Documente Academic

Documente Profesional

Documente Cultură

IEEE Power Factor Table for NEMA Motor Capacitor Ratings

Încărcat de

ing.dmanriq27Descriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

IEEE Power Factor Table for NEMA Motor Capacitor Ratings

Încărcat de

ing.dmanriq27Drepturi de autor:

Formate disponibile

IEEE

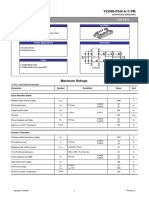

POWER FACTOR AND RELATED CONSIDERATIONS Std 141-1993

Table 8-5-Suggested capacitor ratings, in kilovars,

for NEMA Design C, D, and wound-rotor motors

Design C motor

Induction

motor rating 1800 and 1200 Design D motor Wound-rotor

(hp) r/min 900 r/min 1200 r/min motor

15 5 5 5 5.5

20 5 6 6 7

25 6 6 6 7

30 7.5 9 10 11

40 10 12 12 13

50 12 15 15 17.5

60 17.5 18 18 20

75 19 22.5 22.5 25

100 27 27 30 33

125 35 37.5 37.5 40

150 37.5 45 45 50

200 45 60 60 65

250 54 70 70 75

300 65 90 75 85

NOTE-Applies to three-phase, 60 Hz motors when switched with capacitors as single unit.

b) Continuous operation at 135% of the unit's rated reactive power, including both fun-

damental and harmonic voltages.

c) Continuous operation at 110% of rated terminal voltages.

d) Operating voltage, including harmonics, is 120%.

e) Continuous operation at 180% of rated rms current at one-per-unit voltage. If capaci-

tors are operating close to this limit, the manufacturer should be consulted regarding

fuse selection.

f) Ambient temperature limits depend upon the mounting arrangements and, hence, the

ventilation. The range of 24-hour ambient temperatures is from 35 ºC in enclosed

equipment to 46 ºC for isolated units in open mountings. The minimum ambient tem-

perature is - 40 ºC.

8.10.2 Maximum voltage

Many power capacitors have the ability to operate above their voltage rating for very short

periods of time. This type of application is sometimes used as a local source of reactive power

to control voltage drops during motor start-up. The capacitors are disconnected as the motor

comes up to speed. Wherever capacitors are to be operated above their voltage rating, how-

ever, the application should be referred to the capacitor manufacturer. It should be noted that

overvoltage is the major reason for capacitor failure. Also, see 9.8.2.4 of Chapter 9.

423

S-ar putea să vă placă și

- Kub2015 PDFDocument44 paginiKub2015 PDFWai MinÎncă nu există evaluări

- PowerTips - Motor Starting and Running Currents and Rating Guide PDFDocument14 paginiPowerTips - Motor Starting and Running Currents and Rating Guide PDFankur yadavÎncă nu există evaluări

- Induction Generator - 100255KDocument25 paginiInduction Generator - 100255KChamath Kirinde100% (1)

- Lintels and Arches 2Document60 paginiLintels and Arches 2Aravind SPÎncă nu există evaluări

- Soft Starters for Induction Motors ExplainedDocument9 paginiSoft Starters for Induction Motors ExplainedDũng DungÎncă nu există evaluări

- Motor Cable Size & RatingDocument2 paginiMotor Cable Size & RatingGAGAN100% (1)

- 3406 Marine Engine PDFDocument2 pagini3406 Marine Engine PDFHamilton Miranda50% (4)

- Fan Vanco CatalogueDocument24 paginiFan Vanco CatalogueYizhar Bechamel MestokoÎncă nu există evaluări

- Low Voltage Motors - Price ListDocument32 paginiLow Voltage Motors - Price ListsamuraivickyÎncă nu există evaluări

- Zener Diode Cross Reference ListingDocument6 paginiZener Diode Cross Reference ListingあいうえおかきくけこÎncă nu există evaluări

- Daihatsu Gensets Diesel EngineDocument20 paginiDaihatsu Gensets Diesel Enginexyz1002100% (1)

- Baldor Motors Price ListDocument582 paginiBaldor Motors Price ListMarcos José Quispe Molina100% (1)

- Eaton Model 9tlDocument11 paginiEaton Model 9tlscribd_guirreÎncă nu există evaluări

- Guide To Choosing Generator To Motor Size - National Pump & EnergyDocument2 paginiGuide To Choosing Generator To Motor Size - National Pump & EnergyNiranjan JainÎncă nu există evaluări

- Generator Sizing ChartDocument3 paginiGenerator Sizing ChartReymart ManablugÎncă nu există evaluări

- PowerTips - Motor Starting and Running Currents and Rating GuideDocument14 paginiPowerTips - Motor Starting and Running Currents and Rating Guideankur yadavÎncă nu există evaluări

- CPB - Technical - Catalogue 510Document1 paginăCPB - Technical - Catalogue 510rajÎncă nu există evaluări

- Powerflex® DC Drive Family: A Full Line of High-Performance SolutionsDocument4 paginiPowerflex® DC Drive Family: A Full Line of High-Performance SolutionsJ smithÎncă nu există evaluări

- Si23 Solar Pump Inverter ManualDocument7 paginiSi23 Solar Pump Inverter ManualEduardo ZuletaÎncă nu există evaluări

- اینورتر اسانسورDocument40 paginiاینورتر اسانسور208020Încă nu există evaluări

- Select Motor CT Ratings Based on Load CurrentsDocument2 paginiSelect Motor CT Ratings Based on Load CurrentsMd SharifÎncă nu există evaluări

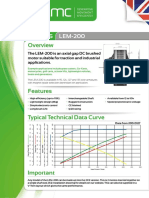

- LMC Lem 200 PDFDocument2 paginiLMC Lem 200 PDFPrathmesh MahajaniÎncă nu există evaluări

- Flyer MCS Synchronous Servo Motors en-GBDocument2 paginiFlyer MCS Synchronous Servo Motors en-GBMahirÎncă nu există evaluări

- 2015SB17ChangesinCoolingsystem PDFDocument3 pagini2015SB17ChangesinCoolingsystem PDFManish SharmaÎncă nu există evaluări

- Ct2000pro Manual PDFDocument71 paginiCt2000pro Manual PDFmajid aliÎncă nu există evaluări

- Vad Series: Adjustable Blades Axial Flow FansDocument3 paginiVad Series: Adjustable Blades Axial Flow FansTedi A MaulanaÎncă nu există evaluări

- Size of CB Protecting of MotorDocument4 paginiSize of CB Protecting of MotorjigarÎncă nu există evaluări

- Alternador Avi128 PDFDocument2 paginiAlternador Avi128 PDFPascual MtzÎncă nu există evaluări

- Contactors FL 002 enDocument1 paginăContactors FL 002 enkhaled kamelÎncă nu există evaluări

- CRD Devices Ltd Industrial Actuator SpecificationsDocument4 paginiCRD Devices Ltd Industrial Actuator SpecificationsFlorent YIBOKOUÎncă nu există evaluări

- TABLE 1.10 Limiting Effect Cable Short-Circuit Currents 208 Volts, Three PhaseDocument23 paginiTABLE 1.10 Limiting Effect Cable Short-Circuit Currents 208 Volts, Three PhaseJuan Carlos Perez ParraÎncă nu există evaluări

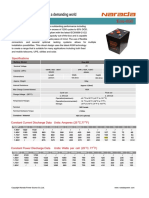

- GFM-HC Fast Charge ModelDocument2 paginiGFM-HC Fast Charge ModelOdai KiwanÎncă nu există evaluări

- Fan MotorDocument3 paginiFan MotorDota NgÎncă nu există evaluări

- HRL12540W Spec Sheet PDFDocument2 paginiHRL12540W Spec Sheet PDFJose Jorge OñateÎncă nu există evaluări

- PVV BLOCK Solar: EcuraDocument2 paginiPVV BLOCK Solar: EcuraCARLOS ANDRES SARMIENTO CUEVASÎncă nu există evaluări

- Catalog SBDocument40 paginiCatalog SBNicho WijayaÎncă nu există evaluări

- 170M 6809Document2 pagini170M 6809bernaÎncă nu există evaluări

- Rated Motor Current Conversion Chart & TableDocument1 paginăRated Motor Current Conversion Chart & Tablemuqtar4uÎncă nu există evaluări

- Ritar 12V 100ah RaDocument2 paginiRitar 12V 100ah RanikolaimendozasÎncă nu există evaluări

- Capacitor RatingsDocument1 paginăCapacitor RatingsAdam BehielsÎncă nu există evaluări

- GA 15-22 Sales Leaflet EN Pune 9096331603Document4 paginiGA 15-22 Sales Leaflet EN Pune 9096331603Владислав СередаÎncă nu există evaluări

- Induction MotorDocument50 paginiInduction MotorMuhammad NurwantaÎncă nu există evaluări

- Ge MD800Document6 paginiGe MD800idontlikeebooksÎncă nu există evaluări

- Nomi.... 1111Document9 paginiNomi.... 1111Noman SaleemÎncă nu există evaluări

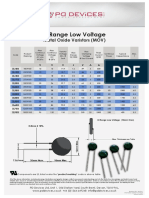

- D Range Low Voltage vPD1 PDFDocument1 paginăD Range Low Voltage vPD1 PDFdeputadozeroÎncă nu există evaluări

- Motors - Ahmed DawoodDocument14 paginiMotors - Ahmed DawoodAhmed WagihÎncă nu există evaluări

- Datasheet Ts 4.5.0Document30 paginiDatasheet Ts 4.5.0AlbertoÎncă nu există evaluări

- Nomi.... 1111Document9 paginiNomi.... 1111Noman SaleemÎncă nu există evaluări

- Automotive: Features and BenefitsDocument2 paginiAutomotive: Features and BenefitsAfzal ImamÎncă nu există evaluări

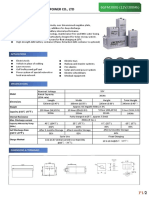

- Stored Energy Solutions For A Demanding World: SpecificationsDocument2 paginiStored Energy Solutions For A Demanding World: SpecificationsThiago FigueiredoÎncă nu există evaluări

- Dow01413875828 845073Document3 paginiDow01413875828 845073geonemesis13Încă nu există evaluări

- Awaiting Image: 12V 100AH 12V 100AHDocument2 paginiAwaiting Image: 12V 100AH 12V 100AHMarcelo MoralesÎncă nu există evaluări

- Unidrive M size 9 and 10 Inverter and Rectifier Technical SpecsDocument7 paginiUnidrive M size 9 and 10 Inverter and Rectifier Technical SpecsDave CárdenasÎncă nu există evaluări

- Mitsubishi Magnetic - Contactors S-N150 DatasheetDocument1 paginăMitsubishi Magnetic - Contactors S-N150 Datasheetjyl12Încă nu există evaluări

- Inverter external dimensions and DC reactor specificationsDocument1 paginăInverter external dimensions and DC reactor specificationsfrufru frutÎncă nu există evaluări

- Parker-VOAC Motor PilyDocument16 paginiParker-VOAC Motor PilyHarwesterÎncă nu există evaluări

- Catalogue Nagakawa VRF - Full - View-Mini - CompressedDocument68 paginiCatalogue Nagakawa VRF - Full - View-Mini - CompressedMạnh ĐinhÎncă nu există evaluări

- Aokly 300ah GelDocument2 paginiAokly 300ah GelYesibeth MartinezÎncă nu există evaluări

- Efficient AC Drive Controls C2000 SeriesDocument48 paginiEfficient AC Drive Controls C2000 SeriesEduardo CamÎncă nu există evaluări

- Metal Oxide Surge ArresterDocument35 paginiMetal Oxide Surge ArresterudhayÎncă nu există evaluări

- Phase To Earth Clearance As Per NECDocument1 paginăPhase To Earth Clearance As Per NECYuvaraj SathishÎncă nu există evaluări

- Tensile Test On Cast IronDocument15 paginiTensile Test On Cast IronElmer Ibanez JrÎncă nu există evaluări

- Hyundai Heavy Industries - Gas Insulated SwitchgearDocument25 paginiHyundai Heavy Industries - Gas Insulated SwitchgearbadbenzationÎncă nu există evaluări

- Stag en MainDocument8 paginiStag en MainFederico AlarconÎncă nu există evaluări

- Solar PV Panels The Best Option: Reliability ServiceDocument2 paginiSolar PV Panels The Best Option: Reliability ServicejprakashusÎncă nu există evaluări

- CABLE CONTROL APANTALLADO BOHM KABEL - YSLCY-JZ Gris 1Document4 paginiCABLE CONTROL APANTALLADO BOHM KABEL - YSLCY-JZ Gris 1ing.dmanriq27Încă nu există evaluări

- Control Ad orDocument1 paginăControl Ad oring.dmanriq27Încă nu există evaluări

- OPTIVISION LED Gen3.5 Mounting InstructionsDocument24 paginiOPTIVISION LED Gen3.5 Mounting Instructionsing.dmanriq27Încă nu există evaluări

- Annexure B-6 Case-3B 3 DG Supply - Phase2B Loads Short Circuit Analysis (Momentary Close)Document1 paginăAnnexure B-6 Case-3B 3 DG Supply - Phase2B Loads Short Circuit Analysis (Momentary Close)ing.dmanriq27Încă nu există evaluări

- Annexure B-3 Case2A (Without Tap) - Grid Supply - Phase2B+Future Loads Short Circuit AnalysisDocument1 paginăAnnexure B-3 Case2A (Without Tap) - Grid Supply - Phase2B+Future Loads Short Circuit Analysising.dmanriq27Încă nu există evaluări

- Annexure B-2 Case1 - Grid Supply-Phase2B Loads Short Circuit AnalysisDocument1 paginăAnnexure B-2 Case1 - Grid Supply-Phase2B Loads Short Circuit Analysising.dmanriq27Încă nu există evaluări

- Annexure B-7 Case-4A 7 DG Supply - Phase2B Loads Short Circuit AnalysisDocument1 paginăAnnexure B-7 Case-4A 7 DG Supply - Phase2B Loads Short Circuit Analysising.dmanriq27Încă nu există evaluări

- Tipos de Tuberia Metalica"TITLE"Excel Tools for Upgrading" TITLE"Response Form for Office"TITLE"OneDrive Documents Folder"TITLE"#tablerosatx on LinkedIn"TITLE"Products for Electrical IndustriesDocument6 paginiTipos de Tuberia Metalica"TITLE"Excel Tools for Upgrading" TITLE"Response Form for Office"TITLE"OneDrive Documents Folder"TITLE"#tablerosatx on LinkedIn"TITLE"Products for Electrical Industriesing.dmanriq27Încă nu există evaluări

- Original WLBVM027Document24 paginiOriginal WLBVM027ing.dmanriq27Încă nu există evaluări

- UPC Monterrico Campus Electrical Panel LocationsDocument2 paginiUPC Monterrico Campus Electrical Panel Locationsing.dmanriq27Încă nu există evaluări

- Annexure B-7 Case-4A 7 DG Supply - Phase2B Loads Short Circuit AnalysisDocument1 paginăAnnexure B-7 Case-4A 7 DG Supply - Phase2B Loads Short Circuit Analysising.dmanriq27Încă nu există evaluări

- Cordsets and Patchcords: SpecificationsDocument1 paginăCordsets and Patchcords: Specificationsing.dmanriq27Încă nu există evaluări

- Reflector Cr-Hinds PDFDocument4 paginiReflector Cr-Hinds PDFMichael UnzuetaÎncă nu există evaluări

- 2 RC L13Reg02240 Electrovolt: Sampling Tests ReportDocument2 pagini2 RC L13Reg02240 Electrovolt: Sampling Tests Reporting.dmanriq27Încă nu există evaluări

- Bulletin 19-9106 - Hps - ProductsDocument12 paginiBulletin 19-9106 - Hps - Productsing.dmanriq27Încă nu există evaluări

- CM Bu9000 Eng Bushings 3Document36 paginiCM Bu9000 Eng Bushings 3ing.dmanriq27100% (1)

- Cordsets and Patchcords: SpecificationsDocument1 paginăCordsets and Patchcords: Specificationsing.dmanriq27Încă nu există evaluări

- Iec Standards PDFDocument3 paginiIec Standards PDFing.dmanriq27Încă nu există evaluări

- Iec StandardsDocument3 paginiIec Standardsing.dmanriq27Încă nu există evaluări

- Section8 PumpDocument17 paginiSection8 Pumping.dmanriq27Încă nu există evaluări

- Arc Fault Protection System REA 10 - : Product GuideDocument32 paginiArc Fault Protection System REA 10 - : Product GuideAlbertoÎncă nu există evaluări

- Is Ky1507Document3 paginiIs Ky1507dayshift5Încă nu există evaluări

- Basic Transformer Training - Chapter 3 - Federal PacificDocument5 paginiBasic Transformer Training - Chapter 3 - Federal PacificfluxÎncă nu există evaluări

- Ground Floor Plan Small Power LayoutDocument1 paginăGround Floor Plan Small Power LayoutCSEC Uganda Ltd.100% (1)

- STI 6400WIR4 Instruction ManualDocument8 paginiSTI 6400WIR4 Instruction ManualJMAC SupplyÎncă nu există evaluări

- Radar Motion Detector For Automatic DoorsDocument4 paginiRadar Motion Detector For Automatic DoorsIndustrial DoorsÎncă nu există evaluări

- Heavy Duty Standby Switch Installation for Billm Blues Junior AmplifierDocument9 paginiHeavy Duty Standby Switch Installation for Billm Blues Junior AmplifierAndrea CeciniÎncă nu există evaluări

- Multi Kabel CatalogueDocument33 paginiMulti Kabel CatalogueHendri AskoroÎncă nu există evaluări

- Dry ContactsDocument2 paginiDry ContactsDiwakar MishraÎncă nu există evaluări

- Matera 27: Bedrooms Bathrooms GarageDocument4 paginiMatera 27: Bedrooms Bathrooms GarageindyanexpressÎncă nu există evaluări

- Vincotech - V23990 P549 A 14Document23 paginiVincotech - V23990 P549 A 14208020Încă nu există evaluări

- Series GMPG 404 694 motor performanceDocument1 paginăSeries GMPG 404 694 motor performanceasad922Încă nu există evaluări

- Mobil Geely MK Wiring DiagramDocument1 paginăMobil Geely MK Wiring DiagramAhmad Zen FiraÎncă nu există evaluări

- Catalogo Paneles Square D PDFDocument22 paginiCatalogo Paneles Square D PDFCarlos MendozaÎncă nu există evaluări

- Freightliner Diesel Engine Starter Troubleshooting GuideDocument8 paginiFreightliner Diesel Engine Starter Troubleshooting GuideАртем БоровськийÎncă nu există evaluări

- 8 Indution MotorDocument4 pagini8 Indution MotorSandrawarman BalasundramÎncă nu există evaluări

- Decoscene Dbp522 322989 Ffs AenDocument5 paginiDecoscene Dbp522 322989 Ffs AenbudituxÎncă nu există evaluări

- P Tel LST 970 30002 3 Rlmu F - SDocument8 paginiP Tel LST 970 30002 3 Rlmu F - SBenkhira HoucineÎncă nu există evaluări

- 3 Requirements For Electrical Installation 1 PDFDocument19 pagini3 Requirements For Electrical Installation 1 PDFApocalypse Cabal100% (1)

- LCD, LED & PLASMA Display TechnologyDocument18 paginiLCD, LED & PLASMA Display TechnologyLabesh SharmaÎncă nu există evaluări

- enDocument2 paginienprabumnÎncă nu există evaluări

- VNX - Su Espace 2 1991 1997 PDFDocument555 paginiVNX - Su Espace 2 1991 1997 PDFamotimoto100% (2)

- Magnum PXR Breaker Manual Mn013016enDocument58 paginiMagnum PXR Breaker Manual Mn013016enChiranzeevi JioÎncă nu există evaluări

- Gothic ArchitectureDocument10 paginiGothic ArchitectureJulia May BalagÎncă nu există evaluări