Documente Academic

Documente Profesional

Documente Cultură

Din. Digital Temperature Controller: Ttm-000 Series User'S Manual Operation Flow and Setting Menu

Încărcat de

EdyTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Din. Digital Temperature Controller: Ttm-000 Series User'S Manual Operation Flow and Setting Menu

Încărcat de

EdyDrepturi de autor:

Formate disponibile

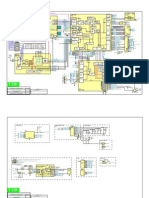

和文の説明は裏面にあります。 OPERATION FLOW AND SETTING MENU Setting display shows the existence of option.

TTM-000 SERIES USER'S MANUAL ●Selection memo for

●Power ON ●Setting mode

/16 DIN. DIGITAL TEMPERATURE CONTROLLER

1

<SET1:Initial Setting> <SET2:Control Setting> <SET3:Event Output 1> <SET4:Event Output 2> <SET5:Digital Input> <SET6:Communication> <SET7:Timer> <SET0:Priority Displays>

priority displays.

Display NO. for record,

Shows for 4 seconds ▲ KEY ▲ KEY ▲ 47. Event output 2 setting ▲ 57. DI setting ▲ 61. Communication setting ▲ 67. Timer setting ▲ 74. Priority displays setting

Thank you for purchasing model TTM-000 SERIES (Warming up) 1. Initial setting display 9. Details of control setting 37. Event output 1 setting

Select priority displays

1st display

Initial setting mode Control setting mode EV1 setting mode EV2 setting mode DI setting mode Communication setting mode Timer setting mode NO.

Digital Temperature Controller. ●Operate mode display Calling display

▼ KEY

Calling display

▼ KEY Calling display

▼ Calling display

▼

Calling display

▼

Calling display

▼

Calling display

▼

Calling display

(Refer to Ex.1.)

Please go through this Instruction Manual carefully A. Primary displays : Press key

MODE key

* After select,

MODE key MODE key MODE key MODE key MODE key MODE key MODE key MODE key

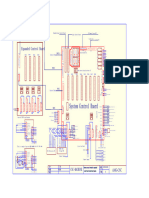

2. Input type setting 10. High limit setting in SV limiter 38. Function setting for EV 1 48. Function setting for EV 2 58. Function setting for DI 62. Parameter setting for communication 68. Timer output setting 75. Setting for 1st priority display 2nd display

and use the unit in proper manner. Process value Set the temperature

Select input type

press MODE key

* Current/Voltage Display of high limit setting * Current/Voltage Select below functions. Select below functions. Select below functions. Select 1st display on NO.

Setting value required 「22」 of setting value. 「9000」 operation mode B.

Refer to Table 1. (Within setting range of Table 1)

NOTICE/WARNING BEFORE OPERATION USE MODE key

MODE key more

than 2 seconds MODE key

3. PV correction gain

MODE key

11. Low limit setting in SV limiter

PV Event functions

0:None

PV Event functions

0:None SV

DI action

SV2

Stop bit length

1 bit

Non-use

Control output

MODE key

76. Setting for 2nd priority display

MODE key

3rd display

B. Priority displays. Refer to Ex.1. 1:Deviation high and low limit 1:Deviation high and low limit

●When having the purchased controller at hand, please be sure that its unit is SET0 : Priority displays by When measurement value Display of low limit setting * Current/Voltage 2:Deviation high limit 2:Deviation high limit

RUN READY 2 bit Event 1 output Select 2nd display on NO.

comes an error, set the of setting value. 「−1000」 AUTO Manual Parity check MODE key operation mode B.

a correct model (See the following "Model Configuration" ). setting and shows max.9 correction value (Multiplication) (Within setting range of Table 1) 3:Deviation low limit 3:Deviation low limit

Reverse Normal

displays by setting. 4:Deviation high and low limit range 4:Deviation high and low limit range Nil 69. Timer function setting

●The following symbol marks provide to prevent incident or damage. Kindly MODE key MODE key 5:Absolute value high and low limit 5:Absolute value high and low limit AT release AT start MODE key MODE key

MODE key, return to A Odd number

6:Absolute value high limit 6:Absolute value high limit 77. Setting for 3rd priority display 4th display

refer to the details of the WARNING/CAUTION when using for the first time. 4. Zero point setting for PV correction 12. Control mode setting

7:Absolute value low limit 7:Absolute value low limit

Reverse SV Normal SV2 Even number

When measurement value Usable for control mode Reset Timer start Select 3rd display on NO.

●Another copy of the user's manual "Advanced Version" is provided at comes an error, set the 8:Absolute value high and low limit range 8:Absolute value high and low limit range Data length

Auto start (ON delay) operation mode B.

correction value (Addition) setting MODE key

customer's request. ●FUNC key Additional Event functions Additional Event functions

59. Polarity setting for DI

7 bit Manual start (ON delay)

MODE key MODE key

MODE key Control performance 0:None 0:None 8 bit (ON delay)

FUNK key operates on the selected 1:EV output hold 1:EV output hold

Event start

setting mode 7. 5. Filtre input Non-control performance Select below polarity. BCC check 78. Setting for 4th priority display 5th display

Due to mishandling, Refer to Ex.2. CR filter effect is operational on

(Manipulated value low limiter output) 2:Stand-by sequence 2:Stand-by sequence Auto start (OFF delay)

Select 4th display on

None Manual start (OFF delay) NO.

serious dangers may occur to software when making first-order Manual control 3:EV output hold & stand-by sequence 3:EV output hold & stand-by sequence operation mode B.

WARNING the operator such as death,

MODE key

lag operation to process value (PV). MODE key MODE key MODE key

Close action

Open action

Available Event start

SV start

(OFF delay)

(OFF delay) MODE key MODE key

electrocution and a skin burn. Ex.1. Priority displays & its setting 13. Selection of control type setting 39. High limit setting for EV 1 49. High limit setting for EV 2

MODE key

MODE key

MODE key

6. Position of decimal point 63. Speed setting 79. Setting for 5th priority display 6th display

This function is to shift the most essential Selectable and switchable below Set high limit value. Set high limit value.

screens on setting mode into operation mode Thermocouple/R.T.D.(Pt100, JPt100) 60. Setting for SV2 70. Timer unit selection Select 5th display on NO.

control modes.

Owing to mishandling, it may as a priority. Please select priority displays Not required Displays only when SV2

operation mode B.

cause some damage to through priority display setting. Required

MODE key MODE key is selected at DI.(℃)

CAUTION the unit or the operator eg. : Basic display Output 1 manipulated value Current/Voltage PID, Control Control output 2

40. Low limit setting for EV 1 50. Low limit setting for EV 2

MODE key, return to 57

1200bps

2400bps Hour/minute

MODE key

80. Setting for 6th priority display

MODE key

7th display

getting slight injury. Setting high limit for event Output 1 Not required

Refer to Ex.3. output 1 0:None Set low limit value. Set low limit value.

4800bps Minute/second Select 6th display on NO.

1 digit 0:Type A 1:PID 1:PID operation mode B.

*Screen is shifted when pressing mode key each time. 1:Type B 2:ON/OFF 2:ON/OFF 9600bps MODE key

2 digits 3:Event output MODE key MODE key

CAUTION Ex.2. FUNC key work

3 digits

MODE key

41. Control sensitivity setting for EV 1 51. Control sensitivity setting for EV 2

19200bps

MODE key

71. Timer SV start permissible range

Thermocouple/R.T.D.(Pt100, JPt100) Input

Setting range : 0∼999

MODE key

81. Setting for 7th priority display

MODE key

8th display

MODE key Set sensitivity when Set sensitivity when

This function is to enable FUNC key to use as 14. Change of normal or reverse 。 。 64. Address setting 0.0∼999.9 Select 7th display on NO.

●Forprevention of its malfunction, do not push the front a specific key, for the following actions selected 7. FUNK key setting (Refer to Ex.2.) required(C ). required(C ).

Setting range : 1∼99 Setting unit : ℃ operation mode B.

in FUNC key setting belonged to setting mode. Switchable below

key with sharp points. Selectable below control output actions.

MODE key MODE key Current/Voltage Input

Setting range : 0∼9999 MODE key MODE key

1.Digit shift

●Spare terminal must not be used for other purposes. Setting digit shift is enabled when setting value is changed.

functions

0:Reverse (Heating)

42. Delay timer setting for EV 1 52. Delay timer setting for EV 2 MODE key (Decimal point at designated position)

82. Setting for 8th priority display 9th display

Set delay timer when Set delay timer when Setting unit : digit

2.RUN/READY None 1:Normal (Cooling) 65. Response delay time setting Select 8th display on

required(sec). required(sec). MODE key NO.

Control stop (READY) and control performance (RUN) are Change of digit operation mode B.

WARNING alternately switched every time FUNC key is pressed.

(READY lamp is ON during control stop)

RUN/READY

Auto-Tuning

MODE key

15. Manipulated value for output 1(%)

MODE key MODE key

Setting range : 0∼250mS

72. Timer time setting

Setting range : 0:00∼99:59 MODE key MODE key

3.Auto-Tuning (AT) Shows process manipulated 43. Abnormal for EV 1 53. Abnormal for EV 2

Timer MODE key 0:00∼59:59 83. Setting for 9th priority display Return to primary display

●Make sure the correct wiring connection before turning on electricity. AT starts instantly after pressing FUNC key. MODE key

value for output 1, and setting For outbreak of sensor For outbreak of sensor

66. Mode selection setting Select 9th display on

(Start/Reset operation is available, each time FUNC key the value on manual control.

and heater abnormal and heater abnormal MODE key

Mis-wiring may cause malfunction of the unit and fire. is pressed) 8. Key lock setting Display range : 0.0∼100.0%

(−10.0∼110.0%)

operation mode B.

Type Type 73. Timer residual time monitor setting

●Never modify the unit to prevent damage or incident such as 4.Timer Key lock setting for protection Setting range : Manipulated value Residual time monitor. MODE key, return to 74

of error operation. low/high limiter 0:None 0:None

Available for start/reset.

malfunction and fire etc. Selectable below functions

MODE key

1:PV abnormal (sensor break) 1:PV abnormal (sensor break) R communication Timer starts when

pressing FUNC key.

None 2:Heater abnormal 2:Heater abnormal RW communication

・Please put this user's manual aside for your reference, when Ex.3. To select PID All lock

3:PV + Heater abnormal 3:PV + Heater abnormal

MODE key, return to 61

MODE key, return to 67

operating the unit. Feature of type A and B Operation mode lock only

0:None

Action

0:None

Action

・Copy or reprint of this manual, wholly or partially, is not allowed. Type A Ordinary PID

Except operation mode 1:Hold 1:Hold

MODE key, return to 1 (Power reset) (Power reset)

・The contents of this manual may change without notice in future. Type B Over shoot protection PID

If control is unstable under self-tuning, <When select PID control> MODE key MODE key

●How to release eg. Release of Timer Setting

please change to type A or B and also to ON/OFF control. 16. Setting for PID tuning type 26. Manipulated value for output 2 (%) 44. Polarity setting for EV 1 54. Polarity setting for EV 2 Mode from BLIND Function

ACCESSORY & CONFIGURATION Tunes suitably for Shows process manipulated

value for output 2, and setting

Normal open/close is

selectable while event

Normal open/close is

selectable while event

BLIND Function before newly its set-up.

setting value. the value on manual control.

Ex.4. ARW output is ON. output is ON.

1) Please be sure that the unit enclosed in packing carton is a right model Anti-reset wind-up take effect for overshooting Auto-tuning output 1 Display range : 0.0∼100.0%

(−10.0∼110.0%) Normal open Normal open

1. Power ON

before using. by over-integral of PID control action. Self-tuning output 1 Setting range : Manipulated value

Automatically

Normal close Normal close

Auto-tuning output 2 low/high limiter taking 4 sec

ARW controls integral action(PV accords with SV). MODE key MODE key

2) Kindly check the following accessory being contained in that carton box. ●

● If integral value goes down, it takes effects. Self-tuning output 2 MODE key 2. Initial Display

45. CT Input Monitor for EV 1 55. CT Input Monitor or EV 2

● Installation Attachment (For installation, please see "INSTALLATION Automatically

CAUTION

If integral value is set "0", it stops integral action. Auto-tuning output 1.2 27. Proportional band setting for output 2 Monitors current value Monitors current value

Auto-tuning : Select above ・ or and press

AND WIRING" on the back.) FUNC key once. Call off autotuning : press

Adjusts proportional of heater current

detector. 1∼60A

of heater current

detector. 1∼60A 3. Operation Mode

band.

● This user's manual : 1 copy Table1. To select input sensors and setting range. unit:℃ FUNC key once on operating.

MODE key MODE key Press MODE Key (10 sec)

MODE key (19. To Set multiple of output proportional band)

3) Model Configuration

Model Input Output 1 Option

Symbol Low limit∼High limit

00 K Thermocouple − 200∼1372 −199.9∼990.0

0.0 Setting

17. AT coefficient setting MODE key

46. Abnormal current value of heater for EV 1

Setting for current

56. Abnormal current value of heater for EV 2

Setting for current

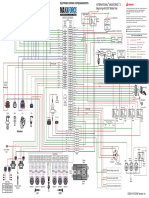

ERROR MESSAGES AND

T T M - □ □ □ −□ −□ −A □ □ □

01 J

02 R

〃

〃

− 200∼ 850 −199.9∼850.0

− 0∼1700

Coefficient is multiplied by

proportional band value

computed at auto-tuning.

28. Proportional cycle setting for output 2

Adjusts proportional

value when heater is

abnormal. 1∼30A

value when heater is

abnormal. 1∼30A TROUBLE SHOOTING 4. Immediately after the "Blink", (Blink once)

03 T 〃 − 200∼ 400 −199.9∼390.0 cycle time MODE key, return to 37 MODE key, return to 47 press FUNC Key, and quickly

04 N 〃 − 200∼1300 −199.9∼990.0 MODE key 1∼120 (second)

press MODE Key.

05 S 〃 − 0∼1700 18. AT sensitivity setting MODE key

MODEL Front Dimensions CODE Option 06 B 〃 − 0∼1800 Sensitivity is set up during ON/OFF 29. High limit setting of manipulated value for output 2

10 Pt100 − 199∼ 500 −199.9∼500.0 control at auto-tuning, particulary

For setting of

002 24×48 mm B Output 2 Relay contact 11 JPt100 − 199∼ 500 −199.9∼500.0

when PV is fairly unstable.

manipulated high limit 5. Press MODE Key (3 sec)

B or P selectable MODE key value. (output 2) (%) **1

004 48×48 mm P Output 2 SSR drive voltage 20 DC0 – 5V −1999∼9999 −199.9∼999.9 (Display) (Description) (Trouble Shooting)

−19.99∼99.99 19. Proportional band setting for output 1 MODE key

X04 48×48 mm R EV 2 Relay contact Not optional for TTM-002/004. −1.999∼9.999 Adjusts proportional band 30. Low limit setting of manipulated value for output 2 Shown whenever input value exceeds the high limit of Check the snapping of thermocouple 6. Press UP Key (△) for 1 7

005 96×48 mm When DI is selected for 21 DC1 – 5V −1999∼9999 −199.9∼999.9 for output 1 (% per SLL

For setting of

display range. Also displays when the wire and R.T.D. input. **2

TTM-005, 006, 007 or 009, ∼SLH)

manipulated low limit thermocouple, ABb terminal of R.T.D is snapped off.

−19.99∼99.99

006 48×96 mm this option is not available. −1.999∼9.999 MODE key value. (output 2) (%) Shown whenever input value exceeds Check short circuit of input lines

20. Integral time setting MODE key the low limit of display range. between A-B and A-b R.T.D. 7. Press FUNC Key

007 72×72 mm 22 DC4 – 20mA −1999∼9999 −199.9∼999.9

for OFF ON **3

D CT input When DI is selected for TTM-002/004, −19.99∼99.99 Adjusts integral time 31. Manual reset setting

009 96×96 mm this option is not usable. −1.999∼9.999 0∼3600 (second) For shifting

Display of memory error. In case this indication shows after the re-

input of power, replace unit if it persists. 8. Power OFF

When I output (4–20mA) is selected, MODE key proportional band.

CODE Input Type this option is not provided. 21. Deviative time setting MODE key

Display of A/D converter error or incorrect sensor Ditto

9. Power ON

NIL Thermocouple (K, J, R, E DI (Digital input) When CT is selected for TTM-002/004, *Either thermocouple or R.T.D. Adjusts deviative time 32. Dead band Setting

connection with selectable input.

Automatically

T, N, S, B) this option cannot be obtained. 0∼3600 (second) Display of auto-tuning error. Check sensor connection or change to

R.T.D. (Pt100, JPt100) (Pt 100/JPt 100) is selectable for For heating and <When select ON/OFF Control>

other tuning.

taking 4 sec

When EV 2 is selected for TTM-005, 006, MODE key cooling control(℃). 33. Contorol sensitivity setting for output 1 10. Initial Display

2 0–5V, 1–5V, 4–20mA 007 or 009, this option cannot be chosen.

input type, by pressing the front key. 22. Proportional cycle setting for output 1 Adjusts control sensitivity of Displayed when parameter is changed in Discontinue to change parameter. Automatically

*Either "B" or "P" is optional. Adjusts proportional ON/OFF control for output1. key-lock condition.

M Communication RS-485 cycle time 11. TIMER Setting Mode (OPERATION Mode)

CODE Output 1 * A (EV1) provided in the standard specifications.

*A (Event 1) : Single alarm is provided 1∼120 (second) MODE key Alternately this and SV/PV display are shown. Normality Press MODE Key (2 sec)

R Relay contact * Without output 2, EV2 is not available. in the standard specifications. MODE key 34. OFF position setting for output 1

23. ARW setting (see Ex. 4) For setting OFF position of 12. Press UP Key (△) for 1 7

P SSR drive voltage * Output 2 is equally used as EV2, but both not Adjusts ARW by % control output1.

Displayed when setting value is changed on SV2 Discontinue to change setting value

activated simultaneously. 0.0∼100.0% (−10.0∼110.0%) control. (during control of SV2)

I Current 4–20 mA DC From 25. MODE key

Displayed when changing setting value of shift on DI. Discontinue to change setting value of 13. Go on TIMER Setting

MODE key 35. Contorol sensitivity setting for output 2

Conformed Standards the self on digital input Press MODE Key consecutively

SPECIFICATIONS Safety : EN61010-1(IEC1010-1)

24. High limit setting of manipulated value for output 1

For setting of

Adjusts control sensitivity of

ON/OFF control for output2. Displayed when making setting value change in Discontinue to change setting value

**1 Please select an appropriate charactor (eg. Timer Setting etc) being of

manipulated high limit control display while function key is on RUN/READY.

Power Supply Voltage 100 to 240V AC, 50/60Hz EMI : EN50081-2 value. (output 1) (%) MODE key BLIND Function effect for the demanding release.

**2 Charactor selected for TIMER Setting.

EMS : EN50082-2 MODE key 36. OFF position setting for output 2 Displayed when altering setting value in control **3 BLIND Function for "SELECTION DISPLAY (Timer Setting Mode)" is released.

Power Consumption Below 10 VA 25. Low limit setting of manipulated value for output 1 For setting OFF position of display while being on timer.

UL3121-1(UL /CUL)

Memory Element EEPROM For setting of control output2.

manipulated low limit *When output 2

Input of Sensor Thermocouple, R.T.D./0–5V, 1–5V, 4–20mA value. (output 1) (%) is ON/OFF,

go to 35.

(Changeable by front key) MODE key MODE key, return to 9

Control Output Relay contact, SSR drive voltage, Current

Control Method Two kinds of PID, ON/OFF CAUTION BEFORE CONTROL ※See also "PARTS INDICATION" & "INSTALLATION AND WIRING" on the reverse.

Operation Environment 0 to 50℃, 20 to 90%RH (Avoid making dew)

●Setting program is stored after power OFF, as non-volatile memory

Storage Environment −25 to 70℃, 5 to 95%RH (Avoid making dew) PID Control ON/OFF Control

Weight TTM-002/004 Less than 180g, TTM-005/006 Less than 240g, is equipped with TTM-000 SERIES controllers for setting storage. Merit Better control result is achieved Life span of relay is generally longer,

TTM-007 Less than 250g, TTM-009 Less than 310g. ●Either thermocouple or R.T.D.(Pt 100/JPt 100) is selectable as opposed to that of ON/OFF control. as it is ON when temperature is below

Location of the Unit Setting Keep away from the followings. input type, but Current/Voltage input needs to be selected SV and it is OFF when temperature is Head office: 1-13-21, Tanashioda, Sagamihara Kanagawa 229-1125 Japan.

・Gas of corrosion, dust and oily smoke. individually. For suitable application, please select most over SV (For heating control).

・The electric noise of generator. Demerit Life span of relay is shorter, as output Control value is worse in comparison Phone: +81-42-777-3311 Fax: +81-42-777-3751

CAUTION ・The influence of electromagnetic field.

appropriate input type and adjust input setup.

exists frequently with relay contact . with that of PID control. E-Mail: info@toho-inc.co.jp

・Mechanical vibration and shock.

・The direct sunlight.

●PID or ON/OFF control is selective for the optimal

performance and each detail of features is specified in the ※ PID constants are automatically reckoned up to write in, TOHO ELECTRONICS INC. Web site: http://www.toho-inc.co.jp

Installation condition Installation category2 table on the right side. when control begins or SV is altered on self-tuning.

S-ar putea să vă placă și

- Self ID Navigation and Radiotelephone SettingDocument1 paginăSelf ID Navigation and Radiotelephone Setting'Egemen KayaÎncă nu există evaluări

- PSANPneumatic EN Manu DRW171185AC 20191014 WDocument1 paginăPSANPneumatic EN Manu DRW171185AC 20191014 Wsinar automationÎncă nu există evaluări

- Digital Temperature ControllerDocument4 paginiDigital Temperature ControllerTim Duncan100% (1)

- Tatsuno Corporation: E Sunny-XeDocument4 paginiTatsuno Corporation: E Sunny-XeFaizan Majid0% (1)

- A01461101 Ice & Water - Automatic Defrost Side by Side - R134ADocument2 paginiA01461101 Ice & Water - Automatic Defrost Side by Side - R134AJOSE JIMENEZÎncă nu există evaluări

- VIOFO A119 ManualeditedenlargedDocument1 paginăVIOFO A119 Manualeditedenlargedhi.i.am noneÎncă nu există evaluări

- Owner's Manual: SetupDocument2 paginiOwner's Manual: SetuptatfutureÎncă nu există evaluări

- A320 Family Maintenance Concept PosterDocument1 paginăA320 Family Maintenance Concept PosterKamran Khan Tareen100% (1)

- Ac1-27 Instruction For Use: PAR Range DescriptionDocument2 paginiAc1-27 Instruction For Use: PAR Range DescriptionIov IftodeÎncă nu există evaluări

- EMKO ESM 3723 Temperature and Humidity Controller Instruction ManualDocument2 paginiEMKO ESM 3723 Temperature and Humidity Controller Instruction ManualHazem Al-kayaliÎncă nu există evaluări

- Digital Temperature - Humidity Controller ESM-3723-ENGDocument2 paginiDigital Temperature - Humidity Controller ESM-3723-ENGCristian SerbanoiuÎncă nu există evaluări

- Schematic Diagram: 7-1 Circuit DescriptionDocument8 paginiSchematic Diagram: 7-1 Circuit Descriptionoppa BaruÎncă nu există evaluări

- User's Manual: OperationsDocument1 paginăUser's Manual: OperationsneyebÎncă nu există evaluări

- FGHS2655PF Ref FrigidaireDocument2 paginiFGHS2655PF Ref FrigidaireVasti Diaz AguilarÎncă nu există evaluări

- Autonics Psan Series ManualDocument1 paginăAutonics Psan Series ManualResaKandhyÎncă nu există evaluări

- Test Signals CC2510Document7 paginiTest Signals CC2510Miguel Angel RupÎncă nu există evaluări

- Poster SafetyDocument1 paginăPoster SafetyJose Ricardo DuranÎncă nu există evaluări

- Operating Instructions Mpa de en FR PT It Es Ja ZH Im0046064Document2 paginiOperating Instructions Mpa de en FR PT It Es Ja ZH Im0046064qway896Încă nu există evaluări

- D200 Quick Installation GuideDocument1 paginăD200 Quick Installation GuideNelson MartinezÎncă nu există evaluări

- Maxxforce 7 Epa 10Document2 paginiMaxxforce 7 Epa 10Juan Martinez100% (4)

- 345B L Excavator Electrical System (SENR1937-01)Document2 pagini345B L Excavator Electrical System (SENR1937-01)sughieantoÎncă nu există evaluări

- Diagrama Cableado Refrigerador Side by Side 23 Pies Mod. FPHS2399PFDocument2 paginiDiagrama Cableado Refrigerador Side by Side 23 Pies Mod. FPHS2399PForkys TenorioÎncă nu există evaluări

- Adjustment Item ListDocument1 paginăAdjustment Item ListKaren SantacruzÎncă nu există evaluări

- Noblex nxc939bt js-15002b Mmotion-Electronics rcd3227bt Car Audio SMDocument17 paginiNoblex nxc939bt js-15002b Mmotion-Electronics rcd3227bt Car Audio SMCiclo TucumanÎncă nu există evaluări

- MR1.9TFT enDocument2 paginiMR1.9TFT ennhnamÎncă nu există evaluări

- Diagrama Electrico Electrico 994f Renr6322renr6322-02 - SisDocument4 paginiDiagrama Electrico Electrico 994f Renr6322renr6322-02 - SisRobert LeytonÎncă nu există evaluări

- PT900 Next Generation AutoPilotDocument12 paginiPT900 Next Generation AutoPilotMacro LoveÎncă nu există evaluări

- 994F Wheel Loader Electrical System: Cab Harness Connector and Component Location GridDocument4 pagini994F Wheel Loader Electrical System: Cab Harness Connector and Component Location GridAlexis MikeÎncă nu există evaluări

- Algae Neptune: RX Mid Channels GSM: CH 62 - 947,4 MHZDocument2 paginiAlgae Neptune: RX Mid Channels GSM: CH 62 - 947,4 MHZaposticaa100% (1)

- D9T Track-Type Tractor Electrical System: Harness and Wire Electrical Schematic SymbolsDocument4 paginiD9T Track-Type Tractor Electrical System: Harness and Wire Electrical Schematic SymbolsfernandoÎncă nu există evaluări

- Addressing ProcedureDocument4 paginiAddressing ProcedureSingh BaldevÎncă nu există evaluări

- Sharp Mipi Ls055d1sx04Document36 paginiSharp Mipi Ls055d1sx04Tercioglu FarukÎncă nu există evaluări

- 3412C EMCP II For MUI Engines Electrical System: Ac Panel DC PanelDocument4 pagini3412C EMCP II For MUI Engines Electrical System: Ac Panel DC Panelfahad pirzadaÎncă nu există evaluări

- Quickstart: Audio/Video Inputs/Outputs/Reference Power Cabling Control CablingDocument2 paginiQuickstart: Audio/Video Inputs/Outputs/Reference Power Cabling Control CablingINTERGUEST GuestÎncă nu există evaluări

- Noblex: PLL Synthesizer Stereo Radio With Compact Disc Player DigitalDocument14 paginiNoblex: PLL Synthesizer Stereo Radio With Compact Disc Player DigitalHernánSchusterÎncă nu există evaluări

- Simatic S5: System Manual CPU 100/102/103Document512 paginiSimatic S5: System Manual CPU 100/102/103SanjeewaÎncă nu există evaluări

- 993K Wheel Loader Electrical System: Harness and Wire Electrical Schematic SymbolsDocument6 pagini993K Wheel Loader Electrical System: Harness and Wire Electrical Schematic SymbolsNorman CoetzeeÎncă nu există evaluări

- BF5 SERIES (Single Display) : Digital Fiber Optic SensorDocument1 paginăBF5 SERIES (Single Display) : Digital Fiber Optic SensorCuong NguyenÎncă nu există evaluări

- Fxs en Ma Drw161280ab 20171213 He 20171214Document1 paginăFxs en Ma Drw161280ab 20171213 He 20171214indofoamsÎncă nu există evaluări

- Uenr2628uenr2628-02 SisDocument12 paginiUenr2628uenr2628-02 SisNicole SmithÎncă nu există evaluări

- Abts Uqair-B.2Document1 paginăAbts Uqair-B.2Anonymous BZQOJwWIh6Încă nu există evaluări

- XR150/XR550: Programming SheetDocument6 paginiXR150/XR550: Programming SheetMahomi ComputacionÎncă nu există evaluări

- 3406C Marine Auxillary Generator Set Electrical System: Pfh1-Up Generator Set: Engine: 1SS1-UP Generator: 8LF1-UP 9FF1-UPDocument2 pagini3406C Marine Auxillary Generator Set Electrical System: Pfh1-Up Generator Set: Engine: 1SS1-UP Generator: 8LF1-UP 9FF1-UPLượng Nguyễn XuânÎncă nu există evaluări

- A380 Family Maintenance ConceptDocument1 paginăA380 Family Maintenance Conceptyazan999100% (1)

- Woolworths Supermarket Main Switchboard Single Line Diagram: ConsultingDocument1 paginăWoolworths Supermarket Main Switchboard Single Line Diagram: ConsultingMitch WennÎncă nu există evaluări

- 036 CerberusPRO IP4 0-92314-EnDocument2 pagini036 CerberusPRO IP4 0-92314-EnvagnerÎncă nu există evaluări

- 345C ExcavatorDocument2 pagini345C ExcavatorAdhittyaz D SaputraÎncă nu există evaluări

- Mapa Informativo de Controle de Componentes E InspeçõesDocument2 paginiMapa Informativo de Controle de Componentes E InspeçõesLuiza AÎncă nu există evaluări

- AMG Electrical Schematic 08Document1 paginăAMG Electrical Schematic 08cristian2340Încă nu există evaluări

- Wa0073.Document1 paginăWa0073.Vane Sánchez EspejelÎncă nu există evaluări

- Dokumen - Tips Samsung GT E1200 SchematicsDocument7 paginiDokumen - Tips Samsung GT E1200 SchematicsHogir DoskyÎncă nu există evaluări

- 928G 6XR ElectricoDocument4 pagini928G 6XR ElectricoRodney Richardson100% (3)

- Batteries: Color Code For Schematic LinesDocument2 paginiBatteries: Color Code For Schematic LinesIsaac NewtonÎncă nu există evaluări

- TabindaDocument1 paginăTabindaAnonymous BZQOJwWIh6Încă nu există evaluări

- Button Instruction Icon Instruction Button Instruction Button Instruction Button Instruction Parameter Setting InstallationDocument1 paginăButton Instruction Icon Instruction Button Instruction Button Instruction Button Instruction Parameter Setting InstallationJan CatalanÎncă nu există evaluări

- 00 F 5 Sebk 320Document40 pagini00 F 5 Sebk 320Mr.K chÎncă nu există evaluări

- C50 1/16-Din Process Controller: Concise Product Manual - Im/C50Document2 paginiC50 1/16-Din Process Controller: Concise Product Manual - Im/C50AnthonyÎncă nu există evaluări

- Dball-Dball2-Tl7 - en - Ig - nf2015 11 19Document19 paginiDball-Dball2-Tl7 - en - Ig - nf2015 11 19Abdul KaderÎncă nu există evaluări

- Nature Explorers Classroom Awards and RewardsDe la EverandNature Explorers Classroom Awards and RewardsÎncă nu există evaluări

- Instant Assessments for Data Tracking, Grade 1: MathDe la EverandInstant Assessments for Data Tracking, Grade 1: MathEvaluare: 4 din 5 stele4/5 (1)

- Gilbert Cell Design PDFDocument22 paginiGilbert Cell Design PDFvysÎncă nu există evaluări

- 01 IntroductionDocument15 pagini01 IntroductionAli FarhatÎncă nu există evaluări

- IDL6543 ModuleRubricDocument2 paginiIDL6543 ModuleRubricSteiner MarisÎncă nu există evaluări

- Curriculum Improvement v2Document47 paginiCurriculum Improvement v2Nica Lagrimas100% (1)

- Power-Miser 12 Water Heater ManualDocument32 paginiPower-Miser 12 Water Heater ManualClaudeVanDammÎncă nu există evaluări

- Activity 2Document5 paginiActivity 2DIOSAY, CHELZEYA A.Încă nu există evaluări

- WallthicknessDocument1 paginăWallthicknessGabriela MotaÎncă nu există evaluări

- Sai Deepa Rock Drills: Unless Otherwise Specified ToleranceDocument1 paginăSai Deepa Rock Drills: Unless Otherwise Specified ToleranceRavi BabaladiÎncă nu există evaluări

- Planetary Yogas in Astrology: O.P.Verma, IndiaDocument7 paginiPlanetary Yogas in Astrology: O.P.Verma, IndiaSaptarishisAstrology50% (2)

- Excavation Trench Permit Ex 1 F0206Document5 paginiExcavation Trench Permit Ex 1 F0206emeka2012Încă nu există evaluări

- PLASSON UK July 2022 Price Catalogue v1Document74 paginiPLASSON UK July 2022 Price Catalogue v1Jonathan Ninapaytan SanchezÎncă nu există evaluări

- Methods of Estimation For Building WorksDocument22 paginiMethods of Estimation For Building Worksvara prasadÎncă nu există evaluări

- Tourism PlanningDocument36 paginiTourism PlanningAvegael Tonido Rotugal100% (1)

- BS7430 Earthing CalculationDocument14 paginiBS7430 Earthing CalculationgyanÎncă nu există evaluări

- The Practice Book - Doing Passivation ProcessDocument22 paginiThe Practice Book - Doing Passivation ProcessNikos VrettakosÎncă nu există evaluări

- APPSC GROUP 4 RESULTS 2012 - Khammam District Group 4 Merit ListDocument824 paginiAPPSC GROUP 4 RESULTS 2012 - Khammam District Group 4 Merit ListReviewKeys.comÎncă nu există evaluări

- Lecture 11 - Performance AppraisalsDocument23 paginiLecture 11 - Performance AppraisalsCard CardÎncă nu există evaluări

- Overview of MEMDocument5 paginiOverview of MEMTudor Costin100% (1)

- Cultural Practices of India Which Is Adopted by ScienceDocument2 paginiCultural Practices of India Which Is Adopted by ScienceLevina Mary binuÎncă nu există evaluări

- EF3e Intplus Filetest 10aDocument4 paginiEF3e Intplus Filetest 10aLin Shufen100% (1)

- Feasibility and Optimization of Dissimilar Laser Welding ComponentsDocument366 paginiFeasibility and Optimization of Dissimilar Laser Welding Componentskaliappan45490Încă nu există evaluări

- Design of CouplingDocument75 paginiDesign of CouplingVatsal BhalaniÎncă nu există evaluări

- Non-Emulsifying Agent W54Document12 paginiNon-Emulsifying Agent W54Pranav DubeyÎncă nu există evaluări

- Power Quality Lab Manual (EE-801)Document12 paginiPower Quality Lab Manual (EE-801)ASHU KÎncă nu există evaluări

- Electronics 12 00811Document11 paginiElectronics 12 00811Amber MishraÎncă nu există evaluări

- Risk Assessment For Harmonic Measurement Study ProcedureDocument13 paginiRisk Assessment For Harmonic Measurement Study ProcedureAnandu AshokanÎncă nu există evaluări

- Distillation Column DesignDocument42 paginiDistillation Column DesignAakanksha Raul100% (1)

- Tensile Strength of Ferro Cement With Respect To Specific SurfaceDocument3 paginiTensile Strength of Ferro Cement With Respect To Specific SurfaceheminÎncă nu există evaluări

- Three Revolutionary Architects - Boullee, Ledoux, and Lequeu PDFDocument135 paginiThree Revolutionary Architects - Boullee, Ledoux, and Lequeu PDFTran LeÎncă nu există evaluări

- A12 CanSat Technlology Forclimate Monitoring PDFDocument10 paginiA12 CanSat Technlology Forclimate Monitoring PDFDany PABON VILLAMIZARÎncă nu există evaluări