Documente Academic

Documente Profesional

Documente Cultură

852 GB

Încărcat de

omar tlebDescriere originală:

Titlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

852 GB

Încărcat de

omar tlebDrepturi de autor:

Formate disponibile

Operating Manual

Combined Refrigerated Circulating

Water Level

CRCWL 852- 300- 160 HS/ AD ..WAD ..WWAD

CRCWL 852- 400- 160 HS/ AD ..WAD ..WWAD

CRCWL 852- 500- 160 HS/ AD ..WAD ..WWAD

CRCWL 852- 600- 160 HS/ WAD ..WWAD

CRCWL 852- 1000- 160 HS/ WAD ..WWAD

CRCWL 852- 1200- 160 HS/ WAD ..WWAD

Geräte - Typ

Model type

Serien- Serial-

Nr.:

Elektro - Schaltplan

Wiring diagram

Nr.:

BALDWIN - Ident.-Nr. DOC.0.090151.02 GB

01.98/CRCWL852/GB Seite / Page 1

Seite / Page 2 01.98/CRCWL852/GB

BALDWIN services Manufacturer

BALDWIN EUROPA BALDWIN-GRAFOTEC GMBH

Baldwin (UK) Ltd. DERCHINGER STR.137

Unit 13, Apex Business Centre D-86165 AUGSBURG

Boscombe Road, Dunstable

Bedfordshire LU5 4SB POSTFACH 41 01 25 (POB)

Great Britain D-86068 AUGSBURG

Tel. +44-1582-477 449

Fax +44-1582-478 510 TELEFON: (08 21 ) 79 42-0

Baldwin France Sarl TELEFAX: (08 21) 7942-222

30, avenue de Bergoďde

F-60550 Verneuil en Halatte

Frankreich

Tel. +33-3-44 25 06 81

Fax +33-3-44 25 16 40

BALDWIN AMERIKA

Baldwin Graphic Products

12 Commerce Drive

Shelton, CT 06484-0941

USA

Tel. +1 203-925-1100

Fax +1 203-929-7856

BALDWIN ASIEN

Baldwin Graphic Equip. Pty. Ltd.

P.O.Box 1234

Rozelle NSW 2039

6/323A Darling Street

Balmain NSW 2041

Australien

Tel. 612-9555-9975

Fax 612-9555-8246

Baldwin Japan Ltd.

4- 34 Toyo 2- chome

Kohtoh- ku

J- Tokyo 135 Japan

Tel. +81 3- 5606- 2771

Fax +81 3- 5606- 2779

Baldwin Printing Controls Ltd.

Unit A, 26th Floor, Seaview Plaza

283 Shaukeiwan Road

Hong Kong

Tel. 852-811-2987

Fax 852-811-0641 Ó All rights reserved. No part of this operating manual

may be reproduced or duplicated in any form (printing,

photocopying or any other process) without the

permission in writing from BALDWIN GmbH.

01.98/CRCWL852/GB Seite / Page 3

Combined Refrigerated Circulating Water Levels by

BALDWIN are sophisticated designs based on our

years of experience in the development and manu-

facture of ancillary equipment for the graphic arts, that

will always be ready for service and reach a long life,

provided they are operated properly and are given

careful maintenance in due time.

Seite / Page 4 01.98/CRCWL852/GB

Contents

Page Page

1. Introduction ................................................ 7 9.3 Density measuring with commercial

hydrometers ............................................... 60

2. Basic notes on safety ................................. 8 9.4 Additive and temperature setting at

2.1 Warning notes and symbols ......................... 8 Alcohol Control Unit .................................... 61

2.2 Usage to the intended purpose .................... 8 9.5 Setting the thermostat ................................ 62

2.3 Organisational measures .............................. 8 9.6 Checking the sight glass ............................. 62

2.4 Selection and qualification of personnel........ 8 9.7 Checking the water pressure in the IRHC... 63

2.5 Operating modes .......................................... 9

2.6 Special dangers ............................................ 9

2.7 Operator/customer ....................................... 9 10. Maintenance ............................................. 65

10.1 General ...................................................... 65

10.2 Maintenance intervals ................................. 65

3. Description ............................................... 11 10.3 Replacing the fountain solution filters ......... 68

3.1 Usage to the intended purpose ................... 11 10.4 Cleaning the fountain solution storage

3.2 Description of the unit ................................. 11 tank ............................................................ 68

10.5 Cleaning the entire fountain solution

system ........................................................ 68

4. Technical data ........................................... 15 10.6 Cleaning the Alcohol Control Unit ............... 69

10.7 Cleaning the fresh water filter ..................... 69

10.8 Checking the maintenance unit .................. 70

5. Mode of operation .................................... 27 10.9 Cleaning the filter in alcohol and/or

5.1 Fountain solution premixing ........................ 32 additive storage tanks ................................. 70

5.2 Alcohol Control Unit .................................... 34 10.10 Cleaning the ribs of the condenser ............. 70

5.3 Return flow filter unit ................................... 36

11. Repairs ...................................................... 72

6. Installation ................................................ 38 11.1 General ...................................................... 72

6.1 Unpacking .................................................. 38 11.2 Replacing the supply line pump or

6.2 Location ...................................................... 39 heat exchanger pump ................................. 72

6.3 Hose connections ....................................... 40 11.3 Replacing the circulating pump IRHC ......... 73

6.4 Connection to cooling centres .................... 42 11.4 Replacing the thermostats .......................... 73

6.5 Alcohol and additive supply ........................ 42

6.6 Filling with alcohol and additives ................. 43

6.7 Refrigerant ................................................. 43 12. Trouble shooting ...................................... 74

6.8 Electrical connection .................................. 43 12.1 Error messages at the display .................... 75

12.2 Failures not indicated at the display ............ 81

7. Start-up and Shut-down ........................... 44

7.1 Controls ...................................................... 44 13. Dismounting ............................................. 84

7.2 Initial operation of the 13.1 Electric connection ..................................... 84

fountain solution cooling RCWL .................. 45 13.2 Hose connections ....................................... 84

7.3 Initial operation of the 13.3 Fountain solution, alcohol (alcohol substi-

ink roll heating/cooling IRHC ...................... 48 tutes) and additives .................................... 84

7.4 Setting the bypass valve (wet and/or 13.4 Antifreezer and anticorrosive ...................... 84

dry offset) ................................................... 51 13.5 Refrigerant ................................................. 84

7.5 Shut-down RCWL and/or IRHC .................. 52 13.6 Scrapping ................................................... 84

8. Operation of display ................................. 53 14. Parts list .................................................... 85

8.1 Description of function ................................ 53 14.1 General ...................................................... 85

8.2 Setup .......................................................... 55 14.2 Notes for using ........................................... 85

8.3 Service mode ............................................. 58 14.3 Illustrated parts list ..................................... 85

9. Adjusting and checking ........................... 59

9.1 General ...................................................... 59

9.2 Basic settings of the maintenance unit ...... 59

01.98/CRCWL852/GB Seite / Page 5

Seite / Page 6 01.98/CRCWL852/GB

Foreword

1.0 Foreword to the operating instructions

Attention:

The markings for transport and stocking

These operating instructions are designed to familiarize indicated on the packaging have to be observed

the user with the machine/plant and its designated use. under all circumstances.

This manual contains important notes which are to be

observed during the installation, operation and

maintenance of the device, in order to guarantee a

safety, proper and economical use of the system. Note:

Please check the type of manual against the

The obeyance of the instructions helps to avoid dangers. label on your BALDWIN device.

The operating instructions must always be available This manual is only valid for:

wherever the machine/plant is in use.

(see title-page)

These operating instructions must be read and applied

by any person in charge of carrying out work with and

on the machine/plant, such as

- operation including setting up, troubleshooting in

the course of work, evacuation of production waste,

care and disposal of fuels and consumables.

- Installation, set-up, wiring

- maintenance (servicing, inspection, repair)

- transport

In addition to the operating instructions and to the

mandatory rules and regulations for accident prevention

and environmental protection in the country and place

of use of the machine/plant, the generally recognized

technical rules for safe and proper working must also be

observed.

01.98/CRCWL852/GB Seite / Page 7

Fundamental safety instructions

2.0 Fundamental safety instructions 2.3 Organizational measures

2.1 Warning notes and symbols 2.3.1 This manual has to be accomplished by the user/

The headings „Warning, Attention and Note“ marked in customer with instructions (national regulations of

this manual have the following meaning: security, regulations for dangerous goods, environ-

mental protection and possible internal working or

security rules) including legal responsibility and

compulsory registration in order to take internal company

peculiarities, regarding working organization or

personnel involved in these working processes into

consideration.

Warning:

This heading is used whenever the ignorance or 2.3.2 Check - at least from time to time - whether the

inaccurate obeying of factory rules, working personnel is carrying out the work in compliance with

rules, laid down work routines, etc.can lead to the operating instructions and paying attention to risks

the death, injuring or an accident of a person. and safety factors.

2.3.3 For reasons of security, long hair must be tied

back or otherwise secured, garments must be close-

fitting and no jewellery - such as rings - may be worn.

Attention: Injury may result from being caught up in the machinery

This heading is used whenever the ignorance or or from rings catching on moving parts.

inaccurate obeying of factory rules, working

rules, laid down work routines, etc. can lead to 2.3.4 Use protective equipment wherever required by

damages on the system. the circumstances or by law.

2.3.5 Observe all safety instructions and warnings

attached to the machine/plant.

Note: 2.3.6 In the event of safety-relevant modifications or

This heading is used when an exceptional feature changes in the behaviour of the machine/plant during

should be taken noticeof. operation, stop the machine/plant immediately and

report the malfunction to the competent authority/

person.

2.3.7 Never make any modifications, additions or

conversions which might affect safety without the

supplier’s approval. This also applies to the installation

2.2 Basic operation and designated use of the and adjustment of safety devices and valves as well as

machine/plant to welding work on load-bearing elements.

2.3.8 Never modify the software of programmable

2.2.1 The machine/plant has been built in accordance control systems.

with state-of-the-art standards and the recognized safety

rules. Nevertheless, its use may constitute a risk to life

and limb of the user or of third parties, or cause damage

to the machine and to other material property. 2.4 Selection and qualification ofpersonnel -

Basic responsibilities

2.2.2 The machine/plant must only be used in technically

perfect condition in accordance with its designated use 2.4.1 Employ only trained or instructed staff and set out

and the instructions set out in the operating manual, clearly the individual responsibilities of the personnel

and only by safety-conscious persons who are fully for operation, set-up, maintenance and repair.

aware of the risks involved in operating the machine/

plant. Any functional disorders, especially those affecting 2.4.2 Work on the electrical system and equipment of

the safety of the machine/plant, should therefore be the machine/plant must be carried out only by a skilled

rectified immediately. electrician or by instructed persons under the supervision

and guidance of a skilled electrician and in accordance

with electrical engineering rules and regulations.

Seite / Page 8 01.98/CRCWL852/GB

Fundamental safety instructions

2.5 Safety instructions governingspecific opera- 2.6.2 Hydraulic and pneumatic equipment

tional phases

2.6.2.1 Check all lines, hoses and screwed connections

2.5.1 Take the necessary precautions to ensure that regularly for leaks and obvious damage. Repair damage

the machine is used only when in a safe and reliable immediately. Splashed medium may cause injury and

state. fire.

Operate the machine only if all protective and safety-

oriented devices, such as removable safety devices, 2.6.2.2 Depressurize all system sections and pressure

emergency shut-off equipment, sound-proofing pipes (hydraulic system, compressed-air system) to be

elements and exhausters, are in place and fully removed in accordance with the specific instructions for

functional. the unit concerned before carrying out any repair work.

2.5.2 Check the machine/plant at least once per working 2.6.2.3 Hydraulic and compressed-air lines must be

shift for obvious damage and defects. Report any laid and fitted properly. Ensure that no connections are

changes (incl. changes in the machine’s working interchanged. The fittings, lengths and quality of the

behaviour) to the competent organization/person hoses must comply with the technical requirements.

immediately. If necessary, stop the machine immediately

and lock it. 2.6.3 Alcohol, Water additives and other chemical

substances

2.5.3 In the event of malfunctions, stop the machine/

plant immediately and lock it. Have any defects rectified 2.6.3.1 Whenever using one of the a.m. substances the

immediately. security regulations valid for the product must be strictly

observed! (Safety data sheet of the manufacturer and

2.5.4 If the machine/plant is completely shut down for generally valid regulations)

maintenance and repair work, it must be secured

against inadvertent starting by: 2.6.3.2 Only approved containers may be used to store

about one day´s supply

- locking the principal control elements and removing

the ignition key and/or

- attaching a warning sign to the main switch.

2.7 User/Customer

2.5.5 Ensure that all consumables and replaced parts

are disposed of safely and with minimum environmen- The safety guard for mobile parts may not be removed

tal impact. while the system is running.

Work at the cooling unit may only be drained by a

specialised firm for refrigeration and air-condition

2.6 Warning of special dangers engineering.

2.6.1 Electric energy Leaks (e.g. tube connections) of dangerous liquids

(e.g. explosive, toxic, hot) have to be drawn off in such

1.6.1.1 Work on the electrical system or equipment a way that neither persons nor the environment will be

may only be carried out by a skilled electrician himself endangered.

or by specially instructed personnel under the control The legal requirements must be fulfilled.

and supervision of such electrician and in accordance

with the applicable electrical engineering rules.

2.6.1.2 If provided for in the regulations, the power

supply to parts of machines and plants, on which

inspection, maintenance and repair work is to be carried Warning:

out must be cut off. Before starting any work, check the Ignoring the safety regulations can have a

de-energized parts for presence of power and ground harmful effect on persons or cause damages to

or short-circuit them in addition to insulating adjacent the system or environment. Ignoring the safety

live parts and elements. regulations may cause a loss of claim for

damages.

2.6.1.3 The electrical equipment of machines/plants is

to be inspected and checked at regular intervals. Defects

such as loose connections or scorched cables must be

rectified immediately.

01.98/CRCWL852/GB Seite / Page 9

Seite / Page 10 01.98/CRCWL852/GB

Description

3. Description alcohol substitutes are metered proportional to volume,

alcohol (isopropanol) via density measuring as required.

3.1 Usage to the intended purpose The evaporated alcohol portion is automatically added

by this system and the adjusted alcohol percentage is

maintained.

The ink roll heating/cooling is controlled by a special

Warning: control unit. The inking unit is cooled by cooled-down

The unit is to be used only for cooling, premixing fountain solution via a water-water-heat exchanger.

and cleaning the fountain solution required for Heating the inking unit is by an integrated heating

offset printing as well as ink roll heating/cooling. element.

- Fountain solution temperature

- Alcohol and/or alcohol substitute

- Additives

Warning: - Consumption of alcohol / additives / water

- Unauthorized modifications of and changes - Alarm functions

to the unit, - Inking unit temperature

- use for any other purpose, and - Conductivity value (option) 0 - 2000 µS/cm

- the use of any other than the above additives - pH-value (option) pH 2 - pH 9

are forbidden for safety reasons.

In emergency mode, the fountain solution temperature

All safety devices such as personnel protecting is controlled by a thermostat should the control unit fail.

switches and emergency stop buttons must be In order to maintain the fountain solution circulation

available. during emergency mode, the outputs of the supply line

and heat exchanger pump are short-circuited.

A conductivity and pH measuring device may be fitted

as an option. The value concerned is determined by the

conductivity and/or pH measuring device by means of

3.2 Description of the unit electrodes and is displayed at the digital control unit.

Depending on the configuration concerned, the fountain

solution is pumped to one or several fountain pan(s) of

the press by the installed submerged pump.

Cooling of the fountain solution is by an integrated

refrigerating unit with heat exchanger and air-cooled

and/or water-cooled condenser or without refrigerating

unit by a central refrigeration and a water-water heat

exchanger.

Control of the refrigerating unit is by the electronics of

the control unit to obtain a constant fountain solution

temperature during printing. The amount of heat dis-

sipated is given to the room air (air-cooled design) or via

a cooling tower (water-cooled design).

Cleaning of the fountain solution is by integrated filters

of the Combined Refrigerated Circulating Water Level.

The CRCWL is provided with an integrated premixing

unit - BALDWIN Automix (AMX) - for adding additive

and alcohol and/or alcohol substitutes. Additives and

01.98/CRCWL852/GB Seite / Page 11

Description

The main components of the BALDWIN CRCWL are:

e) Electric supply

a) Cooling unit The electrical components and safety features as

with compressor (unit type "AD /WAD") well as additional electrical connections are mounted

The compressors are driven by internally protected on a mounting plate in the switchbox.

motors.

- Condensator with fans f) Digital control unit

(with air-cooled design "AD") The digital control unit comprises all possibilities for

and operation for fountain solution and ink roll heating/

- condenser with condensation pressure cooling (IRHC) as well as failure indications and

regulator error messages.

(with water-cooled design "WAD") Connection to the central control console upon prior

The heat exchangers and condensator assemblies consultation of BALDWIN.

are made of corrosion-resistant material.

with central refrigeration (type "WWAD") g) Temperature control

Cooling of the fountain solution is only by central The temperatures are registered for the fountain

refrigeration that is made available by a cooling solution circuit and the ink distributor circuit by one

centre. The heat transfer is in a water-water heat temperature sensor each (Pt 100 = ohmic principle

exchanger. of measurement) and are evaluated in the control

unit.

Emergency operation via thermostat control is

b) Fountain solution cooling tank with filter unit possible.

and pump cover

The fountain solution cooling tank serves as storage

tank for premixed fountain solution. The fountain

solution in the cooling tank is also used as

temperature buffer in wet and dry offset as well as

for cooling in the ink roll heating/cooling system.

The filter unit cleans the fountain solution recirculated

from the water pans.

An integrated alarm sensor signals any conta-

mination of the fountain solution to the control unit

(display and electronic).

c) Alcohol control

The actual value of the alcohol percentage is

constantly measured by the alcohol control to the

density measuring principle (hydrometer) and is

reported to the control unit. When the value drops

below the setpoint, alcohol is added by the automatic

mixing unit.

d) Fountain solution premixing

The fountain solution is mixed proportional to volume

via piston metering pumps. Input is at the digital

control unit.

Seite / Page 12 01.98/CRCWL852/GB

Description

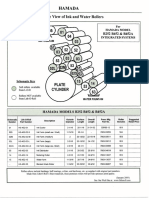

Fig. 3-1

Key to Fig. 3-1

1 Digital control unit 10 Bypass valve

2 Fountain solution storage tank 11 Heating

3 Heat exchanger pump (HEP) 12 Expansion vessel with safety valve and

4 Temperature sensor (fountain solution) automatic ventilating valve

5 Evaporator 13 IRHC-pump

6 Cooling unit 14 Temperature sensor (IRHC)

7 Fountain solution supply pump 15 Flow monitoring switch

8 Water pan 16 Printing unit with inking unit

9 Water-water-plate heat exchanger 17 Mixing valve

01.98/CRCWL852/GB Seite / Page 13

Seite / Page 14 01.98/CRCWL852/GB

Technical data

4. Technical data

Water-cooled design Air-cooled design

Key to model designation

Example: CRCWL 85 2 - 600 - 160 HS / WW A D

Combined Refrigerated

Circulating Water Level (CRCWL)

Product group

Number of circuits

Basic performance number of

cooling unit or heat exchanger

Tank contents in litres (in this case: 160 l)

Upright cabinet

Omitted = heat dissipation via refrigerant and air-cooled condenser

W = heat dissipation via refrigerant and water-cooled condenser

WW= heat dissipation only via cooling water (cooling centres)

Integrated mixing unit

Automix (AMX)

Digital control unit

01.98/CRCWL852/GB Seite / Page 15

Technical data

Technical data (applies to all units)

General

Temperature setting range

for fountain solution .......................................................... 8...19°C

for ink roll heating/cooling ................................................. 14...40°C

Dimensions (length x width x height) ................................. 1450/750/2000 mm

Space requirements (length x width x height) .................... approx. 2450/1900/2500 mm

Noise emission

(A-weighted equivalent continuous mean

sound pressure level) ....................................................... £ 70 dB(A)

Degree of protection for electrical connection .................... IP 54

EMC .................................................................................. as per EN 55011 B and EN 50082-2

Processor .......................................................................... 80-C-188

Connection to central control console ................................ upon consultation of BALDWIN

Remote indication with operator panel ............................... option

Connections, supplies, volumes

Fresh water connection (500 kPa; 5 bar max.) .................. dia. 12 mm

Fountain solution supply to press ...................................... dia. 19/25/32 mm

Fountain solution return from press ................................... dia. 19/25/32 mm

IRHC-supply to press ........................................................ dia. 25/32/40 mm

IRHC-return from press ..................................................... dia. 25/32/40 mm

Alcohol connection ............................................................ dia. 3/8''

Additive connection ........................................................... dia. 12 mm

Compressed air connection (tube type: Mecanyl) .............. dia. 8/12 mm

Compressed air consumption ............................................ 12.5 Nl/min

Recommended additives ................................................... commercial

(pH 4.8...5.2 at a dosage of 0...6 %)

Alcohol ............................................................................... technically pure isopropyl 99 %

Alcohol substitute .............................................................. commercial products

Fountain solution storage tank ........................................... 160 l

Seite / Page 16 01.98/CRCWL852/GB

Technical data

Fountain solution metering

Fountain solution additives ................................................ 1 additiv (option: 2 additives)

Metering method........................................................... volumetric via metering pumps

Setting range ................................................................ 0 - 6 % ±0.5 % (in steps of 0.5 %)

Alcohol (isopropanol)

Measuring method ........................................................ aerometric (density measuring)

Metering method........................................................... volumetric via metering pumps

Setting range ................................................................ 0 - 20 % ±0.5 % (in steps of 0.5 %)

Alcohol substitute

Measuring method ........................................................ --

Metering method........................................................... volumetric via metering pumps

Setting range ................................................................ 0 - 20 % ±0.5 % (in steps of 0.5 %)

Max. fountain solution mixing capacity

with addition of 10 % of Al ............................................ 700 l/h

with addition of 15 % of Al ............................................ 460 l/h

with addition of 20 % of Al ............................................ 350 l/h

Max. mixing period with initial filling (100 l)

with addition of 10 % of Al ............................................ 6 - 10 min

with addition of 15 % of Al ............................................ 9 - 17 min

with addition of 20 % of Al ............................................ 15 - 22 min

Conductivity measurement (option)

Measuring method ........................................................ electrode

Measuring range .......................................................... 0 - 2000 µS/cm ±1 µS/cm

pH measurement (option)

Measuring method ........................................................ electrode

Measuring range .......................................................... pH 2 - pH 9 ±0.1

Ambient conditions

Temperature,

Operation .......................................................................... +5...+40°C

Storage/transport .............................................................. -20...+60°C

Relative air humidity, no moisture condensation ................ 30...95% (max. permissible)

Operation/storage/transport

Perm. site altitude (above mean sea level)

for air-cooled design ......................................................... up to 1500 m 1)

for water-cooled design .................................................... unlimited

1) over 1500 m perm. site altitude the refrigerating capacity decrease

01.98/CRCWL852/GB Seite / Page 17

Technical data

Model ........................................................... 852-300-160-HS/AD ..................... 852-300-160-HS/WAD

Voltage (V/ph/Hz) ......................................... 400±10% /3/50 ............................. 400±10% /3/50

(voltage adjustment 440±10% /3/60 ............................. 440±10% /3/60

see wiring diagram)

Total current input Imax (A) ............................. 24.5 .............................................. 24.5

Total power input (kW) ................................. 14.75 ............................................ 14.75

Refrigerating capacity in dry offset 2) (kW) .... 12.0 (50 Hz) / 13.0 (60 Hz) .......... 12.0 (50 Hz) / 13.0 (60 Hz)

(at 22°C inking unit cooling water

temperature)

Refrigerating capacity in wet offset 2) (kW) ... 8.0 (50 Hz) / 9.0 (60 Hz) .............. 8.0 (50 Hz) / 9.0 (60 Hz)

(at 10°C fountain solution temperature

and 22°C ink uniting cooling water

temperature)

Liquefaction temperature2) ............................ approx. 55°C ................................. approx. 55°C

Kind / quantity of refrigerant .......................... R 134a / see type plate ................. R 134a / see type plate

Total heat dissipation max. (kW) .................. 18.6 .............................................. 18.6

max. air quantity given off (m3/h) ................. * .................................................... --

max. required cooling

water flow rate at Dt 6°C (m3/h) .................... -- ................................................... 3.0 (60 Hz)

Heating capacity (kW) .................................. 5.0 (50 Hz) / 6.0 (60 Hz) .............. 5.0 (50 Hz) / 6.0 (60 Hz)

Supply pump KTE 141

(A/ kW) ........................................................ 1.0/ 0.38 ........................................ 1.0/ 0.38

Heat exchanger pump KTE 141

(A/ kW) ........................................................ 1.0/ 0.38 ........................................ 1.0/ 0.38

IRHC 4) pump CHI 4-20

(A/ kW) ........................................................ 2.4/ 0.8 ......................................... 2.4/ 0.8

Weight (kg) ................................................... approx. 620 ................................... approx. 600

*) not known when this documentation went to print

2) at approx. 40°C ambient- and/or 32°C cooling water temperatur

4) IRHC = Ink Roll Heating/Cooling

Seite / Page 18 01.98/CRCWL852/GB

Technical data

Model ........................................................... 852-300-160-HS/WWAD

Voltage (V/ph/Hz) ......................................... 400±10% /3/50

(voltage adjustment 440±10% /3/60

see wiring diagram)

Total current input Imax (A) ............................. *

Total power input (kW) ................................. *

Refrigerating capacity in dry offset 2) (kW) .... *

(at 22°C inking unit cooling water

temperature)

Refrigerating capacity in wet offset 2) (kW) ... *

(at 10°C fountain solution temperature

and 22°C inking unit cooling water

temperature)

Total heat dissipation max. (kW) .................. *

max. required cooling

water flow rate at Dt 6°C (m3/h) .................... *

Heating capacity (kW) .................................. 5.0 (50 Hz) / 6.0 (60 Hz)

Supply pump KTB 200

(A/ kW) ........................................................ 2.0/ 0.85

Heat exchanger pump KTB 200

(A/ kW) ........................................................ 2.0/ 0.85

IRHC 4) pump CHI 4-20

(A/ kW) ........................................................ 2.4/ 0.8

Weight (kg) ................................................... *

*) not known when this documentation went to print

2) at approx. 40°C ambient- and/or 32°C cooling water temperatur

4) IRHC = Ink Roll Heating/Cooling

01.98/CRCWL852/GB Seite / Page 19

Technical data

Model ........................................................... 852-400-160-HS/AD ..................... 852-400-160-HS/WAD

Voltage (V/ph/Hz) ......................................... 400±10% /3/50 ............................. 400±10% /3/50

(voltage adjustment 440±10% /3/60 ............................. 440±10% /3/60

see wiring diagram)

Total current input Imax (A) ............................. 30 (60 Hz) ..................................... 28 (60 Hz)

Total power input (kW) ................................. 17 (60 Hz) ..................................... 15 (60 Hz)

Refrigerating capacity in dry offset 2) (kW) .... 18 (50 Hz) / 21.5 (60 Hz) ............. 18 (50 Hz) / 21.5 (60 Hz)

(at 22°C inking unit cooling water

temperature)

Refrigerating capacity in wet offset 2) (kW) ... 12 (50 Hz) / 14.4 (60 Hz) ............. 12 (50 Hz) / 14.4 (60 Hz)

(at 10°C fountain solution temperature

and 22°C ink uniting cooling water

temperature)

Liquefaction temperature2) ............................ approx. 55°C ................................. approx. 55°C

Kind / quantity of refrigerant .......................... R 134a / see type plate ................. R 134a / see type plate

Total heat dissipation max. (kW) .................. 37 (60 Hz) ..................................... 37 (60 Hz)

max. air quantity given off (m3/h) ................. 6000 (60 Hz) ................................. --

max. required cooling

water flow rate at Dt 6°C (m3/h) .................... -- ................................................... 5.5 (60 Hz)

Heating capacity (kW) .................................. 5.0 (50 Hz) / 6.0 (60 Hz) .............. 5.0 (50 Hz) / 6.0 (60 Hz)

Supply pump KTB 200

(A/ kW) ........................................................ 2.0/ 0.85 ........................................ 2.0/ 0.85

Heat exchanger pump KTB 200

(A/ kW) ........................................................ 2.0/ 0.85 ........................................ 2.0/ 0.85

IRHC 4) pump CHI 4-20

(A/ kW) ........................................................ 2.4/ 0.8 ......................................... 2.4/ 0.8

Weight (kg) ................................................... approx. 620 ................................... approx. 600

*) not known when this documentation went to print

2) at approx. 40°C ambient- and/or 32°C cooling water temperatur

4) IRHC = Ink Roll Heating/Cooling

Seite / Page 20 01.98/CRCWL852/GB

Technical data

Model ........................................................... 852-400-160-HS/WWAD

Voltage (V/ph/Hz) ......................................... 400±10% /3/50

(voltage adjustment 440±10% /3/60

see wiring diagram)

Total current input Imax (A) ............................. *

Total power input (kW) ................................. *

Refrigerating capacity in dry offset 2) (kW) .... *

(at 22°C inking unit cooling water

temperature)

Refrigerating capacity in wet offset 2) (kW) ... *

(at 10°C fountain solution temperature

and 22°C inking unit cooling water

temperature)

Total heat dissipation max. (kW) .................. *

max. required cooling

water flow rate at Dt 6°C (m3/h) .................... *

Heating capacity (kW) .................................. 5.0 (50 Hz) / 6.0 (60 Hz)

Supply pump KTB 200

(A/ kW) ........................................................ 2.0/ 0.85

Heat exchanger pump KTB 200

(A/ kW) ........................................................ 2.0/ 0.85

IRHC 4) pump CHI 4-20

(A/ kW) ........................................................ 2.4/ 0.8

Weight (kg) ................................................... *

*) not known when this documentation went to print

2) at approx. 40°C ambient- and/or 32°C cooling water temperatur

4) IRHC = Ink Roll Heating/Cooling

01.98/CRCWL852/GB Seite / Page 21

Technical data

Model ........................................................... 852-500-160-HS/AD ..................... 852-500-160-HS/WAD

Voltage (V/ph/Hz) ......................................... 400±10% /3/50 ............................. 400±10% /3/50

(voltage adjustment 440±10% /3/60 ............................. 440±10% /3/60

see wiring diagram)

Total current input Imax (A) ............................. 31 (60 Hz) ..................................... 31 (60 Hz)

Total power input (kW) ................................. 16.5 (60 Hz) .................................. 16.5 (60 Hz)

Refrigerating capacity in dry offset 2) (kW) .... 14.5 (50 Hz) / 17.4 (60 Hz) .......... 14.5 (50 Hz) / 17.4 (60 Hz)

(at 22°C inking unit cooling water

temperature)

Refrigerating capacity in wet offset 2) (kW) ... 12 (50 Hz) / 14.4 (60 Hz) ............. 12 (50 Hz) / 14.4 (60 Hz)

(at 10°C fountain solution temperature

and 22°C ink uniting cooling water

temperature)

Liquefaction temperature2) ............................ approx. 55°C ................................. approx. 55°C

Kind / quantity of refrigerant .......................... R 134a / see type plate ................. R 134a / see type plate

Total heat dissipation max. (kW) .................. 24.3 (60 Hz) .................................. 24.3 (60 Hz)

max. air quantity given off (m3/h) ................. 6000 (60 Hz) ................................. --

max. required cooling

water flow rate at Dt 6°C (m3/h) .................... -- ................................................... 4.4 (60 Hz)

Heating capacity (kW) .................................. 5.0 (50 Hz) / 6.0 (60 Hz) .............. 5.0 (50 Hz) / 6.0 (60 Hz)

Supply pump KTB 200

(A/ kW) ........................................................ 2.0/ 0.85 ........................................ 2.0/ 0.85

Heat exchanger pump KTB 200

(A/ kW) ........................................................ 2.0/ 0.85 ........................................ 2.0/ 0.85

IRHC 4) pump CHI 4-20

(A/ kW) ........................................................ 2.4/ 0.8 ......................................... 2.4/ 0.8

Weight (kg) ................................................... approx. 630 ................................... approx. 610

*) not known when this documentation went to print

2) at approx. 40°C ambient- and/or 32°C cooling water temperatur

4) IRHC = Ink Roll Heating/Cooling

Seite / Page 22 01.98/CRCWL852/GB

Technical data

Model ........................................................... 852-400-160-HS/WWAD

Voltage (V/ph/Hz) ......................................... 400±10% /3/50

(voltage adjustment 440±10% /3/60

see wiring diagram)

Total current input Imax (A) ............................. *

Total power input (kW) ................................. *

Refrigerating capacity in dry offset 2) (kW) .... *

(at 22°C inking unit cooling water

temperature)

Refrigerating capacity in wet offset 2) (kW) ... *

(at 10°C fountain solution temperature

and 22°C inking unit cooling water

temperature)

Total heat dissipation max. (kW) .................. *

max. required cooling

water flow rate at Dt 6°C (m3/h) .................... *

Heating capacity (kW) .................................. 5.0 (50 Hz) / 6.0 (60 Hz)

Supply pump KTB 200

(A/ kW) ........................................................ 2.0/ 0.85

Heat exchanger pump KTB 200

(A/ kW) ........................................................ 2.0/ 0.85

IRHC 4) pump CHI 4-20

(A/ kW) ........................................................ 2.4/ 0.8

Weight (kg) ................................................... *

*) not known when this documentation went to print

2) at approx. 40°C ambient- and/or 32°C cooling water temperatur

4) IRHC = Ink Roll Heating/Cooling

01.98/CRCWL852/GB Seite / Page 23

Technical data

Model ........................................................... 852-600-160-HS/WAD .................. 852-600-160-HS/WWAD

Voltage (V/ph/Hz) ......................................... 400±10% /3/50 ............................. 400±10% /3/50

(voltage adjustment 440±10% /3/60 ............................. 440±10% /3/60

see wiring diagram)

Total current input Imax (A) ............................. 30 (60 Hz) ..................................... *

Total power input (kW) ................................. 18 (60 Hz) ..................................... *

Refrigerating capacity in dry offset 2) (kW) .... 27 (50 Hz) / 33 (60 Hz) ................ *

(at 22°C inking unit cooling water

temperature)

Refrigerating capacity in wet offset 2) (kW) ... 14.5 (50 Hz) / 16 (60 Hz) ............. *

(at 10°C fountain solution temperature

and 22°C ink uniting cooling water

temperature)

Liquefaction temperature2) ............................ approx. 55°C ................................. --

Kind / quantity of refrigerant .......................... R 134a / see type plate ................. --

Total heat dissipation max. (kW) .................. 45 (60 Hz) ..................................... *

max. required cooling

water flow rate at Dt 6°C (m3/h) .................... 6.8 (60 Hz) .................................... *

Heating capacity (kW) .................................. 5.0 (50 Hz) / 6.0 (60 Hz) .............. 5.0 (50 Hz) / 6.0 (60 Hz)

Supply pump KTB 200

(A/ kW) ........................................................ 2.0/ 0.85 ........................................ 2.0/ 0.85

Heat exchanger pump KTB 200

(A/ kW) ........................................................ 2.0/ 0.85 ........................................ 2.0/ 0.85

IRHC 4) pump CHI 4-20

(A/ kW) ........................................................ 2.4/ 0.8 ......................................... 2.4/ 0.8

Weight (kg) ................................................... approx. 640 ................................... approx. 620

*) not known when this documentation went to print

2) at approx. 40°C ambient- and/or 32°C cooling water temperatur

4) IRHC = Ink Roll Heating/Cooling

Seite / Page 24 01.98/CRCWL852/GB

Technical data

Model ........................................................... 852-1000-160-HS/WAD ................ 852-1000-160-HS/WWAD

Voltage (V/ph/Hz) ......................................... 400±10% /3/50 ............................. 400±10% /3/50

(voltage adjustment 440±10% /3/60 ............................. 440±10% /3/60

see wiring diagram)

Total current input Imax (A) ............................. 34 (60 Hz) ..................................... *

Total power input (kW) ................................. 22 (60 Hz) ..................................... *

Refrigerating capacity in dry offset 2) (kW) .... 33 (50 Hz) / 38 (60 Hz) ................ *

(at 22°C inking unit cooling water

temperature)

Refrigerating capacity in wet offset 2) (kW) ... 20 (50 Hz) / 23 (60 Hz) ................ *

(at 10°C fountain solution temperature

and 22°C ink uniting cooling water

temperature)

Liquefaction temperature2) ............................ approx. 55°C ................................. --

Kind / quantity of refrigerant .......................... R 134a / see type plate ................. --

Total heat dissipation max. (kW) .................. 54 (60 Hz) ..................................... *

max. required cooling

water flow rate at Dt 6°C (m3/h) .................... 8.1 (60 Hz) .................................... *

Heating capacity (kW) .................................. 5.0 (50 Hz) / 6.0 (60 Hz) .............. 5.0 (50 Hz) / 6.0 (60 Hz)

Supply pump KTB 200

(A/ kW) ........................................................ 2.0/ 0.85 ........................................ 2.0/ 0.85

Heat exchanger pump KTB 200

(A/ kW) ........................................................ 2.0/ 0.85 ........................................ 2.0/ 0.85

IRHC 4) pump CH 12-20

(A/ kW) ........................................................ 2.8/ 1.6 ........................................ 2.8/ 1.6

Weight (kg) ................................................... approx. 650 ................................... approx. 630

*) not known when this documentation went to print

2) at approx. 40°C ambient- and/or 32°C cooling water temperatur

4) IRHC = Ink Roll Heating/Coolingv

01.98/CRCWL852/GB Seite / Page 25

Technical data

Model ........................................................... 852-1200-160-HS/WAD ................ 852-1200-160-HS/WWAD

Voltage (V/ph/Hz) ......................................... 400±10% /3/50 ............................. 400±10% /3/50

(voltage adjustment 440±10% /3/60 ............................. 440±10% /3/60

see wiring diagram)

Total current input Imax (A) ............................. 45.2 (60 Hz) .................................. *

Total power input (kW) ................................. 29 (60 Hz) ..................................... *

Refrigerating capacity in dry offset 2) (kW) .... 55 (50 Hz) / 60 (60 Hz) ................ *

(at 22°C inking unit cooling water

temperature)

Refrigerating capacity in wet offset 2) (kW) ... 45 (50 Hz) / 50 (60 Hz) ................ *

(at 10°C fountain solution temperature

and 22°C ink uniting cooling water

temperature)

Liquefaction temperature2) ............................ approx. 55°C ................................. --

Kind / quantity of refrigerant .......................... R 134a / see type plate ................. --

Total heat dissipation max. (kW) .................. 78 (60 Hz) ..................................... *

max. required cooling

water flow rate at Dt 6°C (m3/h) .................... 11.7 (60 Hz) .................................. *

Heating capacity (kW) .................................. 5.0 (50 Hz) / 6.0 (60 Hz) .............. 5.0 (50 Hz) / 6.0 (60 Hz)

Supply pump KTB 200

(A/ kW) ........................................................ 2.0/ 0.85 ........................................ 2.0/ 0.85

Heat exchanger pump KTE 142

(A/ kW) ........................................................ 4,1/ 1,7 ......................................... 4,1/ 1,7

IRHC 4) pump CH 12-20

(A/ kW) ........................................................ 2.8/ 1.6 ........................................ 2.8/ 1.6

Weight (kg) ................................................... approx. 660 ................................... approx. 640

*) not known when this documentation went to print

2) at approx. 40°C ambient- and/or 32°C cooling water temperatur

4) IRHC = Ink Roll Heating/Cooling

Seite / Page 26 01.98/CRCWL852/GB

Mode of operation

5. Mode of operation (Fig. 5-1 /5-2 / pressure (loss of refrigerant), the low-pressure manostat

(4.11), in the case of an excess system pressure, the

5-3) high-pressure manostat (4.13) will automatically cut

out the compressor (4.2).

Fountain solution premixing

Fresh water flows via supply line (1.1) and the filter (1.2) Cooling (type “WWAD”)

into the fountain solution storage tank (2.1) of the Cooling of the fountain solution is only by central

CRCWL. Alcohol (1.10) and fountain solution additives refrigeration that is made available by a cooling centre

(1.5) are added as required by the pumps (1.8/1.12). (4.18).The heat transfer is in a water-water heat

The fountain solution premixing unit, that works in exchanger (4.19). The fountain solution temperature

cycles and is controlled electronically, is cut in by the entered is controlled by a pneumatically operated 3/2

solenoid float switch (2.4) and the alcohol control (3.1). way valve (4.20). The fountain solution either flows

The fountain solution level, the fountain solution additi- through the water-water heat exchanger or bypasses

ves and alcohol percentage in the fountain solution the heat exchanger by a bypass line.

storage tank (2.1) are maintained.

Emergency mode

The alcohol control (3.1), that is flushed via connection Should the control unit fail, fountain solution cooling and

(3.2), measures the actual alcohol percentage in the circulation are maintained by emergency mode.

fountain solution. When this value drops below the Emergency mode is called in by switch S4 (see wiring

setpoint entered at the display (6.4) (caused by diagram and/or Fig. 7-1/2), and is indicated by the fault

consumption and evaporation), alcohol is added to the signal lamp (6.5).

fountain solution by the metering pump (1.12) in addition Control of the fountain solution temperature is taken

to the normal filling cycle in percent by volume. over by the thermostat (4.16). Measurement is by the

capillary measuring line and temperature sensor. The

Fountain solution circulation thermostat also supplies an electric signal for cutting

The fountain solution is supplied to the fountain pans of the compressor (4.2) in and out.

the press (2.7) by the supply line pump (2.2) via the The supply line pump and the heat exchanger pump are

supply line valve (2.3). When the fountain solution cut in in emergency mode to maintain the circulation of

returns to the CRCWL, it is cleaned by a filter (2.11). the fountain solution.

The filter condition in the return flow is monitored by a The Ink Roll Heating/Cooling Unit is off during this

level sensor (2.12). Contamination and/or required function.

replacement of filter will be indicated by an alarm signal.

A return flow filter station (2.9) may additonally be Ink Roll Heating/Cooling System

integrated in the fountain solution return flow line. The Ink Roll Heating/Cooling System is a closed-loop

system and is completely isolated from the fountain

Cooling (type "AD/WAD") solution circuit. The "setpoint" of the inking unit

Cooling of the fountain solution is by the heat exchanger temperature is entered at the control unit (display). A

(4.1). The pump (2.13) in the fountain solution temperature sensor (5.7) transmits the temperature

refrigerating circuit recirculates the fountain solution data to the electronic unit. Based on this information, a

through the heat exchanger to the fountain solution mixing valve (5.18) is controlled that directs the cooling

storage tank (2.1). water via the water-water heat exchanger (5.1) or via a

heating element (5.3). The IRHC pump (5.8) supplies

Entering the "setpoint" for the fountain solution the cooling water to the inking units of the press (5.13)

temperature is at the control unit (display) (6.4) of the and back. The air in the system escapes automatically

CRCWL, from where it is transmitted to the electronic via the air relief valve (5.6). The expansion vessel (5.4)

unit. with the safety valve (5.5) maintains the water pressure

in the system.

The temperature control proper is by the electronic unit

of the operator panel (6.3). The heat exchanger circuit Power supply

and the refrigeration circuit are controlled according to Power supply is by the feeder (6.1), the master switch

the value entered and the data by the temperature (6.2), and the control box (6.3).

sensor (4.16).

The manostats measure the pressure in the high

pressure and the low pressure section. These control

signals are supplied by the suction check valve (4.12)

and/or the pressure check valve (4.14) via capillary

measuring lines. In the case of a drop in the system

01.98/CRCWL852/GB Seite / Page 27

Mode of operation

1.9

1.7 1.8 1.7 1.6

2.7 1.5

2.8

2.9 2.6

F 60 P 1.7 1.8 1.7 1.6

1.5

M

1.1

1.4 1.3 1.2

1.6

2.8

1.11 1.7 1.12 1.7 1.11

1.10

3.2 3.3 3.1 3.4 1.13

2.10 2.4 2.5 2.3 1.14

2.11 2.12

M AL M 5.14 5.13 5.12

2.15 2.1 2.2 2.16 2.13

T 5.15 5.11

4.16

5.16 5.10

1 6.3

0

2.14 5.17

0

5.9

6.2 T 5.18

M

4.1

6.4 5.6

6.5 5.5

4.8

4.9 T M

6.1

4.10 4.7

5.1 5.2 5.3 5.19 5.4 5.7 5.8

4.6

LP HP

4.12 4.11 4.2 4.13 4.14 4.3 4.4 4.5

Fig. 5-1 Diagram CRCWL 852-.. AD with air-cooled condenser

Seite / Page 28 01.98/CRCWL852/GB

Mode of operation

1.9

1.7 1.8 1.7 1.6

2.7 1.5

2.8

2.9 2.6

F 60 P 1.7 1.8 1.7 1.6

1.5

M

1.1

1.4 1.3 1.2

1.6

2.8

1.11 1.7 1.12 1.7 1.11

1.10

3.2 3.3 3.1 3.4 1.13

2.10 2.4 2.5 2.3 1.14

2.11 2.12

M AL M 5.14 5.13 5.12

2.15 2.1 2.2 2.16 2.13

T 5.15 5.11

4.16

5.16 5.10

1 6.3

0

2.14 5.17

0

5.9

6.2 T 5.18

M

4.1

6.4 5.6

6.5 5.5

4.8

4.9 T M

6.1

4.10 4.7

5.1 5.2 5.3 5.19 5.4 5.7 5.8

4.3 4.5 4.6

LP HP

T 4.17 4.18

4.12 4.11 4.2 4.14 4.13 4.15

Fig. 5-2 Diagram CRCWL 852-.. WAD with water-cooled condenser

01.98/CRCWL852/GB Seite / Page 29

Mode of operation

1.9

1.7 1.8 1.7 1.6

2.7 1.5

2.8

2.9 2.6

F 60 P 1.7 1.8 1.7 1.6

1.5

M

1.1

1.4 1.3 1.2

1.6

2.8

1.11 1.7 1.12 1.7 1.11

1.10

3.2 3.3 3.1 3.4 1.13

2.10 2.4 2.5 2.3 1.14

2.11 2.12

M AL M 5.14 5.13 5.12

2.15 2.1 2.2 2.16 2.13

T 5.15 5.11

4.16

5.16 5.10

1 6.3

0

2.14 5.17

0

5.9

6.2 4.20 T 5.18

M

6.4 5.6

6.5 5.5

4.19

T M

6.1

5.1 5.2 5.3 5.19 5.4 5.7 5.8

T 4.17 4.18

Fig. 5-3 Diagram CRCWL 852-.. WWAD with water-water-plate heat exchanger and central refrigeration

Seite / Page 30 01.98/CRCWL852/GB

Mode of operation

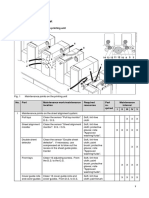

Key to Figs. 5-1 /5-2 /5-3

1. Fountain solution premixing 4.15 Cooling water control valve

1.1 Fresh water supply (water-cooled design)

1.2 Filter 4.16 Temperature sensor (PT100)

1.3 Solenoid valve for water supply 4.17 Cooling water thermometer

1.4 Flow meter (water-cooled design)

1.5 Storage tank for additive 4.18 Cooling centre (cooling tower)

1.6 Filter with nonreturn valve 4.19 Water-water-plate heat exchanger

1.7 Nonreturn valve 4.20 3/2-way valve

1.8 Metering pump for additive (pneumatic)

1.9 Additive 2 (option) 5. Ink roll cooling/heating

1.10 Storage tank for alcohol 5.1 Water-water-plate heat exchanger

1.11 Solenoid valves for alcohol supply 5.2 Bypass valve

1.12 Metering pump for alcohol (pneumatic) 5.3 Heating

1.13 Fountain solution supply (water + additive) 5.4 Expansion vessel

1.14 Alcohol supply 5.5 Safety valve

5.6 Automatic ventilating valve

2. Fountain solution circulating 5.7 Temperature sensor (PT100)

2.1 Fountain solution storage tank 5.8 IRHC-pump

2.2 Supply pump 5.9 Flow monitoring switch

2.3 Supply line valve 5.10 Manometer for supply line

2.4 Float switch 5.11 Check valve supply line

2.5 Ventilation 5.12 Cooling water supply line

2.6 Fountain solution supply line 5.13 Printing unit with inking unit

2.7 Fountain pan in fountain unit 5.14 Cooling water return line

2.8 Fountain solution return line 5.15 Check valve return line

2.9 Return flow filter unit (f.ex.: F 40 P) 5.16 Manometer for return line

2.10 Connection (return line) 5.17 Dirt trap

2.11 Filter foam 5.18 Mixing valve

2.12 Sensor for monitoring the filter condition

2.13 Heat exchanger pump 6. Miscellaneous

2.14 Thermostat for emergency mode 6.1 Mains feeder (see wiring diagram)

2.15 Drain for heat exchanger circiut 6.2 Main switch (option)

2.16 Overflow and discharge for fountain solution 6.3 Switchbox

storage tank 6.4 Digital control unit (display and electronic)

6.5 Fault indicator

3. Measurement of alcohol concentration

3.1 Alcohol Control

3.2 Connection for fountain solution measurement

3.3 Restrictor

3.4 Measurement of the alcohol content

4. Refrigerating system

4.1 Heat exchanger with evaporator

4.2 Compressor (refrigerating set)

4.3 Condenser (air and/or water-cooled)

4.4 Fan motor (air-cooled design)

4.5 Collector

4.6 Dry-type filter

4.7 Sight glass

4.8 Expansion valve

4.9 Temperature sensor

4.10 Pressure compensation line

4.11 Low-pressure manostat

4.12 Suction check valve

4.13 High-pressure manostat

4.14 Pressure check valve

01.98/CRCWL852/GB Seite / Page 31

Mode of operation

5.1 Fountain solution premixing (Fig. 5-4)

Description

The fountain solution premixing unit comprises in the

4 5 6 7 main

- a flowmeter (4) for measuring and controlling the

amount of water for the damping solution prepar-

ation,

- a metering piston pump (7) for adding alcohol as a

function of the adjusted alcohol setpoint and the

measured actual alcohol value of the alcohol control,

- and a metering piston pump (6) for the fountain

solution additive as a function of the adjusted ad-

ditive percentage and the amount of water supplied.

The quantities of alcohol and additive are calculated

and controlled by the control system. When the key

is pressed, the consumption data for water,

additive and alcohol will be displayed.

Mode of operation (Fig. 5-4)

When the unit is put into operation, switching point 1

triggers the initial filling as per the basic adjustment

When the fountain solution level in the storage tank

drops - caused by the consumption of fountain solution

during printing - a float switch triggers a contact

(switching point 2 is left) for another filling cycle with

some 6 litres of premixed damping solution (H2O +

additive + alcohol = 6 l).

A filling cycle comprises the following steps:

a) Simultaneously

- water is metered via an opened solenoid valve (5)

Switching point 3 and flowmeter (4),

- fountain solution additive is metered proportional to

volume via pumps (6) by several pump lifts,

Switching point 2 - alcohol is metered proportional to percentage via

pumps (7) by several pump lifts.

Switching point 1

Fig. 5-4

Seite / Page 32 01.98/CRCWL852/GB

Mode of operation

Attention:

Only "technically pure isopropanol" may be

used with this fountain solution premixing unit.

"Alcohol substitutes", that can be added pro-

portional to volume only, may only be used after

the parameters of the control have been altered.

A density measuring of the alcohol will not be

working in this case.

b) The filling cycle will be completed when the adjusted

metering quantity has been added and will be

repeated until the adjusted level in the damping

solution storage tank (float ball at switching point 2)

is reached.

Note:

With the intial service, the tank will first be filled

to the upper switching point 3 by the integrated

fountain solution premixing unit. The fountain

solution circulating pump will only then be cut

in by the elelctronic control.

During printing, the level will adjust itself at the

middle float switching point 2.

c) In the case of a low alcohol percentage during the

production run (e.g. caused by evaporation) as

measured by the alcohol control, additional alcohol

will be metered by several pump lifts until the adjusted

value has been reached (also see 5.2).

Attention:

The pressure reducer must be set to 400 kPa

(4.0 bar) to ensure a perfect metering function

and error detection.

01.98/CRCWL852/GB Seite / Page 33

Mode of operation

5.2 Alcohol Control Unit (Fig. 5-5)

3

Attention:

Only "technically pure isopropanol" may be

used with this fountain solution premixing unit.

"Alcohol substitutes", that can be added pro-

portional to volume only, may only be used after

the parameters of the control have been altered.

A density measuring of the alcohol will not be

working in this case.

4

The BALDWIN Alcohol Control continuously measures

the actual value of the alcohol percentage in the damping

solution by the density measuring principle.

The desired alcohol percentage (0 to 20%) can be

entered at the display (digital control) of the unit. 2

1

The Alcohol Control is calibrated with 0% of alcohol first

by means of a metering pipe. This is required since the

addition of fountain solution additives will additionally

change the fountain solution density.

The Alcohol Control comprises the following compo-

nents: Fig. 5-5

1) Analysis box with:

Fountain solution supply, standpipe

2) Aerometer:

comprises a special steel float with screwed-on

plastic cap and calibrating discs

3) Housing top with:

optoelectronic reticle scanning

4) Metering pipe for the correction of the fountain

solution density required by the addition of fountain

solution density

Note for repair and/or spare parts orders:

Since the Alcohol Control is accurately calibrated

as an entity with all components, it must be sent

as complete unit to BALDWIN in the case of a

defect.

Seite / Page 34 01.98/CRCWL852/GB

Mode of operation

Mode of operation of the Alcohol Control (Fig. 5-6)

The alcohol portion in the damping solution is measured

by the density measuring principle (areometer). Higher

alcohol percentages cause the density to decrease, 5

which in turn results in a lower buoyancy of the aerometer

float (4), whereas lower percentages cause the density

to increase, which results in a higher buoyance of the 6

aerometer float (4). 1

Fountain solution is recirculated in a continuous circuit

from the fountain solution refrigerating unit via the

connection (1), analysis box (2) and standpipe (3) to the 2 3 4

refrigerating unit.

When the density in the analysis box is changed, the

aerometer (4) moves a position pickup (5) integrated in

the housing top upwards and/or downwards. Values

are converted by an optoelectronic scanning of this

code measure, and the alcohol percentage (actual Fig. 5-6

value) is digitally displayed at the control panel.

When the value drops below the adjusted alcohol

setpoint, alcohol will be metered by several pump lifts

in addition to the normal filling cycle proportional to

volume by the electronically controlled fountain solution

premixing unit (see Section 5.1).

The Alcohol Control is calibrated to the different densities

of fountain solution additives by means of an adjusting

knob (6) at the analysis box (see section "Adjusting and

checking").

Note:

Alcohol measurement is e.g. upon initial service

only 5 minutes after the supply pump has started

to run.

This On delay ensures a perfect measurement

by the analysis box that will then be sufficiently

flushed with fountain solution.

In the case of an alcohol deviation

- to 0.5 % below setpoint,

1 pump lift will be effected per 15 seconds

- to 1.0 % below setpoint,

1 pump lift will be effected per 6 seconds

01.98/CRCWL852/GB Seite / Page 35

Mode of operation

5.3 Return flow filter unit (option)

(Fig. 5-7)

Mode of operation of the return flow filter

The return flow filter is used for pre-cleaning and

recirculating the fountain solution returning from the The fountain solution returning from the fountain pans

water pans of the press into the RCWL. of the press is cleaned by the filter mat (2). A float switch

It is also used as a collecting tank for the fountain (6) monitors the filter condition and signals any clogging

solution when the overall system is switched off. of the filter to the electronic control unit.

The main components of the return flow filter are: An integrated submerged pump (8) recirculates the

fountain solution to the RCWL.

a) filter mat (2) The fountain solution return flow is set by the control

b) filter cage (3) valve (10).

c) float switch (6) A control and/or float valve (9) restricts the pump flow

d) float (7) rate when the fountain solution level in the tank drops,

e) control and/or float valve (9) thus preventing the formation of foam to a large extent.

f) submerged pump (8)

g) tank (5)

h) control valve (10)

Fig. 5-7

Seite / Page 36 01.98/CRCWL852/GB

01.98/CRCWL852/GB Seite / Page 37

Installation

6. Installation

6.1 Remove the packing

General

Check the individual units and components for packing

material (protection for transport, protective covers

etc.) and remove.

Alcohol Control (Fig. 6-1)

Take the packing material (serves as protection during

transport) out of the analysis box of the Alcohol

Control.To do so, loosen the 2 knurled screws (1) at the

front and the rear and remove the electronics section

(2). Remove the float (4) and take the protection for

transport (3) (packing material) out. Align the housing

(5) of the Alcohol Control with the aid of a water level (8)

at 2 sides (A and B) and adjust by means of the

setscrews (7). Now put the float (4) back into the

container.

Warning:

Prior to mounting the black electronics housing,

remove the cap (6) at the bottom

without fail,

to enable the plunger to move freely and to

ensure that the alcohol strength is determined

accurately.

Failing to remove the cap, alcohol Fig. 6-1

will be overdosed.

Attention:

The analysis box must be vertically aligned

during mounting by placing a water level at 2

sides (A and B). To do so, adjust setscrews (7)

correspondingly. Take the packing material out

of the analysis box before putting the unit into

operation ! When mounting, make sure that the

adjusting knob at the housing top (2) points to

the front (operator side).

Seite / Page 38 01.98/CRCWL852/GB

Installation

6.2 Location

Select the location for the unit in such a way that it will 1480

always be easily accessible for the operating personnel 730

min. 600

and that it is not subjected to extreme heat, e.g. near a

heating etc. The distance between the rear side and the

wall must be at least 40 cm (also see Fig. 6-2).

Warning:

The user must provide adequate ventilation for min. 400

(1450)

the dissipation of heat and the removal of harmful CRCWL

vapours, if any (min. 0.5 m to the top). 852-...

Consult BALDWIN before you install an extraction

system that works in upwards direction.

Place the unit on a firm base.

min. 400

Attention:

The ventilation grids at the unit must not be

blocked and/or covered, since perfect cooling

of the partly very hot components will then no

longer be ensured.

Fig. 6-2

For troublefree funktion the unit must be align to two

faces (see Fig. 6-3).

Attention:

Place the CRCWL at the same level as the printing

press

- cooling unit placed at a lower level in the

basement will require a pump with a higher

capacity,

- cooling unit placed at a higher level will

require an additional return-flow filter,

since there will be no free return flow in this

case.

Secure the unit against sliding.

Fig. 6-3

01.98/CRCWL852/GB Seite / Page 39

Installation

6.3 Hose connections

Warning:

Run all hoses in such a way that nobody stumbles

over them (protect by means of suitable cover-

ings).

Note:

Supply and return flow lines will have to be run up to unit type 852-600...

along the press by the customer, depending on

the configuration concerned.

Coordinate this with Messrs. BALDWIN and/or

the press manufacturer.

Note:

The hoses for the ink tempering unit must be run

without any bends and as vertically as possible

to ensure perfect venting of the system. Provide

vent valves at the priting units.

Return flow hoses made of PVC should have a fabric 1 2 3 4 5 6 7

insert due to the hazard of buckling.

Hose connections as per Fig. 6-4. Hose and dimensions

from unit type 852-1000...

of connection see section "Technical data".

1 7 4 2 5 3 6

Fig. 6-4

Key to Fig. 6-4

1 Drain

2 Air connection

3 RCWL supply line

4 Fresh water

5 IRHC supply line

6 RCWL return flow line

(other point of connection feasible)

7 IRHC return line

Seite / Page 40 01.98/CRCWL852/GB

Installation

l Drain (Fig. 6-4, item 1) l Fresh water supply (Fig. 6-4, item 4)

This connection serves as overflow and drain for the When the fresh water supply is from the in-house water

fountain solution storage tank. main to the cooling unit, a pressure reducer is to be

connected on the line side.

The customer must provide a connection with stop

valve and pipe disconnector.

Warning:

Dispose of the fountain solution in accordance Attention:

with the relevant rules in force. The fresh water supply pressure to the cooling

unit must be between 150 kPa (1.5 bar) and 500

kPa (5 bar).

l Air connection (Fig. 6-4, item 2)

The customer must provide a compressed air connection

of at least 350 kPa, max. 1000 kPa for the drive of the l IRHC supply and return flow line (Fig. 6-4,

alcohol and/or additive pumps. item 5/7)

Note:

Attention:

The hoses for the ink roll heating/cooling (IRHC)

Set the air pressure governor of the unit to 400

must be run without any bends and as vertically

kPa (4 bar).

as possible to ensure perfect venting of the

system. Provide vent valves at the printing units.

l RCWL supply and return flow line (Fig. 6-4,

item 3/6)

only applicable to water-cooled design:

Make sure that these are run without any bends and as

vertically as possible so that the fountain solution flows l Cooling centre supply and return flow line

back into the storage tanks of the cooling unit when the

pump is at standstill. The unit is provided with a cooling circuit with water-

cooled condenser and/or heat exchanger. The heat

exchanger is found at the bottom left in the unit and is

Note:

connected to a cooling centre via the supply/return line

These hoses should be insulated to avoid line

connection.

losses.

Note:

The hoses for supply and return line must be

connected to the heat exchanger directly.

01.98/CRCWL852/GB Seite / Page 41

Installation

6.4 Connection to cooling centres

Cooling units are suited for a connection to both cooling out by the high-pressure safety switch, there is

centres (e.g. cooling tower for chill rollers) and municipal no cooling water supply from the cooling centre

water supply. (check the interlocking contacts to the cooling

centre).

Attention:

A continuously working cooling circuit must be When the manometer hunts by more than 5°C

ensured even when the press is at standstill. with the cooling centre running, there is air in

Ensure that the water from the cooling centres the cooling water circuit. Remove this air by

is clean without fail. Any internal contamination venting the circuit, since the chiller will fail very

will prevent the condenser from working soon with this hunting operation, power

perfectly (filter the cooling water, if required). consumption will heavily increase, and the

refrigerating capacity will drop.

Note:

In the case of operation on municipal water,

contact Messrs. BALDWIN prior to initial

operation. A high pH value may damage the

CRCWL.

Cooling water pressure: 6.5 Alcohol and additive supply

min. 200 kPa (2 bar), max. 600 kPa (6 bar)

Alcohol and additive are mixed to the fountain solution

Cooling water temperature: by self-priming pumps from integrated storage tanks

min. +10°C, max. +40°C (from unit type 852-1200..., the storage tanks are

external) .

Cooling water flow rate:

see "Technical data"

When the condenser is supplied with very cold water Warning:

(approx. 10- 15°C), e.g. city water, directly from the line, Improper handling of additives is a danger to life

a pressure reducer (200 kPa / 2 bar) should be connected and limb. Observe the relevant regulations (e.g.

on the line side. Failing this, cutting in and out of the safety regulations, regulation governing the

refrigerating set in the low pressure range might occur. handling of hazardous materials etc.) without

Filters with a mesh width of 80 µm are to be installed fail.

upstream of the cooling unit.

Required nominal widths for supply and return line Attention:

hoses see “Technical data”. Only "technically pure isopropyl" may be used

with this fountain solution premixing unit.

Install stop valves in the cooling lines to allow "Alcohol substitutes", that can be added pro-

maintenance or repair work at the refrigerating set. portional to volume only, may only be used after

the parameters of the control have been altered.

Note: A density measuring of the alcohol will not be

Pressure reducer, filters, air ventilation valves working in this case.

and stop valves are not included in "BALDWIN´s

scope of supply".

Attention:

The unit may only be used for adding commer-

Note only for refrigeration engineering expert: cial fountain solution additives. When 0...6% of

Set the cooling water regulating valve so that additives are added, a pH-value suitable for

the high-pressure manometer will constantly printing (4.8...5.2) must be obtained.

indicate 40°C + 2°C (liquefaction temperature)

with the refrigerating set and the cooling water

supply from the cooling centre running!

When the high-pressure manometer hunts to

some 60°C or when the refrigerating set is cut

Seite / Page 42 01.98/CRCWL852/GB

Installation

6.6 Topping-up alcohol and/or additive (Fig. 6-5) 6.7 Refrigerant

Loosen screw caps (1), remove suction pipe (4) with As a rule, BALDWIN deliver the refrigerating set in filled

filter (5), top up additive (2) and alcohol storage tank (3). condition.

Put suction pipe with filter back in place and mount

screw caps.

Warning:

Topping-up of the units may only be carried out

by a specialised firm for refrigeration and air-

condition engineering upon prior consultation

1 2 of BALDWIN.

The refrigerating set may only be filled with and operated

on the refrigerants stated in the technical data.

Note:

Prior to commissioning, leave the unpacked

unit in its service position for some 24 hours to

allow the refrigerant to gather after transport.

6.8 Electrical connections

- Combined Refrigerated Circulating Water Level