Documente Academic

Documente Profesional

Documente Cultură

Reemplazo Bomba de Alta Presion

Încărcat de

Jonathan Francisco Perez AyalaDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Reemplazo Bomba de Alta Presion

Încărcat de

Jonathan Francisco Perez AyalaDrepturi de autor:

Formate disponibile

4 99-12

1 4 99-12

SUBJECT DATE

Removal of the High Pressure Fuel Pump April 2012

Additions, Revisions, or Updates

Publication Number / Title Platform Section Title Change

Removal of the High Pressure Fuel

Pump Adding a notice to install the high pressure fuel feed line

DDC-SVC-MAN-0082 DD Platform

Installation of the High Pressure kit.

Fuel Pump

All information subject to change without notice. 3

4 99-12 Copyright © 2012 DETROIT DIESEL CORPORATION

2 Removal of the High Pressure Fuel Pump

2 Removal of the High Pressure Fuel Pump

Remove as follows:

1. Disconnect the batteries.

2. Drain the fuel system. Refer to section "Draining the Fuel System Using J-48710 Prior to Repairs"

3. Remove the two bolts from the inspection cover on the bottom of the flywheel housing.

4. Install an engine barring tool (J-46392) to the flywheel housing (3).

5. Rotate the flywheel until the dot located on the inside tooth (2) of the flywheel is aligned with the edge of pointer (1). The

engine should now be at TDC for cylinder one.

6. Remove the Crankshaft Position (CKP) sensor.

7. Install the crankshaft locking tool (W470589001500) into the CKP hole. The tool should sit flush to the flywheel housing.

If not, slowly rotate engine using barring tool until the tool is flush with the flywheel housing.

8. Remove the W470589001500 tool from the CKP hole.

9. Remove the needle return fuel line, Pressure Limiting Valve (PLV) fuel line, and the amplifier return fuel line from the

fuel filter module. Refer to section "Removal of the Needle, Amplifier, and Pressure Limiting Valve Return Lines"

10. Disconnect the needle return fuel line from the high pressure pump flange.

11. Disconnect the Hydrocarbon (HC) fuel doser supply line from the high pressure pump flange.

12. Remove the fuel filter module. Refer to section "Removal of the Fuel Filter Module"

13. Remove the three bolts and remove the high pressure pump flange.

14. Remove the three bolts and remove the low pressure pump flange.

15. Disconnect the quantity control valve electrical harness connector. Disconnect the plastic clip from the high pressure fuel

flange.

16. Remove the high pressure fuel pump mounting bracket.

17. Using HP pressure offset wrench tool (J-48770), remove the high pressure fuel lines from the high pressure fuel pump to

the fuel rail.

NOTICE: The high pressure fuel rail feed lines, vibration dampers, mounting bracket and hardware are one-time-

use components and MUST be replaced any time they are removed

Service kit P/N: A4720707132 contains all of the necessary parts to replace the high pressure fuel feed lines on

EPA07/10 DD13 engines and service kit P/N: 4720707032 contains all of the necessary parts to replace the high

pressure fuel feed lines on EPA07/10 DD15/16 engines.

18. Remove the four bolts attaching the high pressure fuel pump to the cylinder block.

19. Remove the high pressure fuel pump from the block.

4 All information subject to change without notice.

Copyright © 2012 DETROIT DIESEL CORPORATION 4 99-12

4 99-12

3 Installation of the High Pressure Fuel Pump

Install as follows:

1. Ensure flywheel is positioned at Top Dead Center (TDC) on cylinder number one.

2. Inspect the high-pressure fuel pump:

a. If the fuel pump drive gear is installed from the factory, Go to step 11.

b. If the fuel pump drive gear is being replaced (or new) or exchanged from the old pump, Go to step 3.

3. Remove the O-ring from the high-pressure fuel pump flange.

4. Install the high-pressure fuel pump into the high-pressure pump holding device tool (W470589014000) then remove

locking tooth from the tool.

5. Install the half-moon key (1) onto the fuel pump shaft using a brass hammer.

6. Use a suitable de-greaser to remove all oil/grease, etc., from the high-pressure pump shaft and gear mating surfaces prior

to gear installation; install the fuel pump drive gear onto the fuel pump shaft.

7. Prior to installing the nut, mark the gear with paint (1) to show the location of the key way.

a. EPA07 Fuel Pump Driven Gear

All information subject to change without notice. 5

4 99-12 Copyright © 2012 DETROIT DIESEL CORPORATION

3 Installation of the High Pressure Fuel Pump

b. EPA10 Fuel Pump Driven Gear

8. Install the nut and locking tooth for tool WE470589014000. Using the high-pressure fuel pump nut socket tool J-48669,

torque the nut to 250 N·m (184 lb·ft).

9. Remove the locking tooth from the tool and install the eyebrow plate over the gear. Position eyebrow plate to align hash

mark on plate to paint mark on gear.

a. EPA07 Fuel Pump Eyebrow Plate

b. EPA10 Fuel Pump Eyebrow Plate

6 All information subject to change without notice.

Copyright © 2012 DETROIT DIESEL CORPORATION 4 99-12

4 99-12

10. Install three eyebrow mounting bolts:

a. For EPA07 engines, torque the three bolts to 30 N·m (22 lb·ft).

b. For EPA10 engines, torque the three bolts to 8 N·m (6 lb·ft).

11. Using a non-marring strap wrench, rotate the gear until the hash mark is at the 12 o'clock position (1) and lined up with

the dot on the housing.

a. EPA07 Fuel Pump Eyebrow Plate Aligned with Dot

b. EPA10 Fuel Pump Eyebrow Plate Aligned with Dot

All information subject to change without notice. 7

4 99-12 Copyright © 2012 DETROIT DIESEL CORPORATION

3 Installation of the High Pressure Fuel Pump

12. Remove the strap from the high-pressure fuel pump.

13. Clean mounting surface of fuel pump and O-ring groove. If a new fuel pump is being installed, Go to step 16.

14. Remove the fuel pump from the tool and install a new O-ring.

15. Lubricate new O-ring lightly with clean engine oil.

16. Clean the flywheel housing bore. Inspect for burrs or other sharp edges.

NOTE: The pump should slide into the flywheel housing without binding. The bolt hole on the pump housing should

align very close with the mounting hole on the flywheel housing.

NOTE: If the high-pressure pump binds when being installed or if there is misalignment in the bolt holes, remove

the pump and verify the timing mark is at the 12 o'clock position and the engine is at TDC; and reinstall.

17. Install the high-pressure fuel pump to the cylinder block.

8 All information subject to change without notice.

Copyright © 2012 DETROIT DIESEL CORPORATION 4 99-12

4 99-12

NOTICE: Ensure the correct bolt length is used when the high-pressure pump is installed. If an incorrect bolt length

(long) is used the cup plugs installed in the cylinder block can be pushed out into the gear train causing severe

damage to the gear train. The correct bolt length is M10X35 mm (1.37 in.).

18. Install the four bolts securing the high-pressure pump to the engine block and torque to 60 N·m (44 lb·ft).

19. Loosely install the high-pressure pump bracket, and install the two nuts securing the high-pressure fuel pump to the bracket;

torque to 30 N·m (22 lb·ft).

20. Install the two bolts securing the high-pressure fuel pump bracket to the cylinder block and torque to 100 N·m (74 lb·ft).

21. Connect the quantity control valve connector.

22. Install the fuel filter module. Refer to section "Installation of the Fuel Filter Module"

23. Using a new gasket, install the high-pressure pump flange onto the high-pressure pump. Torque to 30 N·m (22 lb·ft).

24. Using a new gasket, install the low pressure pump flange onto the high-pressure pump. Torque to 30 N·m (22 lb·ft).

25. Install the fuel supply line to doser block assembly. Torque to 25 N·m (18 lb·ft).

26. Install two high-pressure lines from the high-pressure pump to the fuel rail.

Refer to section "Installation of the DD13 High Pressure Fuel Rail Feed Lines"

Refer to section "Installation of the DD15 and DD16 High Pressure Fuel Rail Feed Lines"

27. Prime the fuel system. Refer to section "Priming of the Fuel System Using ESOC 350 Fuel Priming Pump"

WARNING: ENGINE EXHAUST (i)(eov34)

To avoid injury from inhaling engine exhaust, always operate the engine in a well-ventilated area.

Engine exhaust is toxic.

WARNING: PERSONAL INJURY

To avoid injury before starting and running the engine, ensure the vehicle is parked on a level surface,

parking brake is set, and the wheels are blocked.

28. Start and run the engine.

WARNING: FIRE

To avoid injury from fire, contain and eliminate leaks of flammable fluids as they occur. Failure to

eliminate leaks could result in fire.

All information subject to change without notice. 9

4 99-12 Copyright © 2012 DETROIT DIESEL CORPORATION

3 Installation of the High Pressure Fuel Pump

29. When the engine has reached operating temperature 60°C (140°F), observe pump for any performance problems or leaks.

10 All information subject to change without notice.

Copyright © 2012 DETROIT DIESEL CORPORATION 4 99-12

S-ar putea să vă placă și

- PDFDocument2 paginiPDFJonathan Francisco Perez Ayala0% (1)

- MJE15028, MJE15030 (NPN) MJE15029, MJE15031 (PNP) Complementary Silicon Plastic Power TransistorsDocument6 paginiMJE15028, MJE15030 (NPN) MJE15029, MJE15031 (PNP) Complementary Silicon Plastic Power TransistorsJonathan Francisco Perez AyalaÎncă nu există evaluări

- Manual Horton DrivemasterDocument36 paginiManual Horton DrivemasterJonathan Francisco Perez Ayala100% (2)

- Cal Tool MenuDocument43 paginiCal Tool MenuJonathan Francisco Perez AyalaÎncă nu există evaluări

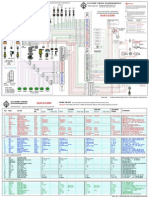

- Diagrama Electronico DT466Document2 paginiDiagrama Electronico DT466Aldo Fran Vargas82% (22)

- Conectores y Numeros de Par TDocument42 paginiConectores y Numeros de Par TJonathan Francisco Perez Ayala100% (1)

- Tablas C-15, C-16Document38 paginiTablas C-15, C-16Jonathan Francisco Perez Ayala100% (1)

- B300 Ficha TecnicaDocument5 paginiB300 Ficha TecnicaJonathan Francisco Perez AyalaÎncă nu există evaluări

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (345)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Electric Motor and Motor ControllerDocument1 paginăElectric Motor and Motor Controllerpkjhan1353Încă nu există evaluări

- #01. DL08 Engine IntroductionDocument48 pagini#01. DL08 Engine IntroductionAugusto Nuñez100% (1)

- Letter From Chairman To Railway Board ChairmanDocument4 paginiLetter From Chairman To Railway Board ChairmanShashank SrivastavaÎncă nu există evaluări

- National High Speed Rail Corporation Limited (NHSRCL)Document7 paginiNational High Speed Rail Corporation Limited (NHSRCL)ANILÎncă nu există evaluări

- EAA Aluminium in Cars Unlocking The Light Weighting PotentialDocument15 paginiEAA Aluminium in Cars Unlocking The Light Weighting PotentialAltairEnlightenÎncă nu există evaluări

- Mitsubishi - Commercial Spec Sheets - Industrial Engine - Variable Speed - S4Q2-Z365SPDocument1 paginăMitsubishi - Commercial Spec Sheets - Industrial Engine - Variable Speed - S4Q2-Z365SPjoanna joannaÎncă nu există evaluări

- Development of New 1.0 L I3 Gasoline Direct Injection Turbocharged Downsizing EngineDocument9 paginiDevelopment of New 1.0 L I3 Gasoline Direct Injection Turbocharged Downsizing EngineLuqie spÎncă nu există evaluări

- Quiz (Questions)Document2 paginiQuiz (Questions)Marianne GeromoÎncă nu există evaluări

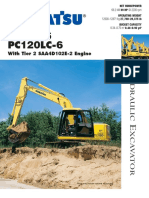

- PC120-6 PC120LC-6: With Tier 2 SAA4D102E-2 EngineDocument12 paginiPC120-6 PC120LC-6: With Tier 2 SAA4D102E-2 EngineJohn MkCito KIÎncă nu există evaluări

- Wheel Hub MotorDocument5 paginiWheel Hub MotorAnonymous Syjpyt4MoÎncă nu există evaluări

- CPC+MCM+ACM Error Codes ListDocument40 paginiCPC+MCM+ACM Error Codes ListMiguel Ángel Ortega CotrinaÎncă nu există evaluări

- Service Manual: 5cinett in IDocument146 paginiService Manual: 5cinett in Ibiteha29520% (1)

- InTech-Train BrakingDocument48 paginiInTech-Train BrakingNaveenkondiÎncă nu există evaluări

- Before You Start - Important NotesDocument9 paginiBefore You Start - Important NotesepyonicÎncă nu există evaluări

- Ufc 4-860-03 Railroad Track Maintenance and Safety Standards (13 February 2008)Document107 paginiUfc 4-860-03 Railroad Track Maintenance and Safety Standards (13 February 2008)Bob VinesÎncă nu există evaluări

- Operator'S Manual: Read and Save This ManualDocument290 paginiOperator'S Manual: Read and Save This ManualKo Zay100% (1)

- Bicycle Design GuidelinesDocument33 paginiBicycle Design GuidelinesActiveUrbesÎncă nu există evaluări

- Yamaha FJR 1300 - Service Manual (06) - Inglés PDFDocument586 paginiYamaha FJR 1300 - Service Manual (06) - Inglés PDFЙордан Василев100% (2)

- Mitsubishi - Pajero - Owners Manual - 2013 - 2013 PDFDocument3 paginiMitsubishi - Pajero - Owners Manual - 2013 - 2013 PDFJan Martin じあん ですÎncă nu există evaluări

- Tecumseh Model Hm80 155438p Parts ListDocument10 paginiTecumseh Model Hm80 155438p Parts ListTroy Pouliot100% (1)

- Break Away From The Everyday: Toyota RushDocument2 paginiBreak Away From The Everyday: Toyota RushmelioneÎncă nu există evaluări

- 2021-02-24 - Traffic Study Report - Bhartiya City Additional Area - R0Document32 pagini2021-02-24 - Traffic Study Report - Bhartiya City Additional Area - R0gulrez94Încă nu există evaluări

- Inventory 01Document5 paginiInventory 01joreyvilÎncă nu există evaluări

- VOLVO FM, FH Version 2 - Fuses Box Diagram and Relays: Volvo Truck Workshop ManualDocument19 paginiVOLVO FM, FH Version 2 - Fuses Box Diagram and Relays: Volvo Truck Workshop ManualDerbel Yassine50% (2)

- Harga Spare Part VixionDocument11 paginiHarga Spare Part VixionharizrzÎncă nu există evaluări

- Man TGX.: Efficiency in Long-Haul TransportDocument21 paginiMan TGX.: Efficiency in Long-Haul TransportNadeem Mohd100% (1)

- State of Colorado Traffic Crash Report: Harmful Event SequenceDocument6 paginiState of Colorado Traffic Crash Report: Harmful Event SequenceDebra DreilingÎncă nu există evaluări

- '21 Yamaha XSR 125 Motorcycle Owner's Manual PDFDocument90 pagini'21 Yamaha XSR 125 Motorcycle Owner's Manual PDFJay L Jan TejadaÎncă nu există evaluări

- Technical Data: DC13 072A, 438-487 KW / 503-553 kVA (Engine Ref. 02-14)Document1 paginăTechnical Data: DC13 072A, 438-487 KW / 503-553 kVA (Engine Ref. 02-14)Mald ShreefÎncă nu există evaluări

- ZF 4 WG-310 PDFDocument53 paginiZF 4 WG-310 PDFAlbert Bhatti75% (8)