Documente Academic

Documente Profesional

Documente Cultură

Safe Operating Procedure For Furnace Operation and Noise Control in Foundry Industry

Încărcat de

MarkTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Safe Operating Procedure For Furnace Operation and Noise Control in Foundry Industry

Încărcat de

MarkDrepturi de autor:

Formate disponibile

ISSN 2319-8885

Vol.03,Issue.07,

May-2014,

Pages:1177-1179

www.semargroup.org,

www.ijsetr.com

Safe Operating Procedure for Furnace Operation and Noise Control in

Foundry Industry

B.KAVINKUMAR1, A.V.BALAN2

Abstract: The ultimate aim of an industry is to create a work place safe for their workers. One of the important ways to achieve

a safe working place is a safe working procedure. The aim of my project is to observe and analyze all unsafe working procedure

in all fettling operations and then prepare a Safe operating procedure in each operation in fettling area. Noise is a serious hazard

in many workplaces over time. If exposure to noise are not properly eliminated or controlled. It may cause permanent hearing

loss and fatigue in workers the foundry industry involves in the process like mould making castings, fettling, grinding and

CNC. In all these process and sub process noise is the important pollution which lead to create problems to the workers and

environment in a foundry enormous amount of noise will be generated. This may leads to employee hearing aids in a long run.

The aim of project is to perform Source noise monitoring and ambient noise monitoring and compare with IS regulations and

Control them with proper control measures where the noise limit is exceeds.

Keywords: Safe Operating Procedure, Furnace, Noise Control.

I. INTRODUCTION Conducting a Needs Assessment, describes elements for

A standard operating procedure is “an industrial directive an industrial process to examine existing SOPs, identify

that establishes a standard course of action.” In other words, shortfalls, and develop an action plan. Processes for

SOPs are written guidelines that explain what is expected and assessing the current operating environment, standard of

required for operating personnel in performing their jobs. A practice, and local needs are discussed.

comprehensive set of SOPs defines in significant detail how Developing standard operating procedure describes

the department intends to operate. Stated differently, SOPs generic steps and requirements for preparing a

don’t describe how to do the job (technical skills), they comprehensive set of SOPs. Related considerations

describe the department’s rules for doing the job (procedural include the use of committees or teams, staffing,

guidance). An example might help to clarify this point. mechanisms for gathering input, document formats, and

Operating an emergency vehicle requires both technical skills review and approval processes.

and procedural guidance. At present industrial organizations Implementing standard operating procedures discusses

face an insurmountable array of challenges in modern the requirements and systems needed to ensure that new

society. In an era of shrinking resources, departments must SOPs are understood and used correctly. Subjects

contend with: Expanding organizational missions emergency include planning, notification, distribution, accessibility,

medical care, hazardous materials response, technical rescue, training, and performance monitoring.

fire prevention/public education, and terrorism incidents.

Increasing legal and regulatory requirements safe work Evaluating standard operating procedure de fines the

practices, public and employee right-to-know, equal purpose and types of formal processes that departments can

opportunity (race, gender, age, disability), performance use to analyze the effectiveness of existing SOPs. General

standards, employee relations, and much more. Thus SOP for steps and a detailed case study are presented. At present

industries intended to serve as a planning guide and reference industrial organizations face an insurmountable array of

document for industries in developing, implementing, and challenges in modern society. In an era of shrinking

maintaining SOPs. It describes general concepts, related legal resources, departments must contend with: Expanding

authorities, specific steps, and resource requirements for organizational missions—emergency medical care, hazardous

managing the SOP process. materials response, technical rescue, fire prevention/public

education, and terrorism incidents. Increasing legal and

A. SOP Management Program regulatory requirements safe work practices, public and

The Role and function of SOPs describes the use and employee right-to-know, equal opportunity (race, gender,

content of SOPs in a typical foundry operation. Sample age, disability), performance standards, employee relations,

SOP categories are presented, and the relationship and much more. Increasing complexity in emergency

between SOPs and other foundry documents is explored. response techniques and equipment-personal protective

Copyright @ 2014 SEMAR GROUPS TECHNICAL SOCIETY. All rights reserved.

B.KAVINKUMAR, A.V.BALAN

measures, chemical safety, infection control, building and Traditionally, Occupational noise has been a hazard linked to

industrial codes, information management, training systems, heavy industries such as ship-building and associated only

and so forth. Increasing coordination and reporting with noise-induced hearing loss (NIHL). Modern thinking

requirements with other groups-emergency response in occupational safety and health identifies noise as

agencies, community managers and planners, mutual aid hazardous to worker safety and health in many places of

organizations, federal and state governments, member employment and by a variety of means. Noise can not only

associations, and others. cause hearing impairment (at long-term exposures of over

85 decibels (dB), known as an exposure action value), but it

also acts as a causal factor for stress and raises systolic blood

pressure. Additionally, it can be a causal factor in work

accidents, both by masking hazards and warning signals, and

by impeding concentration. Noise also acts synergistically

with other hazards to increase the risk of harm to workers. In

particular, noise and dangerous substances (e.g.

some solvents) that have some tendencies towards ototoxity

may give rise to rapid ear damage.

II. METHODOLOGY

A. SOP for Furnace Operations

• Observing and analyzing all operations in Furnace

operations.

• Analyzing the unsafe working procedures in each

operation in furnace.

• Preparing the SAFE OPERATING PROCEDURE for

each operation in furnace.

• Implementing SOP in each operation in furnace.

B. Noise Management System

Measure of Noise level In Different Exposure and

Sections of Industry.

Complying with the OSHA regulations.

Control of Noise Level.

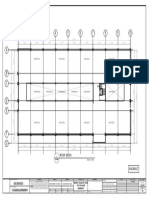

C. SOP for Furnace Operations

Metal charging EOT

Vibration feeder

Fig1. Process Flow In Foundry Slag removing operation

Industries must meet these growing requirements in an Supervisor

environment that it is a challenge. Budgets are tight and Metal transporting EOT

personnel are stretched thin. The experience of the workforce Tractor operator

may be declining due to a decrease in the number of Forklift operator

structural personalities and the retirement of more

experienced personnel. As a result, the decisions that III. RESULT

personnel face are more complex and controversial. Mistakes A. Sop for Furnace

have greater repercussions and costs. Emergency service Safe operating procedure has been created for all furnace

providers need help understanding and navigating the maze operations and verified with safety officer. Then made some

of regulatory and administrative requirements. Managers, on modifications and recommendations in the sop has suggested

the other hand, need a mechanism to convey operational my him and was approved. Soon it will be implemented has a

guidance to the members and ensure departmental safe working procedure which will result in reduction of

compliance with laws, regulations and standards. They need accident.

tools to direct and control the rapid pace of change. Noise is

unwanted sound. It can cause hearing loss disturb verbal B. Noise pollution control in foundry

communication or cause nuisance. By implementing noise management system in foundry

industry all source and ambient noise level have been

The most common sources and industrial noise can cause measured recommendation are provided to reduce the noise

damage to assets radiate noise or cause discomfort to people. level for both source and ambient soon all the recommended

Industrial noise is often a term used in relation to solution will be implemented resulting in reduction of noise

environmental health and safety, rather than nuisance, as level up to 15 dB until.

sustained exposure can cause permanent hearing damage.

International Journal of Scientific Engineering and Technology Research

Volume.03, IssueNo.07, May-2014, Pages: 1177-1179

Safe Operating Procedure for Furnace Operation and Noise Control in Foundry Industry

IV. CONCLUSION Author’s Profile:

Thus by analyzing all procedures, the unsafe actions in all

work procedure are identified and by implementing safe Mr.B.Kavinkumar, received his

operating procedure in all operations they are eliminated. B.TECH degree in Textile Technology

Thus by implementing a noise management system the noise from, K.S.R.College of Technology,

pollution level will be reduced 15dB more by the under Anna University and currently

recommended control measures. pursuing his M.E degree in Industrial

Safety Engineering from K.S.R.

V. REFERENCES College of Engineering under Anna

[1] Ted R. Miler. Injuries to workers and their dependents, University, Chennai. His research

Journal of Safety Research, Vol. 26. No. 2, pp. 75476.1995. interest includes Safety Culture and Behavioral Safety.

[2] MarcelloColledani, TullioTolio, Performance evaluation

of production systems monitored by statistical process Mr. A.V.Balan received B.E degree in

control and off-line inspections, Int. J. Production Economics Mechanical from V.R.S College of

120 (2009) 348–367. Engineering and Technology. He

received M.E degree in Industrial

[3] Kotzin E.L., Powers P.J. and Wagner A.J.: Foundry waste Engineering from Kumaraguru College

Management, American Foundry men’s Society Des Plaines, of Engineering. He is currently working

Illinois, 1982. as Associate Professor in Department of

Mechanical Engineering in K.S.R. College of Engineering,

[4] Nuhu A. Ademoh Evaluation of the foundry properties of Erode. His teaching experience is of 10 years. His research

river Niger sand behind ajaokuta steel company limited, interest includes Dynamics of Machinery, Welding

ajaokuta, Nigeria, American-Eurasian Journal of Scientific Technology and Machine Tools.

Research 3 (1): 75-83, 2008.

[5] Assessment and Control of Noise Pollution in Mining

Industry, Proceedings of National Seminar held by Institution

of Engineers at Madras, 1989.

[6] Environmental Noise Pollution and its Control,

Proceedings of Specialist Course, Institution of Engineers,

Roorkee, India 1992.

[7] Sayed Abas Ali, “Industrial noise levels and annoyance in

Egypt” Department of Architecture, Faculty of Engineering,

Assiut University, Assiut, Egypt 2010.

[8] Oyedepo sunday olayinka “noise map: tool for abating

noise pollution in urban Mechanical Engineering

Department, Covenant University, Ota, Nigeria.

[9] Mangalekar S.B., Jadhav A.S. and Raut P.D“ Study of

Noise Pollution in Kolhapur City, Maharashtra” Department

of Environmental Science, Shivaji University, Kolhapur

416004.

[10] Vartika singh and pramendra dev “ environmental

impacts of noise pollution - a case study of Saharanpur city”

School of Studies in Earth Science, Vikram University,

Ujjain, M. P. 456010, India.

International Journal of Scientific Engineering and Technology Research

Volume.03, IssueNo.07, May-2014, Pages: 1168-1171

S-ar putea să vă placă și

- Dimensions of FurnaceDocument1 paginăDimensions of FurnaceMarkÎncă nu există evaluări

- First Floor Plan As-Built: H A L L W A YDocument1 paginăFirst Floor Plan As-Built: H A L L W A YMarkÎncă nu există evaluări

- Second Floor Plan As-Built: H A L L W A YDocument1 paginăSecond Floor Plan As-Built: H A L L W A YMarkÎncă nu există evaluări

- Math & Eng Eco General Evaluation Exam Problems and Elements (With Answers and Solutions)Document22 paginiMath & Eng Eco General Evaluation Exam Problems and Elements (With Answers and Solutions)JustinMendiolaÎncă nu există evaluări

- General Notes: Marry Cause of Our Joy College SeminaryDocument1 paginăGeneral Notes: Marry Cause of Our Joy College SeminaryMarkÎncă nu există evaluări

- A Bolt Is StrengthenDocument1 paginăA Bolt Is StrengthenMarkÎncă nu există evaluări

- First Floor Plan As-Built: H A L L W A YDocument1 paginăFirst Floor Plan As-Built: H A L L W A YMarkÎncă nu există evaluări

- Elevator Copy AS M1 PDFDocument1 paginăElevator Copy AS M1 PDFMarkÎncă nu există evaluări

- Power Plant Coaching.Document352 paginiPower Plant Coaching.Wati KaÎncă nu există evaluări

- CAFSDDocument1 paginăCAFSDMarkÎncă nu există evaluări

- Roof Deck: Roof Deck Roof Deck Roof Deck Roof DeckDocument1 paginăRoof Deck: Roof Deck Roof Deck Roof Deck Roof DeckMarkÎncă nu există evaluări

- Sample Hydraulic Calculation PDFDocument5 paginiSample Hydraulic Calculation PDFsachinsaklani23Încă nu există evaluări

- Birbal Sahni Institute of Palaeobotany,: 53, University Road, Lucknow - 226 007Document20 paginiBirbal Sahni Institute of Palaeobotany,: 53, University Road, Lucknow - 226 007MarkÎncă nu există evaluări

- SongsDocument1 paginăSongsMarkÎncă nu există evaluări

- Kents Mechanical Engineers Handbook 11th EditionDocument4 paginiKents Mechanical Engineers Handbook 11th EditionMark14% (7)

- Steps To Completing Sprinkler Layout 2012Document24 paginiSteps To Completing Sprinkler Layout 2012Anonymous qrSsYuxyoYÎncă nu există evaluări

- Metric Weight1Document2 paginiMetric Weight1Nilawu Karasi SubramaniamÎncă nu există evaluări

- Article - Tax Aspects of Chillers - Oct 2010 - Corporate Business Taxation MonthlyDocument4 paginiArticle - Tax Aspects of Chillers - Oct 2010 - Corporate Business Taxation MonthlyMarkÎncă nu există evaluări

- Bangsamoro Basic Law PDFDocument101 paginiBangsamoro Basic Law PDFJennifer Sheils Baliog HollanesÎncă nu există evaluări

- Mtcyclestudy 20309 7Document2 paginiMtcyclestudy 20309 7Sk.Abdul NaveedÎncă nu există evaluări

- Birbal Sahni Institute of Palaeobotany,: 53, University Road, Lucknow - 226 007Document20 paginiBirbal Sahni Institute of Palaeobotany,: 53, University Road, Lucknow - 226 007MarkÎncă nu există evaluări

- Insulating Firebrick Data SheetDocument1 paginăInsulating Firebrick Data SheetJackÎncă nu există evaluări

- Determining Thickness of First Layer of FurnaceDocument2 paginiDetermining Thickness of First Layer of FurnaceMarkÎncă nu există evaluări

- Tintin Swot AnalysisDocument1 paginăTintin Swot AnalysisMarkÎncă nu există evaluări

- Mightype Script Help FileDocument1 paginăMightype Script Help FileMarkÎncă nu există evaluări

- Hanoded Fonts License & FAQ - DO READ PDFDocument2 paginiHanoded Fonts License & FAQ - DO READ PDFAnonymous HyIqXpQÎncă nu există evaluări

- PredictAny - Mobile Site - FinalDocument79 paginiPredictAny - Mobile Site - FinalMarkÎncă nu există evaluări

- 2008 RCJ SCR XDocument8 pagini2008 RCJ SCR XMarkÎncă nu există evaluări

- Energy Report PhilippinesDocument45 paginiEnergy Report PhilippinesMark100% (1)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- United Nations Reviewer 100 Questions and AnswersDocument12 paginiUnited Nations Reviewer 100 Questions and Answersdanchristian peregrino100% (1)

- Human Resource DevelopmentDocument150 paginiHuman Resource DevelopmentMeshan Govender100% (1)

- LECTURE 1.COMMUNICATION PROCESSES, PRINCIPLES, AND ETHICS - Ver 2Document24 paginiLECTURE 1.COMMUNICATION PROCESSES, PRINCIPLES, AND ETHICS - Ver 2Trixia Nicole De LeonÎncă nu există evaluări

- Mental Rotations Um, LÑKM,, (PDocument6 paginiMental Rotations Um, LÑKM,, (PAlfonsoÎncă nu există evaluări

- ASEAN Work Plan On Youth 2021 2025Document94 paginiASEAN Work Plan On Youth 2021 2025Gregor CleganeÎncă nu există evaluări

- Brochure PDFDocument10 paginiBrochure PDFKhairatun NisaÎncă nu există evaluări

- Memorandum of Understanding TemplateDocument3 paginiMemorandum of Understanding TemplateMARY ROSE CAGUILLOÎncă nu există evaluări

- PR2 FInals Wk2 ModuleDocument5 paginiPR2 FInals Wk2 ModuleErick John SaymanÎncă nu există evaluări

- 1528300544KS2005Document184 pagini1528300544KS2005GeorgeÎncă nu există evaluări

- Daniel LibeskindDocument26 paginiDaniel LibeskindHit MendaparaÎncă nu există evaluări

- Typical & AtypicalDocument2 paginiTypical & Atypicalzarquexia 02Încă nu există evaluări

- PS Vacancies Gazette Vol. 180 7-9-22 Special Issue (PSC) - 1Document2 paginiPS Vacancies Gazette Vol. 180 7-9-22 Special Issue (PSC) - 1Kiki MateÎncă nu există evaluări

- CHE 311 CHE Calculations IDocument4 paginiCHE 311 CHE Calculations IMikho SaligueÎncă nu există evaluări

- Personal Development Record PDR - 2018-19Document9 paginiPersonal Development Record PDR - 2018-19MickeyÎncă nu există evaluări

- Resume Hamza Rashid 10-19-2023 12-02-17 PM - CompressedDocument2 paginiResume Hamza Rashid 10-19-2023 12-02-17 PM - CompressedSheikh AbdulÎncă nu există evaluări

- 家庭作业奖励Document7 pagini家庭作业奖励ewaefgsvÎncă nu există evaluări

- Cbse - Department of Skill Education Curriculum For Session 2021-2022Document15 paginiCbse - Department of Skill Education Curriculum For Session 2021-2022Ashutosh ParwalÎncă nu există evaluări

- Session Plan: Performing Vehicle Inspection As Per Manufacturer's Specification Light Vehicle 1 HourDocument3 paginiSession Plan: Performing Vehicle Inspection As Per Manufacturer's Specification Light Vehicle 1 HourJude PellerinÎncă nu există evaluări

- Family AssessmentDocument7 paginiFamily Assessmentapi-267488377Încă nu există evaluări

- TLEG 10 Q2Module 1HWM Schedule Clients 1.1 Cummunication Skills 1.2 Telephone EtiquetteDocument16 paginiTLEG 10 Q2Module 1HWM Schedule Clients 1.1 Cummunication Skills 1.2 Telephone EtiquetteKatrina F. SernalÎncă nu există evaluări

- Independent University, Bangladesh Department of Environmental Management Course OutlineDocument9 paginiIndependent University, Bangladesh Department of Environmental Management Course OutlineZarin ChowdhuryÎncă nu există evaluări

- STUDENTS' METACOGNITIVE STRATEGIES, MOTIVATION AND GOAL ORIENTATION: ROLE TO ACADEMIC OUTCOMES IN SCIENCE Authored By: JONATHAN P. CRUZDocument73 paginiSTUDENTS' METACOGNITIVE STRATEGIES, MOTIVATION AND GOAL ORIENTATION: ROLE TO ACADEMIC OUTCOMES IN SCIENCE Authored By: JONATHAN P. CRUZInternational Intellectual Online PublicationsÎncă nu există evaluări

- Abcs and FbaDocument9 paginiAbcs and Fbaapi-494541908Încă nu există evaluări

- Umair Paracha: Contact InfoDocument2 paginiUmair Paracha: Contact InfoUmairÎncă nu există evaluări

- Romeo and Juliet Summative Assessment RubricsDocument2 paginiRomeo and Juliet Summative Assessment Rubricsapi-502300054Încă nu există evaluări

- Importance of HydrologyDocument10 paginiImportance of HydrologyLalith Koushik Ganganapalli100% (1)

- Art of Writing Research Papers - BrochureDocument4 paginiArt of Writing Research Papers - BrochureDr. Felice JoyÎncă nu există evaluări

- Lesson Plan On Formal Letter WritingDocument3 paginiLesson Plan On Formal Letter WritingSonal Bhatia60% (5)

- Managing HR in Turbulent TimesDocument47 paginiManaging HR in Turbulent TimesSushilÎncă nu există evaluări