Documente Academic

Documente Profesional

Documente Cultură

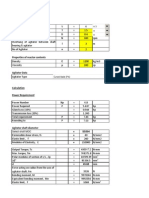

Tank and Vessel Agitator Sheet

Încărcat de

Anonymous jlLBRMAr3O0 evaluări0% au considerat acest document util (0 voturi)

308 vizualizări2 paginiThis document provides specifications for an agitator for a tank or vessel. It includes 37 points covering details of the process, mixing requirements, impeller design, tank/vessel dimensions, electrical and motor specifications, and general information. Specifications include the largest and smallest charge, operating pressure and temperature, viscosity of materials being mixed, impeller type and configuration, power requirements, and electrical standards. Installation details are also noted such as entry position, fixing method, and any guards or safety features required.

Descriere originală:

Datasheet for mixer

Drepturi de autor

© © All Rights Reserved

Formate disponibile

XLS, PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentThis document provides specifications for an agitator for a tank or vessel. It includes 37 points covering details of the process, mixing requirements, impeller design, tank/vessel dimensions, electrical and motor specifications, and general information. Specifications include the largest and smallest charge, operating pressure and temperature, viscosity of materials being mixed, impeller type and configuration, power requirements, and electrical standards. Installation details are also noted such as entry position, fixing method, and any guards or safety features required.

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca XLS, PDF, TXT sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

308 vizualizări2 paginiTank and Vessel Agitator Sheet

Încărcat de

Anonymous jlLBRMAr3OThis document provides specifications for an agitator for a tank or vessel. It includes 37 points covering details of the process, mixing requirements, impeller design, tank/vessel dimensions, electrical and motor specifications, and general information. Specifications include the largest and smallest charge, operating pressure and temperature, viscosity of materials being mixed, impeller type and configuration, power requirements, and electrical standards. Installation details are also noted such as entry position, fixing method, and any guards or safety features required.

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca XLS, PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 2

A.K.C.

TANK & VESSEL AGITATOR DATA SHEET Drawing No:

TECHNOLOGY

Project Name: Project No.:

sheet …….. Of ……..

Equipment No: No. Off: Associated Vessel/Tank* Item No:

Date

1. Largest and smallest charge:

2. Components added during mixing:

3. Agitator operating while vessel is being filled or product withdrawn? Yes / No*

4. If continuous, throughput per hour:

3

PROCESS

PROCESS DEPT. INFORMATION 5. Process duty: Mixing liquids / Dissolving / Suspensions / Emulsions / Gas absorption / Homogenisation*

6. Mixing effect: Violent / Medium / Moderate* Time available for mixing:

Date

7. Working Pressure: Design Pressure:

8. Working Temperature: Design Temperature:

9. Special Remarks:

2

10. Components % by weight:

Date

11. Temperature during mixing:

12. Specific gravity of components:

MIXING

1

13. Viscosity of mixing at mixing temperature:

14. Specific gravity of product at mixing temperature:

15. Size of solid particles:

Approved Process

Made/Revised by

16. Special Remarks:

Checked by

Description

Approved

17. Type of impeller:

18. Number of impellers on shaft:

19. Position of impellers:

20. Distance between shaft end & vessel: Bottom bearing:

21. Preferred impeller speed: Shaft diameter:

22. Type of drive: Direct / Vee belt / Fluid*

IMPELLER

23. Type of seal: Vapor / Packed gland / Mechanical / Easy replacement*

24. Method of installation: Assembled in / Assembled out* of vessel

25. Entry position:

26. Materials of construction:

27. Absorbed HP / KW*: Installed HP / KW*:

DESIGN DEPT. INFORMATION

28. Other information:

29. Dimensions: Capacity:

TANK OR VESSEL

30. Coils, baffles, etc.:

31. Fixing agitator (beams, flanges, etc.):

32. If at atmospheric pressure: Closed / Open* Can stuffing box be greased? Yes / No*

33. Headroom available above agitator:

34. Other information:

35. Agitator installed: Indoors/Outdoors Motor enclosure:

ELECT.

36. Electrical specification:

37. Any other electrical information:

38. Motor to be included: Yes / No*

39. Motor Will / Will not* be sent to manufacturer for assembly and allignment.

GENERAL

40. Threads: Unified /*

41. All rotating parts must be strictly guarded to BS 1649/ASME

42. Fixing bolts supplied by:

43. Net weight including motor:

44. Witnessed run in air:

45. General notes:

NOTE * indicates delete as necessary.

S-ar putea să vă placă și

- Shaft diameter calculation for stainless steelDocument1 paginăShaft diameter calculation for stainless steelAhmad Ashshiddieqy60% (5)

- Cpp-Tank DSGN Calc-Rev CDocument42 paginiCpp-Tank DSGN Calc-Rev CnamasralÎncă nu există evaluări

- Agitator DatasheetDocument2 paginiAgitator Datasheetmshah222Încă nu există evaluări

- Agitator LATESTDocument17 paginiAgitator LATESTHARIPRASAD100% (1)

- Sparger Design GuideDocument11 paginiSparger Design GuideHarshavardhan D. GorakhÎncă nu există evaluări

- Vessel DatasheetDocument1 paginăVessel Datasheetsdrtfg100% (1)

- Design of AgitatorDocument4 paginiDesign of AgitatoralexnomitaÎncă nu există evaluări

- Agitator DesignDocument5 paginiAgitator DesignSaepul RochmanÎncă nu există evaluări

- Tank Baffles Design CalcDocument8 paginiTank Baffles Design CalcJorge Alberto Martinez Ortiz100% (1)

- Design of AgitatorDocument3 paginiDesign of AgitatorManish PatelÎncă nu există evaluări

- AgitatorDocument2 paginiAgitatorThiruvilan Arakkonam Mohan100% (1)

- Gas Scrubbers: DescriptionDocument14 paginiGas Scrubbers: DescriptionPitiporn HasuankwanÎncă nu există evaluări

- 4 KL Reactor Data SheetDocument4 pagini4 KL Reactor Data Sheetpankil patelÎncă nu există evaluări

- Agitator Data (Fluid Properties, Client Data) 50Document23 paginiAgitator Data (Fluid Properties, Client Data) 50Mangesh Mandge100% (2)

- Agitator Power Requirement and Mixing Intensity CalculationDocument27 paginiAgitator Power Requirement and Mixing Intensity Calculation황종서100% (1)

- FRP TankDocument3 paginiFRP TankDota Ng100% (1)

- FRP Pipe BrochureDocument8 paginiFRP Pipe BrochurecrisjhairÎncă nu există evaluări

- Sizing For Vaporiser/Flash Vessel: InputsDocument3 paginiSizing For Vaporiser/Flash Vessel: InputsSaravana ChandranÎncă nu există evaluări

- Design of AgitatorDocument6 paginiDesign of AgitatorVishalÎncă nu există evaluări

- THERMAX BAG FILTER TECHNICAL DATA SHEETDocument18 paginiTHERMAX BAG FILTER TECHNICAL DATA SHEETpavaniÎncă nu există evaluări

- KBK Air Receiver Design Calculations ReportDocument70 paginiKBK Air Receiver Design Calculations ReportTejas ShahÎncă nu există evaluări

- Power Requirement (Agitator and High-Torque Stirrer)Document8 paginiPower Requirement (Agitator and High-Torque Stirrer)DozdiÎncă nu există evaluări

- Heat Exchanger Design Calculation EOR Condition Design InputsDocument4 paginiHeat Exchanger Design Calculation EOR Condition Design InputsSiva baalanÎncă nu există evaluări

- Agitator Guide for Mixing and Stirring Tank ProductsDocument10 paginiAgitator Guide for Mixing and Stirring Tank Productsagrocel_bhv5591Încă nu există evaluări

- Calculate Plate Thickness for Storage TanksDocument247 paginiCalculate Plate Thickness for Storage Tankscumpio425428Încă nu există evaluări

- Agitator Design for Batch Volume 6 VesselDocument2 paginiAgitator Design for Batch Volume 6 VesselDavid Lambert75% (8)

- Vertical Flash TankDocument2 paginiVertical Flash Tankkingathur26681Încă nu există evaluări

- Rotary Dryer Handbook PDFDocument34 paginiRotary Dryer Handbook PDFNichol Salas ManioÎncă nu există evaluări

- Tank DesignDocument2 paginiTank DesignkamleshyadavmoneyÎncă nu există evaluări

- Pipe Mech Design AWWA M45 ADocument5 paginiPipe Mech Design AWWA M45 AalvinchuanÎncă nu există evaluări

- Coil Heat CalculationDocument2 paginiCoil Heat CalculationTarmana Antt100% (1)

- Limpet Coil On Dish Design As Per PD5500Document1 paginăLimpet Coil On Dish Design As Per PD5500ABIDEEN BAMNEÎncă nu există evaluări

- AgitatorDocument10 paginiAgitatorSachin5586Încă nu există evaluări

- Agitator Power Calculation FormatDocument2 paginiAgitator Power Calculation FormatSandeep GosaviÎncă nu există evaluări

- Calculate Surface Area for Cylindrical TankDocument10 paginiCalculate Surface Area for Cylindrical TanksudjonoÎncă nu există evaluări

- Agitator Design Spreadsheet Version 1.2Document7 paginiAgitator Design Spreadsheet Version 1.2AndrewÎncă nu există evaluări

- Design of Flanges - Welded-On Integral Type 2010Document59 paginiDesign of Flanges - Welded-On Integral Type 2010bakellyÎncă nu există evaluări

- Agitator Vessel (Design&Costing)Document34 paginiAgitator Vessel (Design&Costing)imrancenakk100% (2)

- Dennis Gertenbach, and Brian L. Cooper: Solid - Liquid Separations in Pilot-And Commercial - Scale OperationsDocument25 paginiDennis Gertenbach, and Brian L. Cooper: Solid - Liquid Separations in Pilot-And Commercial - Scale Operationssushant_jhawerÎncă nu există evaluări

- FRP RF CalcDocument1 paginăFRP RF CalcmukeshÎncă nu există evaluări

- Agitator SelectionDocument20 paginiAgitator SelectionRamakrishna Koushik100% (2)

- Agitator Design CalcDocument5 paginiAgitator Design Calcranjit34380% (5)

- Tank and Vessel Agitator SheetDocument2 paginiTank and Vessel Agitator SheetSagarÎncă nu există evaluări

- Designer's data sheet for distillation column internalsDocument4 paginiDesigner's data sheet for distillation column internalsTarun BhatiaÎncă nu există evaluări

- Form 26-1 Specification Sheet For Asme Section Viii, Division 1 Mandatory Appendix 26 Bellows Expansion JointsDocument1 paginăForm 26-1 Specification Sheet For Asme Section Viii, Division 1 Mandatory Appendix 26 Bellows Expansion JointsEmma DÎncă nu există evaluări

- RSA-A4-PR-WI-02 (Metalizing) - Rev 0Document1 paginăRSA-A4-PR-WI-02 (Metalizing) - Rev 0Abhishek KadamÎncă nu există evaluări

- RSA-A4-PR-WI-03 (Painting) - Rev 0Document1 paginăRSA-A4-PR-WI-03 (Painting) - Rev 0Abhishek KadamÎncă nu există evaluări

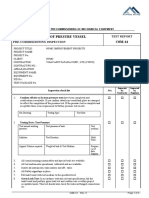

- Inspection/Test Certificate Client: M/S Machinary Sales Corporation. Certificate No.: TECHNO-001Document1 paginăInspection/Test Certificate Client: M/S Machinary Sales Corporation. Certificate No.: TECHNO-001Ankur KansalÎncă nu există evaluări

- CRS -MSJSA For Lube Oil Flushing 43Document3 paginiCRS -MSJSA For Lube Oil Flushing 43Riaz Ali Khan BangashÎncă nu există evaluări

- Application Enquiry / Questionnaire: CustomerDocument3 paginiApplication Enquiry / Questionnaire: CustomerSuhas KODREÎncă nu există evaluări

- TEMA StandardsFAQ 2020Document11 paginiTEMA StandardsFAQ 2020liÎncă nu există evaluări

- IH process-SOPDocument2 paginiIH process-SOPSelvakumar MÎncă nu există evaluări

- P.T. PLN Daily Construction ReportDocument1 paginăP.T. PLN Daily Construction ReportJonri SitompulÎncă nu există evaluări

- C0M-14 Hydrostatic Test of Pressure VesselDocument3 paginiC0M-14 Hydrostatic Test of Pressure VesselHong Trung DuongÎncă nu există evaluări

- Tempering Process-SOPDocument2 paginiTempering Process-SOPSelvakumar MÎncă nu există evaluări

- Format Daily ReportDocument4 paginiFormat Daily ReporttiaralarasatiÎncă nu există evaluări

- CO-M PRECOMMISSIONING REPORTDocument3 paginiCO-M PRECOMMISSIONING REPORTHong Trung DuongÎncă nu există evaluări

- Standard Operating Procedure of Fluidized Bed DryerDocument4 paginiStandard Operating Procedure of Fluidized Bed DryerSolomonÎncă nu există evaluări

- JOB 1 ON OFF SinggleDocument4 paginiJOB 1 ON OFF Singgledh4nyÎncă nu există evaluări

- BaptismDocument1 paginăBaptismAnonymous jlLBRMAr3OÎncă nu există evaluări

- The Orkar Coup of April 22Document14 paginiThe Orkar Coup of April 22Anonymous jlLBRMAr3O100% (1)

- Pioneer Road: Ijegun DepotDocument8 paginiPioneer Road: Ijegun DepotAnonymous jlLBRMAr3OÎncă nu există evaluări

- Inuwa Yahaya 100 Days AchievementsDocument19 paginiInuwa Yahaya 100 Days AchievementsAnonymous jlLBRMAr3OÎncă nu există evaluări

- HAZID StudiesDocument142 paginiHAZID StudiesMartahanManurung100% (1)

- 14, Ajagbodudu RD: Oghara DepotDocument7 pagini14, Ajagbodudu RD: Oghara DepotAnonymous jlLBRMAr3O100% (1)

- Employee organization listDocument1 paginăEmployee organization listAnonymous jlLBRMAr3OÎncă nu există evaluări

- Personal Account Opening Form: Referral CodeDocument2 paginiPersonal Account Opening Form: Referral CodeAnonymous jlLBRMAr3OÎncă nu există evaluări

- Original Research Article Evaluation of Naphtha Hydrotreating Unit (Nhu) of Kaduna Refinery Using Pinch Techology Lukman, Y., Yesufu, I.S., Otoikhian, S.K. and Yesufu, S.IDocument7 paginiOriginal Research Article Evaluation of Naphtha Hydrotreating Unit (Nhu) of Kaduna Refinery Using Pinch Techology Lukman, Y., Yesufu, I.S., Otoikhian, S.K. and Yesufu, S.IAnonymous jlLBRMAr3OÎncă nu există evaluări

- Hydrogen DemandDocument1 paginăHydrogen DemandAnonymous jlLBRMAr3OÎncă nu există evaluări

- Your reservation is confirmedDocument1 paginăYour reservation is confirmedAnonymous jlLBRMAr3OÎncă nu există evaluări

- Aspen Energy Analyzer TutorialDocument101 paginiAspen Energy Analyzer TutorialMcn Serg100% (3)

- Flight Confirmation PDFDocument1 paginăFlight Confirmation PDFAnonymous jlLBRMAr3OÎncă nu există evaluări

- Starting Capital For Satchet Water Factory S/N Item Unit Cost Quantity Total Cost 1 600,000.00Document1 paginăStarting Capital For Satchet Water Factory S/N Item Unit Cost Quantity Total Cost 1 600,000.00Anonymous jlLBRMAr3OÎncă nu există evaluări

- Universal Industrial Gases, Inc. ... Hydrogen Unit Conversion (Gas, Liquid)Document1 paginăUniversal Industrial Gases, Inc. ... Hydrogen Unit Conversion (Gas, Liquid)Anonymous jlLBRMAr3OÎncă nu există evaluări

- Why Self-RelianceDocument16 paginiWhy Self-RelianceAnonymous jlLBRMAr3OÎncă nu există evaluări

- Building Self EsteemDocument3 paginiBuilding Self EsteemAnonymous jlLBRMAr3O100% (1)

- Quotation Quotation Item Quantity Unit Price Total Item QuantityDocument2 paginiQuotation Quotation Item Quantity Unit Price Total Item QuantityAnonymous jlLBRMAr3OÎncă nu există evaluări

- African Adventists and Self-RelianceDocument11 paginiAfrican Adventists and Self-RelianceAnonymous jlLBRMAr3OÎncă nu există evaluări

- Towards Self-Reliance - A Challenge For African Churches and Ministries - Missio NexusDocument18 paginiTowards Self-Reliance - A Challenge For African Churches and Ministries - Missio NexusAnonymous jlLBRMAr3OÎncă nu există evaluări

- Ministry Magazine - Self-Reliance in The Indigenous ChurchDocument9 paginiMinistry Magazine - Self-Reliance in The Indigenous ChurchAnonymous jlLBRMAr3OÎncă nu există evaluări

- Sister Winnie's Insights on Self-RelianceDocument7 paginiSister Winnie's Insights on Self-RelianceAnonymous jlLBRMAr3OÎncă nu există evaluări

- Administration - Self RelianceDocument4 paginiAdministration - Self RelianceAnonymous jlLBRMAr3OÎncă nu există evaluări

- Start Your Own Financially Self-Sufficient School GuideDocument38 paginiStart Your Own Financially Self-Sufficient School GuideAnonymous jlLBRMAr3OÎncă nu există evaluări

- Towards Financial Self RelianceDocument156 paginiTowards Financial Self RelianceAnonymous jlLBRMAr3OÎncă nu există evaluări

- 670,000 People Helped by The Church To Be Self-Reliant Since 2015Document4 pagini670,000 People Helped by The Church To Be Self-Reliant Since 2015Anonymous jlLBRMAr3OÎncă nu există evaluări

- 5 Reasons Why Self-Reliance Is The Key To A Successful LifeDocument13 pagini5 Reasons Why Self-Reliance Is The Key To A Successful LifeAnonymous jlLBRMAr3OÎncă nu există evaluări

- Ministry Magazine - Self-Reliance in The Indigenous ChurchDocument9 paginiMinistry Magazine - Self-Reliance in The Indigenous ChurchAnonymous jlLBRMAr3OÎncă nu există evaluări

- Self-Reliance Initiative - Bentonville Self-Reliance Resource CenterDocument4 paginiSelf-Reliance Initiative - Bentonville Self-Reliance Resource CenterAnonymous jlLBRMAr3OÎncă nu există evaluări

- Oil EstimateDocument1 paginăOil EstimateAnonymous jlLBRMAr3OÎncă nu există evaluări

- Data Collection ProcedureDocument58 paginiData Collection ProcedureNorjenn BarquezÎncă nu există evaluări

- Study apparel export order processDocument44 paginiStudy apparel export order processSHRUTI CHUGH100% (1)

- Direct FileActDocument17 paginiDirect FileActTAPAN TALUKDARÎncă nu există evaluări

- Paulson 2007 Year End Report Earns Nearly 600Document16 paginiPaulson 2007 Year End Report Earns Nearly 600Tunaljit ChoudhuryÎncă nu există evaluări

- GA 7 Parts ManualDocument565 paginiGA 7 Parts ManualDave SchallÎncă nu există evaluări

- MS For The Access Control System Installation and TerminationDocument21 paginiMS For The Access Control System Installation and Terminationwaaji snapÎncă nu există evaluări

- Lecture Notes in Airport Engineering PDFDocument91 paginiLecture Notes in Airport Engineering PDFMaya RajÎncă nu există evaluări

- Case Study ON: The Spark Batteries LTDDocument8 paginiCase Study ON: The Spark Batteries LTDRitam chaturvediÎncă nu există evaluări

- Nikita Project 01-06-2016Document38 paginiNikita Project 01-06-2016Shobhit GoswamiÎncă nu există evaluări

- Open Recruitment Member Kejar Mimpi Periode 2023 (Responses)Document22 paginiOpen Recruitment Member Kejar Mimpi Periode 2023 (Responses)Sophia Dewi AzzahraÎncă nu există evaluări

- Creating Rapid Prototype Metal CastingsDocument10 paginiCreating Rapid Prototype Metal CastingsShri JalihalÎncă nu există evaluări

- OFW Dependent Scholarship AssessmentDocument3 paginiOFW Dependent Scholarship AssessmentJosebeth CairoÎncă nu există evaluări

- Guidelines Regarding The Handling of Cable Drums During Transport and StorageDocument5 paginiGuidelines Regarding The Handling of Cable Drums During Transport and StorageJegan SureshÎncă nu există evaluări

- People VS Yancon-DumacasDocument2 paginiPeople VS Yancon-Dumacasvincent nifasÎncă nu există evaluări

- Tugasan HBMT 4303Document20 paginiTugasan HBMT 4303normahifzanÎncă nu există evaluări

- Oteco 3Document12 paginiOteco 3VRV.RELATORIO.AVARIA RELATORIO.AVARIAÎncă nu există evaluări

- Lilypad Hotels & Resorts: Paul DidriksenDocument15 paginiLilypad Hotels & Resorts: Paul DidriksenN.a. M. TandayagÎncă nu există evaluări

- TMS Software ProductsDocument214 paginiTMS Software ProductsRomica SauleaÎncă nu există evaluări

- Block P2P Traffic with pfSense using Suricata IPSDocument6 paginiBlock P2P Traffic with pfSense using Suricata IPSEder Luiz Alves PintoÎncă nu există evaluări

- Money and Financial InstitutionsDocument26 paginiMoney and Financial InstitutionsSorgot Ilie-Liviu100% (1)

- Training Prospectus 2020 WebDocument89 paginiTraining Prospectus 2020 Webamila_vithanageÎncă nu există evaluări

- CLS1Document3 paginiCLS1Shaina Kaye De GuzmanÎncă nu există evaluări

- Plastic Waste Powerpoint TemplateDocument39 paginiPlastic Waste Powerpoint TemplateVinh Lê KhảiÎncă nu există evaluări

- Grate Inlet Skimmer Box ™ (GISB™ ) Suntree Technologies Service ManualDocument4 paginiGrate Inlet Skimmer Box ™ (GISB™ ) Suntree Technologies Service ManualOmar Rodriguez OrtizÎncă nu există evaluări

- How To Block Facebook in Mikrotik Using L7 Protocols (Layer 7) - Lazy Geek - )Document11 paginiHow To Block Facebook in Mikrotik Using L7 Protocols (Layer 7) - Lazy Geek - )oscar_198810Încă nu există evaluări

- Individual TaxpayersDocument3 paginiIndividual TaxpayersJoy Orena100% (2)

- Vaccination Management System of Brgy 6 (Table of Contents)Document8 paginiVaccination Management System of Brgy 6 (Table of Contents)Ryan Christian MenorÎncă nu există evaluări

- Draft Horse Primer Guide To Care Use of Work Horses and Mules 1977Document396 paginiDraft Horse Primer Guide To Care Use of Work Horses and Mules 1977Radu IliescuÎncă nu există evaluări

- SC upholds invalid donation of land shareDocument3 paginiSC upholds invalid donation of land shareAizza JopsonÎncă nu există evaluări

- Indian Banking SystemDocument10 paginiIndian Banking SystemSony ChandranÎncă nu există evaluări