Documente Academic

Documente Profesional

Documente Cultură

ARIEL JGH and JGE COMPRESSORS Guide

Încărcat de

Dante Cabrera GuzmanTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

ARIEL JGH and JGE COMPRESSORS Guide

Încărcat de

Dante Cabrera GuzmanDrepturi de autor:

Formate disponibile

ARIEL JGH and JGE COMPRESSORS

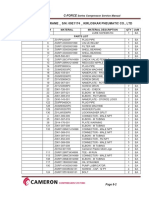

Frame JGH/2 JGH/4 JGE/2 JGE/4 JGE/6

Number of throws 2 4 2 4 6

Rated Power, BHP 680 1360 1070 2140 3210

Rated Power, kW 507 1014 798 1596 2394

Stroke, inches 4.5 4.5 4.5 4.5 4.5

Stroke, mm 114 114 114 114 114

RPM, maximum 1200 1200 1500 1500 1500

Piston speed, FPM 900 900 1125 1125 1125

Piston speed, m/s 4.57 4.57 5.72 5.72 5.72

Total Rod Load, lbs 48000 48000 60000 60000 60000

Total Rod Load, N 213515 213515 266893 266893 266893

Tension, lbs 24000 24000 30000 30000 30000

Tension, N 106757 106757 133447 133447 133447

Compression, lbs 30000 30000 32000 32000 32000

Compression, N 133447 133447 142343 142343 142343

Average Weight with cylinders, lbs 7000 14000 7000 14000 22000

Average Weight with cylinders, kg 3175 6350 3175 6350 9980

Maximum Length, inches 50 96 51 97 141

Maximum Length, mm 1270 2438 1295 2464 3581

Nominal Width, inches 139 139 139 139 139

Nominal Width, mm 3531 3531 3531 3531 3531

Crankshaft CL (from bottom), inches 17 17 17 17 17

Crankshaft CL (from bottom), mm 432 432 432 432 432

FEATURES

The JGH and JGE are medium- to large-size, separable, reciprocating, gas gathering compressors. They are found

by the thousands in gas fields throughout the world. Driver rated, they pair well with modern, high-speed engines

and work year after year as one of the most cost-effective choices for rental fleets.

Serviceability - Entire unit is designed for ease of repair. All components

are readily accessible.

Standardization - Many components are interchangeable throughout

the various lines.

Full Pressure Lubrication - A frame-driven lube oil pump provides JGH/4 frame

pressurized, cooled oil through a full flow oil filter to all moving parts

in the frame. A divider block distribution system supplies metered

oil to cylinder bores and rod packing. Stainless steel tubing is used

throughout the cylinder lubrication system.

Unloading Devices - Manual head-end variable volume clearance

pockets, pneumatic fixed volume clearance pockets and pneumatic Forged steel connecting rod used for JGE

suction valve unloaders are available on a limited optional basis. (Ductile iron connecting rod used for JGH)

Heavy Duty Crankshaft - Forged steel precision machined with integral

counterweights.

Rugged Crankcase - Heavily ribbed (with spacer bars for stiffening), high- JGE/4 forged

forged steel

JGE/4 steel crankshaft

crankshaft

strength cast iron base with removable, lightweight aluminum top cover

and removable end covers for ease of access.

Precision Bearing Shells - Precision-machined, tri-metal main and

connecting rod bearings.

Rugged Crossheads and Guides - Cast iron crosshead guides, external

ribbing and removable side covers. One piece, long life crossheads with

direct full pressure lubrication at top and bottom for minimum wear.

Ductile iron (JGE) crossheads, babbitted

Hardened and ground steel crosshead pins. shoe surface, full-floating crosshead pin

with “through-bolt” and end caps

Rigid Connecting Rods - Forged steel four bolt, heavy duty “H” section.

Quiet Auxiliary Drive - Fully enclosed and continuously lubricated chain

drive adjusted by positive positioning eccentric vernier.

Oil and Dust Seal - Foolproof, non-contacting crankshaft oil seal plus

reliable non-wearing dust seal.

Proven Cylinder Design - Non-cooled compressor cylinders with ample Head-end variable volume pocket

nozzles and large gas passages. Cylinder bodies are ion-nitride hardened unloader

and drilled for indicator ports.

High Strength Bolting - Grade 8 bolts or B-7 studs on all pressurized

components. All bolting designed for accessibility.

Efficient Valving - Ariel uses plate-type valves designed for modern

speeds utilizing non-metallic sealing elements as standard. Selected to

Full array of JGE crossheads and nuts for

adhere to established, low valve velocity standards. precise balancing of pistons

Durable Pistons - Wear-resistant ductile or gray iron with wear bands.

Stout Piston Rods - Short, stiff, precision-ground alloy steel piston rods

with locking crosshead nut. Rolled threads are 1/4” under rod diameter

for easy installation through packing.

JGH/2 ductile iron crankshaft

CYLINDERS A complete list of cylinders is available in the Ariel Compressor Performance Program

BORE BORE MAWP MAWP

Class* inches mm psi bar Material

4-5/8ET 4.250, 4.625 108, 117 2600 179 Ductile Iron

5-1/2ET 5.125, 5.500 130, 140 1725 119 Ductile Iron

6-3/8ET 6.000, 6.375 152, 162 1270 88 Ductile Iron

6-3/8ET 6.000, 6.375 152, 162 1650 114 Ductile Iron

7-3/8ET 7.000, 7.375 178, 187 845 58 Ductile Iron

7-3/8ET 7.000, 7.375 178, 187 1135 78 Ductile Iron

Double-Acting

7-3/8ET 7.000, 7.375 178, 187 1440 99 Ductile Iron

8-3/8ET 8.000, 8.375 203, 213 635 44 Ductile Iron

8-3/8ET 8.000, 8.375 203, 213 800 55 Ductile Iron

9-3/4ET 9.250, 9.750 235, 248 635 44 Ductile Iron

11-1/2ET 11.000, 11.500 279, 292 635 44 Ductile Iron

12 1/4 ET 11.750, 12.250 298, 311 635 44 Ductile Iron

13-1/2ET 13.000, 13.500 330, 343 300 21 Ductile Iron

15-3/4ET 15.250, 15.750 387, 400 200 14 Ductile Iron

17-1/4ET 16.750, 17.250 425, 438 230 16 Ductile Iron

19-1/2ET 19.000, 19.500 483, 495 200 14 Ductile Iron

22-1/2ET 22.500 572 205 14 Ductile Iron

Tandem

5-1/2ET-HE 5.125, 5.500 130, 140 1800 124 Ductile Iron

9-3/4ET-CE 9.250, 9.750 235, 248 635 44 Ductile Iron

NOTE: JGT cylinders also can be mounted on these frames

* HE=Head End, CE=Crank End

More than 35 years ago, Ariel introduced an

innovative cylinder design that eliminated water

cooling from the cylinder jacket. This proven design

yields significant advantages over water-cooled

cylinders:

higher efficiency

larger gas passages

reduced pressure-drop losses

lower maintenance (no scaling or corrosion)

Today, Ariel is the only manufacturer to use an

ion-nitride furnace to increase surface hardness of

all cylinders. This extra step reduces cylinder bore

wear to an absolute minimum. And, to ensure

complete reliability in the field, Ariel pressure-

tests each cylinder to 150% of maximum allowable 22-1/2E cylinders, 205 psig, with head-end variable volume

working pressure (MAWP) during manufacture. clearance pocket unloaders.

THE ARIEL NETWORK

Ariel’s success is based on strong relationships built on

mutual respect and trust. Employees, vendors, distrib-

utors, and end users are all part of the Ariel Network.

Ariel Compressors are marketed and packaged

through a long-established network of elite compres-

sion system engineering companies. Ariel’s Authorized

Distributors integrate the compressor with a structural

skid, a prime mover, piping, pulsation control, cooling

systems, process valving, and control systems.

All Ariel distributors adhere to Ariel’s strict

packaging standards.

Ariel’s large network offers the most complete

service and parts coverage available in the

world. Model JGH/4, electric motor driven, for offshore Nigeria

CUSTOMER SERVICE

We are committed to supporting our compressors for life. ARIEL CORPORATION

If there is a problem with an Ariel compressor, we’ll help WORLD HEADQUARTERS

you solve it — now. 35 Blackjack Road

The Ariel Network is composed of more than 1000 Mount Vernon, Ohio 43050 USA

Ariel-trained field servicemen and technicians, Telephone: 740-397-0311

worldwide. Fax: 740-397-3856

Ariel’s policy has always been to routinely ship stan- 24-HOUR SUPPORT

dard parts within 24 hours of receiving an order. North America: 888-397-7766

Worldwide: +1 740 397 3602

Ariel gas compressors are backed by more than 100

parts and service outlets close to every major natu-

REGIONAL SALES and SUPPORT

ral gas field.

Denver, Colorado, • Fort Worth, Texas

Ariel’s Service and Technical Schools are held fre- Houston, Texas • Sydney, Australia

quently, free of charge, for engineers and field Calgary, AB, Canada • The Netherlands

servicemen. These courses are taught by Ariel Moscow, Russia • Singapore

engineers and technicians directly involved in the Bangkok, Thailand

subject material.

The availability of Ariel manufactured parts at

competitive prices will ensure your Ariel compres-

sor’s maximum reliability and productivity.

Ariel’s goal is to offer the best customer care and

service. Our warranty and our treatment of warranty

issues clearly show our commitment to this goal. www.arielcorp.com

2/10 World Standard Gas Compressors

S-ar putea să vă placă și

- Compression Machinery for Oil and GasDe la EverandCompression Machinery for Oil and GasKlaus BrunEvaluare: 4 din 5 stele4/5 (4)

- 1988 CC Colt Junior Thru 8 Service Manual 507659 PDFDocument5 pagini1988 CC Colt Junior Thru 8 Service Manual 507659 PDFChrisStainton0% (3)

- Manual de Reparacion ARIEL JGH:E:K:TDocument132 paginiManual de Reparacion ARIEL JGH:E:K:ThugoheloÎncă nu există evaluări

- KB 7636 U - Drawing PDFDocument1 paginăKB 7636 U - Drawing PDFhugoheloÎncă nu există evaluări

- Gemini A, D, E, F Series Unbalanced CouplesDocument10 paginiGemini A, D, E, F Series Unbalanced Couplesgustavoespinosam100% (1)

- Automation of Reciprocating Gas Engine Compressor Packages UsingDocument7 paginiAutomation of Reciprocating Gas Engine Compressor Packages UsingGnanaSekar0% (1)

- AXH Air Cooler - For Concept Distribution 4-16-09Document72 paginiAXH Air Cooler - For Concept Distribution 4-16-09sada sivaÎncă nu există evaluări

- Ariel Performance Software DescriptionDocument8 paginiAriel Performance Software Descriptionmichaelxiao100% (2)

- Engine Training D 2876 LF 12/13 Common Rail: Produced by Plank / Schier MAN Steyr 02/ 2003Document181 paginiEngine Training D 2876 LF 12/13 Common Rail: Produced by Plank / Schier MAN Steyr 02/ 2003JuanMa Ag100% (16)

- Mothballing Guidelines For Plant Equipme PDFDocument11 paginiMothballing Guidelines For Plant Equipme PDFamarnath jagirdar100% (1)

- Manual Corolla Engine 4A-FE 3S-GTE 5S-FEDocument311 paginiManual Corolla Engine 4A-FE 3S-GTE 5S-FEanto_jo95% (39)

- Buku Yamaha Mio JDocument10 paginiBuku Yamaha Mio Jobenk techno50% (2)

- Qute (Glass Windows) LHD - RHD ENE18 PDFDocument91 paginiQute (Glass Windows) LHD - RHD ENE18 PDFtaller avansys100% (2)

- CP Process enDocument4 paginiCP Process enromans59Încă nu există evaluări

- Válvulas CP ArielDocument8 paginiVálvulas CP ArielAnonymous FH8OunZrXÎncă nu există evaluări

- Er-96-0-7-1 - Piston Rod Runout CorrectionDocument3 paginiEr-96-0-7-1 - Piston Rod Runout CorrectionJeff LÎncă nu există evaluări

- Superior - Cylinder Databook - ValvesDocument8 paginiSuperior - Cylinder Databook - ValvesJake NavarreteÎncă nu există evaluări

- HOS Frame and Running Gear Data Standard Frame and Running Gear AssembliesDocument8 paginiHOS Frame and Running Gear Data Standard Frame and Running Gear AssembliesJose Luis RattiaÎncă nu există evaluări

- Ariel Coporate BrochureDocument17 paginiAriel Coporate BrochurehugoheloÎncă nu există evaluări

- Improve force feed lubrication upgradesDocument8 paginiImprove force feed lubrication upgradesdiego yecid millan mendozaÎncă nu există evaluări

- D VipDocument6 paginiD VipClemente Rafael Marval EscalonaÎncă nu există evaluări

- A-VIP Compressor BrochureDocument6 paginiA-VIP Compressor BrochureAvrinFakherniaÎncă nu există evaluări

- HOSS ProductDescriptionDocument6 paginiHOSS ProductDescriptionmath62210Încă nu există evaluări

- HOS (Heavy Oilfield Separable Compressor) BrochureDocument6 paginiHOS (Heavy Oilfield Separable Compressor) BrochureakamalapuriÎncă nu există evaluări

- Manual 99 LDDocument20 paginiManual 99 LDCristianÎncă nu există evaluări

- Fisher D and DA Control Valves Product BulletinDocument8 paginiFisher D and DA Control Valves Product Bulletintxlucky80100% (1)

- Compressor Valve Reference DataDocument3 paginiCompressor Valve Reference DataHusnu KusumaÎncă nu există evaluări

- Grove Regulator Engineering Handbook Sections 1-8Document212 paginiGrove Regulator Engineering Handbook Sections 1-8Alfredo CastravelliÎncă nu există evaluări

- LPG Compressors: Sales CatalogDocument40 paginiLPG Compressors: Sales CatalogAn IkhrandiÎncă nu există evaluări

- F34776 ArielDocument119 paginiF34776 ArielBraulio GomezÎncă nu există evaluări

- Ariel J. Lubrication System-03 04 04Document43 paginiAriel J. Lubrication System-03 04 04Manuel LiñeiroÎncă nu există evaluări

- DDDocument3 paginiDDAnkush Sehgal100% (1)

- Howden - FFP Free Floating Piston Lowres PDFDocument4 paginiHowden - FFP Free Floating Piston Lowres PDFdigecaÎncă nu există evaluări

- WH Compressor Frame OverviewDocument43 paginiWH Compressor Frame OverviewArzyman100% (1)

- Biofuels in Gas TurbinesDocument3 paginiBiofuels in Gas TurbinesturkfatalÎncă nu există evaluări

- ELP End User Rev10Document38 paginiELP End User Rev10hugoheloÎncă nu există evaluări

- Compressor Basics May 2009Document163 paginiCompressor Basics May 2009sada siva100% (1)

- Dry Screw Vs Oil Flooded ScrewDocument2 paginiDry Screw Vs Oil Flooded Screwkichas100% (1)

- Smart ChoicesDocument32 paginiSmart ChoicesSUN RAVIÎncă nu există evaluări

- CT valve handles high speeds in gas compressorsDocument5 paginiCT valve handles high speeds in gas compressorsTu PhamÎncă nu există evaluări

- Parts List: Frame AssemblyDocument202 paginiParts List: Frame AssemblylouatiÎncă nu există evaluări

- Centrifugal Compressor SRL 454 - Ge Oil&gasDocument20 paginiCentrifugal Compressor SRL 454 - Ge Oil&gasKamal Buddy50% (2)

- Ariel Corporation Sales Order Cover Sheet and Parts ListsDocument115 paginiAriel Corporation Sales Order Cover Sheet and Parts Listsshahzad100% (1)

- Ajax DPC-2802 PDFDocument2 paginiAjax DPC-2802 PDFdvcher78Încă nu există evaluări

- Shell Turbo T32Document3 paginiShell Turbo T32Agustinus Bayu Dewanto100% (1)

- Compressor Tech 12 2014Document68 paginiCompressor Tech 12 2014Tiffany Johnson100% (1)

- 4000046273-PGCA-EA-C06-003 - C1 - 1 - Datasheet Lube Oil CoolerDocument5 pagini4000046273-PGCA-EA-C06-003 - C1 - 1 - Datasheet Lube Oil Coolerrajindo1Încă nu există evaluări

- Reciprocating Compressor DiagnosticsDocument4 paginiReciprocating Compressor DiagnosticsChandra ShekarÎncă nu există evaluări

- Intro DR Engines July2018Document31 paginiIntro DR Engines July2018Russell DezemeÎncă nu există evaluări

- Installation, Operation and Service Guide for LeROI Gas CompressorsDocument49 paginiInstallation, Operation and Service Guide for LeROI Gas Compressorscesosqui0% (1)

- Peppers Catalogue PDFDocument64 paginiPeppers Catalogue PDFStone123456789Încă nu există evaluări

- SPC - Frick XJF Xjs 95 To 151 PDFDocument4 paginiSPC - Frick XJF Xjs 95 To 151 PDFmiguel callata100% (1)

- s33x UpgradeDocument15 paginis33x UpgradeAlexandre Borges BorgesÎncă nu există evaluări

- SRL CompressorsDocument20 paginiSRL Compressorssthe03Încă nu există evaluări

- Pulsa Series BrochureDocument8 paginiPulsa Series Brochurewhatdidijustwatch manÎncă nu există evaluări

- RG Integrally Geared CompressorsDocument6 paginiRG Integrally Geared CompressorsSauptik SinhaÎncă nu există evaluări

- B-2372-S Drawing ARIELDocument1 paginăB-2372-S Drawing ARIELhugoheloÎncă nu există evaluări

- Ajex Manual1 PDFDocument4 paginiAjex Manual1 PDFVikram JitÎncă nu există evaluări

- DONIT IG Brosura NOVO PDFDocument36 paginiDONIT IG Brosura NOVO PDFMohamed RizkÎncă nu există evaluări

- Peppers Catalogue GlandsDocument28 paginiPeppers Catalogue GlandsVlad Andronache100% (1)

- Turbine + CompressorsDocument3 paginiTurbine + CompressorsRiyadh SalehÎncă nu există evaluări

- API Flanges GasketDocument6 paginiAPI Flanges GasketSurya NarayanÎncă nu există evaluări

- Lufkin Gears Catalog 2C-84 ReducedDocument8 paginiLufkin Gears Catalog 2C-84 ReducedXavier GomezÎncă nu există evaluări

- 41000Document36 pagini41000tetiospamÎncă nu există evaluări

- Metallurgy and Corrosion Control in Oil and Gas ProductionDe la EverandMetallurgy and Corrosion Control in Oil and Gas ProductionÎncă nu există evaluări

- 688 Level Switch For Pressure Vessels Up To 2000 Psig: SeriesDocument2 pagini688 Level Switch For Pressure Vessels Up To 2000 Psig: SeriesDante Cabrera GuzmanÎncă nu există evaluări

- Examples of Fouling With Preventive Measures and Cleaning MethodsDocument1 paginăExamples of Fouling With Preventive Measures and Cleaning MethodsDante Cabrera GuzmanÎncă nu există evaluări

- Design Calculations Raw Water Storage TanksDocument44 paginiDesign Calculations Raw Water Storage TanksDante Cabrera GuzmanÎncă nu există evaluări

- Oil and Gas Company ProfileDocument2 paginiOil and Gas Company ProfileDante Cabrera GuzmanÎncă nu există evaluări

- Acoustically Induced Vibration in Piping - TutorialDocument13 paginiAcoustically Induced Vibration in Piping - TutorialJose PradoÎncă nu există evaluări

- FPM600 Fighting The FireDocument47 paginiFPM600 Fighting The FireDante Cabrera GuzmanÎncă nu există evaluări

- CPI Pressure-Relief Systems ExplainedDocument6 paginiCPI Pressure-Relief Systems Explainedahsan8880% (1)

- Drilltech Services (USA) Inc: Spiro-TorqDocument10 paginiDrilltech Services (USA) Inc: Spiro-TorqDante Cabrera GuzmanÎncă nu există evaluări

- Calcimetro Petron PDFDocument19 paginiCalcimetro Petron PDFDante Cabrera GuzmanÎncă nu există evaluări

- Electrical Area Classification GuideDocument21 paginiElectrical Area Classification GuideDante Cabrera GuzmanÎncă nu există evaluări

- Calcimetro Petron PDFDocument19 paginiCalcimetro Petron PDFDante Cabrera GuzmanÎncă nu există evaluări

- Regulators Spec 4in Single PortDocument2 paginiRegulators Spec 4in Single PortDante Cabrera GuzmanÎncă nu există evaluări

- FID GC ManualDocument32 paginiFID GC ManualDante Cabrera GuzmanÎncă nu există evaluări

- IT Spiro Torq SpecificationsDocument1 paginăIT Spiro Torq Specificationsjulio RDLRÎncă nu există evaluări

- Surge FactsDocument1 paginăSurge FactsDante Cabrera GuzmanÎncă nu există evaluări

- FPM400 Emergency Response Organization PDFDocument30 paginiFPM400 Emergency Response Organization PDFDante Cabrera GuzmanÎncă nu există evaluări

- FPM600 Fighting The FireDocument47 paginiFPM600 Fighting The FireDante Cabrera GuzmanÎncă nu există evaluări

- Flowgrid BrochureDocument12 paginiFlowgrid BrochureDante Cabrera GuzmanÎncă nu există evaluări

- Oil and Gas Company ProfileDocument2 paginiOil and Gas Company ProfileDante Cabrera GuzmanÎncă nu există evaluări

- 3 Rotary Rig PDFDocument0 pagini3 Rotary Rig PDFmazarialhafiz100% (1)

- Spec Engine 3516Document5 paginiSpec Engine 3516Jusril HidayatÎncă nu există evaluări

- Compresor Atlas CopcoDocument16 paginiCompresor Atlas CopcoDante Cabrera GuzmanÎncă nu există evaluări

- Ajax Cause & EffectDocument3 paginiAjax Cause & EffectgustavoespinosamÎncă nu există evaluări

- M 0elec - 2023 01 06Document570 paginiM 0elec - 2023 01 06Tríade MusicÎncă nu există evaluări

- AIM:-Service Positive Crankcase Ventilation System: Practical - 3Document6 paginiAIM:-Service Positive Crankcase Ventilation System: Practical - 3saiyed amanÎncă nu există evaluări

- Hitachi Crane Engine Parts - Mitsubishi, Hino, Mercedes Benz Industrial, Nissan, Isuzu, Engine PartsDocument12 paginiHitachi Crane Engine Parts - Mitsubishi, Hino, Mercedes Benz Industrial, Nissan, Isuzu, Engine PartsEngineParts2100% (1)

- Bajaj Discover 125/150 Spare Parts CatalogueDocument78 paginiBajaj Discover 125/150 Spare Parts Cataloguesanjika luckruwanÎncă nu există evaluări

- Cummins M11 High Soot Test: Standard Test Method ForDocument29 paginiCummins M11 High Soot Test: Standard Test Method ForMohanadÎncă nu există evaluări

- Nfpa 70B - 2013175Document1 paginăNfpa 70B - 2013175AbdulMajidYousoffÎncă nu există evaluări

- Service Manual: For Hyundai Heavy Industries Co.,LtdDocument27 paginiService Manual: For Hyundai Heavy Industries Co.,LtdDmitry100% (1)

- Manual VisatronDocument73 paginiManual Visatronmanuel100% (3)

- 4valve Engine Order Sheet NC250 Parts CatalogDocument4 pagini4valve Engine Order Sheet NC250 Parts Catalogsl_474530362100% (1)

- Brochure MaK M 32 CDocument20 paginiBrochure MaK M 32 CJhoe Vore CastleÎncă nu există evaluări

- Fundamentals of I.C. Engine PDFDocument16 paginiFundamentals of I.C. Engine PDFbansallove2008Încă nu există evaluări

- Product Nomenclature and Basics of Diesel EnginesDocument33 paginiProduct Nomenclature and Basics of Diesel Enginesjuanfer_arevalo3681Încă nu există evaluări

- Automotive Engine Cylinder DesignDocument18 paginiAutomotive Engine Cylinder DesignRam KumarÎncă nu există evaluări

- Pump PresentationDocument206 paginiPump PresentationMohamed Hamed100% (1)

- B30D 3Document150 paginiB30D 3Teknik MakinaÎncă nu există evaluări

- Baudouin 6M16 Parts ManualDocument155 paginiBaudouin 6M16 Parts Manualmohammed mostafa100% (2)

- Downloaded From Manuals Search EngineDocument435 paginiDownloaded From Manuals Search EngineАлександър ПухлевÎncă nu există evaluări

- Detroit DD5 FlyerDocument2 paginiDetroit DD5 Flyerjorge vladimir betancourt sorianoÎncă nu există evaluări

- Audi 3.0 V6 TFSI Engine With Roots BlowerDocument58 paginiAudi 3.0 V6 TFSI Engine With Roots Bloweroscar miguel100% (1)

- Mep - July 2013 - January 2010Document47 paginiMep - July 2013 - January 2010sunchit1986Încă nu există evaluări

- Lo 9 2805 259 12Document5 paginiLo 9 2805 259 12JasonÎncă nu există evaluări

- TNT25 Engine Intro (HD)Document90 paginiTNT25 Engine Intro (HD)Miguel LemosÎncă nu există evaluări

- CH 1 Cylinder Block Cylinder Head, GasketsDocument49 paginiCH 1 Cylinder Block Cylinder Head, GasketsBogdan Constantin CristeaÎncă nu există evaluări