Documente Academic

Documente Profesional

Documente Cultură

QC Staff Rizqi Fatulloh

Încărcat de

RizqiDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

QC Staff Rizqi Fatulloh

Încărcat de

RizqiDrepturi de autor:

Formate disponibile

NO

Registration date

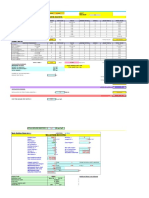

QC Story Sheet 【Section】

Production Engineering △ ×

date

/ GM

Aproval

Manger QC leader

(Subject)

Theme : Optimalization SVC Reduction Activity 【Name】 △ × /

Finish date Rizqi Fatulloh △ × /

Title : Reman Wiring Harness Injector △ × /

1.Background/Theme selection 5.Analysis 7.Result & Effect

- Management Policy 5.1 Metode

1. High Quality Product Reman of analysis

2. Cost SVC Reduction Activity

2.Current Status & Issue

1. Plan Prod Engine All Model FY2017 2. Clarification base 3. Plan Prod Engine Model 12V140

on Model Associativ

e

Base on Machine Diagram

Model, HD 785-7

is Popular Model

Engine 12V140 is Base on this analysis

Popular Model we need Refference Data of Reman Manual, Drawing and Durability of Wire harness for

reman process

4. Pareto Part HD785-7 6. Improvement

(100% Replace & Highest of Amount Cost) Target Improvement : Verification Data Based on Analysis

Reman Wiring Harness Injector with the Good

Quality and Good Durability of wire harness

About Wiring Harness injector

Note

Can't Reman

(policy KLTD)

Finish

Improvement

Target

Improvement

Introduction of measurement insulation resistance

Location Wiring Harness

Injector in Cyl Head

Engine.

it is 1st sense for reman

electrical part

The Function of wire Harness Injector is connectivity electricity from controller engine to

Injector.

Trial 1. Measure Insulation Trial 2. Measure wire harness <2000

3.Target Resistance Base onMΩdata trial 1, we want to know about root cause

Current Condition, Cost Part Wiring Base on BP FY2017 Decide Target problem for each pcs wiring harness <2000 MΩ. so we are

cutting for each portion to know detail problem (portion a, b

and c like in picture)

8.Standarization

TARGET

$ 37,406

SAVING

$ 29,925

All Part, New and Reuse within Standart, but we Create Working Standard base on

found of Reused characteristic different within New Improvement Activity (SOP & Checkhsset)

characteristic

No Correlation between insulation value with

SMR 9.Yokonirami

$ 7,481

Current Model Engine 12V140 Yokonirami to All Engine

Base on this data, why does in portion C value 16D140 ries

Target to Reduce Replacement Ratio decrease?

10.Challenges for future

Become 20%

Dec '15 Jan'17 Feb'17 Mar'17 Apr'17

Item

W3 W4 W1 W2 W3 W4 W1 W2 W3 W4 W1 W2 W3 W4 W1 W2

CONTINUE PDCA FOR

6. Plan & Actual (Sche)

Menentukan Tema ACHIVEMENT

Kondisi saat ini & Menentukan Target REPLACEMENT RATIO

Membuat Rencana Perbaikan WIRING HARNESS UNTIL

20%

Analisa Penyebab Masalah

Melaksanakan Rencana Perbaikan

Evaluasi Hasil

Standarisasi

Rencana Berikutnya

It

Menentukan Tema

6.Plan & Actual

Kondisi saat ini & Menentukan Target

Membuat Rencana Perbaikan

Analisa Penyebab Masalah

Melaksanakan Rencana Perbaikan

Evaluasi Hasil

Standarisasi

Rencana Berikutnya

Schedule

Dec '15 Jan'17

Item

W3 W4 W1 W2

aat ini & Menentukan Target

Rencana Perbaikan

enyebab Masalah

akan Rencana Perbaikan

Plan

Jan'17 Feb'17 Mar'17

W3 W4 W1 W2 W3 W4 W1 W2 W3 W4

Actual

Apr'17

W1 W2

Dec Jan

Item

W3 W4 W1 W2 W3

Menentukan Tema

Kondisi saat ini & Menentukan Target

Membuat Rencana Perbaikan

Analisa Penyebab Masalah

Melaksanakan Rencana Perbaikan

Evaluasi Hasil

Standarisasi

Rencana Berikutnya

Jan Feb Mar Apr

W4 W1 W2 W3 W4 W1 W2 W3 W4 W1 W2

Verification

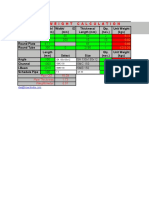

No

1

2

3

4

No

1

Verification

Counter Measure AnalysisPoint Issue and Action

Reman Manual Visual Check

Drawing Standart Issue Visual Check, and Measurement Insulation Resistance

Decide List Facility Prepare Megger Test and Multitester to measurement

Development Durability Detail Analyze to know durability

of Wire Harness 1. Trial Measurement of Reuse Part and New Part (KBN)

2. Compare data SMR (Hours) unit vs Result Trial

Measurement of Reused Part (KBN)

3. Facilitator Analyze About Material of wire harness (MTC)

4. Deeply Analyze to know material composition for

reference decide standart of Durability Wire Harness

(Institute Technology Bandung (ITB))

Counter Measure AnalysisPoint Issue and Action

Reman Manual Mention only Visual Check ( Done)

S-ar putea să vă placă și

- Varroc Engineering BOM for Flywheel Magneto AssemblyDocument60 paginiVarroc Engineering BOM for Flywheel Magneto AssemblyvinodÎncă nu există evaluări

- Lead Time - 001Document18 paginiLead Time - 001Purushothama Nanje GowdaÎncă nu există evaluări

- Management Accounting AssignmentDocument8 paginiManagement Accounting AssignmentAjay VatsavaiÎncă nu există evaluări

- Parth S Shah: Education Technical SkillsDocument1 paginăParth S Shah: Education Technical SkillsParth ShahÎncă nu există evaluări

- MP 461 - F22 Inventory Working May'21Document116 paginiMP 461 - F22 Inventory Working May'21gaurav kumarÎncă nu există evaluări

- You Enter Information Only in The Shaded CellsDocument9 paginiYou Enter Information Only in The Shaded CellsEmba MadrasÎncă nu există evaluări

- INARI 28 Dec 2023 - Financial - Analysis - Explained - V1.1Document36 paginiINARI 28 Dec 2023 - Financial - Analysis - Explained - V1.1sj7953Încă nu există evaluări

- Aj D-Prod-01 Preventive Maintenace PlanDocument5 paginiAj D-Prod-01 Preventive Maintenace PlanMANAGEMENT REPRESENTATIVEÎncă nu există evaluări

- Inj Mold CalculateDocument9 paginiInj Mold CalculateGiap NguyenÎncă nu există evaluări

- KS Munjal Industries responds to customer complaint about dull zinc platingDocument1 paginăKS Munjal Industries responds to customer complaint about dull zinc platingKaramjit SinghÎncă nu există evaluări

- Poly Carbonate - Injection Mould Component Cost EstimationDocument7 paginiPoly Carbonate - Injection Mould Component Cost EstimationVenkateswaran venkateswaranÎncă nu există evaluări

- Cause Amp Effects Rating MatrixDocument5 paginiCause Amp Effects Rating MatrixMuhammad Reza GadranÎncă nu există evaluări

- Project Cost For Injection Moulding Plant: SL No Description Capacity Short Weight Condition Basic PriceDocument2 paginiProject Cost For Injection Moulding Plant: SL No Description Capacity Short Weight Condition Basic PriceNihar RanjanÎncă nu există evaluări

- Scorpio - N - Accessories Catalogue - Rev - 1.9Document70 paginiScorpio - N - Accessories Catalogue - Rev - 1.9Kunal GuptaÎncă nu există evaluări

- 23 - Lightweight Chassis CradlesDocument30 pagini23 - Lightweight Chassis CradlesUnir Welds CoatingsÎncă nu există evaluări

- Suppliers Evaluation Form - Aluminium Suppliers-2007Document6 paginiSuppliers Evaluation Form - Aluminium Suppliers-2007savan anvekarÎncă nu există evaluări

- FPC Flexible Circuit Board Constituting ProcessDocument5 paginiFPC Flexible Circuit Board Constituting ProcessYuan Yong QuanÎncă nu există evaluări

- Customer Survey Form T2m 2009Document1 paginăCustomer Survey Form T2m 2009Peracha EngineeringÎncă nu există evaluări

- Alpha Drives: Vendor RatingDocument10 paginiAlpha Drives: Vendor Ratingdaniel_sasikumarÎncă nu există evaluări

- West Bengal Govt Leave Salary CalculationDocument13 paginiWest Bengal Govt Leave Salary CalculationGourab SarkarÎncă nu există evaluări

- Defect Name Cause For Occurance Rating Pareto Chart Qty Rejected Qty. Produced OCC RankingDocument4 paginiDefect Name Cause For Occurance Rating Pareto Chart Qty Rejected Qty. Produced OCC RankingRavi YadavÎncă nu există evaluări

- Process: Process Control Chart Chart No'Document1 paginăProcess: Process Control Chart Chart No'AngelikaÎncă nu există evaluări

- F.hr.06. On Job TrainingDocument1 paginăF.hr.06. On Job TrainingSaurabhÎncă nu există evaluări

- PO Monitoring Sheet Ver 1 31-03-08Document225 paginiPO Monitoring Sheet Ver 1 31-03-08api-3700469Încă nu există evaluări

- CBI Export Coaching Programme for Moulds and Dies ManufacturersDocument4 paginiCBI Export Coaching Programme for Moulds and Dies Manufacturersprasad_kcpÎncă nu există evaluări

- Cost Weighted OEE TemplateDocument10 paginiCost Weighted OEE TemplateSAMGPROÎncă nu există evaluări

- Costing Calculations:: Date: Revision: 0 Mezzanine MachineDocument5 paginiCosting Calculations:: Date: Revision: 0 Mezzanine MachineRakesh SharmaÎncă nu există evaluări

- Tipos de Tratamientos PDFDocument1 paginăTipos de Tratamientos PDFJose PerezÎncă nu există evaluări

- Ultra High-Strength Steel SheetsDocument6 paginiUltra High-Strength Steel SheetsMihai EnăşelÎncă nu există evaluări

- Quotation Sheet For 755A Roll Form Carpet Page 1 OF 8: PackagingDocument12 paginiQuotation Sheet For 755A Roll Form Carpet Page 1 OF 8: PackagingWak SmithÎncă nu există evaluări

- Excel - Formula Sheet - AitDocument229 paginiExcel - Formula Sheet - AitMukesh jivrajikaÎncă nu există evaluări

- Sidhi Alcast: Machine Maintenance RecordDocument1 paginăSidhi Alcast: Machine Maintenance Recordpulkit gargÎncă nu există evaluări

- Tool Steel - Material Selection Guide: High Speed SteelsDocument1 paginăTool Steel - Material Selection Guide: High Speed SteelsAlok Rawat NLMKÎncă nu există evaluări

- Instructions For Completion of Piece Cost Breakdown WorksheetDocument9 paginiInstructions For Completion of Piece Cost Breakdown WorksheetfranciscoÎncă nu există evaluări

- Rejection & Returned Summary 2022 AnalysisDocument9 paginiRejection & Returned Summary 2022 AnalysisRajkumar PrajapatiÎncă nu există evaluări

- Components % Age Monthly AnnualDocument7 paginiComponents % Age Monthly Annualtarique1189040Încă nu există evaluări

- Kpi ItDocument3 paginiKpi ItShailesh GuptaÎncă nu există evaluări

- Trouble HistoryDocument7 paginiTrouble HistoryShahzaibUsmanÎncă nu există evaluări

- Nabtesco - Annual Appraisal Sheet (For Manager & Above) 2021Document10 paginiNabtesco - Annual Appraisal Sheet (For Manager & Above) 2021Kiran AmboreÎncă nu există evaluări

- Daily costing and efficiency report for IDEPL-6 in October 2016Document74 paginiDaily costing and efficiency report for IDEPL-6 in October 2016Halari MukeshÎncă nu există evaluări

- Injection Mould Component Cost EstimationDocument7 paginiInjection Mould Component Cost EstimationVenkateswaran venkateswaranÎncă nu există evaluări

- F.disp.01 Schedule V-S Dispatch PlanDocument6 paginiF.disp.01 Schedule V-S Dispatch PlanSaurabhÎncă nu există evaluări

- SMS - 67390 8jb0a - K2MCDocument21 paginiSMS - 67390 8jb0a - K2MCmani sÎncă nu există evaluări

- Past defect history details root cause analysis formatDocument10 paginiPast defect history details root cause analysis formatRahulÎncă nu există evaluări

- DPR-KKBMPL Gail-24.10.2018Document46 paginiDPR-KKBMPL Gail-24.10.2018sebincherianÎncă nu există evaluări

- Steel and Pipes For Africa Price ListDocument1 paginăSteel and Pipes For Africa Price ListLazuardhy Vozika Futur100% (1)

- Filter assembly line defect analysis and Pareto chart for February 2022Document2 paginiFilter assembly line defect analysis and Pareto chart for February 2022Iqbal singh DhanjalÎncă nu există evaluări

- Cost Working of Mechanical Press: Description General Formula CostDocument4 paginiCost Working of Mechanical Press: Description General Formula Costazadsingh1Încă nu există evaluări

- Technical Delivery Condition: %C %MN %S %P %si %ni MIN MAX 0.23 1.50 0.045 0.045 0.40 0.42Document1 paginăTechnical Delivery Condition: %C %MN %S %P %si %ni MIN MAX 0.23 1.50 0.045 0.045 0.40 0.42muthuselvanÎncă nu există evaluări

- Rev 12Document2 paginiRev 12api-273257329Încă nu există evaluări

- Kaizen Report Sheet Template for Mechanical Engineering DepartmentDocument1 paginăKaizen Report Sheet Template for Mechanical Engineering DepartmentSaravana VigneshÎncă nu există evaluări

- Cost Comparision WRT VendorsDocument22 paginiCost Comparision WRT Vendorsसंदीप द्विवेदीÎncă nu există evaluări

- DMW Organisation Chart 16082019Document1 paginăDMW Organisation Chart 16082019Mithelesh KoulÎncă nu există evaluări

- 04 421 40033 Clutch CoverDocument1 pagină04 421 40033 Clutch CoverPress TechÎncă nu există evaluări

- Shift Report: Availability Performance Rate Quality Products RateDocument6 paginiShift Report: Availability Performance Rate Quality Products RatehwhhadiÎncă nu există evaluări

- E Weight CalculationDocument20 paginiE Weight CalculationAvish Shah100% (1)

- Calculate Salary, EPF and CTC in RM and SGDDocument2 paginiCalculate Salary, EPF and CTC in RM and SGDDarlene ChongÎncă nu există evaluări

- Jockey Pump Controller Wiring SchematicDocument2 paginiJockey Pump Controller Wiring SchematicUmair BaBer100% (1)

- Z 1081053 - GPD Dimensions - Customer Drawing PDFDocument1 paginăZ 1081053 - GPD Dimensions - Customer Drawing PDFkospi46Încă nu există evaluări

- A3 Story Draft - Aditya Pradana Rev 3Document1 paginăA3 Story Draft - Aditya Pradana Rev 3aditya pradanaÎncă nu există evaluări

- How To Sputter Thin Films of Metal Onto GlassDocument5 paginiHow To Sputter Thin Films of Metal Onto Glassfred_m_48601Încă nu există evaluări

- Sectional Results: Sofistik 2020Document28 paginiSectional Results: Sofistik 2020ec05226Încă nu există evaluări

- Sensotronic Brake ControlDocument20 paginiSensotronic Brake ControlShubhankar Banerjee100% (1)

- Hoarding Guide 2020Document46 paginiHoarding Guide 2020Mohammed HafizÎncă nu există evaluări

- Belgas P630R IOMDocument3 paginiBelgas P630R IOMSMcÎncă nu există evaluări

- Shiela S. Portillo Ang Specification 09112021Document9 paginiShiela S. Portillo Ang Specification 09112021JR De LeonÎncă nu există evaluări

- Pco2Document55 paginiPco2camdentownÎncă nu există evaluări

- SLTRT Service Level Testing Reporting ToolDocument110 paginiSLTRT Service Level Testing Reporting ToolChedli Dhouibi50% (2)

- Deterministic Inventory Control FormulasDocument6 paginiDeterministic Inventory Control FormulasvivekÎncă nu există evaluări

- DiGas 4000 Light E 08.02Document2 paginiDiGas 4000 Light E 08.02manit1963Încă nu există evaluări

- Fontaine Quinta RuedaDocument2 paginiFontaine Quinta RuedaHamilton MirandaÎncă nu există evaluări

- Escorts F-15: Hydraulic Mobile Pick-n-Carry CraneDocument2 paginiEscorts F-15: Hydraulic Mobile Pick-n-Carry CraneChandra MouliÎncă nu există evaluări

- Joy Global SolutionsDocument18 paginiJoy Global Solutionsjvr001100% (1)

- ATS1801 - Interface PC - ImpDocument8 paginiATS1801 - Interface PC - ImpluismantonioÎncă nu există evaluări

- Linthwaite: Conservatio N AreaDocument26 paginiLinthwaite: Conservatio N Areabill baileyÎncă nu există evaluări

- Electrical Measurements and InstrumentationDocument17 paginiElectrical Measurements and InstrumentationRinita Datta100% (1)

- Comb Manual IM 106 6888QSDocument36 paginiComb Manual IM 106 6888QSsathish2829Încă nu există evaluări

- LMS Adaptive FiltersDocument14 paginiLMS Adaptive FiltersalialibabaÎncă nu există evaluări

- Isolation of Caffeine from TeaDocument6 paginiIsolation of Caffeine from TeaDaisy Joyce Seroje BuslonÎncă nu există evaluări

- Windmill ABB MachinesDocument6 paginiWindmill ABB MachinesRadu BabauÎncă nu există evaluări

- Checklist of Requirements in The Application For Mechanical Installation/s of Industrial FacilitiesDocument1 paginăChecklist of Requirements in The Application For Mechanical Installation/s of Industrial FacilitiesoliciakimÎncă nu există evaluări

- DTH Equipment - Product - Catalogue - tcm45-3560033 PDFDocument48 paginiDTH Equipment - Product - Catalogue - tcm45-3560033 PDFJALFAROROÎncă nu există evaluări

- CNA09016 SGDocument8 paginiCNA09016 SGSatyarth SampathÎncă nu există evaluări

- Float Trap PennantDocument2 paginiFloat Trap PennantJinalkumarÎncă nu există evaluări

- HP w2007 w2007v SMDocument75 paginiHP w2007 w2007v SMfeliÎncă nu există evaluări

- Metronidazole AnalysisDocument5 paginiMetronidazole AnalysisHendri WasitoÎncă nu există evaluări

- Zw3d2022 Lite Vs Cadbro 2022Document4 paginiZw3d2022 Lite Vs Cadbro 2022Carlos LimaÎncă nu există evaluări

- Sennheiser MD 441Document2 paginiSennheiser MD 441ndujaÎncă nu există evaluări

- FTS ScaleoEUserManualEN 10 1082177Document2.044 paginiFTS ScaleoEUserManualEN 10 1082177JÎncă nu există evaluări

- IPE 401-Drive SystemDocument16 paginiIPE 401-Drive SystemElmerÎncă nu există evaluări