Documente Academic

Documente Profesional

Documente Cultură

Model 210 Digital Electro-Hydraulic Set Stop

Încărcat de

ykozeDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Model 210 Digital Electro-Hydraulic Set Stop

Încărcat de

ykozeDrepturi de autor:

Formate disponibile

Smith Meter Valves ®

Model 210 Digital

Electro-Hydraulic Set-Stop

Specifications

Issue/Rev. 0.9 (2/12) Bulletin SS03009

The Smith Meter ® Model 210 Valve is typically used in

conjunction with either the Smith Meter A ccuLoad ® or

microLoad Preset Controllers for loading and unloading

at truck racks, bulk plants, or processing installations.

Features

Simple control loop

Control loop needle valves for tuning

Low pressure drop

Separate opening and closing speed control

Compound spring

Horizontal or vertical applications

Full range of optional control functions

Optional cover to vent to low downstream pressure, opening the

main valve. Conversely, de-energizing both solenoids

2" Reduced Port Valve – Ideal for renewable fuels allows high upstream pressure to close the valve.

blending, controlling flow down to 3 GPM. Energizing just the N.O. solenoids locks fluid in the valve

cover, which locks the valve poppet in a fixed position,

to maintain a constant flow rate as long as operating

Operation conditions do not change. When operating conditions

(e.g., pressures) change, causing a change in flow rate

The Smith Meter Model 210 Valve is a Smith Meter 200 for that fixed valve opening, the flow controller (e.g. Ac-

Series Valve with two solenoid controls (see Figure 1). cuLoad or microLoad) signals the appropriate solenoid

The normally-open (N.O.) and normally-closed (N.C.) to open momentarily to readjust flow rate back to its set

solenoids, located in the upstream and downstream value. When the set flow rate changes (e.g., from low

portions of the control loop, respectively, control the op- flow start to high flow limit, or during multi-step valve

eration of the valve. With both solenoids energized, high shutdown), the appropriate solenoid is signalled to open

upstream pressure is blocked allowing the product in the until flow rate adjusts to the new set value. See Figure 2

for a typical truck loading flow rate sequence.

Located between each solenoid and the main valve port is

a valve response control device, typically a needle valve.

N.O. N.C.

Solenoid Solenoid

(30B) (30A)

Flow Rate GPM First Stage Trip*

900

600 Final

Gallons* Stage Trip*

First High Flow Rate*

300

Second High Flow Rate*

0 Low Flow Start*

2,000 60 0

Opening

Gallons to Be Delivered

Closing

Speed Speed *Field programmable.

Control Control

Caution: There must be sufficient pump capacity to achieve

Strainer the flow rate set into the AccuLoad, or microLoad or the

valve may close slowly resulting in a spill.

Flow

Figure 1 – Model 210 Valve Schematic Figure 2 – Typical Load Cycle

The Most Trusted Name In Measurement

This device is used to fine tune the opening/closing rate of Voltage (Solenoids)

the valve, as well as providing total control loop isolation Standard: 120 Vac / 60 Hz or 110 Vac / 50 Hz.

for ease of service. Adjustment of these devices controls

Optional: 240 Vac / 60 Hz or 220 Vac / 50 Hz.

the flow to the cover chamber, permitting adjustments

24 Vdc.

based on product viscosities and pressures.

12 Vdc.

Other voltages, consult factory.

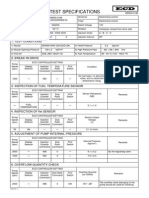

Specifications

Materials of Construction

Maximum Viscosity

Up to 200 SSU (40 mPa•s)1. Housing Internals Seals

Above 200 SSU (40 mPa•s), consult factory. Main Valve Cast Steel Stainless Steel, Low Swell

Carbon Steel, Buna (Std.),

Pressure Rating/Connections 2, 3, 4 Ni-Resist Viton-A or

Class 150 ASME, 285 psi (19.6 bar) Ductile Iron Buna (Opt.)

Solenoid Stainless Steel Stainless Steel Viton-F (Std.),

Class 300 ASME, 300 psi (20.7 bar)

Valves Buna-N,

Temperature Range Chemraz (Opt.)

Needle Steel Steel Viton/PTFE6

Valve Elastomer Temperature Range2, 5 Valves+ See Note Below

LS (Low Swell) Buna -20°F to 200°F (-28°C to 93°C) Tubings & – Steel –

Buna-N -20°F to 200°F (-28°C to 93°C) Fittings See Note Below

Viton -20°F to 350°F (-28°C to 177°C) Ball Valves* Steel Chrome Plated PTFE6

See Note Below Steel Ball/Steel

Body

+Standard.

*Optional (for 4" and 6" only).

Note: Stainless Steel Ball Valves, Needle Valves, and/or Tubing and

Fittings Available.

Pressure Drop (When Valve is Not Flow-Limiting or Wide Open)

Flow Rate (LPM)

40 100 250 500 1,000 2,500 5,000 10,000 20,000

20

18 120

3"

16

4" 6" 100

2” RP

14

2"

12 80

Pressure Drop

∆P ∆P

PSI 10 kPa

60

8

6 40

4

20

2

0

10 50 100 2 3 4 5 6 7 8 1,000 2 3 4 5 6 7 8 10,000

Flow Rate (GPM)

Notes: Assumes that a dual spring is used in 4" and 6" valves.

Test fluid is kerosene with 0.82 sp. gr., 2 cP or mPa•s

The 2" and 2" RP (Reduced Port Valve) have negligible pressure drop below 50 GPM when the valve is not flow limiting.

1 1 mPa•s = 1 cP.

2 Pressure ratings are based on temperatures of -20°F to 100°F (-28°C to 38°C). For operation at higher temperatures, the maximum working

pressure may be derated.

3 PED requirements limit applications to liquids with maximum vapor pressures of .5 bar above atmospheric pressure, at maximum allowable

temperature.

4 PED required for all European countries. Equipment must be manufactured by Ellerbek, Germany facility.

5 For temperature outside these ranges, consult factory.

6 Polytetrafluoroethylene (PTFE).

Page 2 • SS03009 Issue/Rev. 0.9 (2/12)

Dimensions

Inches (mm)

A A B B

Size Class 150 Class 300 Class 150 Class 300 C Weight

ASME ASME ASME ASME (lb)

Flange Flange Flange Flange

C 2" & 8.0" 8.5" 3.0" 3.3" 5.5"

46

2" RP (203) (216) (76) (84) (140)

11.0" 11.8" 3.8" 4.1" 7.0"

3" 83

(279) (300) (97) (104) (178)

13.5" 14.1" 4.5" 5.0" 8.0"

4" 136

B (343) (358) (114) (127) (203)

17.0" 17.9" 5.5" 6.3" 10.8"

6" 258

(432) (455) (140) (160) (274)

A

Note: Dimensions – Inches to the nearest tenth (millimeters to the nearest whole mm), each independently dimensioned from respective

engineering drawings.

Catalog Code

This code is part of the ordering information and should be included on the purchase order.

1 2 3 4 5 6 7 8 9 10 11

K 3 2 1 0 2 L V 1 1 0

ositions 1 and 2: Product Line

P Position 8: Solenoid Elastomers

K3 - Valves V - Viton

C - Chemraz

Positions 3 thru 5: Model

210 - Digital Electrohydraulic Set Stop Positions 9 thru 11: Solenoid Voltage

1 - 110 Vac

Position 6: Size 2 - 220 Vac

2 - 2" 150 ASME

3 - 3" 150 ASME

4 - 4" 150 ASME

Position 7: Main Valve Elastomers

L - Low Swell Buna

B - Buna-N

V - Viton

Ordering Information

1. Consult factory for 300 ANSI rating.

2. Consult factory for other voltage ratings.

3. Consult factory before ordering valve with Buna

Elastomers.

Issue/Rev. 0.9 (2/12) SS03009 • Page 3

Revisions included in SS03009 Issue/Rev. 0.9 (2/12):

Page 1: Removed Model SS1 and MiniLoad controllers; added microLoad controller as option.

Page 2: Revisions made to Materials of Construction.

Page 2: Removed epoxy coating from main valve internals under materials of construction.

Page 2: Voltage (Solenoids) revised.

Editorial Change: 10/13: Elastomer reference was changed to PTFE.

Headquarters: Operations: The specifications contained herein are subject to change without notice and any user of said

500 North Sam Houston Parkway West, Measurement Products and Equipment: specifications should verify from the manufacturer that the specifications are currently in effect.

Suite 100, Houston, TX 77067 USA Ellerbek, Germany +49 (4101) 3040 Otherwise, the manufacturer assumes no responsibility for the use of specifications which

Phone: +1 (281) 260 2190 Erie, PA USA +1 (814) 898 5000 may have been changed and are no longer in effect.

Fax: +1 (281) 260 2191

Contact information is subject to change. For the most current contact information, visit our

Integrated Measurement Systems:

website at www.fmctechnologies.com/measurementsolutions and click on the “Contact Us”

Corpus Christi, TX USA +1 (361) 289 3400 link in the left-hand column.

Kongsberg, Norway +47 (32) 286700

www.fmctechnologies.com/measurementsolutions

Printed in U.S.A. © 2/12 FMC Technologies Measurement Solutions, Inc. All rights reserved. SS03009 Issue/Rev. 0.9 (2/12)

S-ar putea să vă placă și

- Larsen and Toubro RVNL Bid Document Rock Bolts PDFDocument240 paginiLarsen and Toubro RVNL Bid Document Rock Bolts PDFSubhash Kedia100% (1)

- Catalogo Sherwood GLPDocument87 paginiCatalogo Sherwood GLPMiller Alexander Mora VargasÎncă nu există evaluări

- Man Dio55 UkDocument18 paginiMan Dio55 UkQuang BáchÎncă nu există evaluări

- Ahlborn Hymnus IV - Manual de UsuarioDocument94 paginiAhlborn Hymnus IV - Manual de Usuariogonbaa0% (1)

- Fluke 719 721 750P Series CSA Certificate of ConformityDocument2 paginiFluke 719 721 750P Series CSA Certificate of ConformityMiguel Ruiz100% (1)

- Scanner 2000 Technical Data SheetDocument4 paginiScanner 2000 Technical Data SheetDennis Espinoza Rospigliosi100% (1)

- 1 5 1Document5 pagini1 5 1daemsalÎncă nu există evaluări

- HE Mini-Pak 6 ManualDocument100 paginiHE Mini-Pak 6 ManualJavier Alejandro QuingaÎncă nu există evaluări

- COMPRESOR KAESER Ask - T - SeriesDocument136 paginiCOMPRESOR KAESER Ask - T - SeriesTALLER NUEVEDEJULIO SATÎncă nu există evaluări

- 2600 Series Catalog R3Document96 pagini2600 Series Catalog R3Mrr Afrasiabi100% (1)

- Spirajet Spray NozzleDocument2 paginiSpirajet Spray NozzleykozeÎncă nu există evaluări

- UP6 15, UP6 20, UP6 25, UP6 30 60Hz: Intellisys Option Dryer Option High Dust Option Outdoor Module Option PORO OptionDocument226 paginiUP6 15, UP6 20, UP6 25, UP6 30 60Hz: Intellisys Option Dryer Option High Dust Option Outdoor Module Option PORO Optionrfg21100% (1)

- Valvula Set StopDocument107 paginiValvula Set StopAngel LRÎncă nu există evaluări

- Terminal Pisco MDocument821 paginiTerminal Pisco MMarcos Vidal GarciaÎncă nu există evaluări

- RC WBHE Series PDFDocument180 paginiRC WBHE Series PDFGlacialÎncă nu există evaluări

- Tunnels and Suport SystemsDocument33 paginiTunnels and Suport SystemsShella Marie Nartatez-NiroÎncă nu există evaluări

- WEG CFW 11 Variable Speed Drives1Document32 paginiWEG CFW 11 Variable Speed Drives1Marco PosadaÎncă nu există evaluări

- GA Fluxi 2000 TZ InstructionManual 652 099 2025 - TZ - 09 10 2014Document56 paginiGA Fluxi 2000 TZ InstructionManual 652 099 2025 - TZ - 09 10 2014Muhammad Darussalam HerdaniÎncă nu există evaluări

- Er-105-1-1 - Proflo No-Flow SwitchDocument10 paginiEr-105-1-1 - Proflo No-Flow SwitchJeff LÎncă nu există evaluări

- Hoja Tecnica BartonDocument4 paginiHoja Tecnica BartonjairoÎncă nu există evaluări

- Catalogo de Partes Compresor Ingersoll Rand PDFDocument34 paginiCatalogo de Partes Compresor Ingersoll Rand PDFHarold Joel Zurita LinaresÎncă nu există evaluări

- (SB007A3) Smith Meter® AccuLoad® III Controller and Microload - Net™Document3 pagini(SB007A3) Smith Meter® AccuLoad® III Controller and Microload - Net™Roberto Carlos TeixeiraÎncă nu există evaluări

- Hi-T Pigalert IOM ManualDocument14 paginiHi-T Pigalert IOM ManualRaghÎncă nu există evaluări

- Asco Valve 8262h 8263h GP Spec r3Document4 paginiAsco Valve 8262h 8263h GP Spec r3Anonymous 6VCG1YRdÎncă nu există evaluări

- Compact Prover Datasheet PDFDocument12 paginiCompact Prover Datasheet PDFMary Soledad Huarcaya EspinoÎncă nu există evaluări

- Instruction Manual 977 Tank Side IndicatorDocument28 paginiInstruction Manual 977 Tank Side IndicatorThái NgọcÎncă nu există evaluări

- PCM3 Honeywell AditivaciónDocument6 paginiPCM3 Honeywell AditivaciónJESUS SANCHEZ GOMEZÎncă nu există evaluări

- GMP17PX6Document5 paginiGMP17PX6filolocoÎncă nu există evaluări

- Mini Pak HoneywellDocument78 paginiMini Pak Honeywellliviu_dovaÎncă nu există evaluări

- Ccs SW 6900 GZEDocument35 paginiCcs SW 6900 GZEGabriel MendezÎncă nu există evaluări

- Kenco KlceDocument6 paginiKenco KlcenelsonÎncă nu există evaluări

- Carbon Steel Strainer Fig 34 HP-Technical InformationDocument3 paginiCarbon Steel Strainer Fig 34 HP-Technical InformationSouljah KhifferÎncă nu există evaluări

- P0134Document2 paginiP0134johnny_nfs_2Încă nu există evaluări

- Manual de FPP TsDocument28 paginiManual de FPP TsAlexander CallaÎncă nu există evaluări

- Temperature Probes Thermowells: Smith Meter® Electronic EquipmentDocument4 paginiTemperature Probes Thermowells: Smith Meter® Electronic EquipmentiptusÎncă nu există evaluări

- Practica # 2 PRV2SIZE PDFDocument4 paginiPractica # 2 PRV2SIZE PDFCarmen Zurita VeizagaÎncă nu există evaluări

- Slide Bearing EM9S 80 100Document6 paginiSlide Bearing EM9S 80 100Pierre RiquelmeÎncă nu există evaluări

- BOA H DatabookletDocument14 paginiBOA H DatabookletRicardo BarrosÎncă nu există evaluări

- IQ3 Standard Uhendusskeem 100B0000Document2 paginiIQ3 Standard Uhendusskeem 100B0000hassan hassanÎncă nu există evaluări

- Aggregate Sieve Analysis Quality Control and Inspection Report FormDocument1 paginăAggregate Sieve Analysis Quality Control and Inspection Report FormMOST PASONÎncă nu există evaluări

- Powerpress ANDRITZDocument4 paginiPowerpress ANDRITZCesar LapaÎncă nu există evaluări

- Instructions 95-8581: Inspector Monitor Software For Use With Det-Tronics X-Series Flame DetectorsDocument19 paginiInstructions 95-8581: Inspector Monitor Software For Use With Det-Tronics X-Series Flame DetectorsRoberto HernandezÎncă nu există evaluări

- Genie Manual Genie em InglesDocument69 paginiGenie Manual Genie em Inglescesar892000Încă nu există evaluări

- Annex 5 API 650 Storage Tanks Certificate of Compliance SampleDocument3 paginiAnnex 5 API 650 Storage Tanks Certificate of Compliance SampleLi LiuÎncă nu există evaluări

- DELTA VFD-MS300 ManualDocument512 paginiDELTA VFD-MS300 ManualDavidÎncă nu există evaluări

- Am25ck PDFDocument2 paginiAm25ck PDFLogan Marquez AguayoÎncă nu există evaluări

- MODELS 202E/208E Differential Pressure Recorders Installation ManualDocument48 paginiMODELS 202E/208E Differential Pressure Recorders Installation Manualcami90_384375Încă nu există evaluări

- Engrasadora NEUMATICAFLOWSERVERDocument16 paginiEngrasadora NEUMATICAFLOWSERVERLuis E. Barcelo TovarÎncă nu există evaluări

- D.P.transmitter Spriano 47B ManualDocument22 paginiD.P.transmitter Spriano 47B ManualBruno100% (1)

- FUP1010 Inst PDFDocument286 paginiFUP1010 Inst PDFKristen CollierÎncă nu există evaluări

- ZLND 080400Document2 paginiZLND 080400Planeador MantenimientoÎncă nu există evaluări

- HNS Quick Start Guide - Rev.0 PDFDocument9 paginiHNS Quick Start Guide - Rev.0 PDFCarlos MagÎncă nu există evaluări

- MEDIDAS TURBINA Dresser Imtm MeretDocument3 paginiMEDIDAS TURBINA Dresser Imtm MeretronaldÎncă nu există evaluări

- Válvula 2 Stage Step StopDocument34 paginiVálvula 2 Stage Step Stopmichelin25Încă nu există evaluări

- Genesis Series 3 Steel Meter Parts ListDocument4 paginiGenesis Series 3 Steel Meter Parts Listjimbo2032Încă nu există evaluări

- Stock List PDFDocument4 paginiStock List PDFAL Wahid SpareÎncă nu există evaluări

- 096500-0180 Plano TesteDocument4 pagini096500-0180 Plano TesteJunior IungÎncă nu există evaluări

- Golink Temperature Controller Fy SeriesDocument2 paginiGolink Temperature Controller Fy SeriesJulio OchoaÎncă nu există evaluări

- Ss 03009Document4 paginiSs 03009hesam asgariÎncă nu există evaluări

- 210 Control Valve NewDocument4 pagini210 Control Valve Newabdulhayee199811Încă nu există evaluări

- Válvula 210 FMC - CatálogoDocument4 paginiVálvula 210 FMC - CatálogoGustavoSilvinoSilvinoÎncă nu există evaluări

- Ss 03034Document4 paginiSs 03034Necati Yunus OrbayÎncă nu există evaluări

- Series Features: Two-Stage Preset ValveDocument2 paginiSeries Features: Two-Stage Preset Valvefernando.juarezpetroserviciosÎncă nu există evaluări

- Ss 03010Document4 paginiSs 03010Necati Yunus OrbayÎncă nu există evaluări

- Rate of Flow and Fuel Shut Off Valve: ModelDocument2 paginiRate of Flow and Fuel Shut Off Valve: Modelanon_867776278Încă nu există evaluări

- Flow Control PDFDocument4 paginiFlow Control PDFachmadinÎncă nu există evaluări

- 3 PM Project Execution 2015Document81 pagini3 PM Project Execution 2015ykozeÎncă nu există evaluări

- Spiral Jet Technical DocumentDocument3 paginiSpiral Jet Technical DocumentykozeÎncă nu există evaluări

- Smith Meter MicroLoadnet Installation ManualDocument46 paginiSmith Meter MicroLoadnet Installation ManualykozeÎncă nu există evaluări

- Alfa 50 RegulatorDocument2 paginiAlfa 50 Regulatorykoze100% (1)

- HAZOP TemplateDocument1 paginăHAZOP TemplateykozeÎncă nu există evaluări

- Cmus Cheat SheetDocument1 paginăCmus Cheat Sheetvoll macuserÎncă nu există evaluări

- Carrier SelectionDocument13 paginiCarrier SelectionRanesh SinglaÎncă nu există evaluări

- CTK230Document15 paginiCTK230barryhernsÎncă nu există evaluări

- PTWDocument3 paginiPTWAngel Silva VicenteÎncă nu există evaluări

- Exact Solution Tank DrainageDocument8 paginiExact Solution Tank DrainageFelipe CastÎncă nu există evaluări

- ARM926EJ-S System CoreWare Product BriefDocument2 paginiARM926EJ-S System CoreWare Product Briefmakumba1972Încă nu există evaluări

- Articles TurbineDocument442 paginiArticles TurbineKevin RichardÎncă nu există evaluări

- K SedimentationDocument13 paginiK SedimentationKitty VÎncă nu există evaluări

- QUBEDocument2 paginiQUBEJován MéridaÎncă nu există evaluări

- 2018 Radio Programming GuidesDocument21 pagini2018 Radio Programming GuidesCesar Del CastilloÎncă nu există evaluări

- Workshop Microproject ListDocument2 paginiWorkshop Microproject ListABDUL KADIR MUZAMMIL HUSAIN KHANÎncă nu există evaluări

- UL FM Vertical Indicator Post Maintenance and Operation Manual - Fire Protection - Models 5400 & 5450Document7 paginiUL FM Vertical Indicator Post Maintenance and Operation Manual - Fire Protection - Models 5400 & 5450Juan Jose Teodoro AguilarÎncă nu există evaluări

- Congratulations On The Purchase of Your New Antari Z Series Fog MachineDocument20 paginiCongratulations On The Purchase of Your New Antari Z Series Fog MachineWalter SeidlÎncă nu există evaluări

- Schneider ElectricCahier Technique No. 199Document36 paginiSchneider ElectricCahier Technique No. 199Alda EnglandÎncă nu există evaluări

- Flow Meters Butt WeldDocument3 paginiFlow Meters Butt WeldPan GulfÎncă nu există evaluări

- Cooling Coil SizingDocument4 paginiCooling Coil SizingRanu JanuarÎncă nu există evaluări

- AdClient SDK For Android 4.3.0 PDFDocument48 paginiAdClient SDK For Android 4.3.0 PDFOscarGomezÎncă nu există evaluări

- MZP10000000-30010-MTS-TC - 000007 - T&C Ahu & Fahu - FinalDocument59 paginiMZP10000000-30010-MTS-TC - 000007 - T&C Ahu & Fahu - FinalFaiyazsulthanÎncă nu există evaluări

- ColorCells CC784 ProgrammingGuideDocument20 paginiColorCells CC784 ProgrammingGuideTom SteinhauerÎncă nu există evaluări

- Wireless Local Loop: A Seminar Report OnDocument12 paginiWireless Local Loop: A Seminar Report OnYesh DamaniaÎncă nu există evaluări

- Certification For 4 Hyton Crescent, KewDocument1 paginăCertification For 4 Hyton Crescent, KewWaelElMeligiÎncă nu există evaluări

- Experiment 1Document5 paginiExperiment 1Cheng BauzonÎncă nu există evaluări

- What MobileDocument100 paginiWhat MobiledoarraulÎncă nu există evaluări

- Parts Manual: L6/L8 60HZ (C45, C48, C49, D88, D89, G10, & G11) L6/L8 50HZ (B39)Document77 paginiParts Manual: L6/L8 60HZ (C45, C48, C49, D88, D89, G10, & G11) L6/L8 50HZ (B39)Marquinhos CastroÎncă nu există evaluări

- Modeling Complex Zo For Op AmpsDocument28 paginiModeling Complex Zo For Op Ampswalid OUNISÎncă nu există evaluări