Documente Academic

Documente Profesional

Documente Cultură

763 PDF

Încărcat de

इंजि कौस्तुभ पवारTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

763 PDF

Încărcat de

इंजि कौस्तुभ पवारDrepturi de autor:

Formate disponibile

IS : 763 - 1988

( Reaffirmed 1999 )

Indian Standard

METHOD FORDETERMINATlON OF COLOUR

0 FASTNESS OF TEXTILE MATERIALS TO

PEROXIDE BLEACHING

( First Revision )

UDC 667*016+473-4:535-684.32

0 Copyright 1988

cl BUREAU OF INDIAN STANDARDS

MANAK BHAVAN, 9 BAHADUR SHAH ZAFAR MARG

NEW DELHI 110002

December 1988

Gr 1

IS : 763 - 1988

Indian Standard

METHOD FOR DETERMINATION OF COLOUR

FASTNESS OF TEXTILE MATERIALS TO

PEROXIDE BLEACHING

( First Revision )

0. FOREWORD /

!’

0.1 This Jndian Standard ( First Revision ) w&s 0.3 Colour fastness of textile materials is of consi-

adopted by the Bureau of Indian Standards on derable importance to the consumer. The fast-

20 May 1988, after the draft finalized by the ness depends not only upon the nature and depth

Chemical Methods of Test Sectional Committee of shade of the dyestuff used but also upon the

had been approved by the Textile Division Council. nature of the fibre and the method of dyeing or

printing employed; the same colouring matter,

0.2 This standard was first published in 1956 and when used in dyeing or printing different fibres

has been revised to align it with,ISO 105/N 1978 or when applied by different methods upon the

Textiles-Tests for colour fastness NO2 Colour same fibre, may give vastly different results.

fastness to Bleaching: Peroxide, issued by the Formulation of standard methods of test for

International Organization for Standardization determining colour fastness of textile materials

( IS0 ) and also to incorporate changes in hne to different agencies likely to effect change in

with other standards on colour fastness tests. colour is, therefore, necessary.

1. SCOPE 4.2 Reflux Condenser-fitting the test tube to

reduce evaporation from the bleaching bath during

1.1 This standard prescribes a method for the the test.

determination of colour fastness of textile materials

of all kinds and in all forms to the action of 4.3 Two Adjacent Fabrics - each measuring

bleachiig baths containing peroxide in concen- 10 cm x 4 cm, one piece made of the same kind of

trations commonly used in textile processing. fibre as that of the textile to be tested or that

predominating in the case of blends, the second

2. PIuNc!rPLE piece made of the fibre as indicated below or, in

2.1 A specimen of the textile in contact with the case of blends, of the kind of fibre second in.

adjacent fabrics is immersed in the bleaching order of predominance or as otherwise specified.

solution, rinsed and dried. The change in colour If the First Adjacent Second Piece to be

of the specimen and the staining of adjacent Fhbric is

fabrics are assessed with the grey scales.

Wool, silk, linen, viscose,

3. SAMPLING polyester, acrylic Cotton

3.1 Sample to determine conformity of a lot of Cotton, acetate Viscose

coloured textile material to a specification shall

be selected so as to be representative of the lot. 4.4 Grey Scales- for evaluating change in colour

and staining.

3.2 Sample drawn in compliance with the relevant

material specification or as agreed to between 5. REAGENTS

the buyer and the seller to evaluate colour fast-

ness of the material in the lot shall be represen- 5.0 Quality of Reagents - Unless otherwise speci-

tative of the lot. Red, pure chemicals shall be employed in tests

and distilled water ( see IS : 1070 - 1977* ) shall

4. APPARATUS be used where the use of water as a reagent is

4.1 Test Tube - having diameter and length intended.

such that the composite specimen when rolled

will have a reasonably snug fit in the tube and be *Specification for water for general laboratory w

covered by the bleach bath. ( second revision ).

IS:763-1988

NOTE- Pure chemicals shall mean chemicals that bleaching solution ( see 5.1) and keep it well

do not contain impurities which affect the test results. covered by the bleaching solution for the time

and temperature indicated in 5.1.

5.1 Bleaching Baths - of the composition given

in Table 1. 7.2 Remove the composite specimen, rinse it

for 10 min in cold running tap water and squeeze

6. PREPARATION OF COMPOSITE it. Open the composite specimen by breaking

SPECIMEN the stitching on all sides except one of the shorter

6.1 If the textile to be tested is fabric, place a sides and dry by hanging it in air in shade at a

specimen 10 cm x 4 cm between two adjacent temperature not exceeding 60°C with the three

fabrics ( see 4.3 ) and sew along all four sides to parts in contact only at the remaining line of

form a composite specimen. stitching.

6.2 If the textile to be tested is yarn, knit or weave 7.3 Assess the change in colour of the specimen

it into fabric and treat as in 6.1, or form a layer and the staining of the adjacent fabrics by the

of parallel lengths of it between the two adjacent methods prescribed in IS : 768 - 1982* and IS :

fabrics ( see 4.3 ), the amount of yarn taken being 769 - 1982t respectively.

approximately equal to half the combined mass NOTE1 - Treated test specimens and the pieces of

of the adjacent fabrics, sew along all four sides adjacent fabrics should have cooled after drying and

to hold the yarn in place and to form a composite should have regained their normal moisture content before

specimen. evaluation.

NOTE 2 - In cases of doubt in the colour fastness

6.3 If the textile to be tested is loose fibre, comb rating as assessedby an observer, the assessment should

and compress an amount approximately equal be done by at least three observers and the overall

to half the combined mass of the adjacent fabrics average rating should be reported.

( see 4.3 ) into a sheet 10 cm x 4 cm. Place the

8. REPORT

sheet between the two adjacent fabrics ,and sew

along all four sides to hold the fibre in place and 8.1 Report the bleaching solution used, the

to form a composite specimen. numerical rating for change in colour of the speci-

men and the numerical rating for staining of each

7. PROCEDURE kind of adjacent fabric used individually.

7.1 Loosely roll the composite specimen in the

direction of the long edge, place the 4 cm roll *Method for evaluating change in colour (first revision ).

into the test tube containing the appropriate ?Method for evaluating staining (first revision ).

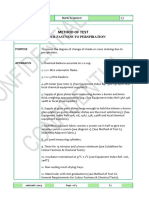

TABLE 1 COMPOSITION OF BLEACHING BATHS

( Clause 5.1 )

STARTING

BATH BATH1 BACH2 BATH3 BATEr4

(PER L~~RROFDI~TKLEDWATER) (FOR NATURAL ( FOR NATURAL ( FORWOOLANo (FOR SILK)

AND ERGENRRATED

AND&ORNRRATRD ACETATE)

CELL~JLO~E) CELLUrosE)

Hydrogen peroxidt* solution, ml 3 - 12.2 12.2

Sodiumt peroRide, g 3 - -

Sodium silicate$ solution, ml 5 5 5

Sodium pyrophosphate$, g - 5 -

Magnesium chloride113g 0.1 0.1 - 0.1

pH, initial valuett f 0.2 10.5 11.5 9.3** 10*0**

Temperature, “C & 2°C 90 80 50 70

Duration of treatment, h 1 1 2 2

Liquor ratio 3O:l 3O:l 3O:l 3O:l

*Containing 602 g/l HIOP ( 500 k/jg HIOI ).

7100 percent NasO,.

$Relative density at 20°C = 1.32; SiO,/Na,O ratio = 2.7 : 1

$SNa,P,O,. 10HsO.

” MgCls. 6H,O.

ttAdjust by addition of NaOH solution , if necessary.

**ThepH of the bath at the end of the test should not be less than 9.0.

2

Printed at Central Electric Press. Delhi-l 10007

S-ar putea să vă placă și

- Is 766 1988Document6 paginiIs 766 1988Asian Test EquipmentsÎncă nu există evaluări

- Is 4636 1988Document6 paginiIs 4636 1988Asian Test EquipmentsÎncă nu există evaluări

- Methods For Quantitative Chemical Analysis of Binary Mixtures of Nylon 6 or Nylon 6.6 Fibres and Certain Other FibresDocument7 paginiMethods For Quantitative Chemical Analysis of Binary Mixtures of Nylon 6 or Nylon 6.6 Fibres and Certain Other FibresVishalÎncă nu există evaluări

- Aatcc TM15-2021Document4 paginiAatcc TM15-2021Kunal ShingalaÎncă nu există evaluări

- AATCC - 15 - 2002 - CF To PerspirationDocument3 paginiAATCC - 15 - 2002 - CF To PerspirationNguyễn Công ThoạiÎncă nu există evaluări

- C07 - Colour Fastness To PerspirationDocument5 paginiC07 - Colour Fastness To PerspirationChandru TGÎncă nu există evaluări

- A New Approach in Printing Wool and WoolPolyester Fabrics With Disperse DyeDocument6 paginiA New Approach in Printing Wool and WoolPolyester Fabrics With Disperse Dyefathi mustafaÎncă nu există evaluări

- One-Bath Dyeing Process For Polyester Cotton Blend Using Physical Mixtures of Reactive and DisperseDocument11 paginiOne-Bath Dyeing Process For Polyester Cotton Blend Using Physical Mixtures of Reactive and DisperseariefÎncă nu există evaluări

- Investigation of Performance Properties of Graphene Coated FabricsDocument6 paginiInvestigation of Performance Properties of Graphene Coated FabricsIjmret JournalÎncă nu există evaluări

- Is 3561 1989Document9 paginiIs 3561 1989Asian Test EquipmentsÎncă nu există evaluări

- Cat IonizerDocument6 paginiCat IonizerAnonymous 5HRD46hÎncă nu există evaluări

- Effct TempratureDocument12 paginiEffct TempratureMohamed ElnobyÎncă nu există evaluări

- Colorfastness To Water: Sea: AATGG Test Method 106-2009Document2 paginiColorfastness To Water: Sea: AATGG Test Method 106-2009Milagros WieczorekÎncă nu există evaluări

- FT-IR Fingerprinting of A Non-Aqueous Liquid Paint As Supplied in The Manufacturer's ContainerDocument6 paginiFT-IR Fingerprinting of A Non-Aqueous Liquid Paint As Supplied in The Manufacturer's ContainerJuan F Alvarez100% (1)

- 10 5923 J Textile 20160504 03 PDFDocument5 pagini10 5923 J Textile 20160504 03 PDFAkshay DolasÎncă nu există evaluări

- Retraccion TierraDocument3 paginiRetraccion TierraNadiaAtariguanaÎncă nu există evaluări

- Determining The Rate of Sorption and Sorptive Capacity of Nonwoven FabricsDocument4 paginiDetermining The Rate of Sorption and Sorptive Capacity of Nonwoven Fabricsmohammed karasnehÎncă nu există evaluări

- A Comparative Studies of Physio Chemical Properties of Linen Yarn Dyed Fabric Dyed With Reactive & Vat DyeDocument7 paginiA Comparative Studies of Physio Chemical Properties of Linen Yarn Dyed Fabric Dyed With Reactive & Vat DyeInternational Journal of Innovative Science and Research TechnologyÎncă nu există evaluări

- AATCC 127 Water Resistance Hydrostatic Pressure TestDocument2 paginiAATCC 127 Water Resistance Hydrostatic Pressure TestVeronica GozdalskaÎncă nu există evaluări

- 16 271.fullDocument8 pagini16 271.fullpriyaÎncă nu există evaluări

- Bulk Density of Peat and Peat Products: Standard Test Methods ForDocument3 paginiBulk Density of Peat and Peat Products: Standard Test Methods ForJesus Luis Arce GuillermoÎncă nu există evaluări

- Mechanical Analysis of Extracted Aggregate: Standard Method of Test ForDocument2 paginiMechanical Analysis of Extracted Aggregate: Standard Method of Test ForEvert RiveraÎncă nu există evaluări

- Breaking Strength 1Document47 paginiBreaking Strength 1Bhavyata ChavdaÎncă nu există evaluări

- D4531-86-2008 Standard Test Methods For Bulk Density of Peat and Peat ProductsDocument3 paginiD4531-86-2008 Standard Test Methods For Bulk Density of Peat and Peat Productsfokat67395Încă nu există evaluări

- D 421 - 85 R98 - Rdqyms04nvi5oa - PDFDocument2 paginiD 421 - 85 R98 - Rdqyms04nvi5oa - PDFEnmanuel CruzÎncă nu există evaluări

- IS 7016 Part 10Document11 paginiIS 7016 Part 10sabaris ksÎncă nu există evaluări

- Aatcc 61-2010Document5 paginiAatcc 61-2010郭哲宏Încă nu există evaluări

- D 4770 - 00 Rdq3nzaDocument3 paginiD 4770 - 00 Rdq3nzaJuanÎncă nu există evaluări

- 22 Water Repellency Spray Test PDFDocument3 pagini22 Water Repellency Spray Test PDFTimmi Timmi Choice100% (1)

- Water Repellency (Spray Test)Document3 paginiWater Repellency (Spray Test)sadia100% (2)

- B0511117 PDFDocument7 paginiB0511117 PDFHasanuzzaman SumonÎncă nu există evaluări

- FTR 33 (1) (2008) 80-87-Effect of Colour On WashingDocument8 paginiFTR 33 (1) (2008) 80-87-Effect of Colour On WashingRaviChandranÎncă nu există evaluări

- Cotton TreatmentDocument7 paginiCotton TreatmentShoaib ArifÎncă nu există evaluări

- Dyes and Pigments: Mohammad Nazmul Karim, Muriel Rigout, Stephen G. Yeates, Chris CarrDocument7 paginiDyes and Pigments: Mohammad Nazmul Karim, Muriel Rigout, Stephen G. Yeates, Chris Carrjakariya nugrahaÎncă nu există evaluări

- Disclosure To Promote The Right To InformationDocument13 paginiDisclosure To Promote The Right To InformationMaeon LaboratoriesÎncă nu există evaluări

- Development of Sound Proofing Composite Materials Using Jute ProductsDocument78 paginiDevelopment of Sound Proofing Composite Materials Using Jute ProductsAuto ChannelÎncă nu există evaluări

- Eas 238 2001Document13 paginiEas 238 2001Buvanesh WaranÎncă nu există evaluări

- Is 179 2009Document11 paginiIs 179 2009Universal YarnsÎncă nu există evaluări

- Evaluating Clothing Appearance and ColorfastnessDocument69 paginiEvaluating Clothing Appearance and ColorfastnesspsbhirudÎncă nu există evaluări

- Art. No 344 Pag. 13-18Document6 paginiArt. No 344 Pag. 13-18AshutoshÎncă nu există evaluări

- Determination of Length and Width of Woven Fabrics - MethodsDocument9 paginiDetermination of Length and Width of Woven Fabrics - Methodsanuragbhattacharjee56Încă nu există evaluări

- D 5908 - 96 Rdu5mdgtotyDocument3 paginiD 5908 - 96 Rdu5mdgtotyJuan GutierrezÎncă nu există evaluări

- Color Research Application - 2021 - Nikam - Assessment of The Factors Affecting The Weathering Properties of PigmentDocument8 paginiColor Research Application - 2021 - Nikam - Assessment of The Factors Affecting The Weathering Properties of PigmentGehad MoawadÎncă nu există evaluări

- Coating Adhesion and Heat Tests Performance Standard: Change Level Date Description of ChangeDocument4 paginiCoating Adhesion and Heat Tests Performance Standard: Change Level Date Description of Changeerik0007Încă nu există evaluări

- LS-806 - Rev 34 - May 2020Document8 paginiLS-806 - Rev 34 - May 2020ming_zhu10Încă nu există evaluări

- Interrelation Between Dyeing and Thermal Properties of PET FibersDocument10 paginiInterrelation Between Dyeing and Thermal Properties of PET Fibersapi-3733260Încă nu există evaluări

- Expt 1 - 2022-2023Document4 paginiExpt 1 - 2022-2023MAYRELL PUN-ANÎncă nu există evaluări

- Textile Testing GuideDocument5 paginiTextile Testing GuideRezaul Karim TutulÎncă nu există evaluări

- Is 101 4 1 1988 PDFDocument10 paginiIs 101 4 1 1988 PDFdombipinÎncă nu există evaluări

- Measurement of Shives in Retted Flax: Standard Test Method ForDocument3 paginiMeasurement of Shives in Retted Flax: Standard Test Method ForDanZel Dan100% (1)

- Processing Laboratory TestsDocument45 paginiProcessing Laboratory TestsNavaneeth Natarajan80% (5)

- Is 15489 2004 PDFDocument15 paginiIs 15489 2004 PDFAfroj ShaikhÎncă nu există evaluări

- Effect of Different Softeners and Sanforising Treatment On Pilling Performance of Polyester-Viscose Blended FabricsDocument4 paginiEffect of Different Softeners and Sanforising Treatment On Pilling Performance of Polyester-Viscose Blended FabricsAhsan NazirÎncă nu există evaluări

- Azo DyesDocument5 paginiAzo DyesShoaib ArifÎncă nu există evaluări

- Ijaret: ©iaemeDocument11 paginiIjaret: ©iaemeIAEME PublicationÎncă nu există evaluări

- Apparent Density, Bulk Factor, and Pourability of Plastic MaterialsDocument6 paginiApparent Density, Bulk Factor, and Pourability of Plastic Materialsiipmnpti iipm0% (1)

- ASTM D 6093 - 97Document3 paginiASTM D 6093 - 97shgsuhermanÎncă nu există evaluări

- Textile Finishing: Recent Developments and Future TrendsDe la EverandTextile Finishing: Recent Developments and Future TrendsÎncă nu există evaluări

- Handbook of Renewable Materials for Coloration and FinishingDe la EverandHandbook of Renewable Materials for Coloration and FinishingMohd YusufÎncă nu există evaluări

- Checklist For BrickworkDocument2 paginiChecklist For Brickworkइंजि कौस्तुभ पवारÎncă nu există evaluări

- Technical Details: PDF Created With Pdffactory Trial VersionDocument1 paginăTechnical Details: PDF Created With Pdffactory Trial Versionइंजि कौस्तुभ पवारÎncă nu există evaluări

- Types of CofferdamsDocument35 paginiTypes of Cofferdamsइंजि कौस्तुभ पवारÎncă nu există evaluări

- Check List For FootingsDocument1 paginăCheck List For Footingsइंजि कौस्तुभ पवारÎncă nu există evaluări

- EPC Model RFQ & RFP Document for Highway ProjectsDocument74 paginiEPC Model RFQ & RFP Document for Highway Projectsइंजि कौस्तुभ पवारÎncă nu există evaluări

- Acceptance Criteria For All MaterialsDocument1 paginăAcceptance Criteria For All Materialsइंजि कौस्तुभ पवारÎncă nu există evaluări

- Check List For Beam & SlabDocument1 paginăCheck List For Beam & Slabइंजि कौस्तुभ पवारÎncă nu există evaluări

- Check List For PileDocument1 paginăCheck List For Pileइंजि कौस्तुभ पवारÎncă nu există evaluări

- Irc Gov in 067 2012Document152 paginiIrc Gov in 067 2012Akash Agarwal86% (7)

- Check List For Beam & SlabDocument1 paginăCheck List For Beam & Slabइंजि कौस्तुभ पवारÎncă nu există evaluări

- Cement CoeDocument3 paginiCement Coeइंजि कौस्तुभ पवारÎncă nu există evaluări

- Irc Gov in 092 1985 PDFDocument28 paginiIrc Gov in 092 1985 PDFMari MuthuÎncă nu există evaluări

- SoilDocument3 paginiSoilmp SinghÎncă nu există evaluări

- Acceptance Criteria For All MaterialsDocument1 paginăAcceptance Criteria For All Materialsइंजि कौस्तुभ पवारÎncă nu există evaluări

- Check List For Columns PDFDocument1 paginăCheck List For Columns PDFइंजि कौस्तुभ पवारÎncă nu există evaluări

- RunoffDocument6 paginiRunoffqutabshÎncă nu există evaluări

- Is 458-1988Document46 paginiIs 458-1988Rajashekhar Katta100% (2)

- 3812 1 PDFDocument14 pagini3812 1 PDFइंजि कौस्तुभ पवारÎncă nu există evaluări

- RCC Thumb RuleDocument7 paginiRCC Thumb RuleRahat ullah100% (6)

- Performas For Material Testing Laboratory (Civil)Document22 paginiPerformas For Material Testing Laboratory (Civil)M HAFEEZ RAJA0% (1)

- 300 Solved Problems in Geotechnical EngineeringDocument0 pagini300 Solved Problems in Geotechnical Engineeringmote3488% (17)

- Blasting CodeDocument59 paginiBlasting Codeइंजि कौस्तुभ पवारÎncă nu există evaluări

- 459Document10 pagini459rambinodÎncă nu există evaluări

- Types of Ties For and Placement of Reinforcing SteelDocument8 paginiTypes of Ties For and Placement of Reinforcing Steelइंजि कौस्तुभ पवारÎncă nu există evaluări

- Chemical Quality of TMT Bars: View Previous Topic View Next TopicDocument6 paginiChemical Quality of TMT Bars: View Previous Topic View Next Topicpatrik710Încă nu există evaluări

- Is 458-1988Document46 paginiIs 458-1988Rajashekhar Katta100% (2)

- Building Construction Damp ProofingDocument120 paginiBuilding Construction Damp Proofingइंजि कौस्तुभ पवारÎncă nu există evaluări

- MaterialsDocument147 paginiMaterialsइंजि कौस्तुभ पवारÎncă nu există evaluări

- Is 458-1988Document46 paginiIs 458-1988Rajashekhar Katta100% (2)

- SDS Sodium GluconateDocument4 paginiSDS Sodium GluconatemeÎncă nu există evaluări

- Chapter TwoDocument14 paginiChapter TwoEboO QQÎncă nu există evaluări

- Application of CFD in Thermal Power Plants PDFDocument4 paginiApplication of CFD in Thermal Power Plants PDFSylvesterÎncă nu există evaluări

- Porphyrins PDFDocument17 paginiPorphyrins PDFPk JaatÎncă nu există evaluări

- D 2564 - 96 - Rdi1njqtotzb PDFDocument5 paginiD 2564 - 96 - Rdi1njqtotzb PDFAndre CasteloÎncă nu există evaluări

- CR8047 Sulzer CompaX Short Report1Document20 paginiCR8047 Sulzer CompaX Short Report1DucVikingÎncă nu există evaluări

- WILKO - ASTM Type L PDFDocument1 paginăWILKO - ASTM Type L PDFAnonymous M0nvcv4Încă nu există evaluări

- Awwa C218 2008Document36 paginiAwwa C218 2008Moito Carvalho100% (1)

- Chem26.1 - ATQ6 - Double Indicator TitrationDocument2 paginiChem26.1 - ATQ6 - Double Indicator TitrationAlexander Gordon InesÎncă nu există evaluări

- Nuclear ReactorDocument13 paginiNuclear ReactorMouth with No teethÎncă nu există evaluări

- Metallurgy For Non Metallurgist - Module-2Document65 paginiMetallurgy For Non Metallurgist - Module-2ajaysharma_1009Încă nu există evaluări

- Ewald Summation Method for Calculating Ionic Crystal Configuration EnergiesDocument19 paginiEwald Summation Method for Calculating Ionic Crystal Configuration Energieservina dwiÎncă nu există evaluări

- Wobbe Index Calorific Value Handout Natural GasDocument8 paginiWobbe Index Calorific Value Handout Natural GasZuli VívnesÎncă nu există evaluări

- Chapter 1 - Chemical Reactions and Equations: Class - X ScienceDocument9 paginiChapter 1 - Chemical Reactions and Equations: Class - X ScienceMiten Gandhi100% (1)

- Carbonate Acidizing Design PDFDocument15 paginiCarbonate Acidizing Design PDFNelson PuentsÎncă nu există evaluări

- ADA Detectable Warning Plates - EJDocument8 paginiADA Detectable Warning Plates - EJironworkÎncă nu există evaluări

- Debye Specific Heat TheoryDocument3 paginiDebye Specific Heat TheoryJuly T Widya R100% (1)

- Contineous Dyeing of Reactive DyesDocument9 paginiContineous Dyeing of Reactive DyesMohammed Atiqul Hoque ChowdhuryÎncă nu există evaluări

- Bulletin 114 IOM Manual GP Steam DsfilterDocument4 paginiBulletin 114 IOM Manual GP Steam DsfiltervextersÎncă nu există evaluări

- Greener One-Pot Synthesis of Chromeno Oxazin and Oxazin Quinoline Derivatives and Their Antibacterial ActivityDocument5 paginiGreener One-Pot Synthesis of Chromeno Oxazin and Oxazin Quinoline Derivatives and Their Antibacterial ActivityIJAERS JOURNALÎncă nu există evaluări

- N ch3 07Document2 paginiN ch3 07yashÎncă nu există evaluări

- Biodegradation of Mineral Oils - A ReviewDocument6 paginiBiodegradation of Mineral Oils - A ReviewAlex RichardÎncă nu există evaluări

- HW Proteins EnzymesDocument2 paginiHW Proteins Enzymesapi-524061079Încă nu există evaluări

- Electronic Structure Calculations For Solids and Molecules: Theory and Computational MethodsDocument387 paginiElectronic Structure Calculations For Solids and Molecules: Theory and Computational MethodsJavier Gómez100% (1)

- Global Warming DebateDocument2 paginiGlobal Warming DebateAry WulanÎncă nu există evaluări

- Flat RollingDocument39 paginiFlat Rollinglamia97Încă nu există evaluări

- Small Scale Bu Is I Ness of Production of Liquid SoapDocument27 paginiSmall Scale Bu Is I Ness of Production of Liquid SoapIbrahem DahabÎncă nu există evaluări

- Achillea Millefolium L.Document5 paginiAchillea Millefolium L.Miroslav IlicÎncă nu există evaluări

- Active AbsorptionDocument2 paginiActive AbsorptionAÎncă nu există evaluări

- Gamma RayDocument5 paginiGamma RayDenisha Betaci GultomÎncă nu există evaluări