Documente Academic

Documente Profesional

Documente Cultură

Reservoir Fluid Sampling (2) - Unlocked

Încărcat de

Esneider Galeano Ariza0 evaluări0% au considerat acest document util (0 voturi)

49 vizualizări8 paginiddd

Titlu original

Reservoir Fluid Sampling (2)_unlocked

Drepturi de autor

© © All Rights Reserved

Formate disponibile

DOCX, PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentddd

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca DOCX, PDF, TXT sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

49 vizualizări8 paginiReservoir Fluid Sampling (2) - Unlocked

Încărcat de

Esneider Galeano Arizaddd

Drepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca DOCX, PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 8

Reservoir-Fluid Sampling Revisited—

A Practical Perspective

Johannes Bon,* SPE, and Hemanta Sarma, SPE, Australian School of Petroleum, University of Adelaide;

Teof Rodrigues, SPE, Santos Limited; and Jan Bon, SPE, Petrolab Pty. Limited, Australia

Summary Mostly the samples are required to obtain a better knowledge of

Pressure/volume/temperature (PVT) fluid properties are an inte- a combination of these effects; however, it must be kept in mind

gral part of determining the ultimate oil recovery and character- that often the sample is not required to resolve all of these issues.

ization of a reservoir, and are a vital tool in our attempts to enhance The properties of fluid samples from oil and gas reservoirs, at

the reservoir’s productive capability. However, as the experimen- original conditions and as found at different stages during produc-

tal procedures to obtain these are time consuming and expensive, tion, have been of great interest for as long as the oil industry has

they are often based on analyses of a few reservoir-fluid samples, had reservoir engineers. The quality of these samples is of utmost

which are then applied to the entire reservoir. Therefore, it is of importance in making the right reservoir-management decisions.

utmost importance to ensure that representative samples are taken, Also, constantly improving the compositional data helps are help-

as they are fundamental to the reliability and accuracy of a study. ing the downstream industry with the planning of facilities. Further

Critical to the successful sampling of a reservoir fluid is the improvement of more-detailed fluid properties is expected, and the

correct employment of sampling procedures and well conditioning fact that many specialists in this field are now being called “flow-

before and during sampling. There are two general methods of assurance experts” highlights the need downstream for good-

sampling—surface and subsurface sampling. However, within quality compositional, fluid-property, and phase-behavior data.

these, there exist different methods that can be more applicable to Bottomhole sampling goes back more than 60 years (Reudel-

a particular type of reservoir fluid than to another. In addition, well huber 1957, Fevang and Whitson 1994), when most operators came

conditioning can differ depending on the type of reservoir fluid. up with their own bottomhole-sampler designs. These were either

Sampling methods for each reservoir type will be discussed with flow-through samplers—purging fluid constantly—or pre- viously

an emphasis on scenarios where difficulties arise, such as near- evacuated chambers that, when actuated by clocks or other

critical reservoir fluids and saturated reservoirs. Methods, includ- mechanical devices, trapped downhole-fluid samples.

ing single-phase sampling and isokinetic sampling, which have There was greater consensus in surface sampling, and most

been used increasingly in the last decade, will also be discussed everyone agreed on how to sample from separators and, in some

with some detail, as will preservation of the representatives of other cases, from the wellhead. From early on, engineers were aware of

components in the sample including asphaltenes, mercury, and occasional carryover of entrained liquid droplets in the gas phase,

sulfur compounds. and early attempts at isokinetic sampling were initially superseded

The paper presents a discussion aimed at better understand- by improving the separation properties of the separators, increas-

ing the methods available, concepts behind the methods, well ing their size, and/or lowering the flow rates to allow more time for

conditioning, and problems involved in obtaining representative equilibrium (Fevang and Whitson 1994).

fluid samples. The biggest challenge lies in improving the quality of the ever-

more-popular openhole wireline samples taken with wireline for-

Introduction

mation testers (WFTs). WFTs were first introduced to the industry

Reservoir-fluid samples are obtained for a number of rea- in 1955 (Ayan et al. 1996) The main purpose of the tool was to

sons, including measure a formation pressure point and collect a fluid sample. It

• PVT analysis for subsequent engineering calculations wasn’t until the mid-1970s that many advances were made on the

• Determination of the components that exist in a particular res- tools’ technology. The samples taken with these tools were com-

ervoir to have an understanding of the economic value of the fluid pletely discredited by the fluid experts until the 1990s when tool

• Knowledge of the contents of certain components that exist technology improved greatly, addressing issues particularly relat-

in the reservoir fluid for further planning and future drilling ing to fluid typing and sampling. As a result, these samplers are of

programs, such as the content of sulfur compounds and carbon irreplaceable importance today.

dioxide, and the corrosiveness of the fluid. This will have an impact All these issues have been addressed again since then, and

on the material used for casing, tubing, and surface equip- ment that changes and improvements are being made wherever possible, and

may be necessary will continue to be ongoing.

• Knowledge of the fluid’s ability to flow through production Representative samples taken with typical single-phase bottom-

tubing, pipelines, and other flow lines, and possible problems that hole samplers are often taken for reservoir-fluid composition, PVT

may arise because of viscosity changes because of the precipitation analysis, and, depending on the reservoir, asphaltene studies. How-

of solids such as wax and/or of asphaltene ever, these tools are often not suitable for measuring sulphur-

• Determining the contaminating components that affect plant compound or mercury content. A good knowledge of the wax

design, such as the mercury content, sulfur components, and radio- content and problems that may arise because of wax can be ob-

active components tained from studies performed on stock-tank oil. Sulfur compounds

• If the saturation pressure is approximately equal to the reser- and mercury are mostly present in the gas stream, so analysis can

voir pressure, then a second phase may be present. This is par- be performed on separator or wellhead gas streams. While ideally

ticularly relevant for gas reservoirs, where further drilling may all the parameters could be obtained from the same sample, in

discover an oil or condensate leg. practice, different samples can suit different needs. First and fore-

most, the need for the sample should be established so the correct

samples can be taken. This can avoid extra costs of sampling for

* Now with Petrolab, S.A., Venezuela. parameters that will not be measured or the cost of having to sample

again. But key to a successful sampling program is to first answer

Copyright © 2007 Society of Petroleum Engineers

the question, “What are you sampling for?”

This paper (SPE 101037) was accepted for presentation at the 2006 SPE Asia and Pacific This paper aims at discussing different sampling methods and

Oil and Gas Conference and Exhibition, Adelaide, Australia, 11–13 September, and revised

for publication. Original manuscript received for review 9 June 2006. Revised manuscript what they are most suited for. The focus is on obtaining represen-

received for review 12 April 2007. Paper peer approved 19 April 2007. tative samples of live reservoir fluid with the aim of characterizing

December 2007 SPE Reservoir Evaluation & Engineering 589

reservoir production; however, this paper also touches on some of provided the well is not drawn down below the dewpoint pres-

the downstream issues. sure—condensate will stay in solution.

If the reservoir fluid is saturated or reservoir pressure is near

Understanding Our Reservoir Processes the dewpoint pressure, a flow period resulting in a drawdown will

Immediately after a well is drilled, the well will first go online with inevitably result in condensate coming out of the solution. Similar

a cleanup-flow period of reasonably hard flow to push drilling to the gas in saturated oil, the condensate that initially comes out

fluids out of the near-wellbore region and the wellbore (Reudel- of solution will fill pore space until a critical saturation is reached.

huber 1957; McCain and Alexander 1992; El-Banbi and McCain This fluid needs to be flushed out with virgin reservoir fluid. After

2001; Cobenas and Crotti 1999; Strong et al. 1993; Towler 1989). this, condensate will flow with the gas through the wellbore. For

Depending on how undersaturated the reservoir fluid is (some- surface sampling, another problem arises: The flow rate must be

times not at all), the pressure drop induced to create the flow may large enough to carry the condensate to the surface, but if the flow

result in a drawdown of pressure below the saturation pressure. is too high, stable flow will not be achieved, and perhaps there will

This causes either dissolved gas (for oil wells) or dissolved con- even be poor separation at the separator because the fluid has little

densate (for gas wells) to come out of solution. The subsequent time to reach equilibrium.

effects are discussed further for each reservoir type. The condensate dropout in the near-wellbore region has other

effects—particularly in low-permeability reservoirs; as condensate

Undersaturated-Oil Reservoirs. In principle, sampling under- drops out and fills pore spaces, the permeability is reduced, some-

saturated oil reservoirs should be the simplest. Ideally, if the reser- times severely affecting flow.

voir is greatly undersaturated, the drawdown because of flowing Reducing the flow rate results in an increase in the flowing

the well never pulls the flowing bottomhole pressure below the bottomhole pressure and the pressure in the drainage radius. This

saturation pressure, and thus the wellbore will have virgin reser- causes some of the condensate in the pore spaces to revaporize,

voir fluid flowing through it. decreasing the GOR below that of the virgin reservoir fluid. After

If because of cleanup flow or any other reason the reservoir is a rate reduction, one must wait a period of days or even months for

drawn down below the bubblepoint pressure, then two-phase fluid low-permeability reservoirs before sampling (McCain and Alex-

needs to be driven out with virgin reservoir fluid. This can be done ander 1992).

by flowing at a lower rate—hence minimizing the drawdown so

flowing bottomhole pressure is still above the saturation pressure. Recovering Poor-Quality Samples. If poor-quality samples have

Initially, because of capillary pressure effects, released solution been obtained, recovery of the samples may be possible in the

gas will remain immobile in the pore spaces until a critical gas laboratory. Note that the processes described in the following

saturation is achieved, and after that an excess of gas may flow. paragraphs will result in changes in composition and should

At the surface, monitoring the gas/oil ratio (GOR) can indicate only be implemented if resampling is not viable. Judgment should

when the sampling operation should start. Initially, the GOR will be made on how poor the quality of the initial sample is and how

be too low. A rate should be sought such that a stable GOR is large the change in composition will be from the following pro-

attained after prolonged flow. cesses. The difference in composition and subsequent PVT param-

For bottomhole samples, the fluid entering the wellbore needs eters measured may be small and, therefore, within an acceptable

to be single phase. If considerable water is flowing together with error margin.

the oil, the flow may not be great enough to push the water from If the samples obtained have a bubblepoint pressure above the

the wellbore. To avoid sampling water, a static gradient should be reservoir pressure, a representative sample may still be attained.

run before sampling. Once in the laboratory, the sample can be charged into a PVT cell,

For surface samples, so long as the fluid (assuming two-phase equilibrium established at the reservoir pressure, and the excess

flow of gas and liquid flowing into and up the wellbore) is in the gas blown off, leaving a sample saturated at the reservoir pressure.

same ratio as the original reservoir fluid, the separator samples will If the samples obtained have a low GOR and separator gas or

be good. wellhead gas is available, additional gas can be added to raise the

GOR to reservoir pressure. This results in a slightly different com-

Saturated-Oil Reservoirs. Sampling saturated reservoirs is not position, because the gas will have a different composition

simple because flowing the reservoir results in a drawdown, which (lighter) than the solution gas.

will pull the flowing bottomhole pressure below the bubblepoint An equation of state (EOS) or correlations can be used to help

pressure (Reudelhuber 1957; Strong et al. 1993; Towler 1989; calculate the volume of gas required to increase the bubble-

Dake 1994). The possible issues that could arise and need to be point pressure.

avoided are: For gas/condensate systems, if the collected sample has too high

• Drawdown because of flow; this results in the release of a dewpoint and condensate/gas ratio (CGR), a representative

solution gas from the reservoir fluid. sample can still be obtained by establishing equilibrium in the PVT

• Samples should be taken at the separator. Bottomhole cell at reservoir conditions. Once equilibrium is achieved and the

samples are not recommended, as they may collect a dispropor- excess condensate is in the liquid phase, the gas phase is sub-

tionate amount of liquid or gas (Towler 1989). sampled from the PVT cell. This process yields a gas sample that

Shutting in the reservoir to build up pressure again will redis- is saturated at the reservoir conditions.

solve gas into the oil (Towler 1989). Obtaining a stable GOR is Well Conditioning

more difficult for saturated oil reservoirs. However, by flowing at

a lower rate, a stabilized flow can eventually be reached and a PVT samples need to represent the fluid to be produced from the

constant GOR can be observed. The fluid—although flowing in reservoir. The sooner the well is sampled after drilling, the greater

two-phases—carries the liquid and the gas at the same GOR as in the chances of representative sampling, because it is more likely

the virgin reservoir fluid. that pressure drops that can create two phases in the reservoir have

If the only option is bottomhole sampling, the sample should be not occurred (Dake 1994, Amyx et al. 1960). If the reservoir fluid

taken at a trickle flow so that the drawdown is as small as possible, in the near-wellbore region has been drawn into two phases, well

therefore minimizing disturbance to the solution gas in the pores conditioning is applied to correct this effect and bring single-phase

and maximizing solution gas dissolved within the liquid. If a gas fluid back into the wellbore and its vicinity.

cap exists, the pressure at the gas/oil contact (GOC) should be Because WFT generally are run immediately after drilling

used as the saturation pressure for the reservoir fluid, if correction when no flow or drawdown has yet occurred, usually no rigorous

is required. conditioning is necessary besides eliminating as much drilling

fluid as possible. This is especially important when oil-based mud

Gas/Condensate Reservoirs. Similarly to an undersaturated oil (OBM) has been used during drilling. The drilling fluid is removed

reservoir, if a gas/condensate reservoir is undersaturated— with a pump-out option of the WFT (Michaels et al. 1995), where

590 December 2007 SPE Reservoir Evaluation & Engineering

the reservoir fluid is passed over a variety of sensors and then into accepted. Reconditioning is therefore of utmost importance under

the annulus until indications of maximum purity are obtained. After these circumstances to ensure that the best possible and most rep-

this, the flow of fluid is directed to the sample chamber. resentative sample is obtained.

In the case of conventional- or single-phase-bottomhole sam- For gas/condensate reservoirs, surface sampling through a

pling, the issue of well conditioning is of more importance be- stable separator is recommended. The well is usually produced at

cause, the well will have already undergone a flow period before successively higher rates (McCain and Alexander 1992). Retro-

sampling. The flow period will have resulted in a drawdown, and grade liquid dropout will occur once the reservoir is drawn down

hence, there is need for more prudence when conditioning the well into two phases. This liquid will accumulate in the near-wellbore

for sampling. Exposing the reservoir fluid to lower-than-original region; but eventually, with continued flow of fluid through those

reservoir pressures can cause the fluid to go into two or three pore spaces, this same fluid will be mobilized, and its production

phases, depending on its saturation pressure and phase behavior. will result in a constant CGR. The best samples will be taken at the

The pressure will have to be increased to above the saturation lowest rate that produces a stable CGR, but it is recommended to

pressure with a stepwise approach of brief flowing periods and take duplicate sets at other rates as well.

shut-in periods with successively lower rates to return the fluid The conditioning principle extends into conditioning or clean-

flowing through the well back to its original state. This is contin- ing/purging of the wellbore, separators, sampling lines, equipment,

ued until the lowest rate at which there exists a stable GOR is and cylinders of all foreign material.

established. When this happens, it implies that single-phase fluid is

flowing into the wellbore. This is generally followed by a longer On-Site Validity Checks for Bottomhole Samples. The more

shut-in period in order to build up the bottomhole pressure at the on-site checks to evaluate the overall quality of sampled ma-

wellbore. This stable GOR can be confirmed by trial-and-error terial that are made, the easier it is to decide to change the con-

bottomhole sampling, which is expensive; can be assumed because ditioning process for improved or repeated sampling. These on-site

of stable wellhead pressure after several reduced-rate flow periods; checks include

or, preferably, can be determined by measuring the GOR while • Tool opening pressure

producing through a test separator. In the last case, separator • Surface-condition bubblepoint pressure

samples should always be taken also, to confirm the quality of the • Any on-site analyses

bottomhole samples and to provide backup samples in the case of The opening pressure of the tool is a key measurement of any

near-saturated pressures that cannot be reconditioned easily. bottomhole sample taken. The opening pressure of different

Taking conventional- or single-phase-bottomhole samples is samples from the same formation should fall within an acceptable

usually, but not always, done in conjunction with a well test error margin and should be compared to bottomhole pressures.

through a surface separator. The well tests will give bottomhole With conventional samples (nonsingle phase), the saturation

pressure at different rates. Single-phase fluid needs to be brought pressure can be measured at surface conditions with a varying

back into the wellbore. This is easiest to do if the flowing-pressure degree of accuracy. Accurate measurements were easily attained in

history indicates it has not been below the estimated saturation earlier years by measuring the bubblepoint pressure by use of

pressure. In case this is not known, the worst-case scenario (that mercury with conventional flow-through-type samplers. This is no

the reservoir fluid is saturated) must be assumed and the well must longer an option, but the same principle can be applied. With a

be conditioned as such. piston-type sampler, the measurement will be accurate if the tool

If taking surface samples, the criterion of having single-phase contains a mixing mechanism inside. The saturation-pressure mea-

representative reservoir fluid in the shut-in wellbore is superseded surements of samples from the same formation should then be

by the influx of two-phase fluid, where the gas and oil flow at the compared to one another, and these samples can then be taken to

GOR of the virgin reservoir fluid. reservoir conditions and used to verify the sample. Sometimes a

Even though the same conditioning principles apply for drill- saturation pressure is found to be higher than bottomhole pressure,

stem testing (DST) sampling, they are usually not adhered to, as implying that the samples are not representative and that too much

these samples typically are taken only for fluid identification and gas has been collected.

to determine stock-tank-fluid properties. However, if the fluid is If single-phase samples have been taken, the opening pressure

undersaturated, good quality bottomhole samples can be obtained is preset and, thus, of no value. The saturation pressure can be

in bottomhole DST sampling subs. Furthermore, if the DST can be measured, but either one sample from a batch or a small portion of

extended long enough through a separator, successful PVT-quality each sample must be sacrificed. However, the validity checks are

separator samples can be obtained. more complicated, more expensive, and require more equipment.

If a selection of wells is available for sampling, wells with better If some analyses are performed on site, such as bubblepoint-

productivity should have higher bottomhole pressures. When pressure measurements (surface temperature or bottomhole tem-

selecting a representative well for sampling, the well with the perature) or a flash to obtain the GOR, the sample validity can be

highest bottomhole pressure at a stabilized flow rate and GOR will determined immediately by comparing one sample to the next and

be the best well to sample from. If an increase in GOR is seen, it corroborating the determined values against production-test data.

indicates that free solution gas is being produced, and the satu- Reservoir-Fluid-Sampling Methods

ration conditions bottomhole will not give representative samples. Reservoir-fluid-sampling techniques can be generalized into two

Wells that produce water should be avoided; however, if this can- groups: surface and subsurface.

not be done, it is important to run a static gradient survey to find

the oil/water contact within the wellbore in order to sample above Surface Sampling Techniques.

this depth. 1. Separator samples, from test or production separators. These

If the samples are needed for asphaltene analyses, all attempts are often recommended for gas-condensate or saturated-black- and

to minimize drawdown should be made. If the fluid is drawn volatile-oil reservoir fluids. The equilibrium separator liquid and

down below the onset-of-asphaltene-precipitation (OAP) pressure gas are recombined in their produced ratio to obtain representative

(Jamaluddin et al. 2001), then the sample will require recondition- reservoir-fluid samples.

ing in the laboratory before analysis. There is no consensus on the 2. Wellhead samples, for undersaturated fluids still in single

method to recondition samples with asphaltenes that have been phase at wellhead conditions.

below the OAP pressure, or even concerning whether it can be 3. Split-phase, or isokinetic, sampling—scaled-down recondi-

done. However, it is often achieved or the attempt is made using a tioned homogeneous two-phase flow through a miniseparator.

prolonged period (a week) of maintaining the sample at reservoir 4. Samples from pipelines or plant flowlines.

pressure and temperature or above and inverting the sample peri- Whichever way is chosen, it is essential to ensure that the actual

odically. This is done with the intention of redissolving the pre- fluid obtained is as close as possible to the virgin fluid discovered

cipitated asphaltenes. If possible, samples are taken at ideal con- in the reservoir, thus ensuring that it is as representative as pos-

ditions (single phase), but if this is not possible, this fact has to be sible. To do that, all wells usually have to be conditioned to bring

December 2007 SPE Reservoir Evaluation & Engineering 591

such fluid into the wellbore or separator. Since this process is more Split-phase sampling is applicable particularly for condensate

complicated than it sounds, it is recommended to take samples in reservoirs that produce at low rates with low CGR. It is also

more than one way, therefore obtaining differently conditioned applicable for separator gas streams with a large volume of en-

fluids from the same reservoir, to define its properties better. trained liquid to correct the CGR and improve the separator-test

data: In this case, it is not replacing the separator test but improv-

The advantage of awareness of all new developments should

ing the data. However, this method of sampling is not always

also allow us to evaluate simpler situations with simpler sampling

economic and also not always better than simultaneously obtained

solutions, while at the same time provide solutions for more-

separator samples.

complex problems when required.

Split-phase-sampling technology is more than 60 years old

(Fevang and Whitson 1994); however, in recent years, it has been

Surface Sampling Methods. Separator Sampling. A recom-

used increasingly. The technology has improved, particularly in

mended guideline to good separator sampling is to flow the well the measurement of GOR as it is distributed through the cross

through the separator at a stable pressure, temperature, and section of the pipe (not actually homogeneous). Previously, it was

GOR for two to three separator volumes to ensure that the fluid that assumed that the mixing head distributed the liquid droplets per-

collected in the separator at any other points in the equilibrium state fectly across the pipe cross section. This assumption was found to

is flushed out. At any pressure and temperature (within the two- be not exactly correct. So, to improve the GOR measurement and

phase conditions), the gas and liquid coexist in equilibrium. The minimize the error because of this effect, the probe now samples

individual components of the reservoir fluid coexist, to some at three different points across the pipe and averages the result

degree, in both phases. The ratio of the fraction of a component (Dybdahl 2006).

in the gas phase to its fraction in the liquid phase is termed A simple alternative to the need to measure the volume of liquid

the K-value. If either pressure or temperature is changed dras- carry-over is to flow at a lower rate, if possible, so that the fluid

tically, the K-value will change, and hence some of the component has more time to reach equilibrium in the separator (Fevang and

that exists in the gas phase may condense, or conversely, some of Whitson 1994).

the component that exists in the liquid phase may vaporize. When Another simple alternative is to take the separator gas samples

the samples are taken, the pressure and temperature of the as is normally done. These will bring the entrained liquid along

separator are recorded along with—as accurately as possible—the with them. Once in the laboratory, the gas samples are returned to

gas- and liquid-flow rates. Furthermore, the GOR should be based separator conditions by heating to separator temperature. The cyl-

on oil-flow rate at separator conditions, and the correction fac- inder is placed vertically upside-down, allowing the entrained liq-

tors used should be noted (Williams 1994). No matter how good uid to drop out and flow to the bottom of the cylinder. This liquid

the sampling and well conditioning are, if the rates measured can then be removed, analyzed, and the volume measured, and

and subsequent GOR are incorrect, the recombined sample will then both mathematically and physically added to the total well-

be unrepresentative. stream composition.

Separator samples can be taken by the following methods.

For gases Subsurface Sampling Techniques

• Sampled directly into an evacuated cylinder (preferred method) 1. Slickline-run tools usually in cased holes using conventional

• If evacuated cylinders are not available, the air in the cylin- flow-through or piston-type samplers. This method is recom-

der can be removed by dilution: filling the bottle and emptying mended for normal undersaturated-oil and gas reservoir fluids

before sampling. 2. Slickline-run tools, again, usually in cased holes with pres-

For liquids sure-compensated single-phase fluid samplers. This is recom-

• Brine displacement (preferred method). Cylinder is first mended for undersaturated-oil and gas reservoir fluids with pos-

filled with brine. The brine is then displaced with separator sible solids (wax/asphaltenes) or precipitation problems.

liquid ensuring that fluid remains at separator pressure throughout 3. Exothermic samplers: These samplers not only keep the

the sampling. sample pressure-compensated but also temperature-compensated,

• Evacuated cylinder. The fluid is sampled directly into an to further reduce any chance of solids precipitation before sample

evacuated cylinder as for a gas sample. Although the sample will transfer and analysis.

separate into two phases within the cylinder, since the fluid is single 4. WFT run with electrical line, tied into the logging string,

phase, up to cylinder valve the sample will be representa- tive. usually taken in open holes before casing being set. There are a

However, if the sample is taken too quickly, it will separate into range of proprietary samplers with only subtle differences in tools

two phases in the flow lines before entering the cylinder and a poor from different companies, and these types of tools will be referred

sample will be taken. Fore this reason, the brine displace- ment to throughout the paper as WFTs.

method is preferred. 5. Pressure-compensated WFT.

• Separator-gas displacement. Sample cylinder is first filled 6. Samples taken during openhole drill-stem testing.

with separator gas, which is then displaced as the fluid enters the 7. Samples taken with a sub carried in the drillstring accom-

bottle (from the bottom). modating the samplers described in items 1, 2, and 3.

Wellhead Sampling. Sampling at the wellhead is done only if

it is known that the wellhead pressure and temperature are greater Subsurface / Bottomhole Sampling Tools. WFTs. Representative

than the reservoir-fluid saturation pressure. Dry gases can be samples are often taken with WFTs (Jamaluddin et al. 1999). If this

sampled at the wellhead, as can some lean gases and low-GOR oils. is the case, the added expense of obtaining bottomhole

However, if the sample is flowing in two-phases at the well- head, samples later can be avoided. So, rather than assuming the samples

then an unrepresentative sample will be taken because the two to be bad, they should be assumed good and quality-checked be-

individual phases will not flow into the cylinder in the same ratio fore a decision is made on their validity. However, if there is any

they exhibit in the reservoir. doubt with respect to how representative the sample is, samples

Split-Phase Sampling. Isokinetic, or split-phase, sampling can should be taken during a DST since not having a solid grasp of the

be used to sample two-phase wellhead fluid or to measure the PVT properties of the reservoir fluid may have much larger reper-

volume of entrained liquid in a gas stream (Williams 1994; Riley cussions over the long term. WFTs are run open hole and require

et al. 1978 Dybdahl 2006). Once a stable GOR is established, the inserting a probe into the formation. The fluid flows into the cham-

two-phase fluid is mixed using a mixing head. The mixing head is ber at a low drawdown. The sample taken at this stage is com-

designed to homogeneously spread the liquid droplets carried pletely virgin before any flow and drawdown in the reservoir.

through with the vapor. A probe then collects the gas-and-liquid More-modern WFTs can also supply backpressure and maintain the

sample at the corresponding GOR. An on-site laboratory ensures sample in single phase.

that GOR is stable before sampling and a miniseparator separates For gas/condensate reservoirs, the sample volume collected

the fluid according to the correct ratio. may be too small for good analysis on the reservoir fluid.

592 December 2007 SPE Reservoir Evaluation & Engineering

The WFT has a limited capacity to clear out the mud filtrate Flow-through samplers will not work well for heavy- and ex-

from the formation. More-recent WFTs have a pump-out option, traheavy-oil samples (<10 °API), and since slickline-piston-

so fluid initially pumped from the reservoir can be dumped into the bottomhole samplers need to be brought down on sucker rods, the

well rather than collected. If OBM has been used, the samples will extralong delay in clock setting and tool filling-up justifies plan-

ning bottomhole sampling of these fluids only by WFTs.

be contaminated, limiting the accuracy on subsequent analysis

Piston-Type Samplers. Piston-type samplers are in principle

performed on the sample.

the same as flow-through samplers. However, the sample chamber

WFTs have the key advantage that they are used before any

has a piston so that sample transfer into a cylinder for trans-

other form of sampling can be used. This is particularly vital for

portation can be accomplished without the use of mercury or brine.

saturated reservoirs.

Instead, the piston is pushed with glycol to displace the reser-

However, because of the drawdown to which the samples are voir fluid from the sample chamber. However, to re-establish

exposed, the samples may not be of good quality. This is particu- the sample into the original single phase, some sort of mixing

larly an issue for gas condensates because the dewpoint pressure is mechanism should exist in the sample chamber to speed up equi-

nonmonotonic—it does not constantly increase with increasing librium and ensure that all solution gas, condensate, and/or wax

pressure and temperature, it instead increases and then decreases is redissolved.

after the cricondenbar point is reached. Thus, an unrepresentative The tool is run in the hole, closed, and triggered open once at

sample may have a dewpoint pressure that is higher, lower, or equal depth. The sample is collected, the valves are closed again, and the

to the actual dewpoint pressure (Fevang and Whitson 1994). sampler is then retrieved.

Also, these samplers often return to surface with drilling fluid Since mercury is rarely used these days, most liquid-sample

and little sample. cylinders and piston-type sampling chambers have become exces-

Improved downhole sensors to monitor other fluid properties sively complicated. An array of O-rings accommodating pistons

could improve the sample quality, but unfortunately, a pressure has made these expensive appliances unsuitable for long-term stor-

drawdown cannot be eliminated but only minimized. age because of the interchanging of fluids across the seals through

Remaining convinced of future improvements, we believe the osmosis/adsorption. If conventional cylinders are not acceptable,

present position of these tools is quite acceptable and that, more alternative sample cylinders using inert diaphragms have to be

often than not, samples obtained this way give reliable fluid- considered for long-term storage.

properties data, for both the upstream and the downstream petro- Single-Phase Samplers. Single-phase samplers were designed

leum industry. These improvements will be especially needed for for sampling of reservoirs that may have asphaltene problems, to

problem fluids from which solid material precipitates with changes keep the asphaltenes in solution so they can be studied in a labo-

in temperature and pressure because the reservoir is exposed to ratory (Jamaluddin et al. 1999). Since asphaltene precipitation may

less change at the WFT sampling stage. not be reversible, the idea is not to allow the asphaltenes to come

Instead of bringing up the samples and subjecting them to out of solution. These samplers supply a backpressure with nitro-

changes, it may be worth combining the race for better sensors with gen against a piston in the sample chamber, maintaining the

looking at the downhole samples in situ and simulate a down- hole sample well above reservoir pressure. By overpressuring, the idea

depletion at different depths (temperatures) to evaluate the solid- is that even when the sample cools off, it will remain above the

phase-envelope part better. To better evaluate the contami- nants conditions for OAP.

of interest to the production engineers, downhole sensors have been Too many expensive single-phase samples are taken in reser-

developed to give indications, and they are improving in accuracy. voirs with no solids-precipitation problems, and this is something

Flow-Through Samplers/Conventional Bottomhole Samplers. that perhaps should be addressed rather than accepted.

The flow-through-type bottomhole samplers are the simplest and An occupational-health and safety issue arises for high-

oldest bottomhole sampling tools. The tool is run into the well on pressure reservoirs. Reservoirs with pressures near the 15,000-psi

a wireline with the valves open. As it travels through the wellbore, mark would in principle require the nitrogen chamber to be

the fluid present in the wellbore flows through the sampler. When charged to 17,000 psi or more. These pressures begin to be very

it reaches the sampling depth, the valves close by some mechanism dangerous to operate with and are at the upper limit of the equip-

(be it mechanical, electrical, or triggered by a clock). The sampler ment rating. Charging the nitrogen chamber with a lower pressure

is then retrieved, and the sample is transferred. is safer; however, it will not overpressure the sample, and the

When the sample is retrieved, the temperature decreases and sample may still be drawn below the OAP. This is where exother-

therefore the pressure of the sample decreases; for oil samples, this mic samplers will help, as the temperature compensation will also

almost always draws the sample into two phases. At the surface, the help keep the sample from the OAP.

solution gas must be dissolved back into the liquid before Exothermic Samplers. As for single-phase samplers, exother-

transferring the sample to a cylinder. The old-fashioned method mic samplers were designed for the sampling of reservoirs that may

pressurized the oil with mercury; however, because of occupa- have asphaltene problems, to keep the asphaltenes in solution so

tional health and safety measures, this is seldom/not used anymore. they can be studied in a laboratory. However, these samplers not

The great advantage of using mercury is that accurate validity only provide pressure compensation, they also maintain a high

checks can be performed, and as a mixing mechanism when re- temperature. The single-phase sampler avoids the issue of the tem-

turning the sample to single phase, mercury is unsurpassable. The perature dependence of asphaltene precipitation by keeping the

alternative is to transfer the sample back in the laboratory—this is sample overpressured. However, temperature also affects asphalt-

not a good practice because you are then sampling blind, and this ene precipitation, and therefore the exothermic sampler was de-

should not be done unless absolutely necessary. The other option signed. Problems have been found with the temperature mainte-

is to use acidified brine, but because of the low difference in density nance, and the samplers do cool off; however, the temperature is

with oil, it is not effective as a mixing mechanism, and the sample kept higher than that of any other tool. Once at the surface, the

cannot be analysed for its water content. In order to avoid the use sample temperature is maintained by use of a battery-operated

of mercury in the field and the issues that using brine may incur, heating jacket, and the samples are taken back to the laboratory

samplers with pistons were designed. immediately where they are transferred hot and kept at reservoir

Quality checks should always be performed on site for bottom- pressure and temperature, or greater. Further development is still

hole samples, even if only an opening pressure. These important required, and ongoing, to perfect the tool.

quality checks cannot be performed on single-phase bottomhole

samples, hence the need for more-sophisticated on-site analysis Sampling Heavy Oils

such as compositions and saturation pressures in an on-site labo- Difficulties arise when sampling heavy oils because of the high

ratory. Otherwise, the quality of the single-phase sample relies viscosity of the fluid. For bottomhole sampling, generally speak-

solely on the opening pressure of the tool. ing, samples are best taken with a WFT (Achourov et al. 2006;

Nagarajan et al. 2006; Morton et al. 2005). Having said that, suc-

December 2007 SPE Reservoir Evaluation & Engineering 593

cessful samples have been taken with DST-type bottomhole sam- before transferring the sample into sample cylinders. This is per-

plers, but these are applicable only if the reservoir is undersatu- formed with a prolonged period of heating at reservoir temperature

rated. If the reservoir is saturated, the WFTs are recommended. The and stirring (even as long as 12 hours for severe cases). If a mixing

key issues with bottomhole sampling of heavy oils are as follows mechanism exists in the sample chamber, this time can be short-

(Achourov et al. 2006; Nagarajan et al. 2006; Morton et al. 2005). ened; otherwise, stirring has to be performed by gravity—lifting

one end of the chamber for 30 minutes, and then the other end.

Pressure Drawdown. The pressure drawdown should be mini- Patience is required.

mized so that the fluid remains single phase, sand production is

controlled, and foaming can be minimized. The drawback is that a Sulfur Compounds. Sampling for analysis of the sulfur content

low drawdown may not mobilize high-viscosity fluid. present in the reservoir fluid is not easy and is still developing. The

key issue is that sulfur compounds such as H2S, mercaptans, and

Mud Contamination. The mud filtrate in the near-wellbore region carbonyl sulphide are adsorbed onto the walls of cylinders or

needs to be cleaned up with the pump-out option of the WFT. sample chambers, particularly those made of stainless steel (Elsha-

However, with an extended period of pumping, the risk of the pump hawi and Hashem 2005). Alternative materials are recommended

getting stuck is increased. With OBM, contamination poses a to preserve the content of the sulfur compounds. This is particu-

particular issue because excessive miscible contamination will larly important if analysis is to be performed in a laboratory be-

result in unrepresentative samples. cause the time required for the sample to reach the laboratory

(even if only a week) is enough for the analysis to measure greatly

Dual Packer. The conventional small probe and rubber packer are reduced H2S contents.

not applicable for heavy oils. It is recommended that a dual-packer This problem is, for now, best solved using current technology

module be used to hydraulically isolate the formation. With the in metallurgy by using cylinders made from other materials and

dual-packer module, the flow area is increased, lowering the draw- metal alloys. In addition to this, coatings have been made to reduce

down. The risks are in a poor-packer seal or leak, if seating and/or the reaction of conventional stainless-steel cylinders with H2S.

inflation fail. These coatings tend to be either polytetrafluoroethylene-based

Surface sampling may also be an option with heavy-oil reser- (PTFE-based) or the latest generation of cylinders, which are sili-

voirs. An easy way of acceptable accuracy is to recombine crude con-based (Elshahawi and Hashem 2005).

from the wellhead and gas from the annulus or the wellhead, When taking WFT samples, adsorption often occurs in the

provided an accurate GOR can be attained. Extrapolating into a flowlines into the sample chambers and, most of all, at the pump-

PVT study on a recombined reservoir fluid with a GOR that is too ing unit.

high is acceptable if the real GOR is known only after the study is The error margin because of adsorbed sulfur is less if there is

performed. Separator tests are usually performed on fluid with a higher sulfur content in the sample. This is because, even though

added diluents to decrease the viscosity and, provided good volu- a larger volume is adsorbed, it is a smaller percentage.

metrics are kept track of, an accurate GOR can be backcalculated Some analysis can also be performed on site. Again, an issue

for the wellhead samples. In important cases, it might be necessary still remains whether the sulfur compounds are adhering to the

to convince the operator to cut the diluents for as short a time as walls of the tubing, casing, and surface equipment before being

possible to obtain good-quality separator samples of uncontami- sampled for analysis. Typical analysis for sulfur compounds is as

nated composition. GOR measurements might be weak because follows (Elshahawi and Hashem 2005):

most of the solution gas will stay in the separator liquid and will • Potentiometric titration

not be measured with the liberated separator gas. • Iodometric titration (highly accurate but time consuming)

• Tutwiler method (higher concentrations)

Other Components of Interest • Gas chromatography

Asphaltenes. If in reservoir sampling the engineer is very confi- • Gas detection tubes.

dent that asphaltenes will not be a problem, and no study is in- In addition to this, downhole sensors now exist that can at least

tended to be conducted for solids, then single-phase or exothermic- give an indication of whether surface-measured-sulfur-compound

sampling tools are superfluous. concentrations are wrong or approximate. The future of measure-

However, in fields where asphaltene problems may arise and ment of concentrations of sulfur compounds is likely to be an

whose samples are intended for asphaltene analysis, the samples improvement of this technology.

should be taken single phase so as to preserve the asphaltenes in

solution for subsequent analysis. Although the sampling and analy- Mercury Content. It is also important to measure the mercury

sis of asphaltenes are costly, a prior knowledge of the problems the content in the well stream to determine whether extra requirements

field may have can be of economic benefit in the long run. How- are necessary in the refining process. Mercury can cause metallic

ever, if analysis has already been performed and/or no asphaltene parts to fail by amalgamating and changing the mechanical prop-

analysis is intended for the samples, single-phase sampling may not erties of the metal, particularly aluminium or copper.

be required. Similarly to sulfur compounds, the measurable mercury content

Asphaltene problems should also be kept in mind—in particu- decreases with time because it is adsorbed onto the walls of stain-

lar, if gas injection is intended at some stage in the reservoir’s life. less-steel cylinders and sample chambers. On-site analysis can be

It may be too late to take representative samples later. performed on the separator gas stream. In general, the mercury

Analysis for asphaltenes performed on live single-phase fluid is compounds that may naturally occur in a reservoir fluid are el-

performed in laboratories with specialized equipment. However, emental mercury (Hg0) in hydrocarbon-gas streams and both el-

some analysis can be performed on stock-tank fluids on site, if emental mercury and organic mercury [Hg(CxHy)2] in hydrocar-

required, such as weight percent of asphaltenes in stock-tank oil by bon-liquid streams (Wilhelm and McArthur 1995).

n-heptane precipitation or saturates, aromatics, resins, and asphalt- Several methods for measuring mercury content in gas streams

enes analysis. exist (Bingham 1990). In the field, the mercury compounds are

The reversibility of asphaltene precipitation is questionable. removed by passing the gas through a permanganate solution. The

For this reason, single-phase and exothermic samplers were designed, solution is analysed in a laboratory by atomic absorption spec-

so that the sample does not cross the OAP-point before analysis. troscopy. This can also be performed on stock-tank liquid/

condensates. The samples should be kept in glass vials with mini-

Wax. Wax can be treated and controlled by maintaining high mal head space for transportation to the laboratory.

temperature and pressure. If any indications of wax issues are The mercury content in gas can also be measured using a gold-

encountered during WFT sampling, the transfer of samples to cyl- film mercury-vapor analyzer (Bingham 1990). These mercury de-

inders for further analysis becomes more difficult. The solidified tectors have a small built-in pump that takes in a volume of gas

wax is a third phase and needs to be redissolved into the fluid through the sample probe, which consists of a film of gold onto

594 December 2007 SPE Reservoir Evaluation & Engineering

which the mercury adsorbs. The mercury detectors operate at at- Conclusions

mospheric pressure. One method of using these machines is to pass • Sample as early as possible in the life of the reservoir. Generally

the gas through a plastic bottle with an outlet to maintain pressure speaking, the earlier you sample, the higher the likelihood of

at atmospheric pressure and another outlet for the gas that is to be obtaining representative samples.

passed through the machine. • Well conditioning is of utmost importance. Ensure that the well

is conditioned as well as possible before sampling. The preparation

OBM. For WFT sampling, the use of OBM can contaminate of a good conditioning program will improve sample quality.

• Keep your WFT samples under pressure, and transfer them into

samples (Dybdahl 2006, Achourov et al. 2006). If this is the case

a cylinder. It is common for these samples to be released to stock

for oil wells, depending on the severity of the contamination, the

tank conditions with only some basic analyses performed. How-

composition can be backcalculated if the OBM composition is

ever, advanced technology in this area has greatly improved the

known. This is done by determining the composition of the con-

quality of these samples, which should be considered represen-

taminated oil sample, then a sample with a known added volume

tative until proved not so, rather than the opposite. The chance

of OBM, and the full OBM composition. to collect bottomhole or separator samples later may not come.

With gas condensates, a much smaller contamination will have However, bear in mind that WFT samples still require a draw-

more severe effects. Not only in terms of the composition, but also down and suffer problems from drilling-fluid issues and may not

measured dewpoints can be far too high. However, the same prin- be representative.

ciple as for oils can be applied to gases. • If a separator is online while taking bottomhole samples, take

separator samples also to back up the bottomhole samples.

Case Studies • If no asphaltenes or solids are present, you may be able to use a

less expensive alternative to single-phase sampling.

The following section describes case studies where sampling was • If asphaltenes may be a problem, take single phase samples.

performed in a nonconventional manner and the reasons behind it. • More research needs to be conducted on the temperature depen-

dence of asphaltenes, and this should be translated into better

Case 1. In a low-permeability saturated gas/condensate reservoir design of exothermic samplers. Since single-phase sampling has

(<1 md), separates sampling was intitally attempted. However, advanced, comparative studies should be performed on conven-

as the flow rate was through the separator and the CGR of the tional samples vs. single-phase samples for different reservoir

well stream was low, there was insufficient condensate to collect and asphaltene types.

a sample. The separator pressure was lowered; however, there • For difficult situations, a good hindsight quality check is to

was still not enough condensate to collect a sample. Split-phase compare the laboratory or onsite live reservoir fluid density with

sampling was economically unviable; therefore, it was decided the one calculated from the pressure gradients during MDT log-

to collect bottomhole samples. Saturated-gas samples are rarely ging. The new developments in the field are excellent advances

taken bottomhole; however, in this case, it was the most viable and should be used to improve sampling. However, the problem

option. Isokinetic sampling would have proved better in this should not be over-complicated and complex solutions should be

case; however, the economics of the field could not justify iso- used only when necessary.

kinetic sampling.

Acknowledgments

Case 2. A bottomhole gas sample was collected that had a satu- The authors would like to thank their affiliated companies, the

ration pressure that was too high (above reservoir pressure). The Australian School of Petroleum at the University of Adelaide,

samples were taken after conditioning, with the well shut in be- Santos Ltd., and Petrolab Pty. Ltd., for providing their support,

cause any flow at all was creating excessive drawdown. A static knowledge, and time.

pressure gradient was run to ensure that there were no liquids in

the wellbore before sampling. It was concluded that, during con- References

ditioning, the reservoir fluid had been drawn into two phases and Achourov, V., Khamitov, I., and Yatsenko, V. 2006. A Technique for

that the well had not been shut in long enough to re-establish Measuring Permeability Anisotropy and Recovering PVT Samples in a

equilibrium. As a result, it was likely that condensate mist was Heavy Oil Reservoir in North West Siberia. Paper SPE 102460

taken as well as the reservoir-gas sample. Compositional analysis presented at the SPE Russian Oil and Gas Technical Conference and

was performed by equilibrating the sample in a PVT cell at the Exhibition, Moscow, 3–6 October. DOI: 10.2118/102460-MS.

reservoir pressure and temperature, allowing the surplus conden- Amyx, J.W., Bass, D.M., and Whiting, R.L. 1960. Petroleum Reservoir

sate to drop out, and flashing only the gas. Engineering 360, New York City: McGraw-Hill.

Ayan, C., Douglas, A., and Kuchuk, F. 1996. A Revolution in Reservoir

Case 3. An unexpected zone was encountered during drilling. Characterization. Schlumberger Middle East Well Evaluation Review

Drilling was ceased until it was determined whether it was a sepa- 16: 44–55.

rate reservoir that had been discovered or if the targeted zone was Bingham, M.D. 1990. Field Detection and Implications of Mercury in Natural

at a shallower depth than expected. Bottomhole samples were taken Gas. SPEPE 5 (2): 120–124. SPE-19357-PA. DOI: 10.2118/19357-PA.

as soon as possible to measure gravity in °API. In this case, well

Cobenas, R.H. and Crotti, M.A. 1999.Volatile Oil. Determination of Res-

conditioning, contamination with drilling mud, and asphalt- enes

ervoir Fluid Composition From a Non-Representative Fluid Sample.

were not issues for the sampling program. Conventional bot-

Paper SPE 54005 presented at the SPE Latin American and Caribbean

tomhole samples were taken because they are quick and easy to

Petroleum Engineering Conference, Caracas, 21–23 April. DOI:

run and rerun. The samples, although not representative PVT 10.2118/54005-MS.

samples, did suit the purpose of the sampling job.

Dake, L.P. 1994. The Practice of Reservoir Engineering, 33, Amsterdam:

Elsevier Science B.V.

Case 4. A volatile-oil well from a tight formation was sampled at

the separator. Drawdown from the DST caused the bottomhole Dybdahl, B. 2006. A Systematic Approach to Sampling During Well Test-

flowing pressure to be well below the saturation pressure. The GOR ing. Paper presented at the ENI E&P Division and ENI Technology

at the test separator was observed to be moving continuously, first a Conference, Milan, Italy, 23 February.

dip and then increasing gradually, but not stabilizing. As the El-Banbi, A.H. and McCain, W.D. Jr. 2001. Sampling Volatile Oil Wells.

increase was slow, separator gas and oil samples were taken; how- Paper SPE 67232 presented at the SPE Production and Operations

ever, recombining at the separator GOR would have given too high Symposium, Oklahoma City, Oklahoma, 24–27 March. DOI: 10.2118/

a saturation pressure; so, using an EOS package, the GOR was 67232-MS.

backcalculated on the basis of a saturation pressure. This method, Elshahawi, H. and Hashem, M. 2005. Accurate Measurement of the Hy-

although not perfect, will still yield representative samples. drogen Sulfide Content in Formation Fluid Samples—Case Studies.

December 2007 SPE Reservoir Evaluation & Engineering 595

Paper SPE 94707 presented at the SPE Annual Technical Conference

and Exhibition, Dallas, 9–12 October. DOI: 10.2218/94707-MS. SI Metric Conversion Factors

Fevang, Ø. and Whitson, C.H. 1994. Accurate Insitu Compositions bbl × 1.589 874 E−01 m3

in Petroleum Reservoirs. Paper SPE 28829 presented at the Euro- ft3 × 2.831 685 E−02 m3

pean Petroleum Conference, London, 25–27 October. DOI: 10.2118/ scf/STB × 5.6146 E+00 m3/m3

28829-MS.

psi × 6.894 757 E+00 kPa

Jamaluddin, A.K.M., Ross, B., and Daigle, T. 1999. Single-Phase Reser-

voir Sampling: Is it a Necessity or Luxury? Paper CIM 99-36 presented

at the 1999 CSPG and Petroleum Society Joint Convention, Calgary, Jan Bon holds a BEng degree in Petroleum Engineering from

14–18 June. the University of New South Wales. Email: jbon@petrolab.net.

He is currently finishing his PhD thesis in Petroleum Engineering

Jamaluddin, A.K.M., Creek, J., Kabir, C.S. et al. 2001. A Comparison of at the Australian School of Petroleum (ASP), the University of

Various Laboratory Techniques to Measure Thermodynamic Asphalt- Adelaide while working at Petrolab, S.A. in Venezuela as a

ene Instability. Paper SPE 72154 presented at the SPE Asia Pacific laboratory manager. His duties include taking care of the

Improved Oil Recovery Conference, Kuala Lumpur, 6–9 October. DOI: analyses and sampling of reservoir fluid. Hemanta Sarma holds

10.2118/72154-MS. the Reg Sprigg Chair in Petroleum Engineering in the Australian

McCain, W.D. Jr. and Alexander, R.A. 1992. Sampling Gas-Conden- School of Petroleum (ASP), University of Adelaide. Email:

hemanta.sarma@adelaide.edu.au. He is also the founding Di-

sate Wells. SPERE 7 (3): 358–362. SPE-19729-PA. DOI: 10.2118/

rector of the Centre for Improved Petroleum Recovery at the

19729-PA. ASP and was a Research Project Leader for CO2 sequestration

Michaels, J., Moody, M., and Shwe, T. 1995. Wireline Fluid Sampling. projects on enhanced petroleum recovery and enhanced

Paper SPE 30610 presented at the SPE Annual Technical Conference coal-bed methane recovery in the CO2CRC, an Australian

and Exhibition, Dallas, 22–25 October. DOI: 10.2118/30610-MS. Cooperative Research Centre for Greenhouse Gas Technolo-

gies. Previously Sarma was a senior staff reservoir engineer with

Morton, K.L., Osman, M.S., and Kew, S.A. 2005. Heavy-Oil Uncertainties

the Alberta Research Council, Canada, and an invited re-

Facing Operators in the North Sea. Paper SPE 97898 presented at the search advisor at the Technology Research Center of Japan

SPE/PS-CIM/CHOA International Thermal Operation and Heavy Oil National Oil Corporation, where he worked in domestic and

Symposium, Calgary, 1–3 November. DOI: 10.2118/97898-MS. international R&D projects and field pilots. Sarma holds a

Nagarajan, N.R., Honarpour, M.M., and Sampath, K. 2006. Reservoir Fluid BTech degree in petroleum engineering from the Indian

Sampling and Characterization—Key to Efficient Reservoir Manage- School of Mines, an MSc degree in chemical engineering from

ment. Paper SPE 101517 presented at the Abu Dhabi International the University of Calgary and a PhD degree in petroleum en-

gineering from the University of Alberta. He is a Review Chair

Petroleum Exhibition and Conference, Abu Dhabi, UAE, 5–8 Novem-

and Technical Editor of SPE Reservoir Evaluation and Engineer-

ber. DOI: 10.2118/101517-MS. ing. Teof Rodrigues holds a BSc degree in chemical engineer-

Reudelhuber, F.O. 1957. Sampling Procedures for Oil Reservoir Fluids. ing from the University of Nottingham in the United Kingdom.

JPT 9 (12): 15–18. SPE-816-G. DOI: 10.2118/816-G. Email: teof.rodrigues@santos.com. He has 27 years in the oil

Riley, W.D., Walters, R.P., Cramer, S.D., and McCawley, F.X. 1978. industry, initially with Core Laboratories for four years working

on PVT and SCAL projects. He joined Santos Ltd. in 1984 as a

Isokinetic Technique for Sampling Geothermal Fluid In Two-Phase

reservoir engineer and has since worked in a number of super-

Flow. Unsolicited from US Dept. of the Interior. SPE-7885-MS. visory and management positions within the company in both

Strong, J., Thomas, F.B., and Bennion, D.B. 1993. Reservoir Fluid Sam- the Adelaide and Brisbane offices. He presently manages the

pling and Recombination Techniques for Laboratory Experiments. Pa- non-operated assets for Santos Ltd. in Australia. Jan G. Bon

per CIM 93–54 presented at the CIM Annual Technical Conference, started his career with Shell (KSEPL) in Rijswijk, the Netherlands

Calgary, 9–12 May. where he worked five years. Email: adelaide@petrolab.net. He

then joined Core Laboratories for some 14 years in total working

Towler, B.F. 1989. Reservoir Engineering Aspects of Bottomhole Sam- in Australia, Asia, South America, North America, Africa, and Eu-

pling of Saturated Oils for PVT Analysis. Unsolicited paper from the rope in sampling and analyses of reservoir fluid and core. He also

University of Wyoming. SPE-19438-MS. worked with SGS, introducing the company to their first upstream

Wilhelm, S.M. and McArthur, A. 1995. Removal and Treatment of Mer- venture setting up, and managing for five years a reservoir fluid

cury Contamination at Gas Processing Facilities. Paper SPE 29721 analyses operation in Venezuela. In 1987, Bon started his own

presented at the SPE/EPA Exploration and Production Environmental business, Petrolab Australia Pty. Ltd.—a PVT Analyses laboratory

Conference, Houston, 27–29 March. DOI: 10.2118/29721-MS. with cased hole and surface sampling capabilities. Through

Petrolab, he has since expanded and had operations in Asia

Williams, J.M. 1994. Getting the Best Out of Fluid Samples. JPT 46 (9): and South America out of bases in Malaysia, Bolivia and Vene-

752. SPE-29227-PA. DOI: 10.2118/29227-PA. zuela, of which the Venezuelan operation is still active.

596 December 2007 SPE Reservoir Evaluation & Engineering

S-ar putea să vă placă și

- ALIMENTACIONDocument1 paginăALIMENTACIONEsneider Galeano ArizaÎncă nu există evaluări

- NEWSDocument183 paginiNEWSSebastian BaqueroÎncă nu există evaluări

- Sample RunDocument5 paginiSample RunJudith Thatcher HerreraÎncă nu există evaluări

- 000Document1 pagină000Esneider Galeano ArizaÎncă nu există evaluări

- Leyenda LandCoverDocument3 paginiLeyenda LandCoverEsneider Galeano ArizaÎncă nu există evaluări

- Taller GirsDocument2 paginiTaller GirsEsneider Galeano ArizaÎncă nu există evaluări

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (344)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (399)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (73)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (120)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- CH 4 Bending StressesnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnDocument26 paginiCH 4 Bending StressesnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnnndudescapeÎncă nu există evaluări

- Evaluating The Effect of Laboratory Aging On Fatigue Behavior of Asphalt Mixtures Containing Hydrated LimeDocument8 paginiEvaluating The Effect of Laboratory Aging On Fatigue Behavior of Asphalt Mixtures Containing Hydrated LimeEizu YangÎncă nu există evaluări

- Secadores Sullair RN y OtrsoDocument268 paginiSecadores Sullair RN y Otrsoramiro alvarezÎncă nu există evaluări

- Chapter 6Document44 paginiChapter 6Teddy Matthew AudleyÎncă nu există evaluări

- Unit-IV-Shear Reinforcement and Bond by Limit State MethodDocument50 paginiUnit-IV-Shear Reinforcement and Bond by Limit State MethodAshish KaleÎncă nu există evaluări

- Indrakanty Surya ShashankDocument10 paginiIndrakanty Surya ShashankINDRAKANTY SURYA SHASHANKÎncă nu există evaluări

- CY6151 - Engineering Chemistry - I - 2 MarksDocument11 paginiCY6151 - Engineering Chemistry - I - 2 Markssunil1237Încă nu există evaluări

- Mechanics of CompositesDocument10 paginiMechanics of Compositesdeepakjournal100% (2)

- Cehdra 1 Obe Syllabus T2 2019 2020Document6 paginiCehdra 1 Obe Syllabus T2 2019 2020Jemina SamsonÎncă nu există evaluări

- Fluid Mechanics Lab Report 1Document9 paginiFluid Mechanics Lab Report 1Héctor GómezÎncă nu există evaluări

- Direct Design of Reinforced Concrete Beams Under Combined Bending Shear and TorsionDocument10 paginiDirect Design of Reinforced Concrete Beams Under Combined Bending Shear and TorsionKemoHÎncă nu există evaluări

- Ampacity of Cables in Solid Bottom Trays With and Without CoversDocument4 paginiAmpacity of Cables in Solid Bottom Trays With and Without CoversStefanos DiamantisÎncă nu există evaluări

- Estimating Evaporation From Water SurfacesDocument27 paginiEstimating Evaporation From Water SurfacesVinh Do ThanhÎncă nu există evaluări

- DW2005 Pro Outline 4 Day MetricDocument7 paginiDW2005 Pro Outline 4 Day MetricFernando TorresÎncă nu există evaluări

- 14960-000-ME-DAS-003 Data Sheet For Sump PumpsDocument8 pagini14960-000-ME-DAS-003 Data Sheet For Sump PumpsAshish TIwariÎncă nu există evaluări

- Engg Mechanics Assignment and QuizDocument5 paginiEngg Mechanics Assignment and QuizYaagik GoelÎncă nu există evaluări

- 4th ExamDocument1 pagină4th Examquice reviewÎncă nu există evaluări

- Wellbore Stability AnalysisDocument148 paginiWellbore Stability Analysishagh1234Încă nu există evaluări

- Lecture Five Energy BalancesDocument51 paginiLecture Five Energy BalancesHebron DawitÎncă nu există evaluări

- Pile Analysis in Accordance With EN 1997-1:2004 Incorporating Corrigendum Dated February 2009 and The Recommended ValuesDocument4 paginiPile Analysis in Accordance With EN 1997-1:2004 Incorporating Corrigendum Dated February 2009 and The Recommended ValuesRuemu Godwin InikoriÎncă nu există evaluări

- Design Criteria of Stilling BasinDocument22 paginiDesign Criteria of Stilling Basinjagmeet singhÎncă nu există evaluări

- Astm e 473 Rev A 2006 PDFDocument3 paginiAstm e 473 Rev A 2006 PDFJORGE ARTURO TORIBIO HUERTAÎncă nu există evaluări

- Praveen Et Al-2018-Advanced Engineering MaterialsDocument22 paginiPraveen Et Al-2018-Advanced Engineering Materialscam nhung NguyenÎncă nu există evaluări

- Vapor Mistlift OtecDocument6 paginiVapor Mistlift OtecemergingengineerÎncă nu există evaluări

- SRMTEC-SRH High Pressure CompressorDocument12 paginiSRMTEC-SRH High Pressure CompressornascasÎncă nu există evaluări

- Simulation of Vars Component (Evaporator) Using Ansys SoftwareDocument22 paginiSimulation of Vars Component (Evaporator) Using Ansys SoftwareSanket BhilareÎncă nu există evaluări

- Chem 2 - SolutionDocument21 paginiChem 2 - SolutionMherwin RetanalÎncă nu există evaluări

- Modelling of Airflow in Wood Kilns: UBC Mechanical Engineering CFD Modelling Process Simulations LTDDocument75 paginiModelling of Airflow in Wood Kilns: UBC Mechanical Engineering CFD Modelling Process Simulations LTDMô Dion100% (1)

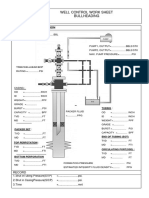

- Worksheet BullheadDocument3 paginiWorksheet BullheadHary WijayaÎncă nu există evaluări