Documente Academic

Documente Profesional

Documente Cultură

Impeller Bioprocessintl 1 09 Good-1

Încărcat de

Suman TripathyDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Impeller Bioprocessintl 1 09 Good-1

Încărcat de

Suman TripathyDrepturi de autor:

Formate disponibile

Which Impeller Is Right

for Your Cell Line?

A Guide to Impeller Selection for

Stirred-Tank Bioreactors

Rich Mirro and Kevin Voll

Reprinted with permission from BioProcess International 7(1) (Jamuary 2009)

W

hen growing microbes or oxygen and nutrients to cells for healthy Figure 1: Axial and radial flow models

animal cells in a stirred- growth, keeps them from settling to the

tank reactor, it is critical to bottom of the vessel, and helps to

choose the impeller type maintain a uniform culture temperature.

that is best suited to your process. Select Depending on the impeller type you

the wrong impeller, and you could make select, mixing will be imparted as a radial

chop suey of your filamentous fungi. Pick flow, axial flow, or a combination of the

the right impeller, and you could greatly two.

increase yields of your fussy mammalian As Figure 1 shows, radial flow occurs

cultures such as Chinese hamster ovary when fluid is pushed away from the

(CHO) and Vero kidney epithelial cells. impeller’s axis toward the vessel wall.

Radial

With a wide range of impeller designs to Axial flow occurs when fluid is pushed up

choose from, how do you tell which is or down along the axis or shaft of the

right for your application? Here we impeller. The orientation of an impeller

describe six commonly used fermentor (left- or right-handed) and its agitating

and bioreactor impellers, explain how direction determine whether the

they work, and identify which may direction of axial flow is up or down. A

perform best for culturing certain animal, right-handed impeller option will push

insect, plant, yeast, and bacterial cell fluid in an upward direction toward the

lines. top of the vessel if agitation is clockwise

How Blade Orientation Affects (as viewed from the top). A left-handed

Mixing: All impellers are designed to option paired with a clockwise agitation Axial

homogenously mix cells, gases, and will push fluid down toward the bottom

nutrients throughout the culture vessel. of the vessel. Therefore, when positioning

The mixing action evenly distributes blades on an impeller shaft, it’s important Figure 2: A six-bladed Rushton-type impeller

to know which direction your impeller

will be turning (clockwise or

Product Focus: Biologics

counterclockwise). To increase mixing

Process Focus: R&D/production action in some applications, one impeller

blade may be oriented for up flow while

Who Should R ead: Process

the other is positioned for down flow.

development, manufacturing

Although there is no right or wrong way

K eywords: Aeration, mixing, to position an impeller blade(s), reversing

fermentors, bioreactors, shear flow direction could improve yields in

some instances.

Level: Basic

52 BioProcess International January 2009

Figure 3: Pitched-blade impeller, right- Figure 5 Spin filter assembly

Rushton Impellers handed orientation

for F ermentation

J.H. Rushton originally called the

impellers he designed flat-bladed

turbines. So Rushton impeller is today the

most common generic term applied to

flat-bladed or disk-turbine impellers (e.g.,

Figure 2). Their blades are flat and set

vertically along an agitation shaft, which

produces a unidirectional radial flow.

Rushton and Rushton-type impellers are Dip tube

commonly used in fermentations of cell (harvest,

waste)

lines that are not considered shear-

sensitive, including yeasts, bacteria, and

some fungi. Figure 4: Marine-blade impeller, left-handed

orientation

Pitched-Blade Impellers Impeller

for Shear-Sensitive Cells

shaft

The blades on pitched-blade impellers

(Figure 3) are flat and set at ~45°

angles, which produces a simultaneous

axial and radial flow. This combination

provides better overall mixing and

creates a higher oxygen mass transfer

rate (K l a) than that of unidirectional

marine blade impellers.

Pitched-blade impellers are low- Spin F ilters

shear impellers designed to gently mix Spin filters are retention devices

the contents of a culture without commonly used to keep cells inside a

causing cell damage. They are most vessel during continuous or perfusion

often used with mammalian, insect, or culture. In New Brunswick Scientific (NBS)

other shear-sensitive cell lines growing bioreactors, for example, spin filters with

in suspension or with the aid of low-shear marine blade impellers are

microcarriers. These impellers are often designed for suspension and microcarrier Outer

used in batch or fed-batch cultures, but applications. A spin-filter kit consists of a screen

they can also be used for continuous screened cage surrounding an impeller (10 µm

and perfusion processes. Because of shaft with very small filter pore openings or 75 µm)

their proficient mixing design, pitched- that keep cells isolated outside the cage

blade impellers are also widely used in (Figure 5). Inside that rotating cage, a dip

fermentation processes that involve tube is provided for continuous

highly viscous cultures, such as withdrawal of culture broth. A media

filamentous bacteria and fungi, as well feed tube outside the cage provides a

as in some anaerobic biofuels processes. steady supply of fresh nutrients.

Although pore openings vary from one

Gentle M arine- manufacturer to the next, NBS spin filters

Blade Impellers come with 10-µm openings for

The leading face of the blades on a suspension cultures and 75-µm openings Support

marine-blade impeller (Figure 4) can be for microcarrier cultures. cage

flat or concave, whereas their back sides Because of its gentle mixing nature,

are convex. This produces an axial flow. a spin filter is typically used with

Like pitched-blade impellers, marine- microcarrier-dependent cell lines or

blade impellers are used for applications those that are highly sensitive to shear.

that require gentle mixing without These mechanisms are ideal for use in Marine

causing cell damage. Due to the production of secreted proteins blade

because they keep harvested media impeller

unidirectional flow, however, the Kla

values of marine-blade impellers tend to cell-free, which simplifies purification

be slightly lower than those of impellers in downstream processing. Over time,

that produce both axial and radial mixing. however, the screen material covering a

54 BioProcess International January 2009

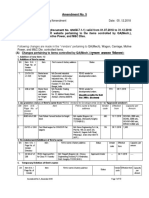

Figure 6: Cell-lift impellers for microcarrier Table 1: A general guide to choosing impellers by cell line

culture

Rushton and Pitched- Marine-

Foam Rushton-Like Blade Blade Spin Filter Cell Lift Basket

Cell Line Impellers Impeller Impeller Impeller Impeller Impeller

breaker

cage Human

HEK 293 X X X X X

HeLa X X X X

Discharge HL60 X X X X

ports Lncap X X X X

THP-1 X X X X

UMSCC X X X X X

HFF X X X X X

Mesh KB X X X X X

lining MRC-5 X X X X X

(85 µm)

Hybridoma

DA4.4 X X X X

123A X X X X

127A X X X X

GAMMA X X X X

67-9-B X X X X

Aeration SP20 X X X X

cage

Primate

Vero X X X X X

COS-7 X X X X X

Rat Tumor

GH3 X X X X

spin-filter cage will become clogged 9L X X X X

with cell debris and require PC12 X X X X

replacement. Culture run times are Mouse

limited by this factor. 3T3 X X X X

MC3T3 X X X X

NS0 X X X X X

Special Impellers for

Hamster

Microcarrier Cultures

CHO X X X X X

The CelliGen cell-lift impeller (Figure 6)

BHK X X X X X

designed and patented by New Brunswick

Zebrafish

Scientific provides uniform circulation for

ZF4 X X X X

microcarrier cultures. This is an ultralow- AB9 X X X X

shear impeller in which flow is caused by

Insect

three discharge ports located on the

SF9 X X X

impeller shaft. Rotation of those ports Hi-5 X X X

creates a low-differential pressure at the Sf21 X X

base of the impeller tube, lifting Yeast

microcarriers up through the tube and Saccharomyces

X

expelling them out through its ports. This cereviseae

continuous recirculation loop keeps cells Baker’s yeast X

uniformly dispersed throughout a vessel. Pichia pastoris X

Gases are introduced through a ring Candida

X X

albicans

sparger, which generates bubbles that

pass along the impeller between the Bacteria

Streptomyces X X

exterior of the inner tube and an outer

Bacillus X

membrane, known as the aeration cage. Echerichia coli X

A mesh lining on the outer membrane of

Algae

this cage has penetrations that are small Red/Green X X

enough (85 µm) to ensure that cells

growing on the microcarriers cannot pass

through. Gas exchange occurs at the ports (located at the top of the impeller) shear-sensitive animal cells. They can also

membrane–media interface, ensuring into a second screened-in cage. A foam be used for continuous perfusion

that cells remain in a bubble-free breaker directs air, supplied by a gas processes when a decanting column(s)

environment and are not subjected to overlay, into the cage to break up foam. and media feed-in and broth pump-out

shear due to bubble breakage. The Cell-lift impellers are typically used in setup are added.

bubbles are then expelled through two batch and fed-batch processes involving

56 BioProcess International January 2009

Packed-Bed Basket Impellers from external shear forces throughout

Another New Brunswick Scientific design each culture run.

is the packed-bed basket impeller used Media circulates by way of a hollow

in the manufacture of secreted products impeller tube with discharge ports

from either anchorage-dependent or positioned above the basket. As with

suspension cultures. A basket includes the cell-lift impeller, rotation of these

two horizontally positioned, perforated discharge ports creates a low-

metal screens that extend to the walls of differential pressure at the base of the

a bioreactor vessel (Figure 7). Enclosed impeller tube, which circulates media

between those screens, a bed of FibraCel throughout the system. The medium

disks serves as a solid support matrix for receives gases through a sparger

cell growth. Cells growing in the disk located at the bottom of the inner tube,

bed become immobilized on or between which protects cells from being

the disks, where they remain protected exposed to the gas–liquid interface.

This results in low turbulence and low

Figure 7 Packed-bed basket impellers for shear stress for the culture.

secreted products Exceptionally high cell densities are

achievable with packed-bed baskets

because of a high surface-to-volume

ratio for cell growth provided by the

disk bed coupled with an ability to use

perfusion or medium-replacement

techniques. Culture periods in excess of

three months have been reported (1, 2).

By ensuring that cells remain entrapped

in the bed, this system also simplifies

protein harvesting from the resulting

cell-free media.

A Gener al Guide

Metal (to form

screens the basket) Impeller designs are almost as varied as

the types of cell lines they are designed

to help grow. Table 1 lists several cell

lines commonly used in fermentation

and cell culture processes and matches

each with the impeller(s) best suited for

its growth.

R eference

1 Wang G, Zhang W. Bioreactor Design

for High Cell Density Culture Using

Microcarriers. Nanjing Vaccine Conference,

Nanjing, China, 3–4 August 2001. New

Brunswick Scientific, Edison, NJ.

2 Wang G, et al. Modified CelliGen

Discharge Packed Bed Bioreactors for Hybridoma Cell

Cultures. Cytotechnol. 9, 1992: 41–49. c

ports Packed

bed

(FibraCel

disks not

shown) Corresponding author Rich Mirro is a

product manager, and Kevin Voll is an

assistant product manager at New Brunswick

Scientific, PO Box 4005, Edison, NJ 08818-4005;

1-800-631-5417, 1-732-287-1200; www.nbsc.

Harvest com/b5e; bioinfo@nbsc.com.

dip tube

S-ar putea să vă placă și

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- Spectroscopic Techniques For Pharmaceutical and Biopharmaceutical Industries - Unit 9 - Week 8 PDFDocument1 paginăSpectroscopic Techniques For Pharmaceutical and Biopharmaceutical Industries - Unit 9 - Week 8 PDFantony bevanÎncă nu există evaluări

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- Soal Soal Kimia Kelas 10Document4 paginiSoal Soal Kimia Kelas 10rohmatul aziziÎncă nu există evaluări

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Truss Problem 6.1 Johnston and Beer Book-Static 1-1Document15 paginiTruss Problem 6.1 Johnston and Beer Book-Static 1-1mahfuzul_haqueÎncă nu există evaluări

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- We Are Intechopen, The World'S Leading Publisher of Open Access Books Built by Scientists, For ScientistsDocument28 paginiWe Are Intechopen, The World'S Leading Publisher of Open Access Books Built by Scientists, For ScientistsBRIGHT TECH INDUSTRIALS INDIA PVT LTDÎncă nu există evaluări

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- 100-028-544 - ALLIANT SPORT PISTOL POWDER, 1LB - 69B - DefaultDocument13 pagini100-028-544 - ALLIANT SPORT PISTOL POWDER, 1LB - 69B - DefaultDavid WilliamsÎncă nu există evaluări

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- Chapter No 6 - Chemical KineticsDocument45 paginiChapter No 6 - Chemical KineticsTanish SalviÎncă nu există evaluări

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Tyfo UGDocument2 paginiTyfo UGdediodedÎncă nu există evaluări

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Evaluation of The Sludge Drying Beds at Sana'a Wastewater Treatment PlantDocument29 paginiEvaluation of The Sludge Drying Beds at Sana'a Wastewater Treatment PlanthazimpzkÎncă nu există evaluări

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- Diafragma Neumatica-Av-04960Document8 paginiDiafragma Neumatica-Av-04960Karen VásconezÎncă nu există evaluări

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- Bioactive Thiazine and Benzothiazine Derivatives Green Synthesis Methods and Their Medicinal Importance PDFDocument20 paginiBioactive Thiazine and Benzothiazine Derivatives Green Synthesis Methods and Their Medicinal Importance PDFMiguelAlejandroMantaChavezÎncă nu există evaluări

- Products DatabaseDocument104 paginiProducts DatabaseAlexÎncă nu există evaluări

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Bio Gas Seminar ReportDocument49 paginiBio Gas Seminar ReportLalitBisht100% (2)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- Vendor Directory Amendment No - 5Document10 paginiVendor Directory Amendment No - 5annayya.chandrashekar Civil EngineerÎncă nu există evaluări

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- Types of Chemical ReactionsDocument35 paginiTypes of Chemical ReactionsJemina R. B. EspedillonÎncă nu există evaluări

- 0 - Relative Atomic MassDocument7 pagini0 - Relative Atomic MassMohamedÎncă nu există evaluări

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- Gamma RayDocument5 paginiGamma RayDenisha Betaci GultomÎncă nu există evaluări

- DISC Thermal AnalysisDocument11 paginiDISC Thermal AnalysisAkrit Kumar ChaturvediÎncă nu există evaluări

- Eco-Friendly Polymer Composites For Green Packaging Future Vision PDFDocument10 paginiEco-Friendly Polymer Composites For Green Packaging Future Vision PDFAncuţa-IonelaPartinÎncă nu există evaluări

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- User Manual Buble Cpap PDFDocument7 paginiUser Manual Buble Cpap PDFmamahosieleÎncă nu există evaluări

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- Design Installation & Maintenance Guide For Electric TracingDocument20 paginiDesign Installation & Maintenance Guide For Electric Tracinghon choong chongÎncă nu există evaluări

- Chemistry 1 - JJ Thomson's Plum Pudding Model and Discovery of ElectronsDocument2 paginiChemistry 1 - JJ Thomson's Plum Pudding Model and Discovery of ElectronsPat RiveraÎncă nu există evaluări

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Me22 E02 Tumangan M2a2Document3 paginiMe22 E02 Tumangan M2a2Jihoo JungÎncă nu există evaluări

- Livro Shape Memory AlloysDocument218 paginiLivro Shape Memory AlloysJefferson SegundoÎncă nu există evaluări

- Isolation of Acetylsalicylic AcidDocument4 paginiIsolation of Acetylsalicylic AcidPrince Pulvera100% (1)

- The Delta RatioDocument2 paginiThe Delta RatioFirstglobalsupercopÎncă nu există evaluări

- HandoutDocument57 paginiHandoutJan Sy100% (1)

- Cyano Compounds, Inorganic: 1. Hydrogen CyanideDocument38 paginiCyano Compounds, Inorganic: 1. Hydrogen CyanideRasoulÎncă nu există evaluări

- A26 193Document13 paginiA26 193Syarif HidayatÎncă nu există evaluări

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Kids' Conditioners: INCI Name, Trade Name Weight % Weight % Function Product PropertiesDocument2 paginiKids' Conditioners: INCI Name, Trade Name Weight % Weight % Function Product Propertiesgabriel oliveira monteiroÎncă nu există evaluări

- Test Bank For Principles of Biochemistry 4th Edition HortonDocument12 paginiTest Bank For Principles of Biochemistry 4th Edition Hortonhightpiprall3cb2Încă nu există evaluări

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)