IF ALLOWED AND AT OPEN SEA

A

00 4 WARM NATURAL GAS

16

20 A A 20 30 30 THE FUEL GAS PUMP IS ALWAYS RUNNING, BUT CAN BE STOPPED

A0

06 6

G

C

00

3

00

6

6L

C A

56 CG605

6

G

C

S0C *

H

10

0

G

WHEN LOAD CHANGE WHEN THE TEMPERATURE IS PROPER.

G C

5 C

200A 300A GAS MAIIN 300A

400A 600A VAPOR MAIN 500A

CS002 CG107

CL601

CS004

80A 80A STRIPPING/SPRAY MAIN 65A CS001

CS601

450A 600A LIQUID MAIN 450A 400A

CL107

CS603 01 41 01

CS415 * CS315 CL310 * 3S

C

3S

C CL210 * 2S

C CL110 *

A0 A

H H H H H H

CS416 CL410 CS408 CS404

4 CS316 CS308 CS304 04 CS208 CS108

A 40A * 144 A0 A0 A

0 A

05 40A * A

04 A

00 A0 A0 40A *CS204 A0 00A A0 A0 40A * A0 A

00 A

00 A

0 A

04

540 4 02 40 04 54 4 04 54 04 40

H H H

S 2 2

H

3 2

* * 4 * * * *

A

56

H

C

H

5

04

SC

H

H

5

03

SC

A0

4 H

5

02

SC

A0

4

CS104

G

*

061 H 051

G H

50

S1C

91 A A 91 A A5 C C

200A 4S 5 56 200A 3S 5 200A 200A 56A

60 C6 20 60 C 6 20 6 6 20 60 20

A A

00 A0 4L

A5 204 81 4 A A

00 A

00 3LC 20 81 3 00A A0 A0 20L 20 2 A0 A 00A LC

1 20 1