Documente Academic

Documente Profesional

Documente Cultură

Short Circuit Force Calculations-SS2

Încărcat de

Joyce ChepkiruiDescriere originală:

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Short Circuit Force Calculations-SS2

Încărcat de

Joyce ChepkiruiDrepturi de autor:

Formate disponibile

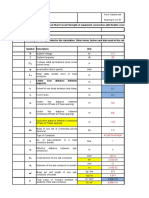

1.

0 INPUT PARAMETERS:

1.1 General Project Data:

System operating frequency, f = 50.0 Hz

3-phase initial symmetrical short-circuit current (rms), I" k3 = 40.0 kA

Duration of the first current flow, T k1 = 0.3 sec

Nature of conductor installation (Strained or Slack) = Strained ; Let insulator length (m) = 5.500

Centre-line distance between supports, l = 99.500 m No. Insul. = 2

Cord length of main conductor in the span, l c = 88.500 m

Mean centre-line distance between conductors, a = 6.800 m

Number of subconductors of a main conductor, n = 2

Resultant spring constant of both span supports, S = 500,000 N/m

Lowest value of bending stress (σ) when Young's

= 5.00E+07 N/m 2

Modulus (E) becomes Constant, σ fin

Conventional value of acceleration due to gravity, g n = 9.80700 m/sec2

Magnetic constant permeability of vacuum, µ o = 4π x 10

-7

( 1.2566E-06 )

1.2 Conductor Properties:

Conductor Type/Name = ACSR 710 mm2 JIS

Total Cross-Sectional Area (A s) = 7.5900 cm

2

Material:

Diameter of the conductor, (d s) = 35.90 mm ACSR

Effective distance between sub-conductors, (a s) = 400.00 mm Al [ mm2 ]= 710.00

Unit Weight of the Conductor with Grease (m' s) = 2.51269 Kg/m St [ mm2 ]= 49.10

Young’s Modulus of Elasticity (Final) (E f) = 67,000.00 N/mm 2 Rat. (Al/St) = 14.46

Young’s Modulus of Elasticity (Initial) (E i) = 67,000.00 N/mm 2

Ultimate Tensile Strength (U.T.S.) = 18,641.432 Kg

Distance spacers within a span, (ls) = 4.214 m

1.3 Static Conductor Tensile Force at Respective Temperature:

0 Force, Fst (N)

Temp. ( C)

Minimum local temperatures 24.0 22,043

Maximum operating temperature 74.0 17,639

2.0 Electro-Magnetic Force Calculations [F] :

2.1 Electro-magnetic force per unit length, F'

= 31.392 N/m

2.2 Ratio of electromagnetic force to gravitational force on a conductor

= 0.637 N/m

2.3 Direction of the resulting force, δ1

= 32.496 0

2.4 Equivalent static conductor sags at midspan, bc

At minimum local temperature = 2.767 m

At maximum operating temperature = 3.458 m

2.5 Periods T of the conductor oscillations without current flow in the conductor, T

0.4*T [sec]

At minimum local temperature = 2.985 sec 1.1940

At maximum operating temperature = 3.337 sec 1.3348

2.6 Resulting periods of the conductor oscillations during short-circuit current flow, T res

At minimum local temperature = 3.021 sec

At maximum operating temperature = 3.378 sec

SC Force Calcs-Flexible Page 1 of 5 15-07-19 9:08 AM

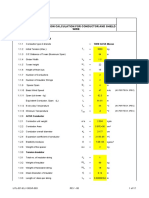

2.7 Actual Young's Modulus, Es

Temperature (0C)

24.0 74.0

= 1.452E+07 1.162E+07

2 2

[N/m ] [N/m ]

At minimum local temperature = 4.08E+10 N/m

2

At maximum operating temperature = 3.68E+10 N/m

2

2.8 Stiffness Norms, N

At minimum local temperature = 3.626E-08 N

-1

At maximum operating temperature = 3.798E-08 N

-1

2.9 Stress Factors, ξ, of the main conductor

At minimum local temperature = 2.580

At maximum operating temperature = 4.807

###### Span Swing-out Angles, δ k:

Temperature (0C)

24.0 74.0

(Tk1/Tres) 0.099 0.089

At minimum local temperature = 6.121 0

At maximum operating temperature = 4.930 0

###### Maximum Swing-out Angles, δ m:

Factor chi,

χ δm

At minimum local temperature 0.932 26.549

At maximum operating temperature 0.945 23.808

3.0 Calculation of Tensile Forces [F] :

3.1 Tensile Force, Ft, during Short-Circuit caused by Swing-out (SC Tensile Force):

3.1.1 Load Parameter, φ

Temperature (0C)

24.0 74.0

T k1 0.300 0.300

(T res /4) 0.755 0.844

At minimum local temperature = 0.18666

At maximum operating temperature = 0.15313

3.1.2 Factor, ψ

Dependent on φ & ξ

Temperature (0C) 24.0 74.0

φ 0.187 0.153

ξ 2.580 4.807

Factor, ψ 0.820 0.895

= 0.000195 -0.000013

SC Force Calcs-Flexible Page 2 of 5 15-07-19 9:08 AM

3.1.3 Short-Circuit Tensile Force, Ft

At minimum local temperature = 27.957 kN

At maximum operating temperature = 22.062 kN

Thus, Tensile Force Before Short Circuit, Ft = 27.957 kN

3.2 Tensile Force, Ff, After Short-Circuit caused by Drop (Drop Force):

r > 0.6 ; Tensile force after short-circuit is significant,

At minimum local temperature, δm = 27 < 70 ; Tensile Force Insignificant

At maximum operating temperature, δm = 24 < 70 ; Tensile Force Insignificant

At minimum local temperature = 0.000 kN

At maximum operating temperature = 0.000 kN

Thus, Tensile Force after Short-Circuit, Ff = 0.000 kN

3.3 Horizontal Span Displacement b h and Air Clearance, amin:

Elastic expansion: 𝜀𝑒𝑙𝑎 = 𝑁 ⋅ 𝐹𝑡 − 𝐹𝑠𝑡 = 2.1444E-04 [ At minimum local temperature ]

𝜀𝑒𝑙𝑎 = 𝑁 ⋅ 𝐹𝑡 − 𝐹𝑠𝑡 = 1.6798E-04 [ At maximum operating temperature ]

Horizontal Span Displaceement b h and Air Clearance, amin:

Temperature (0C)

24.0 74.0

T k1 0.300 0.300

(T res /4) 0.755 0.844

Material constant, cth = 2.700E-19 4 2

m / (A s)

Thermal expansion:

At minimum local temperature = 5.6242E-05

At maximum operating temperature = 5.6242E-05

Dilatation factor: Allows for sag increase due to elastic and thermal elongation of conductor:

= 1.06361 [ At minimum local temperature ]

= 1.05297 [ At maximum operating temperature ]

Form factor: Allows for possible increase in dynamic sag due to change in shape of conductor curve:

= 1.05000

Maximum horizontal displacement within a span due to a short circuit, b h:

Slack conductor:

=

=

Strained conductor:

= 1.381 m [ At minimum local temperature ]

= 1.543 m [ At maximum operating temperature ]

Minimum distance between phase conductors under short circuit conditions, a min:

𝑎𝑚𝑖𝑛 = (a - 2 𝑏ℎ ) = 4.038 m [ At minimum local temperature ]

= 3.714 m [ At maximum operating temperature ]

3.4 Tensile Force caused by the Pinch Effect of Sub-conductors, F pi:

Check if subconductors clash effectively or NOT?

They are considered to class effectively if conditions represented by below equations are fullfilled:

(as / ds) = 11.142

50 as = 20.000 m 70 as = 28.000 m

(as / ds) > 2.0 and ls = 4.214 m < 50 as = 20.000 m : Non-effective clash

(as / ds) > 2.5 and ls = 4.214 m < 70 as = 28.000 m : Non-effective clash

SC Force Calcs-Flexible Page 3 of 5 15-07-19 9:08 AM

Short circuit current force, Fv:

Factor ν2 from Annex A.6 - Figure 8 is given as a function of ν1 whose value is given by;

Factor, = 3.38170

Factor,

k= 1.863359

−3

𝜏= = 0.063594 sec

𝑘 − 1.02

2𝜋𝑓 ⋅ ln

0 ⋅ 98

𝛾 = 𝑎𝑟𝑐 tan 2𝜋𝑓𝜏 = 1.520785 radians

𝜈1

𝑓 ⋅ 𝑇𝑝𝐼ሶ = = 2.426815 [ Tpi = 0.0485363 sec ]

𝜈2

Therefore factor, ν 2 = 1.941574 f.Tpi - (ν1 / √ν2) = -0.000118

Factor ν3 from Annex A.7 - Figure 9 is given by;

= 0.225672

The above yields a value of F v = 7,251.805 N

Strain factors characterising the bundle contraction (ε st & εpi):

= 0.16064 [ At minimum local temperature ]

= 0.13464 [ At maximum operating temperature ]

= 0.30586 [ At minimum local temperature ]

= 0.32035 [ At maximum operating temperature ]

Parameter 'j' for determining bundle configuraton during short circuit:

j = √ [ εpi / (1+ εst) ] = 0.51335 <1 [ At minimum local temperature ]

= 0.53136 <1 [ At maximum operating temperature ]

Note: Sub-conductors reduce their distance but do NOT clash both at min. local and max. operating temperatures

3.4.1 Tensile Force in the case of clashing Sub-conductors, F pi: (When j ≥ 1)

Factor ν4 = (as - ds ) / ds = 10.14206

Stress factor of the flexible main conductor (ξ): - Obtained as a real solution of equation below;

ξ= 0.62419 -0.000082 [ At minimum local temperature ]

ξ= 0.64212 -0.000084 [ At maximum operating temperature ]

check that 0.6411 > ξ = 0.6242 and j = 0.5133 < ξ = 0.6242 [Local temp.]

j2/3 = 0.6560 > ξ = 0.6421 and j = 0.5314 < ξ = 0.6421 [Oper. Temp]

Factor,

Therefore factor, ν e =

=

=

=

SC Force Calcs-Flexible Page 4 of 5 15-07-19 9:08 AM

3.4.1 Tensile Force in the case of non-clashing sub-conductors, F pi: (When j < 1)

Factor, η = 0.32377 -0.000929 [ At minimum local temperature ]

η= 0.35532 -0.000790 [ At maximum operating temperature ]

ya = 0.5 * [ as - η (as - ds) ] = 141.06 mm [ At minimum local temperature ]

ya = 135.31 mm [ At maximum operating temperature ]

Effective centre-line distance between the sub-conductors in the bundle, a sw:

= 317.79 mm [At minimum local temperature ]

= 309.31 mm [At maximum operating temperature]

Factor, ν4 = η { [as - ds] / [as - η (as - ds)] } = 0.41786 [ At minimum local temperature ]

Factor, ν4 = = 0.47805 [ At maximum operating temperature ]

= 90.269 mm [At minimum local temperature ]

= 90.269 mm [At maximum operating temperature]

Factor characterising bundle contraction, f η = (as ν3) / asw = 0.28405 [ At minimum local temperature ]

fη = 0.29184 [ At maximum operating temperature ]

Therefore factor, ν e = 1.94013 [ At minimum local temperature ]

= 1.77258 [ At maximum operating temperature ]

= 49,950.40 N [ At minimum local temperature ]

= 46,958.75 N [ At maximum operating temperature ]

Pinch force, Fpi = 49.950 kN [ At minimum local temperature ]

46.959 kN [ At maximum operating temperature ]

Thus, Tensile force due to the pinch effect, F pi = 49.950 kN

Results Summary

Tensil Forces (kN) Required distances [m]

Description of Condition Due to Swing Drop Force, Due to Pinch Min. air Horizontal

Out Ft Ff Effect, Fpi clear., amin displ., bh

At minimum local temeperature 27.957 0.000 49.950 4.038 1.381

At maximum operating temperature 22.062 0.000 46.959 3.714 1.543

Maximum values 27.957 0.000 49.950 4.038 1.543

4.0 Design load for Insulators, their Supports and Connectors (clause 2.4.1) - Slack:

Rating Force for Flexible Conductor Connectors = Maximum value of (1.5 Ft), (1.0 Ff) and (1.0 Fpi)

= 49.950 kN

Design load Structures, Insulators and Connectors with tensile forces transmitted by insulator chains

4.1

(clause 2.4.2) - Strained:

Rating Force for Flexible Conductor Connectors = Maximum value of (1.0 Ft), (1.0 Ff) and (1.0 Fpi)

= 49.950 kN

NB: Applied as a Static Load

SC Force Calcs-Flexible Page 5 of 5 15-07-19 9:08 AM

S-ar putea să vă placă și

- Strength of Materials and Structures: An Introduction to the Mechanics of Solids and StructuresDe la EverandStrength of Materials and Structures: An Introduction to the Mechanics of Solids and StructuresEvaluare: 4 din 5 stele4/5 (1)

- 33 SCF Tower Span 18mDocument25 pagini33 SCF Tower Span 18mamrit90320Încă nu există evaluări

- Acsr Panther Conductor Sizing Xls 0 PDFDocument6 paginiAcsr Panther Conductor Sizing Xls 0 PDFRavindra GoyalÎncă nu există evaluări

- SCF Calculations For A Rigid Conductor - Detailed Method PDFDocument3 paginiSCF Calculations For A Rigid Conductor - Detailed Method PDFJoyce ChepkiruiÎncă nu există evaluări

- Mechanical Short Circuit StrengthDocument12 paginiMechanical Short Circuit Strengthanoop13Încă nu există evaluări

- Short Circuit Force For Equipment InterconnectionDocument17 paginiShort Circuit Force For Equipment Interconnectionudayakumart100% (4)

- Calculations For Sag and Swing of Strung ConductorDocument27 paginiCalculations For Sag and Swing of Strung ConductorHugh cabÎncă nu există evaluări

- SCF CalculationDocument158 paginiSCF Calculationvikasrajput1989100% (2)

- 33 KV TowerDocument4 pagini33 KV TowerJayabalan R KÎncă nu există evaluări

- Sag Tension 765kVDocument11 paginiSag Tension 765kVvikasrajput1989100% (1)

- 400KV 34.5MTRS Sag Tension CalculationDocument7 pagini400KV 34.5MTRS Sag Tension CalculationRaisinghani BhushanÎncă nu există evaluări

- 220 KV Sag Tension Calculation - ThyottarDocument13 pagini220 KV Sag Tension Calculation - Thyottarannuvyas100% (3)

- SAG Tension For TWIN-QUAD Conductor Considering Wind Effect - InputsDocument2 paginiSAG Tension For TWIN-QUAD Conductor Considering Wind Effect - InputsCassie Harvey100% (2)

- Sag-Tension Calculation IEEE STD 605 2008Document10 paginiSag-Tension Calculation IEEE STD 605 2008vishnuvyasÎncă nu există evaluări

- Short-Circuit Currents - Calculation of Effects The Second Edition of Iec Publication 865Document10 paginiShort-Circuit Currents - Calculation of Effects The Second Edition of Iec Publication 865Hassan Bagheri100% (1)

- Short Circuit Force CalculationDocument11 paginiShort Circuit Force CalculationAchint Kumar100% (2)

- Sagging CalculationDocument3 paginiSagging Calculationwiizt100% (5)

- 315 MVA Trafo PDFDocument12 pagini315 MVA Trafo PDFzeeshanyg100% (2)

- DSLP (11 3m)Document7 paginiDSLP (11 3m)Ashutosh MishraÎncă nu există evaluări

- Minimum Clearance in SubstationDocument33 paginiMinimum Clearance in SubstationBijaya Kumar MohantyÎncă nu există evaluări

- Pathlaiya SS 132kV Busbar DesignDocument9 paginiPathlaiya SS 132kV Busbar DesignSantosh GairheÎncă nu există evaluări

- Aluminium Conductor Sizing - 275kVDocument10 paginiAluminium Conductor Sizing - 275kVsitifarhaniÎncă nu există evaluări

- ACSR Conductor SizingDocument13 paginiACSR Conductor SizingraghuvarmaÎncă nu există evaluări

- Forces On Gantry-34Document5 paginiForces On Gantry-34vkjainabc100% (1)

- 123Document29 pagini123Pravin Narkhede100% (1)

- Transmission Line Sag & TensionDocument37 paginiTransmission Line Sag & TensionCatrina Federico100% (2)

- Claulation For Check Suitability of IPSDocument45 paginiClaulation For Check Suitability of IPSannuvyas100% (1)

- Sag Tension 765kVDocument27 paginiSag Tension 765kVAnurag SarrafÎncă nu există evaluări

- DSLP Calculation by VikasDocument7 paginiDSLP Calculation by Vikasvikasrajput1989100% (2)

- Sag Tension 765kVDocument11 paginiSag Tension 765kVzain abideenÎncă nu există evaluări

- Acsr Panther Conductor Sizing - Xls 0Document6 paginiAcsr Panther Conductor Sizing - Xls 0Rakesh Kumar Shukla0% (2)

- Busbar Sizing For SubstationDocument22 paginiBusbar Sizing For Substationdundi_kumarÎncă nu există evaluări

- 132kV SAG CalculationDocument14 pagini132kV SAG CalculationPramod B.Wankhade100% (4)

- Technical Schedule of Surge Arrester 400 KV - ABBDocument5 paginiTechnical Schedule of Surge Arrester 400 KV - ABBmohammadkassarÎncă nu există evaluări

- Creep IEEEDocument45 paginiCreep IEEEPablo DavelozeÎncă nu există evaluări

- SAG Tension For TWIN-QUAD Conductor Considering No Wind - InputsDocument2 paginiSAG Tension For TWIN-QUAD Conductor Considering No Wind - InputsAnupam0103Încă nu există evaluări

- 3VYN191246 - Busdesign CalculationsDocument9 pagini3VYN191246 - Busdesign CalculationsManiKantÎncă nu există evaluări

- Short-Circuit Design Forces in Power Lines & SubstationsDocument28 paginiShort-Circuit Design Forces in Power Lines & Substationscustomerx100% (2)

- 33 KV Transmission Line Design Drawings PDFDocument265 pagini33 KV Transmission Line Design Drawings PDFkapilsharma404Încă nu există evaluări

- Sag Tension Calculation-765 KVDocument13 paginiSag Tension Calculation-765 KVHugh cabÎncă nu există evaluări

- Power Grid Corporation of India LTDDocument13 paginiPower Grid Corporation of India LTD1382aceÎncă nu există evaluări

- National Contracting Co. LTD.: ProjectDocument58 paginiNational Contracting Co. LTD.: ProjectNavneeth100% (1)

- Cantilever Strength CalculationsDocument2 paginiCantilever Strength Calculationsakash_ing7683100% (5)

- Engineering Method For Calculation of Short-CircuitDocument8 paginiEngineering Method For Calculation of Short-CircuitHakkim Sheik Thauth J100% (1)

- 220 V DC Battery Sizing 220 KV Main Station 1Document25 pagini220 V DC Battery Sizing 220 KV Main Station 1Madhu BTÎncă nu există evaluări

- Stub Cleat Design DD-DDEDocument1 paginăStub Cleat Design DD-DDEHikmat AyerÎncă nu există evaluări

- Sag CalculationDocument20 paginiSag Calculationrahu111112000Încă nu există evaluări

- Razevig Method DSLPDocument19 paginiRazevig Method DSLPsunny171083_901235920% (2)

- Sample Calculations Sag and Tension UNEVEN Max TempDocument2 paginiSample Calculations Sag and Tension UNEVEN Max TempAgnichandra SubediÎncă nu există evaluări

- Earthing Calculation: A General Design DataDocument6 paginiEarthing Calculation: A General Design DataHOFFERÎncă nu există evaluări

- SAG TENSION CALCULATION FOR CONDUCTOR AND SHIELD WIRE - Rev-0Document20 paginiSAG TENSION CALCULATION FOR CONDUCTOR AND SHIELD WIRE - Rev-0ANAND100% (6)

- CATENARY SAG-TENSION CALCULATOR (By: Jared Cuchapin, 2018) : 300 DrakeDocument12 paginiCATENARY SAG-TENSION CALCULATOR (By: Jared Cuchapin, 2018) : 300 Drakedursun_yerlikaya100% (2)

- Pallavi Adss ReportDocument9 paginiPallavi Adss Reportraj patilÎncă nu există evaluări

- DSLPDocument9 paginiDSLPjack paglaÎncă nu există evaluări

- DEBA-DD-EL-CC-3141-0.1-flexible Conductor Size CalculationDocument4 paginiDEBA-DD-EL-CC-3141-0.1-flexible Conductor Size Calculationjie zhangÎncă nu există evaluări

- Substation Grounding Grid Calculation: Basic Design ParametersDocument9 paginiSubstation Grounding Grid Calculation: Basic Design Parametersclark ian manuel ongchuaÎncă nu există evaluări

- 110kv Sagtension Calculation 1 PDF FreeDocument13 pagini110kv Sagtension Calculation 1 PDF FreeAnonymous 5XvUbWynnÎncă nu există evaluări

- SC Calculations - EditDocument118 paginiSC Calculations - Editeps.hvdc.ocÎncă nu există evaluări

- Catenary Sag-Tension Calculator (Even and Uneven)Document2 paginiCatenary Sag-Tension Calculator (Even and Uneven)mohsin160Încă nu există evaluări

- Conductor Sag and Tension CalculatorDocument11 paginiConductor Sag and Tension CalculatorSanjeev KumarÎncă nu există evaluări

- Tower Spotting Data Computation - Reduced DeviationDocument1 paginăTower Spotting Data Computation - Reduced DeviationJoyce ChepkiruiÎncă nu există evaluări

- Midspan Clearance - Calc SheetDocument1 paginăMidspan Clearance - Calc SheetJoyce ChepkiruiÎncă nu există evaluări

- Timber Design CheckDocument1 paginăTimber Design CheckJoyce ChepkiruiÎncă nu există evaluări

- Design of Transformer Foundation PDFDocument3 paginiDesign of Transformer Foundation PDFJoyce ChepkiruiÎncă nu există evaluări

- Swing Angle Calculations PDFDocument1 paginăSwing Angle Calculations PDFJoyce ChepkiruiÎncă nu există evaluări

- Study On Rigid Pavement Analysis and DesignDocument11 paginiStudy On Rigid Pavement Analysis and DesignAbdinur Ibrahim AnshurÎncă nu există evaluări

- MecexerciciosDocument14 paginiMecexerciciosJoão PadilhaÎncă nu există evaluări

- EMM3526 - Assignment 1 - FEM - TasksDocument12 paginiEMM3526 - Assignment 1 - FEM - TasksaffanÎncă nu există evaluări

- BS en 14620-4-2006Document34 paginiBS en 14620-4-2006ramadoss_alwar7307Încă nu există evaluări

- Heat & Thermodynamics by KAMRAN SOOMRODocument8 paginiHeat & Thermodynamics by KAMRAN SOOMROSTUDY.Încă nu există evaluări

- PTB ExpansionDocument26 paginiPTB Expansionshahid hamzaÎncă nu există evaluări

- IACS Rec 109 Acceptance Criteria Tank Filling Limits Higher 98%Document3 paginiIACS Rec 109 Acceptance Criteria Tank Filling Limits Higher 98%carlocftÎncă nu există evaluări

- Guide For Cast-in-Place Low-Density Cellular Concrete: ACI 523.1R-06Document25 paginiGuide For Cast-in-Place Low-Density Cellular Concrete: ACI 523.1R-06Gasoline L’orroreÎncă nu există evaluări

- Victaulic Modeling by AutoPipe PDFDocument18 paginiVictaulic Modeling by AutoPipe PDFlimin zhangÎncă nu există evaluări

- A Problem of Underestimating Contraction For A Shrink FitDocument2 paginiA Problem of Underestimating Contraction For A Shrink FitParag NaikÎncă nu există evaluări

- NORSOK U CR 006r1 - Subsea Production Control UmbilicalDocument14 paginiNORSOK U CR 006r1 - Subsea Production Control UmbilicalNils Antoine FreundÎncă nu există evaluări

- Thermal Expansion CalculatorDocument2 paginiThermal Expansion CalculatorPriyanathan ThayalanÎncă nu există evaluări

- Astm - C598Document5 paginiAstm - C598KuNtii Devi VerdejofÎncă nu există evaluări

- Multiple Culverts: Example 4Document16 paginiMultiple Culverts: Example 4raghurmiÎncă nu există evaluări

- BD 2101Document77 paginiBD 2101babarkhattakÎncă nu există evaluări

- Properties of Solids and Liquids PDFDocument63 paginiProperties of Solids and Liquids PDFNarendra KumarÎncă nu există evaluări

- Class X Full Mock Physics Hari Sir 9064194423Document2 paginiClass X Full Mock Physics Hari Sir 9064194423physicshari.bwnÎncă nu există evaluări

- 2012-06 TurboMach ThermalGrowthDocument2 pagini2012-06 TurboMach ThermalGrowthGilberto PérezÎncă nu există evaluări

- Is 15328 PDFDocument28 paginiIs 15328 PDFakgupta7337790% (1)

- Secondary School Physics Form One Notes 2020Document51 paginiSecondary School Physics Form One Notes 2020Danny KimÎncă nu există evaluări

- Cold Weather Concreting, 2020Document236 paginiCold Weather Concreting, 2020mehrdadÎncă nu există evaluări

- Jain PE Piping System, p17 - Old PipesDocument119 paginiJain PE Piping System, p17 - Old PipesVaios Anyfantis100% (1)

- EVA Test PropeetiesDocument37 paginiEVA Test Propeetiessimon sembiringÎncă nu există evaluări

- Thermostat: Chapter 19Document12 paginiThermostat: Chapter 19KATHLEEN MAY BARRILÎncă nu există evaluări

- Cutnell & Johnson: "Physics," Sixth Edition: Introduction and Mathematical ConceptsDocument28 paginiCutnell & Johnson: "Physics," Sixth Edition: Introduction and Mathematical ConceptsMariano Valiente Jr.Încă nu există evaluări

- First Year Important Very Short Answers by Mr. Hameed Ali Khan M.SC B.Ed (PH.D)Document4 paginiFirst Year Important Very Short Answers by Mr. Hameed Ali Khan M.SC B.Ed (PH.D)Shoaib Al KaseriÎncă nu există evaluări

- The 2016 Revision of ISO 1 - Standard Reference TeDocument8 paginiThe 2016 Revision of ISO 1 - Standard Reference TeFabianoCRZÎncă nu există evaluări

- 2 - Heat Transfer and Thermal ExpansionDocument5 pagini2 - Heat Transfer and Thermal ExpansionJhanice TargaÎncă nu există evaluări

- Dental Materials II - The Differences Between Porcelain & Acrylic Teeth - by Noor Al-Deen M. Al-KhanatiDocument1 paginăDental Materials II - The Differences Between Porcelain & Acrylic Teeth - by Noor Al-Deen M. Al-KhanatiNoor Al-Deen Maher50% (2)

- Revision Checklist For O-Level Physics 5054: WWW - Revision-Notes - Co.ccDocument24 paginiRevision Checklist For O-Level Physics 5054: WWW - Revision-Notes - Co.ccLion Jude Tissera0% (1)