Documente Academic

Documente Profesional

Documente Cultură

2009-08-15 011411 h4222300wm

Încărcat de

Anguchamy AnguchamyTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

2009-08-15 011411 h4222300wm

Încărcat de

Anguchamy AnguchamyDrepturi de autor:

Formate disponibile

Meritor WABCO Pneumatic Antilock Braking System

(ABS) 42.22

Troubleshooting for D-Version ABS

Troubleshooting To check the type of fault code recorded, stop the

vehicle and turn off the engine. Then, turn on the

ignition switch, but don’t start the engine. If the light

WARNING stays on after the 3-second self-test, there is an ac-

tive system fault that must be repaired to ensure

Before testing a vehicle equipped with Automatic proper system operation.

Traction Control (ATC) on a dynamometer, the

ATC system must be disabled. See Subject 160 If the light does not stay on, a stored or intermittent

for instructions. Activation of the vehicle ATC on fault (indicating a loose connector or broken wire)

a dynamometer will cause unequal drive-wheel has been recorded in the ABS electronic control unit

torque that can result in loss of vehicle control (ECU) memory.

and personal injury or death. If either light does not come on during the self-test,

check the bulb, all related circuit breakers in the

This subject includes troubleshooting procedures for electrical panel, or the batteries (the ABS/ATC sys-

diagnosing problems indicated by the ABS warning tem requires at least 9.5 volts to function correctly).

light(s) or the ATC wheel spin indicator light (if

equipped) on the instrument panel. If any of these If a fault has been corrected since the ABS warning

lights come on after the initial self-test, use one of light originally came on, the system must be cali-

the following methods to identify the problem: brated by driving the vehicle a short distance at 4

mph (6 km/h) or more before the light will go out.

• Troubleshoot using the Meritor WABCO PC

Diagnostics software. USING MERITOR WABCO PC

• Troubleshoot using J1587 codes viewed on a DIAGNOSTICS

computer with Freightliner’s ServiceLink in-

stalled. Follow the instructions in the Meritor WABCO PC

Diagnostics manual for troubleshooting the ABS/ATC

• Troubleshoot using the instrument panel blink system.

codes (with or without Pro-Link 9000®).

The J1587-code method provides more information USING J1587 FAULT CODES

about the specific problem than can be obtained from

Use Freightliner’s ServiceLink to diagnose the ABS/

the blink codes.

ATC system if detailed fault codes are needed or if

The ABS (and ATC, if equipped) system has built-in the diagnosis must be done remotely. Connect a

diagnostics to ensure that all components are operat- computer, with ServiceLink installed, to the J1587

ing correctly. The first step is an automatic self-test. datalink connector located under the left-hand dash.

Under normal conditions, the ABS warning light(s) Follow the instructions found in the ServiceLink

(ABS, TRAILER ABS, or ANTI LOCK) and ATC manual.

wheel spin indicator light (TRAC) light up on the in-

The J1587 fault codes are eight-digit numbers.

strument cluster when the ignition is turned on. After

about 3 seconds, these lights should go out if all of • The first three digits refer to the message iden-

the vehicle’s ABS/ATC components are working. tifier (MID) that indicates the ECU reporting the

fault. The MID is 136 for the ABS/ATC ECU.

If any of the lights stay on, or come back on later, a

problem within the ABS/ATC system has occurred. • The next three digits (preceded by a lower-

The driver can continue to drive the vehicle, but the case "s") represents the subsystem identifier

ABS system could be partially or completely inopera- (SID), which indicates the component at fault.

tive. • The last two digits, the Failure Mode Identifier

(FMI), represent the specific problem with the

NOTE: The TRAC indicator stays lit when the component.

ATC is controlling wheel spin and blinks continu-

ously if the ATC switch (TRAC MUD/SNOW) is The tables provided in "Troubleshooting Tables" all

activated. These are normal conditions and do have an MID code of 136. Each table lists all the FMI

not indicate a fault. codes for a specific component (SID). See Table 1

for a list of the first six digits of the fault codes with

L-Line and A-Line Workshop Manual, Supplement 6, August 2000 300/1

Meritor WABCO Pneumatic Antilock Braking System

42.22 (ABS)

Troubleshooting for D-Version ABS

their corresponding components and troubleshooting

table references.

J1587 Fault Code Cross-Reference

Troubleshooting

Fault Code, First 6 Digits Component or Area

Table

136001 Left Front Wheel Sensor Table 4

136002 Right Front Wheel Sensor Table 5

136003 Left Rear Wheel Sensor Table 6

136004 Right Rear Wheel Sensor Table 7

136005 Left Third Wheel Sensor * Table 8

136006 Right Third Wheel Sensor * Table 9

136007 Left Front Modulator Valve Table 10

136008 Right Front Modulator Valve Table 11

136009 Left Rear Modulator Valve Table 12

136010 Right Rear Modulator Valve Table 13

136011 Left Third Modulator Valve † Table 14

136012 Right Third Modulator Valve Table 15

136013 Retarder Table 16

136014 Ground (diagonal 1) Table 17

136015 Ground (diagonal 2) Table 18

136018 ATC Valve Table 19

136023 Warning Light Table 20

136248 SAE-J1939 Datalink Table 21

136249 SAE-J1922 Datalink Table 22

136251 Voltage Table 23

136253 Configuration Table 24

136254 Miscellaneous Table 25

* The left or right third wheel sensor is located at the wheel end of the rearmost axle on a 6S/4M or 6S/6M

configuration.

† The left or right third modulator valve is located on the chassis near the rearmost axle on a 6S/6M

configuration.

Table 1, J1587 Fault Code Cross-Reference

Active faults cannot be cleared until they are re- clearing them. Stored faults cannot be cleared if ac-

paired. A wheel sensor fault that has been repaired tive faults exist.

will not be cleared from memory until the vehicle has

been driven at least 4 mph (6 km/h) to calibrate the USING THE INSTRUMENTATION

system. PANEL BLINK CODES

To erase all the stored fault codes from the ECU

memory, refer to the ServiceLink manual. Make sure NOTE: If troubleshooting the system with the

to make a note of all the stored fault codes before Pro-Link 9000, use the instruction booklet that is

supplied with the WABCO D-Version ABS car-

tridge.

300/2 L-Line and A-Line Workshop Manual, Supplement 6, August 2000

Meritor WABCO Pneumatic Antilock Braking System

(ABS) 42.22

Troubleshooting for D-Version ABS

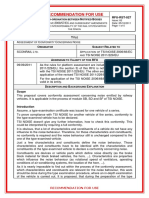

Use the ABS CHECK switch and the ABS warning indicated by two blinks, a pause of 1-1/2 seconds,

light to: followed by three blinks and a 4-second pause.

• Display any active or stored faults (press the • If it is an active fault, the same fault code will

ABS CHECK switch 1 second for the Diagnos- repeat until the ignition switch is turned off.

tic mode). See Fig. 1.

• Erase stored faults from the ECU memory or • If it is a stored fault, the next fault in the ECU

display the system identification code (press memory will be displayed after the 4-second

the ABS CHECK switch 3 seconds for the pause. See Fig. 2. The last fault stored in

Clear All mode). memory is displayed first; each stored fault is

displayed only once.

NOTE: For simplicity, the ABS warning light will

be referred to as the ABS light in this procedure. • If there are no fault codes in the ECU memory,

The warning light(s) on your vehicle may indi- blink code 1–1 is displayed, meaning the sys-

cate ABS, TRAILER ABS, or ANTI LOCK. tem is clear. See Fig. 3.

Displaying Fault Codes Identifying Blink Codes

Fault codes are displayed as follows: The first digit in a blink code identifies the type of

fault; the second digit indicates the specific location

• With the ignition switch on, press the ABS of the fault. See Table 2 to identify the blink codes.

CHECK switch for about 1 second (Diagnostic

mode), then release. The ABS light should go

out during the 1-1/2 second pause. See Fig. 1. CAUTION

1−1/2 4 1−1/2 4

1 sec

+ sec

+ + sec

+ sec

+ + sec

A B B B

05/18/2000 f151013

NOTE: An active fault code repeats until the ignition switch is turned off.

A. Press the ABS CHECK switch 1 second. The ABS light goes out during a 1-1/2 second pause.

B. Blink code 2–3: two blinks, a 1-1/2 second pause, three blinks, and a 4-second pause.

Fig. 1, Active Fault Codes Repeat (blink code 2-3 shown)

• The ABS light will blink (flash) a number equal The ignition switch must be off when connecting

to the first digit of the two-digit fault code. The or disconnecting connectors from the ECU.

first digit is a number from one to eight. Power applied to the ECU during connector in-

stallation or removal could damage the pins.

• After a 1-1/2 second pause, the light will blink

the second digit. The number of blinks for the Once a fault code has been identified, use a multim-

second digit is from one to six. eter to check the electrical harness at the ABS ECU

• After a 4-second pause, the cycle repeats an connectors. See Testing, 200 for wire numbers and

active fault code until it is repaired. connector pin locations on the frame-mounted ECU.

• If there are no active faults but one or more Refer to the applicable table in "Troubleshooting

stored faults are in the ECU memory, the sys- Tables" for fault codes, pins to be tested, and the

tem will display all recorded faults in sequence correct multimeter readings. Repair or replace the

starting with the most recent, with a 4-second components and/or wiring if the readings are not

pause between codes. correct.

For example, after the ABS CHECK switch is NOTE: Wire repairs may require the use of spe-

pressed 1 second and released, fault code 2–3 is cial tools for certain connectors and terminals.

L-Line and A-Line Workshop Manual, Supplement 6, August 2000 300/3

Meritor WABCO Pneumatic Antilock Braking System

42.22 (ABS)

Troubleshooting for D-Version ABS

1−1/2 4 1−1/2 4

1 sec

+ sec

+ + sec

+ sec

+ + sec

A B C D

05/18/2000 f151014

NOTE: The last fault stored is displayed first; each stored fault is displayed only once.

A. Press the ABS CHECK switch 1 second. The ABS light goes out during a 1-1/2 second pause.

B. The newest stored fault is displayed (blink code 2–3 is shown).

C. The second newest stored fault is displayed if one exists (blink code 3–2 is shown).

D. The third newest stored fault is displayed if one exists.

Fig. 2, Stored Fault Codes Display in Sequence

• After releasing the switch, the ABS light will go

out during the 1-1/2 second pause.

1−1/2

1 sec

+ sec + • If there were stored faults but no active faults,

B

the ABS light will blink eight times meaning all

A

05/18/2000 f151012

stored faults have been cleared. See Fig. 4. (If

there are active faults, only the system identifi-

A. Press the ABS CHECK switch 1 second. The ABS cation code will be displayed. See Fig. 5).

light goes out during a 1-1/2 second pause.

B. Blink code 1–1: one blink, a 1-1/2 second pause, • After a 4-second pause, the ABS light will dis-

and 1 blink. play the system identification code followed by

another 4-second pause repeatedly until the

Fig. 3, No Faults, System OK ignition switch is turned off.

Refer to Group 54 for information on special If there are active faults, only the system identifica-

terminals and connectors, and ordering tools for tion code will be displayed. See Fig. 5.

them. The system identification code indicates the number

Refer to the wiring diagrams in Specifications, 400 of ABS wheel speed sensors (S) and modulator

when troubleshooting the ABS system. valves (M) installed on the vehicle. See Table 3 for a

list of system identification codes.

After the repair is complete, drive the vehicle at least

4 mph (6km/h) to calibrate the ABS/ATC system.

Then, shut down the engine and turn the ignition

switch on to verify the fault is no longer active. After

pressing the ABS CHECK switch 1 second, a 1–1

"no fault" blink code should be displayed if there are

no stored faults in the ECU memory.

Erasing Stored Faults

An active fault code cannot be erased from ECU

memory but stored faults can be erased all at once

without being repaired. Make sure that all stored fault

codes are recorded before they are erased because

they should be repaired as soon as possible.

Stored faults can be erased from the ECU memory

as follows:

• Press the ABS CHECK switch for 3 to 6 sec-

onds (Clear All mode).

300/4 L-Line and A-Line Workshop Manual, Supplement 6, August 2000

Meritor WABCO Pneumatic Antilock Braking System

(ABS) 42.22

Troubleshooting for D-Version ABS

4 4 4

3 sec

+ sec

+ sec

+ sec

A B C C C

05/18/2000 f151015

A. Press the ABS CHECK switch 3 seconds. The ABS light goes out during a 1-1/2 second pause.

B. Eight quick blinks followed by a 4-second pause. (Faults cleared.)

C. The system ID code followed by a 4-second pause repeats until the ignition switch is turned off. (The system ID

code for a 4 x 4 vehicle is two quick blinks.)

Fig. 4, Stored Faults Cleared

4 4 4

3 sec

+ sec

+ sec

+ sec

A B B B B

05/18/2000 f151016

A. Press the ABS CHECK switch 3 seconds. The ABS light goes out during a 1-1/2 second pause.

B. The system ID code followed by a 4-second pause repeats until the ignition switch is turned off.

Fig. 5, Faults Not Cleared (active faults still exist)

ABS Blink Codes

1st Digit 2nd Digit

Type of Fault Specific Location of Fault

(blinks) (blinks)

1 No Faults 1 —

2 ABS Modulator Valve 1 Right Front Steer Axle

2 Left Front Steer Axle

3 Right Rear Drive Axle

4 Left Rear Drive Axle

5 Right Rear Additional Axle

6 Left Rear Additional Axle

3 Sensor Gap Too Large

4 Short or Open Sensor Circuit

See 2nd digit and fault-location list above.

5 Erratic Sensor Signal

6 Tone Wheel

L-Line and A-Line Workshop Manual, Supplement 6, August 2000 300/5

Meritor WABCO Pneumatic Antilock Braking System

42.22 (ABS)

Troubleshooting for D-Version ABS

ABS Blink Codes

1st Digit 2nd Digit

Type of Fault Specific Location of Fault

(blinks) (blinks)

7 System Function * 1 J1922 or J1939 Datalink

2 ATC Valve

3 Retarder Relay † (third

brake)

4 ABS Warning Light

5 ATC Configuration

6 Reserved for future use

8 ECU 1 Low Power Supply

2 High Power Supply

3 Internal Fault

4 System Configuration

5 Ground

* Reconfigure the ECU if fault messages appear for components not installed on the vehicle.

† The ECU detects only fault code 136 S013 03, indicating the retarder relay is shorted to power. See

"Troubleshooting Tables," Table 16. If the retarder relay circuit is open or if it is shorted to ground, the system

will not indicate a fault.

Table 2, ABS Blink Codes

System Identification Blink Codes If a fault cannot be repaired or erased from ECU

memory, contact your Meritor district service man-

Sensors/ Vehicle Wheel ager or call Meritor WABCO at 1-800-535-5560.

Blink Code

Modulators Positions

1 Blink 6S/6M 6x2

Troubleshooting Tables

2 Blinks 4S/4M 4x4

4 Blinks 6S/4M 6x4

5 Blinks 6S/6M 6x4

Table 3, System Identification Blink Codes

Left Front Wheel Sensor Troubleshooting (SID = s001)

J1587 Fault Code Blink

Problem Diagnostic Procedure

MID SID FMI Code

136 001 01 Excessive air gap Adjust the sensor. Verify the adjustment by measuring the 3–2

voltage across pins 7 and 8 of the X2 (black) connector. A good

measurement should be above 0.2 volt AC when the tire is

rotated 30 rpm. Check for loose wheel bearings and/or

excessive hub runout.

136 001 02 Incorrect tire Check for correct tire size. Check for correct number of teeth 5–2

on the tone wheel.

300/6 L-Line and A-Line Workshop Manual, Supplement 6, August 2000

Meritor WABCO Pneumatic Antilock Braking System

(ABS) 42.22

Troubleshooting for D-Version ABS

Left Front Wheel Sensor Troubleshooting (SID = s001)

J1587 Fault Code Blink

Problem Diagnostic Procedure

MID SID FMI Code

136 001 03 Shorted to power Measure the voltage across pin 7 of the X2 (black) connector 4–2

and ground, and pin 8 of the X2 connector and ground. If the

measurement indicates a voltage, the sensor is shorted to

power.

136 001 04 Shorted to ground Check the continuity between pin 7 of the X2 (black) connector

and ground, and pin 8 of the X2 connector and ground. If

continuity exists in either pin, the sensor is shorted to ground.

136 001 05 Open circuit Check the continuity between pins 7 and 8 of the X2 (black)

connector. A good resistance measurement will be between

500 and 2000 ohms. If the resistance is not within this range,

check the sensor and the chassis wiring.

136 001 06 Short circuit Check the continuity between pins 7 and 8 of the X2 (black)

connector. A good resistance measurement will be between

500 and 2000 ohms. If the resistance is not within this range,

check the sensor and the chassis wiring.

136 001 07 Damaged tone wheel Check the tone wheel for damage such as missing teeth. 6–2

136 001 08 Wheel slip Adjust the sensor. Verify the adjustment by measuring the 3–2

voltage across pins 7 and 8 of the X2 (black) connector. A good

measurement should be above 0.2 volt AC when the tire is

rotated 30 rpm. A fault is triggered if the wheel slips longer than

16 seconds.

136 001 09 Wires mismatched Check for a mismatch fault of another sensor and correct the 5–2

problem in the wiring harness.

136 001 10 Intermittent signal loss Adjust the sensor. Verify the adjustment by measuring the 3–2

voltage across pins 7 and 8 of the X2 (black) connector. A good

measurement should be above 0.2 volt AC when the tire is

rotated 30 rpm. *

136 001 11 Erratic signal Check the sensor wiring and connectors for intermittent contact. 5–2

Check the tone wheel for damage. Verify the signal by

measuring the voltage across pins 7 and 8 of the X2 (black)

connector. A good measurement should be above 0.2 volt AC

when the tire is rotated 30 rpm. *

136 001 12 Frequency incorrect Check the sensor wiring and connectors for intermittent contact.

The ECU may be at fault if the problem persists.

* Use Meritor WABCO PC Diagnostics software to view the wheel speed signals. If there is an intermittent loss of the signal, check the connections.

Table 4, Left Front Wheel Sensor Troubleshooting (SID = s001)

Right Front Wheel Sensor Troubleshooting (SID = s002)

J1587 Fault Code Blink

Problem Diagnostic Procedure

MID SID FMI Code

136 002 01 Excessive air gap Adjust the sensor. Verify the adjustment by measuring the 3–1

voltage across pins 5 and 6 of the X2 (black) connector. A good

measurement should be above 0.2 volt AC when the tire is

rotated 30 rpm. Check for loose wheel bearings and/or

excessive hub runout.

L-Line and A-Line Workshop Manual, Supplement 6, August 2000 300/7

Meritor WABCO Pneumatic Antilock Braking System

42.22 (ABS)

Troubleshooting for D-Version ABS

Right Front Wheel Sensor Troubleshooting (SID = s002)

J1587 Fault Code Blink

Problem Diagnostic Procedure

MID SID FMI Code

136 002 02 Incorrect tire Check for correct tire size. Check for correct number of teeth 5–1

on the tone wheel.

136 002 03 Shorted to power Measure the voltage across pin 4 of the X2 (black) connector 4–1

and ground, and pin 6 of the X2 connector and ground. If the

measurement indicates a voltage, the sensor is shorted to

power.

136 002 04 Shorted to ground Check the continuity between pin 4 of the X2 (black) connector

and ground, and pin 6 of the X2 connector and ground. If

continuity exists in either pin, the sensor is shorted to ground.

136 002 05 Open circuit Check the continuity between pins 5 and 6 of the X2 (black)

connector. A good resistance measurement will be between

500 and 2000 ohms. If the resistance is not within this range,

check the sensor and the chassis wiring.

136 002 06 Short circuit Check the continuity between pins 5 and 6 of the X2 (black)

connector. A good resistance measurement will be between

500 and 2000 ohms. If the resistance is not within this range,

check the sensor and the chassis wiring.

136 002 07 Damaged tone wheel Check the tone wheel for damage such as missing teeth. 6–1

136 002 08 Wheel slip Adjust the sensor. Verify the adjustment by measuring the 3–1

voltage across pins 5 and 6 of the X2 (black) connector. A good

measurement should be above 0.2 volt AC when the tire is

rotated 30 rpm. A fault is triggered if the wheel slips longer than

16 seconds.

136 002 09 Wires mismatched Check for a mismatch fault of another sensor and correct the 5–1

problem in the wiring harness.

136 002 10 Intermittent signal loss Adjust the sensor. Verify the adjustment by measuring the 3–1

voltage across pins 5 and 6 of the X2 (black) connector. A good

measurement should be above 0.2 volt AC when the tire is

rotated 30 rpm. *

136 002 11 Erratic signal Check the sensor wiring and connectors for intermittent contact. 5–1

Check the tone wheel for damage. Verify the signal by

measuring the voltage across pins 5 and 6 of the X2 (black)

connector. A good measurement should be above 0.2 volt AC

when the tire is rotated 30 rpm. *

136 002 12 Frequency incorrect Check the sensor wiring and connectors for intermittent contact.

The ECU may be at fault if the problem persists.

* Use Meritor WABCO PC Diagnostics software to view the wheel speed signals. If there is an intermittent loss of the signal, check the connections.

Table 5, Right Front Wheel Sensor Troubleshooting (SID = s002)

300/8 L-Line and A-Line Workshop Manual, Supplement 6, August 2000

Meritor WABCO Pneumatic Antilock Braking System

(ABS) 42.22

Troubleshooting for D-Version ABS

Left Rear Wheel Sensor Troubleshooting (SID = s003)

J1587 Fault Code Blink

Problem Diagnostic Procedure

MID SID FMI Code

136 003 01 Excessive air gap Adjust the sensor. Verify the adjustment by measuring the 3–4

voltage across pins 1 and 2 of the X3 (green) connector. A

good measurement should be above 0.2 volt AC when the tire

is rotated 30 rpm. Check for loose wheel bearings and/or

excessive hub runout.

136 003 02 Incorrect tire Check for correct tire size. Check for correct number of teeth 5–4

on the tone wheel.

136 003 03 Shorted to power Measure the voltage across pin 1 of the X3 (green) connector 4–4

and ground, and pin 2 of the X3 connector and ground. If the

measurement indicates a voltage, the sensor is shorted to

power.

136 003 04 Shorted to ground Check the resistance between pin 11 and 14 of the X3 (green)

connector and ground, and pin 2 of the X3 connector and

ground. If continuity exists in either pin, the sensor is shorted to

ground.

136 003 05 Open circuit Check the continuity between pins 1 and 2 of the X3 (green)

connector. A good resistance measurement will be between

500 and 2000 ohms. If the resistance is not within this range,

check the sensor and the chassis wiring.

136 003 06 Short circuit Check the continuity between pins 1 and 2 of the X3 (green)

connector. A good resistance measurement will be between

500 and 2000 ohms. If the resistance is not within this range,

check the sensor and the chassis wiring.

136 003 07 Damaged tone wheel Check the tone wheel for damage such as missing teeth. 6–4

136 003 08 Wheel slip Adjust the sensor. Verify the adjustment by measuring the 3–4

voltage across pins 1 and 2 of the X3 (green) connector. A

good measurement should be above 0.2 volt AC when the tire

is rotated 30 rpm. A fault is triggered if the wheel slips longer

than 16 seconds.

136 003 09 Wires mismatched Check for a mismatch fault of another sensor and correct the 5–4

problem in the wiring harness.

136 003 10 Intermittent signal loss Adjust the sensor. Verify the adjustment by measuring the 3–4

voltage across pins 1 and 2 of the X3 (green) connector. A

good measurement should be above 0.2 volt AC when the tire

is rotated 30 rpm. *

136 003 11 Erratic signal Check the sensor wiring and connectors for intermittent contact. 5–4

Check the tone wheel for damage. Verify the signal by

measuring the voltage across pins 1 and 2 of the X3 (green)

connector. A good measurement should be above 0.2 volt AC

when the tire is rotated 30 rpm. *

136 003 12 Frequency incorrect Check the sensor wiring and connectors for intermittent contact.

The ECU may be at fault if the problem persists.

* Use Meritor WABCO PC Diagnostics software to view the wheel speed signals. If there is an intermittent loss of the signal, check the connections.

Table 6, Left Rear Wheel Sensor Troubleshooting (SID = s003)

L-Line and A-Line Workshop Manual, Supplement 6, August 2000 300/9

Meritor WABCO Pneumatic Antilock Braking System

42.22 (ABS)

Troubleshooting for D-Version ABS

Right Rear Wheel Sensor Troubleshooting (SID = s004)

J1587 Fault Code Blink

Problem Diagnostic Procedure

MID SID FMI Code

136 004 01 Excessive air gap Adjust the sensor. Verify the adjustment by measuring the 3–3

voltage across pins 3 and 4 of the X3 (green) connector. A

good measurement should be above 0.2 volt AC when the tire

is rotated 30 rpm. Check for loose wheel bearings and/or

excessive hub runout.

136 004 02 Incorrect tire Check for correct tire size. Check for correct number of teeth 5–3

on the tone wheel.

136 004 03 Shorted to power Measure the voltage across pin 3 of the X3 (green) connector 4–3

and ground, and pin 4 of the X3 connector and ground. If the

measurement indicates a voltage, the sensor is shorted to

power.

136 004 04 Shorted to ground Check the continuity between pin 3 of the X3 (green) connector

and ground, and pin 4 of the X3 connector and ground. If

continuity exists in either pin, the sensor is shorted to ground.

136 004 05 Open circuit Check the continuity between pins 3 and 4 of the X3 (green)

connector. A good resistance measurement will be between

500 and 2000 ohms. If the resistance is not within this range,

check the sensor and the chassis wiring.

136 004 06 Short circuit Check the continuity between pins 3 and 4 of the X3 (green)

connector. A good resistance measurement will be between

500 and 2000 ohms. If the resistance is not within this range,

check the sensor and the chassis wiring.

136 004 07 Damaged tone wheel Check the tone wheel for damage such as missing teeth. 6–3

136 004 08 Wheel slip Adjust the sensor. Verify the adjustment by measuring the 3–3

voltage across pins 3 and 4 of the X3 (green) connector. A

good measurement should be above 0.2 volt AC when the tire

is rotated 30 rpm. A fault is triggered if the wheel slips longer

than 16 seconds.

136 004 09 Wires mismatched Check for a mismatch fault of another sensor and correct the 5–3

problem in the wiring harness.

136 004 10 Intermittent signal loss Adjust the sensor. Verify the adjustment by measuring the 3–3

voltage across pins 3 and 4 of the X3 (green) connector. A

good measurement should be above 0.2 volt AC when the tire

is rotated 30 rpm. *

136 004 11 Erratic signal Check the sensor wiring and connectors for intermittent contact. 5–3

Check the tone wheel for damage. Verify the signal by

measuring the voltage across pins 3 and 4 of the X3 (green)

connector. A good measurement should be above 0.2 volt AC

when the tire is rotated 30 rpm. *

136 004 12 Frequency incorrect Check the sensor wiring and connectors for intermittent contact.

The ECU may be at fault if the problem persists.

* Use Meritor WABCO PC Diagnostics software to view the wheel speed signals. If there is an intermittent loss of the signal, check the connections.

Table 7, Right Rear Wheel Sensor Troubleshooting (SID = s004)

300/10 L-Line and A-Line Workshop Manual, Supplement 6, August 2000

Meritor WABCO Pneumatic Antilock Braking System

(ABS) 42.22

Troubleshooting for D-Version ABS

Left Third Wheel Sensor Troubleshooting (SID = s005)

J1587 Fault Code Blink

Problem Diagnostic Procedure

MID SID FMI Code

136 005 01 Excessive air gap Adjust the sensor. Verify the adjustment by measuring the 3–6

voltage across pins 3 and 4 of the X4 (brown) connector. A

good measurement should be above 0.2 volt AC when the tire

is rotated at 30 rpm. Check for loose wheel bearings and/or

excessive hub runout.

136 005 02 Incorrect tire Check for correct tire size. Check for correct number of teeth 5–6

on the tone wheel.

136 005 03 Shorted to power Measure the voltage across pin 3 of the X4 (brown) connector 4–6

and ground, and pin 4 of the X4 connector and ground. If the

measurement indicates a voltage, the sensor is shorted to

power.

136 005 04 Shorted to ground Check the continuity between pin 3 of the X4 (brown) connector 4–6

and ground, and pin 4 of the X4 connector and ground. If

continuity exists in either pin, the sensor is shorted to ground.

136 005 05 Open circuit Check the continuity between pins 3 and 4 of the X4 (brown) 4–6

connector. A good resistance measurement will be between

700 and 3000 ohms.

136 005 06 Short circuit Check the continuity between pins 3 and 4 of the X4 (brown) 4–6

connector. A good resistance measurement will be between

700 and 3000 ohms.

136 005 07 Damaged tone wheel Check the tone wheel for damage such as missing teeth. 6–6

136 005 08 Wheel slip Adjust the sensor. Verify the adjustment by measuring the 3–6

voltage across pins 3 and 4 of the X4 (brown) connector. A

good measurement should be above 0.2 volt AC when the tire

is rotated at 30 rpm. A fault is triggered if the wheel slips longer

than 16 seconds.

136 005 09 Wires mismatched Check for a mismatch fault of another sensor and correct the 5–6

problem in the wiring harness.

136 005 10 Intermittent signal loss Adjust the sensor. Verify the adjustment by measuring the 3–6

voltage across pins 3 and 4 of the X4 (brown) connector. A

good measurement should be above 0.2 volt AC when the tire

is rotated at 30 rpm. *

136 005 11 Erratic signal Check the sensor wiring and connectors for intermittent contact. 5–6

Check the tone wheel for damage. Verify the signal by

measuring the voltage across pins 3 and 4 of the X4 (brown)

connector. A good measurement should be above 0.2 volt AC

when the tire is rotated at 30 rpm. *

136 005 12 Frequency incorrect Check the sensor wiring and connectors for intermittent contact. 5–6

The ECU may be at fault if the problem persists.

* Use Meritor WABCO PC Diagnostics software to view the wheel speed signals. If there is an intermittent loss of the signal, check the connections.

Table 8, Left Third Wheel Sensor Troubleshooting (SID = s005)

L-Line and A-Line Workshop Manual, Supplement 6, August 2000 300/11

Meritor WABCO Pneumatic Antilock Braking System

42.22 (ABS)

Troubleshooting for D-Version ABS

Right Third Wheel Sensor Troubleshooting (SID = s006)

J1587 Fault Code Blink

Problem Diagnostic Procedure

MID SID FMI Code

136 006 01 Excessive air gap Adjust the sensor. Verify the adjustment by measuring the 3–5

voltage across pins 5 and 6 of the X4 (brown) connector. A

good measurement should be above 0.2 volt AC when the tire

is rotated at 30 rpm. Check for loose wheel bearings and/or

excessive hub runout.

136 006 02 Incorrect tire Check for correct tire size. Check for correct number of teeth 5–5

on the tone wheel.

136 006 03 Shorted to power Measure the voltage across pin 5 of the X4 (brown) connector 4–5

and ground, and pin 6 of the X4 connector and ground. If the

measurement indicates a voltage, the sensor is shorted to

power.

136 006 04 Shorted to ground Check the continuity between pin 5 of the X4 (brown) connector 4–5

and ground, and pin 6 of the X4 connector and ground. If

continuity exists in either pin, the sensor is shorted to ground.

136 006 05 Open circuit Check the continuity between pins 5 and 6 of the X4 (brown) 4–5

connector. A good resistance measurement will be between

700 and 3000 ohms.

136 006 06 Short circuit Check the continuity between pins 5 and 6 of the of the X4 4–5

(brown) connector. A good resistance measurement will be

between 700 and 3000 ohms.

136 006 07 Damaged tone wheel Check the tone wheel for damage such as missing teeth. 6–5

136 006 08 Wheel slip Adjust the sensor. Verify the adjustment by measuring the 3–5

voltage across pins 5 and 6 of the X4 (brown) connector. A

good measurement should be above 0.2 volt AC when the tire

is rotated at 30 rpm. A fault is triggered if the wheel slips longer

than 16 seconds.

136 006 09 Wires mismatched Check for a mismatch fault of another sensor and correct the 5–5

problem in the wiring harness.

136 006 10 Intermittent signal loss Adjust the sensor. Verify the adjustment by measuring the 3–5

voltage across pins 5 and 6 of the X4 (brown) connector. A

good measurement should be above 0.2 volt AC when the tire

is rotated at 30 rpm. *

136 006 11 Erratic signal Check the sensor wiring and connectors for intermittent contact. 5–5

Check the tone wheel for damage. Verify the signal by

measuring the voltage across pins 5 and 6 of the X4 (brown)

connector. A good measurement should be above 0.2 volt AC

when the tire is rotated at 30 rpm. *

136 006 12 Frequency incorrect Check the sensor wiring and connectors for intermittent contact. 5–5

The ECU may be at fault if the problem persists.

* Use Meritor WABCO PC Diagnostics software to view the wheel speed signals. If there is an intermittent loss of the signal, check the connections.

Table 9, Right Third Wheel Sensor Troubleshooting (SID = s006)

300/12 L-Line and A-Line Workshop Manual, Supplement 6, August 2000

Meritor WABCO Pneumatic Antilock Braking System

(ABS) 42.22

Troubleshooting for D-Version ABS

Left Front Modulator Valve Troubleshooting (SID = s007)

J1587 Fault Code Blink

Problem Diagnostic Procedure

MID SID FMI Code

136 007 01 Open circuit in the inlet Check the modulator valve wiring. Check for damaged wiring in 2–2

and/or outlet solenoid the inlet, outlet and ground circuits. Check the resistance

circuits between pins 10 and 11 of the X2 (black) connector, and

between pins 2 and 11. A good measurement should be

between 4 and 8 ohms.

136 007 03 Shorted to power Check the modulator valve wiring. Check for damaged wiring in

the inlet, outlet and ground circuits. Measure the voltage across

pins 2, 10, and 11 of the X2 (black) connector and ground. If

any of the measurements indicate a voltage, the valve is

shorted to power.

136 007 05 Open circuit Check the modulator valve wiring. Check for damaged wiring in

the inlet, outlet and ground circuits. Check the resistance

between pins 10 and 11 of the X2 (black) connector, and

between pins 2 and 11 of the X2 connector. A good

measurement should be between 4 and 8 ohms.

136 007 06 Shorted to ground Check continuity between pin 2 of the X2 (black) connector and

ground, and pin 10 of the X2 connector and ground. If

continuity exists in either pin, the valve is shorted to ground.

Table 10, Left Front Modulator Valve Troubleshooting (SID = s007)

Right Front Modulator Valve Troubleshooting (SID = s008)

J1587 Fault Code Blink

Problem Diagnostic Procedure

MID SID FMI Code

136 008 01 Open circuit in the inlet Check the modulator valve wiring. Check for damaged wiring in 2–1

and/or outlet solenoid the inlet, outlet and ground circuits. Check the resistance

circuits between pins 3 and 9 of the X2 (black) connector, and between

pins 4 and 9. A good measurement should be between 4 and 8

ohms.

136 008 03 Shorted to power Check the modulator valve wiring. Check for damaged wiring in

the inlet, outlet and ground circuits. Measure the voltage across

pins 3, 4, and 9 of the X2 (black) connector and ground. If any

of the measurements indicate a voltage, the valve is shorted to

power.

136 008 05 Open circuit Check the modulator valve wiring. Check for damaged wiring in

the inlet, outlet and ground circuits. Check the resistance

between pins 3 and 9 of the X2 (black) connector, and between

pins 4 and 9 of the X2 connector. A good measurement should

be between 4 and 8 ohms.

136 008 06 Shorted to ground Check continuity between pin 3 of the X2 (black) connector and

ground, and pin 4 of the X2 connector and ground. If continuity

exists in either pin, the valve is shorted to ground.

Table 11, Right Front Modulator Valve Troubleshooting (SID = s008)

L-Line and A-Line Workshop Manual, Supplement 6, August 2000 300/13

Meritor WABCO Pneumatic Antilock Braking System

42.22 (ABS)

Troubleshooting for D-Version ABS

Left Rear Modulator Valve Troubleshooting (SID = s009)

J1587 Fault Code Blink

Problem Diagnostic Procedure

MID SID FMI Code

136 009 01 Open circuit in the inlet Check the modulator valve wiring. Check for damaged wiring in 2–4

and/or outlet solenoid the inlet, outlet and ground circuits. Check the resistance

circuits between pins 10 and 11 of the X3 (green) connector, and

between pins 12 and 11. A good measurement should be

between 4 and 8 ohms.

136 009 03 Shorted to power Check the modulator valve wiring. Check for damaged wiring in

the inlet, outlet and ground circuits. Measure the voltage across

pins 10, 11, and 12 of the X3 (green) connector and ground. If

any of the measurements indicate a voltage, the valve is

shorted to power.

136 009 05 Open circuit Check the modulator valve wiring. Check for damaged wiring in

the inlet, outlet and ground circuits. Check the resistance

between pins 10 and 11 of the X3 (green) connector, and

between pins 12 and 11 of the X3 connector. A good

measurement should be between 4 and 8 ohms.

136 009 06 Shorted to ground Check continuity between pin 10 of the X3 (green) connector

and ground, and pin 12 of the X3 connector and ground. If

continuity exists in either pin, the valve is shorted to ground.

Table 12, Left Rear Modulator Valve Troubleshooting (SID = s009)

Right Rear Modulator Valve Troubleshooting (SID = s010)

J1587 Fault Code Blink

Problem Diagnostic Procedure

MID SID FMI Code

136 010 01 Open circuit in the inlet Check the modulator valve wiring. Check for damaged wiring in 2–3

and/or outlet solenoid the inlet, outlet and ground circuits. Check the resistance

circuits between pins 7 and 8 of the X3 (green) connector, and

between pins 9 and 8. A good measurement should be

between 4 and 8 ohms.

136 010 03 Shorted to power Check the modulator valve wiring. Check for damaged wiring in

the inlet, outlet and ground circuits. Measure the voltage across

pins 7, 8, and 9 of the X3 (green) connector and ground. If any

of the measurements indicate a voltage, the valve is shorted to

power.

136 010 05 Open circuit Check the modulator valve wiring. Check for damaged wiring in

the inlet, outlet and ground circuits. Check the resistance

between pins 7 and 8 of the X3 (green) connector, and

between pins 9 and 8 of the X3 connector. A good

measurement should be between 4 and 8 ohms.

136 010 06 Shorted to ground Check continuity between pin 7 of the X3 (green) connector

and ground, and pin 9 of the X3 connector and ground. If

continuity exists in either pin, the valve is shorted to ground.

Table 13, Right Rear Modulator Valve Troubleshooting (SID = s010)

300/14 L-Line and A-Line Workshop Manual, Supplement 6, August 2000

Meritor WABCO Pneumatic Antilock Braking System

(ABS) 42.22

Troubleshooting for D-Version ABS

Left Third Modulator Valve Troubleshooting (SID = s011)

J1587 Fault Code Blink

Problem Diagnostic Procedure

MID SID FMI Code

136 011 01 Open circuit in the inlet Check the modulator valve wiring. Check for damaged wiring in 2–6

and/or outlet solenoid the inlet, outlet and ground circuits. Check the resistance

circuits between pins 10 and 11 of the X4 (brown) connector, and

between pins 12 and 11. A good measurement should be

between 4 and 8 ohms.

136 011 03 Shorted to power Check the modulator valve wiring. Check for damaged wiring in

the inlet, outlet and ground circuits. Measure the voltage across

pins 10, 11, and 12 of the X4 (brown) connector and ground. If

any of the measurements indicate a voltage, the valve is

shorted to power.

136 011 05 Open circuit Check the modulator valve wiring. Check for damaged wiring in

the inlet, outlet and ground circuits. Check the resistance

between pins 10 and 11 of the X4 (brown) connector, and

between pins 12 and 11 of the X4 connector. A good

measurement should be between 4 and 8 ohms.

136 011 06 Shorted to ground Check continuity between pin 10 of the X4 (brown) connector

and ground, and pin 12 of the X4 connector and ground. If

continuity exists in either pin, the valve is shorted to ground.

Table 14, Left Third Modulator Valve Troubleshooting (SID = s011)

Right Third Modulator Valve Troubleshooting (SID = s012)

J1587 Fault Code Blink

Problem Diagnostic Procedure

MID SID FMI Code

136 012 01 Open circuit in the inlet Check the modulator valve wiring. Check for damaged wiring in 2–5

and/or outlet solenoid the inlet, outlet and ground circuits. Check the resistance

circuits between pins 7 and 8 of the X4 (brown) connector, and

between pins 9 and 8. A good measurement should be

between 4 and 8 ohms.

136 012 03 Shorted to power Check the modulator valve wiring. Check for damaged wiring in

the inlet, outlet and ground circuits. Measure the voltage across

pins 7, 8, and 9 of the X3 (green) connector and ground. If any

of the measurements indicate a voltage, the valve is shorted to

power.

136 012 05 Open circuit Check the modulator valve wiring. Check for damaged wiring in

the inlet, outlet and ground circuits. Check the resistance

between pins 7 and 8 of the X4 (brown) connector, and

between pins 9 and 8 of the X4 connector. A good

measurement should be between 4 and 8 ohms.

136 012 06 Shorted to ground Check continuity between pin 7 of the X4 (brown) connector

and ground, and pin 9 of the X4 connector and ground. If

continuity exists in either pin, the valve is shorted to ground.

Table 15, Right Third Modulator Valve Troubleshooting (SID = s012)

L-Line and A-Line Workshop Manual, Supplement 6, August 2000 300/15

Meritor WABCO Pneumatic Antilock Braking System

42.22 (ABS)

Troubleshooting for D-Version ABS

Retarder Troubleshooting (SID = s013)

J1587 Fault Code Blink

Problem Diagnostic Procedure

MID SID FMI Code

136 013 03 Shorted to power Measure the voltage between pin 5 of the X1 (gray) connector 7–3

and ground. If the measurement indicates a voltage, the relay

circuit is shorted to power.

136 013 05 Open circuit Check continuity of the retarder relay circuit 376R. Replace the

wire if continuity does not exist. Reconfigure the ECU if the

fault message appears but no retarder is installed.

136 013 06 Shorted to ground Check continuity between pin 5 of the X1 (gray) connector and

ground. If continuity exists, the retarder relay circuit is shorted

to ground.

Table 16, Retarder Troubleshooting (SID = s013)

Ground (diagonal 1–right front, left rear) Troubleshooting (SID = s014)

J1587 Fault Code Blink

Problem Diagnostic Procedure

MID SID FMI Code

136 014 04 Voltage, diagonal 1, Check the 10A circuit breaker F43. Check pin 1 in the X1 (gray) 8–1

low voltage/open connector for proper contact. Check circuit 16, 16E. Check the

circuit vehicle batteries and charging system.

136 014 07 ABS ECU Replace ECU if the fault repeats. 8–3

Table 17, Ground (diagonal 1; right front, left rear) Troubleshooting (SID = s014)

Ground (diagonal 2–left front, right rear) Troubleshooting (SID = s015)

J1587 Fault Code Blink

Problem Diagnostic Procedure

MID SID FMI Code

136 015 04 Voltage, diagonal 2, Check the 10A circuit breaker. Check pin 1 in the X1 (gray) 8–1

low voltage/open connector for proper contact. Check circuit 16A,16F.

circuit

136 015 07 ABS ECU Replace ECU if the fault repeats. 8–3

Table 18, Ground (diagonal 2; left front, right rear) Troubleshooting (SID = s015)

300/16 L-Line and A-Line Workshop Manual, Supplement 6, August 2000

Meritor WABCO Pneumatic Antilock Braking System

(ABS) 42.22

Troubleshooting for D-Version ABS

ATC Valve Troubleshooting (SID = s018)

J1587 Fault Code * Blink

Problem Diagnostic Procedure

MID SID FMI Code

136 018 03 ATC valve, shorted to Measure the voltage between pin 5 of the X3 (green) connector 7–2

power and ground, and pin 6 of the X3 connector and ground. If

measurements indicate a voltage, the ATC valve is shorted to

power.

136 018 05 ATC valve, open circuit Check the resistance between pins 5 and 6 of the X3 (green)

connector. A good measurement will read between 8 and 14

ohms. Check the wiring and the valve.

136 018 06 ATC valve, shorted to Check the continuity between pin 6 of the X3 (green) connector

ground and ground. If continuity exists, there is a short to ground.

* Reconfigure the ECU if the fault message appears but ATC is not installed.

Table 19, ATC Valve Troubleshooting (SID = s018)

Warning Light Troubleshooting (SID = s023)

J1587 Fault Code Blink

Problem Diagnostic Procedure

MID SID FMI Code

136 023 05 Warning Light Check the bulb and continuity of the warning light circuit. Was 7–4

the blink code switch activated longer than 16 seconds? If so,

cycle the ignition off and on to verify the fault.

Table 20, Warning Light Troubleshooting (SID = s023)

J1939 Datalink Troubleshooting (SID = s231)

J1587 Fault Code Blink

Problem Diagnostic Procedure

MID SID FMI Code

136 231 02 J1939 plausibility error Check the speedometer calibration. Check for tire size 7–1

mismatch.

136 231 05 The J1939 datalink Check J1939 datalink connections. Check for continuity of

has an open circuit. datalink wires. Reconfigure the ECU if the fault message

appears but no J1939 datalink is installed.

136 231 06 J1939 shorted to Check the continuity between pin 6 of the X1 (gray) connector

ground and ground, and pin 7 of the X1 (gray) connector and ground. If

continuity exists, the J1939 datalink is shorted to ground.

136 231 09 J1939 time-out Check other J1939 ECUs for incorrect communication.

136 231 12 J1939, internal error Cycle the ignition off and on. If the fault detection repeats, 8–3

replace the ABS ECU.

Table 21, J1939 Datalink Troubleshooting (SID = s231)

L-Line and A-Line Workshop Manual, Supplement 6, August 2000 300/17

Meritor WABCO Pneumatic Antilock Braking System

42.22 (ABS)

Troubleshooting for D-Version ABS

J1922 Datalink Troubleshooting (SID = s249)

J1587 Fault Code Blink

Problem Diagnostic Procedure

MID SID FMI Code

136 249 05 The J1922 datalink Check the J1922 datalink connections. Check continuity of the 7–1

has an open circuit. datalink wires. Reconfigure the ECU if the fault message

appears but no J1922 datalink is installed.

136 249 06 The J1922 datalink is Check continuity between pin 6 of the X1 (gray) connector and

shorted to ground. ground, and pin 7 of the X1 (gray) connector and ground. If

continuity exists, the J1922 datalink is shorted to ground.

136 249 10 The J1922 bus is not Check other J1922 ECUs for incorrect communication.

free.

Table 22, J1922 Datalink Troubleshooting (SID = s249)

Overvoltage Troubleshooting (SID = s251)

J1587 Fault Code Blink

Problem Diagnostic Procedure

MID SID FMI Code

136 251 03 Overvoltage, diagonal Check the alternator output and the battery voltage. Supply 8–2

1 or 2 voltage is greater than 14 volts for more than 5 seconds.

Table 23, Overvoltage Troubleshooting (SID = s251)

Configuration Troubleshooting (SID = s253)

J1587 Fault Code Blink

Problem Diagnostic Procedure

MID SID FMI Code

136 253 01 ATC configuration Check the wires responsible for parameter setting. 7–5

136 253 02 EEPROM or ABS Cycle the ignition off and on. If the fault detection repeats, 8–4

configuration, wheel replace the ABS ECU.

parameter incorrect

136 253 12 EEPROM, checksum Check the parameter setting. Diagnostic device disconnected

during active diagnosis. Cycle the ignition off and on. If the fault

detection repeats, replace the ABS ECU.

Table 24, Configuration Troubleshooting (SID = s253)

Miscellaneous ABS/ATC Troubleshooting (SID = s254)

J1587 Fault Code Blink

Problem Diagnostic Procedure

MID SID FMI Code

136 254 02 Internal error Cycle the ignition off and on. If the fault detection repeats, 8–3

replace the ABS ECU.

136 254 05 ABS/ATC ECU, no No modulators connected. Fault not memorized. 8–4

loads

136 254 08 Excessive slip/ Check the wheel sensor air gaps, one axle is much faster than 7–1

dynamometer the other.

300/18 L-Line and A-Line Workshop Manual, Supplement 6, August 2000

Meritor WABCO Pneumatic Antilock Braking System

(ABS) 42.22

Troubleshooting for D-Version ABS

Miscellaneous ABS/ATC Troubleshooting (SID = s254)

J1587 Fault Code Blink

Problem Diagnostic Procedure

MID SID FMI Code

136 254 09 Modulator Valve, Modulator valve was activated for too long. 2–1

activation time

136 254 12 Internal error Cycle the ignition off and on. If the fault detection repeats, 8–3

replace the ABS ECU.

Table 25, Miscellaneous ABS/ATC Troubleshooting (SID = s254)

L-Line and A-Line Workshop Manual, Supplement 6, August 2000 300/19

S-ar putea să vă placă și

- VolvoDocument3 paginiVolvoAnguchamy AnguchamyÎncă nu există evaluări

- Wiring Code Identification Information: Main Menu Site MapDocument8 paginiWiring Code Identification Information: Main Menu Site MapAnguchamy AnguchamyÎncă nu există evaluări

- 2013 Fault Codes PDFDocument286 pagini2013 Fault Codes PDFAnguchamy Anguchamy89% (35)

- Electricidad Automotriz ToyotaDocument24 paginiElectricidad Automotriz ToyotaRonald Castro Quintero100% (4)

- Wiring Symbols in PneumaticDocument14 paginiWiring Symbols in PneumaticConstantin CosminÎncă nu există evaluări

- Wiring Code Identification Information: Main Menu Site MapDocument8 paginiWiring Code Identification Information: Main Menu Site MapAnguchamy AnguchamyÎncă nu există evaluări

- 2009-08-15 011411 h4222300wmDocument19 pagini2009-08-15 011411 h4222300wmAnguchamy AnguchamyÎncă nu există evaluări

- Volvo MID 128 Fault Codes PDFDocument172 paginiVolvo MID 128 Fault Codes PDFModestas100% (11)

- 2013 Fault Codes PDFDocument286 pagini2013 Fault Codes PDFAnguchamy Anguchamy89% (35)

- 2013 Fault Codes PDFDocument286 pagini2013 Fault Codes PDFAnguchamy Anguchamy89% (35)

- 2013 Fault Codes PDFDocument286 pagini2013 Fault Codes PDFAnguchamy Anguchamy89% (35)

- 2013 Fault Codes PDFDocument286 pagini2013 Fault Codes PDFAnguchamy Anguchamy89% (35)

- Electricidad Automotriz ToyotaDocument24 paginiElectricidad Automotriz ToyotaRonald Castro Quintero100% (4)

- Hydraulic Schematic SymbolsDocument12 paginiHydraulic Schematic SymbolsswainpiyushÎncă nu există evaluări

- En Automotive Auto Electric Basic Technology Part1Document36 paginiEn Automotive Auto Electric Basic Technology Part1Calligraphie D'un CicatriceÎncă nu există evaluări

- En Automotive Auto Electric Basic Technology Part1Document36 paginiEn Automotive Auto Electric Basic Technology Part1Calligraphie D'un CicatriceÎncă nu există evaluări

- En Automotive Auto Electric Basic Technology Part1Document36 paginiEn Automotive Auto Electric Basic Technology Part1Calligraphie D'un CicatriceÎncă nu există evaluări

- Electricidad Automotriz ToyotaDocument24 paginiElectricidad Automotriz ToyotaRonald Castro Quintero100% (4)

- Man Fault-Messages-TGA PDFDocument203 paginiMan Fault-Messages-TGA PDFNadeem Mohd100% (8)

- Wiring Symbols in PneumaticDocument14 paginiWiring Symbols in PneumaticConstantin CosminÎncă nu există evaluări

- Wabco Mid136Document19 paginiWabco Mid136Nuno Silva94% (16)

- V.Anguchamy: Experience All Truki Enterprise L.L.CDocument1 paginăV.Anguchamy: Experience All Truki Enterprise L.L.CAnguchamy AnguchamyÎncă nu există evaluări

- V.Anguchamy: Experience All Truki Enterprise L.L.CDocument1 paginăV.Anguchamy: Experience All Truki Enterprise L.L.CAnguchamy AnguchamyÎncă nu există evaluări

- V.Anguchamy: Experience All Truki Enterprise L.L.CDocument1 paginăV.Anguchamy: Experience All Truki Enterprise L.L.CAnguchamy AnguchamyÎncă nu există evaluări

- V.Anguchamy: Experience All Truki Enterprise L.L.CDocument1 paginăV.Anguchamy: Experience All Truki Enterprise L.L.CAnguchamy AnguchamyÎncă nu există evaluări

- Volvo MID 128 Fault Codes PDFDocument172 paginiVolvo MID 128 Fault Codes PDFModestas100% (11)

- V.Anguchamy: Experience All Truki Enterprise L.L.CDocument1 paginăV.Anguchamy: Experience All Truki Enterprise L.L.CAnguchamy AnguchamyÎncă nu există evaluări

- PV776 88946390Document64 paginiPV776 88946390Anonymous HlBpJe5ve100% (6)

- Volvo MID 140 Fault CodesDocument20 paginiVolvo MID 140 Fault CodesModestas89% (19)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (119)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Agenda for Commercial Vehicle Industry ConferenceDocument2 paginiAgenda for Commercial Vehicle Industry ConferenceVishnupriya Sharma ThirumaleÎncă nu există evaluări

- Preventing Maintaince Procedure Froklift HanlerDocument2 paginiPreventing Maintaince Procedure Froklift HanlerAli AlahmaÎncă nu există evaluări

- MF2617 M1 Uk PDFDocument4 paginiMF2617 M1 Uk PDFShane LinÎncă nu există evaluări

- Part ListDocument143 paginiPart ListawemetalÎncă nu există evaluări

- Still - MX PDFDocument8 paginiStill - MX PDFtomy112Încă nu există evaluări

- 20 Engine & Transmission Components Page 176-193 PDFDocument18 pagini20 Engine & Transmission Components Page 176-193 PDFmarcosluna68100% (1)

- Diff. SpicerDocument113 paginiDiff. SpicerAdal Vera100% (3)

- 50-60 Series: Armatrac Tier 3ADocument2 pagini50-60 Series: Armatrac Tier 3AdesiréÎncă nu există evaluări

- RFU-RST-027 Noise Conformity AssessmentDocument5 paginiRFU-RST-027 Noise Conformity AssessmentЛюбомир РангеловÎncă nu există evaluări

- VAG Manual PDFDocument16 paginiVAG Manual PDFAutomotriz HercaÎncă nu există evaluări

- 2.0 Engine Mechanical System - General InformationDocument16 pagini2.0 Engine Mechanical System - General InformationstevoxÎncă nu există evaluări

- RPDCatalog 9 23colorDocument10 paginiRPDCatalog 9 23colorRafael VillanuevaÎncă nu există evaluări

- 416E Vs 416D Product Buletin (TEJB9168)Document36 pagini416E Vs 416D Product Buletin (TEJB9168)firman manaluÎncă nu există evaluări

- Kalyani Powertrain Ltd-4Nov2022Document32 paginiKalyani Powertrain Ltd-4Nov2022Sreekanth DevarasettyÎncă nu există evaluări

- SKF Wheel Bearing Installation Guide With Free End PlayDocument20 paginiSKF Wheel Bearing Installation Guide With Free End Play2bjornÎncă nu există evaluări

- Manual 152 Rev. 10Document675 paginiManual 152 Rev. 10Julio Alberto Vite PuescasÎncă nu există evaluări

- Diagrama Hidráulico - Case Af 4150Document1 paginăDiagrama Hidráulico - Case Af 4150Geovanni MarconÎncă nu există evaluări

- 2005 Chevrolet Spark engine sensor connector views and functionsDocument14 pagini2005 Chevrolet Spark engine sensor connector views and functionsData TécnicaÎncă nu există evaluări

- Benni Mini Workshop Manual 2013 Cap 2Document298 paginiBenni Mini Workshop Manual 2013 Cap 2Daniel Pérez ObandoÎncă nu există evaluări

- Moviltec 20Document3 paginiMoviltec 20sf wÎncă nu există evaluări

- EP25N - EP25CN - EP30N EP30CN - EP35N: SpecificationsDocument4 paginiEP25N - EP25CN - EP30N EP30CN - EP35N: SpecificationsVitor HugoÎncă nu există evaluări

- Design and Fabrication of Hoverboard With Forklift: A Project Report Submitted byDocument35 paginiDesign and Fabrication of Hoverboard With Forklift: A Project Report Submitted byv.s.muhammed sawad sawadÎncă nu există evaluări

- Motorized Trolley Without CraneDocument6 paginiMotorized Trolley Without CraneAnsarMahmoodÎncă nu există evaluări

- 2-Gaikindo Brand Data Janfeb2021Document2 pagini2-Gaikindo Brand Data Janfeb2021Faisal FaiÎncă nu există evaluări

- PV776 TSP144528Document250 paginiPV776 TSP144528Registr Registr100% (4)

- Exame de Atr72-212aDocument6 paginiExame de Atr72-212aobsirionÎncă nu există evaluări

- Duke Engines' Valveless Axial Engine Shows PromiseDocument11 paginiDuke Engines' Valveless Axial Engine Shows PromiserajnagpÎncă nu există evaluări

- E-Scooter User Manual GuideDocument38 paginiE-Scooter User Manual Guiderod excelÎncă nu există evaluări

- Xpress 2020-12-31Document70 paginiXpress 2020-12-31Juan Carlos Maguiña L.Încă nu există evaluări

- Isuzu Engine Control System 6HK1 Model 2008, 2009 MY F&G Series Workshop ManualDocument392 paginiIsuzu Engine Control System 6HK1 Model 2008, 2009 MY F&G Series Workshop ManualToan75% (4)