Documente Academic

Documente Profesional

Documente Cultură

Imds Efficiency and Effectiveness V 1 2

Încărcat de

Satyawan SableTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Imds Efficiency and Effectiveness V 1 2

Încărcat de

Satyawan SableDrepturi de autor:

Formate disponibile

IMDS Efficiency & Effectiveness Version 1.

IMDS Efficiency & Effectiveness

Foreword

The purpose of this document is to provide guidance in evaluating the efficiency and effectiveness of a

Business Unit IMDS process. It can be accomplished by utilizing the attached Efficiency and

Effectiveness Questionnaire. The document is optional. It was approved by the IMDS Steering

Committee.

IMDS Steering Committee is convinced that the questions as such could be very helpful to prepare or

optimise the company internal IMDS-processes, but the IMDS Steering Committee do not see the need to

do audits of the supply chain.

IMDS Steering Committee

Chair J. Lundström,

September2007

Created on 11.Oct.2007 © R.Dües & H.Traiser Page 1 of 14

IMDS Efficiency and Effectiveness V.1.2

IMDS Efficiency & Effectiveness

1.0 Purpose

The purpose of this document is to provide guidance in evaluating the efficiency and effectiveness of a

Business Unit (BU) IMDS process. It can be accomplished by utilizing the attached Efficiency and

Effectiveness Questionnaire. The document is optional. It was approved by the IMDS Steering

Committee.

Definition: Effectiveness means completing activities so that organizational goals are attained ("doing the

right things") concerned with ends. Effectiveness optimizes the reach of accomplishment whereas

efficiency optimizes the effort and accomplishment.

2.0 References

• All IMDS Recommendations

• Global Automotive Declarable Substance List (GADSL) under www.gadsl.org

• Legal requirements to automotive industry (EU and worldwide) as mentioned in this document

• DIN-ISO 9000

3.0 Periodic Process Evaluation

To achieve optimum efficiency and effectiveness, the following IMDS Efficiency and Effectiveness

Questionnaire will be needed to be repeated periodically by the upper tiern-1 Business Unit (the

customer) once being chosen as the valid document for inter-business unit purposes. The interval

between the periodical evaluations should not exceed 2 years. In alternative the Business Unit’s

efficiency and effectiveness can also be assessed by external but accredited consultants.

4.0 Definitions/Descriptions

4.1 Definition: Business Unit (BU)

A Business Unit (BU) is an entity providing its automotive product(s) (assemblies) to the next

higher tier level. The product is then incorporated into the customer’s product. A BU can have only

one single IMDS ID org.-address.

The automotive BU is part of the supply chain, producing materials (especially in the beginning of

the supply chain) or components and assemblies (mid/end of the supply chain). Parallel to the

flow of the materials/components/assemblies there exists a flow of information. The material

declaration through IMDS system is part of this information flow.

Created on 11. Okt. 2007 © Dües & Traiser Page 2 of 14

IMDS Efficiency and Effectiveness V.1.2

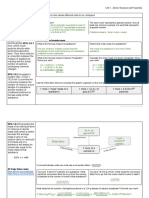

Input Flow of products along the supply chain Output

Flow of material information along the supply chain

BU (Business Unit)

4.2 Definition: Component

4.2.1 Definition per EU Directive 2005/64/EC (‘RRR’-Directive):

‘Component part’ means any part or any assembly of parts which is included in a vehicle at the

time of its production. It also covers components and separate technical units as defined in Article

No. 2 of Directive 70/156/EEC.

4.2.2 Definition per IMDS

The definition in IMDS follows the ‘sender-recipient model’. Any product put onto the market from

one BU to the other BU, along the automotive supply chain and which is used to build up an

automotive vehicle is a component, as noted in this .

For a better understanding please follow this illustration here:

BU1 ships product BU2 ships product BU3

This definition covers in IMDS terms components, semi-components and materials (see IMDS

REC001), once shipped within the supply chain. It does not cover basic substances.

Created on 11. Okt. 2007 © Dües & Traiser Page 3 of 14

IMDS Efficiency and Effectiveness V.1.2

4.2.3 Raw material supplied to the automotive industry

4.2.3.1 Substance (EU Directive 76/769/EEC, article 1, clause 3)

“Substance" describes a chemical element and its compounds as it occurs in the natural

state or as produced by industry.

4.2.3.2 Preparation (EU Directive 76/769/EEC, article 1, clause 3)

"Preparations" are defined as mixtures or solutions composed of two or more substances,

where both, "Preparation" and "Substance", are covered by IMDS terminology of

“materials”. Metallic alloys which consist of different substances can be defined as

“preparation” as well.

4.2.3.3 MDS Reporting Requirement starts at (Semi-) Component Level

Raw materials supplied to a next tier level must be reported in IMDS as materials. Raw

materials, which are mixed to a new homogenous material (e.g. master batch colour from

supplier A and a basic material plastic granular from a supplier B), have to be described in

the same way.

A component per definition also covers the IMDS definition of a semi-component due to the fact

that also raw materials are being supplied to the automotive tier customers. All Business Units BU

supplying products into the automotive supply chain are affected by the IMDS material

documentation requirement. Business units trading components, semi-components and/or

materials for automotive industry are not exempted.

5.0 Business Unit (BU) requirements

An IMDS process should contain the following:

5.1 Business Unit (BU) material data collection

The Business Unit (BU) is required to collect material data information of all incoming automotive

products from its suppliers. All IMDS component material data needs to reference suppliers’ data.

5.2 Business Unit (BU) assessing its supplier

The Business Unit (BU) is required to assess its sub-supplier’s material collection process by utilizing

the Efficiency and Effectiveness Questionnaire (see in following).

5.3 Business Unit (BU) IMDS personnel requirements

The Business Unit (BU) is required to have only IMDS trained personnel assigned to the IMDS

process to validate in-coming MDS from suppliers and create MDS for customers.

5.4 Business Unit (BU) IMDS Efficiency Questionnaire

The Business Unit (BU) is to utilize the Efficiency and Effectiveness Questionnaire.

Created on 11. Okt. 2007 © Dües & Traiser Page 4 of 14

IMDS Efficiency and Effectiveness V.1.2

5.5 Additional general Efficiency and Effectiveness Requirements

5.5.1 Final Assessment Result

The final assessment result is to be signed by both assessing and assessed BU, while the

questionnaire responses are to be treated with confidentiality. Only the assessed BU is allowed to

give information about assessment results to third parties.

5.5.2 Qualification of Auditor

The auditor assessing the BU needs to be qualified and is to have at least 3 years of experience

on/with IMDS.

5.5.3 Re-assessment

Should the assessment result not be satisfactory, corrective measures are to be implemented and

a new target date of re-assessment is to be arranged. In the re-assessment the results of the

previous assessment are to be utilized. The re-assessment date is to be no later than 8 weeks

from the date of the unsatisfactory assessment.

5.5.4 Quality of Material Data

The quality of the BU’s material data is defined by all IMDS Recommendations valid at the time of

the material datasheets’ submission and by customer IMDS reporting requirements.

5.5.5 Detect and avoid System

The BU is to have established a suitable process system in order to detect and avoid non-

conformities regarding IMDS Recommendations and must have a corrective action plans in place.

Any violation of the quality of material data (ref. 5.5.4) is a non-conformity.

5.5.6 Traceability

For traceability reasons any defect or non-compliant IMDS datasheet generated by the BU must

be comprehensible, identifiable and allocable per program and component. An example of a

defect or non-compliant material datasheet would be a material datasheet that is in non-

compliance to the GADSL-list (ref. www.gadsl.org).

5.5.7 Necessity to perform Tiern+1 assessments

The assessed BU is to regularly assess all its own suppliers (Tiern+1) using this document.

Created on 11. Okt. 2007 © Dües & Traiser Page 5 of 14

IMDS Efficiency and Effectiveness V.1.2

6.0 IMDS Efficiency and Effectiveness Questionnaire

6.1 Purpose

Efficiency is the relationship between results achieved and resources used. The following

questionnaire should be used to establish a benchmark to the IMDS processes of the assessed

Business Unit (BU).

6.2 General Criteria Requirement

Any of the criteria that will be assumed or considered for a BU IMDS process requires the provision

of proof or sufficient level of evidence by the certified and assessed BU. It is up to the

auditing/assessing party (i.e. tiern-1 level BU) whether to accept the required BU’s feedback or if the

BU’s customer will follow the maximum requirement in this document.

6.3 Efficiency Calculation

The following questionnaire should help the BU to analyze its own process of material declaration

and to run a lean in-house IMDS process. The questionnaire will identify all parties which are

involved in the process of material tracking between the tiern+1 supplier, the BU (as part of the supply

chain) and the tier n-1 supplier (next level customer in the supply chain).

6.4 IMDS Material Data by internal or external source

The BU can decide to create and/or validate IMDS material data with its own personnel or to have

external expert personnel (e.g. consultants) performing the IMDS process on behalf of the BU. In

either case the BU is solely responsible for the BU’s material data and audit result, and therefore is

also responsible for ensuring the qualification of the personnel (external or internal) involved in the

IMDS process.

An external source (i.e. consultant) needs not to be assessed if a valid IMDS Efficiency proof was

made available to the assessing party before the audit.

Created on 11. Okt. 2007 © Dües & Traiser Page 6 of 14

IMDS Efficiency and Effectiveness V.1.2

7.0 IMDS Efficiency and Effectiveness Assessment Evaluation

This section covers basic requirements keeping the BU’s IMDS process efficient.

Note: The assessment is not to be continued by the assessing party if any of the Business Unit

requirements described in this document per section 5 were not met by the assessed BU.

7.1 Personnel and Organizational Requirements to the BU

7.1.1 Qualification of Employee(s)

BU employee(s), directly involved in the validation, creation and submission process of IMDS

material datasheets, is/are continuously trained (minimum annually) in IMDS and the training

certificates are made available.

Alternative: Employee(s), concerned in the validation and creation process of IMDS material

datasheets, is/are working with the IMDS System a minimum of 3 years.

Answer (20 Points): Result: 0

7.1.2 Employees’ job description covers IMDS

BU employee(s), directly involved in the validation, creation and submission process of IMDS

material datasheets, have a detailed job description that specifies all IMDS deliverables.

Answer (10 Points): Result: 0

7.1.3 Employee(s) educational status

BU employee(s), directly involved in the validation, creation and submission process of IMDS

material datasheets, has/have a technical degree (preferable in chemistry, materials or science)

or has/have a minimum of 3 years experience working with the IMDS.

Answer (20 Points): Result: 0

7.1.4 Employee(s) performing IMDS Material Data Validation

Only the BU’s IMDS qualified personnel (ref. 5.1.1) is/are authorized in the material data

validation process and can accept the BU’s supplier material datasheets. Any other

personnel is/are excluded from this.

Answer (20 Points): Result: 0

Created on 11. Okt. 2007 © Dües & Traiser Page 7 of 14

IMDS Efficiency and Effectiveness V.1.2

7.1.5 BU’ IMDS personnel included in BU’s organization

All BU’s personnel involved in the IMDS process, covering the BU’s IMDS qualified personnel

(ref. 5.1.1) as well as peripherally involved personnel, is/are located in the BU’s organizational

chart, such as for

Program Management

Quality, for PPAP and part submission warrant

Purchasing

Materials and Design (Engineering)

Answer (20 Points): Result: 0

7.1.6 Involvement of Research and Development

The BU owns and utilises an IMDS process workflow involving the research, development and

engineering department(s). Those departments are informed and take action considering when

a component status is updated due to legal restriction and customer concern (ref. GADSL-list /

substance of concern threshold updates). The BU shows evidence that its design as well as its

production processes is legal and customer reporting compliant.

Answer (10 Points): Result: 0

7.2 General Process related Requirements to the BU

7.2.1 IMDS Process Flow Chart

The IMDS process flow chart describes all steps of the BU’s IMDS process. For each IMDS

process step all characteristics are defined and individual deliverables described.

Answer (10 Points): Result: 0

7.2.2 Process Flow Communication

The IMDS process flow chart is communicated within the BU’s organization to all IMDS-involved

employees, to the BU’s IMDS experts as well as partially involved personnel.

Answer (10 Points): Result: 0

7.2.3 Process Operation Instruction

Derived from the BU IMDS process flow chart the instructions are available in a procedure

manual and/or in operational instructions.

Answer (20 Points): Result: 0

7.2.4 Process Key Indicators

The BU’s IMDS process key indicators are recognized, identified and being recorded.

Answer (10 Points): Result: 0

Created on 11. Okt. 2007 © Dües & Traiser Page 8 of 14

IMDS Efficiency and Effectiveness V.1.2

7.2.5 Process steps of potential risk

The BU has a system in place to identify potential IMDS process risks (internal and external)

and can name responsible parties and corrective activities within the BU.

Answer (10 Points): Result: 0

7.3 BU Validation of Material Data

Data being submitted to the BU is to be validated against current IMDS Recommendations.

7.3.1 Utilization of IMDS Upload Request Function

Does the BU utilize the IMDS (Upload) Request Function in IMDS for sending IMDS reporting

requests to the BU’s Tiern+1 supplier?

Answer (20 Points): Result: 0

7.3.2 GADSL-List as Reference for Substances of Concerns

The current version GADSL listed under www.gadsl.org is used to identify Substances of

Concern (SoC) and is the BU’s standard reference list (worldwide/locally).

Note: The assessment is to be stopped, if the answer is negative.

Answer (30 Points): Result: 0

7.3.3 GASDL Substance of Concern “Expiration Date”

All reported part numbers with GADSL listed substances having an expiration date are under the

BU’s control.

Answer (30 Points): Result: 0

7.3.4 Reference to BU’s Supplier(s) data

The BU can prove and make evident that all BU IMDS material datasheets are referenced to

material datasheets from the BU’s supplier(s) (exception: material(s) produced/shipped within

the BU or provided by the IMDS Steering Committee Org.-ID 423.).

The assessment is to be stopped, if the answer is negative.

Answer (20 Points): Result: 0

7.3.5 Identification of Substances of Concerns

The BU can prove and make evident that it can identify Substances of Concern (ref. GADSL) for

all its products (e.g. by in-house tool) at any time and flags such substances.

Answer (30 Points): Result: 0

Created on 11. Okt. 2007 © Dües & Traiser Page 9 of 14

IMDS Efficiency and Effectiveness V.1.2

7.4 Consolidation of the BU’s supplier IMDS Data (assembled data)

Validated IMDS data submitted to the BU is to be consolidated/assembled reflecting the BU’s

product(s) shipped to the tiern-1 customer.

7.4.1.a Plant/Manufacturing BOMs used to consolidate the BU’s Datasheets

The BU utilizes its product manufacturing Bill of Material (short: Man.-BoM) in order to

consolidate the validated supplier IMDS material data (exp.: BU’s MDS produced in-house)

Answer (20 Points): Result: 0

7.4.1.b Engineering BOMs used to consolidate the BU’s IMDS Datasheets

The BU utilizes its Engineering Bill of Material (short: Eng.-BoM) in order to consolidate the

validated supplier IMDS material data (exp.: BU’s materials produced in-house)

Answer (10 Points): Result: 0

Note: Both methods of 7.4.1.a and 7.4.1.b can be established in the BU, but only one answer

shall be evaluated and chosen (exclusion clause with Manu.-BOM preference)

7.4.2 IMDS Data is validated before submission

The IMDS data to be submitted to the BU’s tiern-1 customer(s) is validated again against the

GADSL-list and against customer specific material data reporting requirements before

submission.

Answer (10 Points): Result: 0

7.4.3 Rejected IMDS Data Planning

In case where the IMDS data submitted to the BU’s tiern-1 customer(s) is rejected, the BU can

provide corrective planning initiatives in order to become GADSL and customer compliant

(categories, disputation, rejection loops)?

Answer (20 Points): Result: 0

7.5 The BU performing supplier audits

The assessed BU is to assess its Tiern+1 supplier(s) using this Recommendation and its annex.

7.5.1 Requirement of IMDS compliance to Tiern+1 suppliers

The BU requires all its Tiern+1 suppliers to be compliant with all IMDS Recommendations.

Answer (30 Points): Result: 0

Created on 11. Okt. 2007 © Dües & Traiser Page 10 of 14

IMDS Efficiency and Effectiveness V.1.2

7.5.2 Tiern+1 supplier performance evaluations

The BU performs statistical analysis of each Tiern+1 supplier IMDS effectiveness performance of

IMDS data submitted to the BU. The statistic is updated monthly and reflects a ½ year (6 month)

period. The error rate required of the BU Tiern+1 supplier(s) is maximum 2% according to the

following equation:

Rejected Material datasheets [6 month]

≤ 2 % [error rate]

Submitted Material datasheets [6 month]

Answer (20 Points): Result: 0

7.5.3 IMDS Efficiency and Effectiveness Assessment Planning

The BU performs on regular basis (maximum interval of 2 years) Tiern+1 supplier assessments,

or in alternative performed by external accredited consultants, utilizing the IMDS Efficiency &

Effectiveness Evaluation (IMDS E&E)?

Answer (20 Points): Result: 0

7.5.4 List of Assessed / to be Assessed Tiern+1 suppliers

The BU can provide a list of already assessed Tiern+1 suppliers and/or can provide planning

details of assessed Tiern+1 suppliers for the coming 12 months time (= provision of future

assessment planning).

Answer (20 Points): Result: 0

7.5.5 Material Data Management as part of the BU’s Purchasing Strategy

The BU can provide defined (purchasing/quality) sanctioned processes for controlling Tiern+1

suppliers infringing IMDS submission deadlines and repeated incorrect IMDS reporting.

Answer (30 Points): Result: 0

7.5.6 Material Data Management as part of the BU’s Exclusion Strategy

The BU can provide a defined (purchasing) process wherein Tiern+1 suppliers are excluded from

future development process for repeated material non-compliances and violation of IMDS

Recommendations or customer IMDS reporting requirements.

Answer (30 Points): Result: 0

Created on 11. Okt. 2007 © Dües & Traiser Page 11 of 14

IMDS Efficiency and Effectiveness V.1.2

7.6 Additional Environmental Applications

This section covers the BU’s environmental design capabilities.

7.6.1 BU’s Policy and Objective Reducing Material Variety

The BU’s material data and management are used to reduce material variations in development

programs and products. Note: Those points will be only added to the BU’s final result if the BU

was rated minimum AB during the assessment.

Answer (10 Points): Result: 0

7.6.2 BU’s Recycling Policy and Objective

The BU’s material data and management are used in the BU’s development programs and

environmental considerations/decisions (DfE - Design for Environmental). The BU brings the

material data information (from all stages of the product life cycle) into the design process to

improve design decision-making and optimize product performance. Note: Those points will be

only added to the BU’s final result if the BU was rated minimum AB during the assessment.

Answer (10 Points): Result: 0

8.0 BU IMDS Performance Evaluation *1

The BU performs statistical analysis of its own IMDS effectiveness performances regarding IMDS

datasheets submitted to the BU’s Tiern-1 customer(s). The statistic is updated monthly and reflects a ½

year (6 month) period. The maximum error rate required to the BU is 2%, using this equation:

Rejected Material datasheets [6 month]

≤ 2 % [error rate]

Submitted Material datasheets [6 month]

The total of submitted datasheets includes every version of a material datasheet submitted to the BU’s

Tiern-1 customer(s) and includes datasheets rejected by the BU’s Tiern-1 customer(s) for the given period.

Only material datasheets submitted according to the IMDS Recommendations and to customer

requirements are to be considered into the equation, whereas material datasheets under disputation are

not being considered.

Datasheets, rejected by the BU’s Tiern-1 customer(s) over the last 6 months, are [qty] 1

Datasheets, the BU submitted to Tiern-1 customer(s) over the last 6 months, are [qty] 1

Derived from above the current BU effectiveness error rate to the auditing Tiern-1 customer

a.) is ≤ 1 percent (40 Points): Result: 0

b.) is> 1 percent ≤ 2 percent (20 Points): Result: 0

c.) is > 2 percent (0 Points): Result: 0

Created on 11. Okt. 2007 © Dües & Traiser Page 12 of 14

IMDS Efficiency and Effectiveness V.1.2

9.0 Final Business Unit Evaluation – Summary

The final efficiency calculation is to be performed during the BU’s audit. Its assessment result is to be

presented immediately to the BU. The assessment evaluation takes only applicable items into the

calculation. Non-applicable questionnaire items will not be considered.

Example: If the BU does not use GASDL-listed substances for its products then it is not applicable to

control GASDL expiration dates. In such a case the audit questionnaire item “GASDL Substance of

Concern “Expiration Date”” is not considered and will not be counted into the BU Efficiency Calculation

9.1 Basic Evaluation

The basic evaluation covers the audit items of section 7.1 to 7.5. The basic evaluation is weighted by

60 percent to the final audit result.

9.1.1 Evaluation of BU’s Performance – Section 7.1

The performances on “Personnel and Organizational Requirements to the BU” are evaluated.

The maximum achievable number of points is [Total Possible: 100 ].

The assessed BU achieved [Total Achieved: 0 ].

9.1.2 Evaluation of BU’s Performance – Section 7.2

The performances on “General Process related Requirements to the BU” are evaluated.

The maximum achievable number of points is [Total Possible: 60 ].

The assessed BU achieved [Total Achieved: 0 ].

9.1.3 Evaluation of BU’s Performance – Section 7.3

The performances on “BU Validation of Material Data” are evaluated.

The maximum achievable number of points is [Total Possible: 130 ].

The assessed BU achieved [Total Achieved: 0 ].

9.1.4 Evaluation of BU’s Performance – Section 7.4

The performances on “Consolidation of the BU’s supplier IMDS Data” are evaluated.

The maximum achievable number of points is [Total Possible: 50 ].

The assessed BU achieved [Total Achieved: 0 ].

9.1.5 Evaluation of BU’s Performance – Section 7.5

The performances on “The BU performing supplier audits” are evaluated.

The maximum achievable number of points is [Total Possible: 150 ].

The assessed BU achieved [Total Achieved: 0 ].

9.2 Additional Environmental Evaluation – Section 7.6

The additional environmental evaluation covers the audit items underneath section 7.6.

The additional environmental evaluation is weighted by 10 percent to the final audit result.

The performances on “Additional Environmental Applications” are evaluated.

The maximum achievable number of points is [Total Possible: 20 ].

The assessed BU achieved [Total Achieved: 0 ].

9.3 Effectiveness Evaluation – Section 8.0

The effectiveness evaluation covers the items of section 8 and it is weighted by 40 percent to the

final assessment result. The performances on “BU IMDS Effectiveness Performance Evaluation” are

evaluated.

The maximum achievable number of points is [Total Possible: 40 ].

The assessed BU achieved [Total Achieved: 0 ]

Created on 11. Okt. 2007 © Dües & Traiser Page 13 of 14

IMDS Efficiency and Effectiveness V.1.2

10.0 Assessment Result

The efficiency assessment result has maximum 110% points according to the formula:

[∑ (section 7.1 to section 7.5)] *60 + [ ∑ (section 8.0) ] * 40 + [∑ (section 7.6)] * 10

if BU reaches AB Rating

The Business Unit [BU name]

with the IMDS ID address [IMDS-ID-No.]

was assessed on IMDS Efficiency and Effectiveness on [date]

by Customer / or by accredited Company

with the following final audit result [Total 0.00 % achieved].

Performance Degree

The performance degrees are categorized as in following

Rating Grade Grade Name Grade Vision

> 90 fully satisfied A

80 to <90 mostly satisfied AB

60 to <80

below 60

limited satisfied

not satisfied

B

C C

Assessment Confirmation

Both parties, the assessed and assessing party, confirm hereby the assessment results:

____________________________ ____________________________

assessed Business Unit Customer or accredited Company

(signature and stamp) (signature and stamp)

11.0 Co-operation and Assistance

Dr. Helmut Traiser, Executive of Traiser Consulting

Ralf Dües, Manager IMDS Europe of Lear Corporation

12.0 Annex & Remarks

Annex *1: This document will be revised when node quantities will be assessable in IMDS.

Created on 11. Okt. 2007 © Dües & Traiser Page 14 of 14

S-ar putea să vă placă și

- IMDS General Rules and Guidelines SummaryDocument25 paginiIMDS General Rules and Guidelines Summarymiguel_sp100% (1)

- CFUSA Supplier HandbookDocument24 paginiCFUSA Supplier HandbookBrenda GillÎncă nu există evaluări

- GADSL Guidance Document PDFDocument9 paginiGADSL Guidance Document PDFJetesh DevgunÎncă nu există evaluări

- Global Automotive Declarable Substance ListDocument40 paginiGlobal Automotive Declarable Substance ListFebry FakhrinaÎncă nu există evaluări

- Greenhouse Gas Assessment For The Young NTUC Run 350 March 20 2010 Pulau UbinDocument13 paginiGreenhouse Gas Assessment For The Young NTUC Run 350 March 20 2010 Pulau Ubinbenjamintan13Încă nu există evaluări

- Analysis of Power Quality Issues and Implementation of UPQC Topologies To Enhance Power System StabilityDocument16 paginiAnalysis of Power Quality Issues and Implementation of UPQC Topologies To Enhance Power System StabilityEditor IJTSRDÎncă nu există evaluări

- Prowess Example)Document9 paginiProwess Example)prashantkumarsinha007Încă nu există evaluări

- Global Automotive Declarable Substance List (GADSL) (Day 1-2)Document61 paginiGlobal Automotive Declarable Substance List (GADSL) (Day 1-2)Bambang Murtjahjanto100% (1)

- Reliability Management 2Document23 paginiReliability Management 2Naresh BÎncă nu există evaluări

- MeasuringAndManagingCO2EmissionOfEuropeanTransport McKinnon Report 24.01.2011Document40 paginiMeasuringAndManagingCO2EmissionOfEuropeanTransport McKinnon Report 24.01.2011Djordje StakicÎncă nu există evaluări

- Basic Control System PDFDocument176 paginiBasic Control System PDFJunaldi100% (1)

- IRIS TrianingDocument66 paginiIRIS TrianingSANKUSIÎncă nu există evaluări

- GADSL Guidance Document PDFDocument9 paginiGADSL Guidance Document PDFcvazquez999Încă nu există evaluări

- MDSReport 459824619Document56 paginiMDSReport 459824619hita tevaÎncă nu există evaluări

- BIS Application FormDocument15 paginiBIS Application FormJagannath Majhi80% (5)

- ACL Lab 1Document11 paginiACL Lab 1cool_vinayÎncă nu există evaluări

- International Material Data SystemDocument3 paginiInternational Material Data SystemsafialiÎncă nu există evaluări

- Gadsl FaqDocument10 paginiGadsl Faqnrajesh1Încă nu există evaluări

- 9 Types of MaintenanceDocument63 pagini9 Types of MaintenanceDaniel ErgichoÎncă nu există evaluări

- Manual Stack Emission Monitoring Guidance For OrganisationDocument19 paginiManual Stack Emission Monitoring Guidance For OrganisationMilena MaksimovicÎncă nu există evaluări

- GADSLDocument26 paginiGADSLmal singhÎncă nu există evaluări

- RM13000 - 8D Problem Solving MethodDocument47 paginiRM13000 - 8D Problem Solving Methodmizar.g91Încă nu există evaluări

- V Cem5000 Ops A4Document43 paginiV Cem5000 Ops A4Quan Nguyen Van100% (1)

- (Draft) MYNI 2019 of The RSPO Principles and Criteria 2018-EnglishDocument34 pagini(Draft) MYNI 2019 of The RSPO Principles and Criteria 2018-EnglishahmadÎncă nu există evaluări

- List of Participants : Order No.: 4153166070 Client No.: 116820-01 ClientDocument3 paginiList of Participants : Order No.: 4153166070 Client No.: 116820-01 ClientCorrosion FactoryÎncă nu există evaluări

- Bunkering FacilityDocument25 paginiBunkering FacilitySaid Abu khaulaÎncă nu există evaluări

- Toyota Process Flow Analysis: ToyotaprocessflowanalysisDocument5 paginiToyota Process Flow Analysis: ToyotaprocessflowanalysisRoel DavidÎncă nu există evaluări

- Understanding Correction, Corrective Action and Preventive ActionDocument3 paginiUnderstanding Correction, Corrective Action and Preventive ActionMohammad Jaid Alam100% (1)

- LRQA Practical Guidance ISO 50001 FIN LR Singles 02-27-12 Small Tcm163-236268Document8 paginiLRQA Practical Guidance ISO 50001 FIN LR Singles 02-27-12 Small Tcm163-236268Mario ArmelaoÎncă nu există evaluări

- Benchmarking Oil and Gas IBPDocument7 paginiBenchmarking Oil and Gas IBPDhanes PratitaÎncă nu există evaluări

- Navigation Search: or Is Required On Packaged Perishable FoodsDocument4 paginiNavigation Search: or Is Required On Packaged Perishable FoodsAaron Paul Hernandez OcampoÎncă nu există evaluări

- Oman Labour LawDocument35 paginiOman Labour Lawraghu.cecri8058100% (1)

- The Asset Management Industry in 2010Document42 paginiThe Asset Management Industry in 2010dare7devil100% (2)

- Montana Source Test Protocol and Procedures ManualDocument32 paginiMontana Source Test Protocol and Procedures Manualmdawg467Încă nu există evaluări

- RC 14001 StandardDocument7 paginiRC 14001 StandardMohammed Mehran100% (1)

- RSPO Certifications Systems For Principles & Criteria June 2017Document44 paginiRSPO Certifications Systems For Principles & Criteria June 2017Heru MulyonoÎncă nu există evaluări

- Comparison of Iso 9001 and Iso 22000Document4 paginiComparison of Iso 9001 and Iso 22000Eddie Ajalcriña Bocangel100% (1)

- Using Leading Indicators To Drive Sustainability PerformanceDocument7 paginiUsing Leading Indicators To Drive Sustainability Performancesl1828Încă nu există evaluări

- Harmonization Conference 2021 Case StudiesDocument4 paginiHarmonization Conference 2021 Case StudiesKram NawkÎncă nu există evaluări

- 【文章】Stationary Source EmissionsDocument26 pagini【文章】Stationary Source Emissionslaoying qdÎncă nu există evaluări

- InTech-Glp Good Laboratory PracticeDocument24 paginiInTech-Glp Good Laboratory PracticeTiwi100% (1)

- FDA CFR 806 Format PDFDocument2 paginiFDA CFR 806 Format PDFSriÎncă nu există evaluări

- Accounting Computer Language: Dacones, Mariz P. Malazzab, Ezekiel D. Uy, Mary Eloisa CDocument19 paginiAccounting Computer Language: Dacones, Mariz P. Malazzab, Ezekiel D. Uy, Mary Eloisa CEzekiel MalazzabÎncă nu există evaluări

- Sustainable Production: Submitted ByDocument9 paginiSustainable Production: Submitted ByRichi Buru TutiÎncă nu există evaluări

- How To Budget An ISO 45001 Implementation ProjectDocument12 paginiHow To Budget An ISO 45001 Implementation ProjectShahnawaz PathanÎncă nu există evaluări

- NQA ISO 50001 Implementation GuideDocument36 paginiNQA ISO 50001 Implementation GuideCHAFAIÎncă nu există evaluări

- Building Asset Performance FrameworkDocument27 paginiBuilding Asset Performance FrameworkRisya rantikaÎncă nu există evaluări

- Guidelines On Occupational Safety and Health in Construction, Operation and Maintenance of Biogas Plant 2016Document76 paginiGuidelines On Occupational Safety and Health in Construction, Operation and Maintenance of Biogas Plant 2016kofafa100% (1)

- ISO 35001 2019descDocument29 paginiISO 35001 2019descAlexander Neves100% (2)

- Industrial Energy Management Standard RequirementsDe la EverandIndustrial Energy Management Standard RequirementsÎncă nu există evaluări

- Cas and GacapDocument23 paginiCas and GacapMuraliprasad SaÎncă nu există evaluări

- Corporate Deck 2022Document34 paginiCorporate Deck 2022Deepa Revankar100% (1)

- Iso 22003 1 and Iso 22003 2 Presentation GeneralDocument25 paginiIso 22003 1 and Iso 22003 2 Presentation Generaldenisenko.marina2017Încă nu există evaluări

- ISO9001 Vs 21 CFR 820Document2 paginiISO9001 Vs 21 CFR 820Hairulanuar SuliÎncă nu există evaluări

- Health IndexDocument6 paginiHealth IndexAz_111Încă nu există evaluări

- Achieving Chartered Chemist status requirementsDocument11 paginiAchieving Chartered Chemist status requirementsbukkysuccessÎncă nu există evaluări

- CMMS Technical Object and Preventative Maintenance FormDocument7 paginiCMMS Technical Object and Preventative Maintenance Formken1962Încă nu există evaluări

- IBM Maximo Asset Configuration Manager A Complete Guide - 2020 EditionDe la EverandIBM Maximo Asset Configuration Manager A Complete Guide - 2020 EditionÎncă nu există evaluări

- Effective Implementation of an ISO 50001 Energy Management System (EnMS)De la EverandEffective Implementation of an ISO 50001 Energy Management System (EnMS)Evaluare: 4 din 5 stele4/5 (1)

- Asset Management A Complete Guide - 2020 EditionDe la EverandAsset Management A Complete Guide - 2020 EditionÎncă nu există evaluări

- IMDS Creation TipsDocument64 paginiIMDS Creation TipsSatyawan SableÎncă nu există evaluări

- High Tensile FastenersDocument1 paginăHigh Tensile FastenersSandeep Kumar0% (1)

- A Study of Post Plating Heat Treatment in Automotive Fastener SteelsDocument8 paginiA Study of Post Plating Heat Treatment in Automotive Fastener SteelsSatyawan SableÎncă nu există evaluări

- 6th Central Pay Commission Salary CalculatorDocument15 pagini6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- VIJAY JR 01 02 V 1Document2 paginiVIJAY JR 01 02 V 1Piyush KumarÎncă nu există evaluări

- Chem 3.1Document21 paginiChem 3.1johnqÎncă nu există evaluări

- Dwnload Full Anatomy Physiology and Disease For The Health Professions 3rd Edition Booth Solutions Manual PDFDocument36 paginiDwnload Full Anatomy Physiology and Disease For The Health Professions 3rd Edition Booth Solutions Manual PDFgeincupola.06zi100% (13)

- Module 1 - IntroductionDocument7 paginiModule 1 - IntroductionFidhez TanÎncă nu există evaluări

- Matter Quiz With AnswersDocument8 paginiMatter Quiz With AnswersRalph Edward LeeÎncă nu există evaluări

- Brochure ELEMENT-COMPOUND-MIXTUREDocument2 paginiBrochure ELEMENT-COMPOUND-MIXTURElerrie surioÎncă nu există evaluări

- ThesisDocument2 paginiThesisammarah sanwalÎncă nu există evaluări

- Test Bank For Introductory Chemistry 1st Edition Kevin RevellDocument36 paginiTest Bank For Introductory Chemistry 1st Edition Kevin Revellsheolunlandvc7b100% (44)

- KEY Unit 1 AP Chemistery Review GuideDocument10 paginiKEY Unit 1 AP Chemistery Review GuideMohammad AmmadÎncă nu există evaluări

- Full Report: Synthesis of AspirinDocument3 paginiFull Report: Synthesis of AspirinNor Ashikin IsmailÎncă nu există evaluări

- GC1-chapter 01Document70 paginiGC1-chapter 01Heidi CotillionÎncă nu există evaluări

- Final Presentation On Super CapacitorDocument40 paginiFinal Presentation On Super Capacitorapi-3798420100% (1)

- Green Chemistry, A Pharmaceutical Perspective: AbstractDocument4 paginiGreen Chemistry, A Pharmaceutical Perspective: AbstractRamesh AadityaÎncă nu există evaluări

- Advanced Composite MaterialDocument2 paginiAdvanced Composite MaterialDinesh KumarÎncă nu există evaluări

- MDMB 4en Pinaca Review 2020Document16 paginiMDMB 4en Pinaca Review 2020AlfonsoÎncă nu există evaluări

- Common Names and Formulas of Important Chemical CompoundsDocument7 paginiCommon Names and Formulas of Important Chemical Compoundsayush singhÎncă nu există evaluări

- Tarea Balances Semana1Document3 paginiTarea Balances Semana1ANDRES FELIPE PARRA BARRAGANÎncă nu există evaluări

- Chemistry - John Green and Sadru Damji - Third Edition - IBID 2008Document566 paginiChemistry - John Green and Sadru Damji - Third Edition - IBID 2008daisybb100% (4)

- Science Performance Task: Andrea Felize Parenia Grade 7 - BeigeDocument17 paginiScience Performance Task: Andrea Felize Parenia Grade 7 - BeigeAndrea Felize PareniaÎncă nu există evaluări

- Balancing EquationsDocument6 paginiBalancing EquationsTatiana Acosta17% (12)

- Lab Report: Qualitative Analysis of Everyday Chemicals: Name: Date: Lab Partner: Lab SectionDocument3 paginiLab Report: Qualitative Analysis of Everyday Chemicals: Name: Date: Lab Partner: Lab SectionTécnicos QuímicosÎncă nu există evaluări

- Green Solvents For Chemistry - Perspectives and Practice - W. Nelson (Oxford, 2003) WW PDFDocument399 paginiGreen Solvents For Chemistry - Perspectives and Practice - W. Nelson (Oxford, 2003) WW PDFapc108Încă nu există evaluări

- WS5-6-1a Working With MolesDocument2 paginiWS5-6-1a Working With MolesJim Teston0% (1)

- Preview Lesson StarterDocument9 paginiPreview Lesson StarterKim JalmÎncă nu există evaluări

- Chemical Reactions and Chemical Equations: Prepared By: Ariza D. Capucao, R.PH., MaedDocument27 paginiChemical Reactions and Chemical Equations: Prepared By: Ariza D. Capucao, R.PH., MaedJungkook JeonÎncă nu există evaluări

- Introduction To Chemistry and Its Branches - Print - QuizizzDocument3 paginiIntroduction To Chemistry and Its Branches - Print - QuizizzandieÎncă nu există evaluări

- 1,1,2,2,3-Pentamethyl-2,3-dihydro-1H-indene - C14H20 - PubChemDocument12 pagini1,1,2,2,3-Pentamethyl-2,3-dihydro-1H-indene - C14H20 - PubChemRohan PrajapatiÎncă nu există evaluări

- Classification of MatterDocument6 paginiClassification of MatterAngel PerezÎncă nu există evaluări

- PHYSICAL SCIENCE - Lesson Plan On Solubility and MiscibilityDocument7 paginiPHYSICAL SCIENCE - Lesson Plan On Solubility and MiscibilityBarbeicaht Sallin100% (1)

- GSO Labelling Packaged Food SubstancesDocument7 paginiGSO Labelling Packaged Food Substancesjacky786Încă nu există evaluări