Documente Academic

Documente Profesional

Documente Cultură

Demag Overhead Crane

Încărcat de

Wanto SitinjakTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Demag Overhead Crane

Încărcat de

Wanto SitinjakDrepturi de autor:

Formate disponibile

Demag Standard Cranes

Performance and efficiency at the highest level

20855744-0210-EN MHE Standardkrane RZ.indd 1 09.08.10 09:50

Demag Cranes & Components sets standards for industrial cranes

Standard crane solutions made by Demag offer outstand- The C shape of the Demag DR rope hoist design is ideally

ing quality, efficiency and reliability at the highest level. suited to crane applications. Thanks to the many benefits

Every crane and every crane component reflects our offered by the rope hoist, the entire crane operates much

decades of crane expertise and reliability as a partner more efficiently.

for the industry.

Demag DR rope hoist benefits:

Innovation for greater efficiency ■■ Reproducible connection geometry and effective spare

With the Demag DR rope hoist, for example, we present parts management provide the basis for optimum

you an extended state-of-the-art for Standard Cranes in planning and the certainty of a reliable investment

applications for loads weighing up to 50 t and have again ■■ Proven crane geometry with welded crane girders

set the standard for crane engineering. guarantees high design rigidity, optimum travel charac-

teristics and minimum wear

■■ Longer hook paths, improved utilization of the available

space and lower construction and running costs thanks

to possible raised crane girders, designs tailored to

match the roof structure and compact crabs with

minimum approach dimensions

■■ Highly convenient operation and safe load handling

thanks to ergonomic operating elements and bi-direc-

tional radio control; the standard display provides

complete transparency for control of the installation

and enables operating status data to be read out, for

example

■■ Infinitely variable speed control in all motion axes

thanks to frequency inverter-fed drives eliminates load

sway, facilitates exact and gentle positioning and re-

duces the mechanical load on the crane installation

■■ Faster handling rates and improved efficiency thanks to

high lifting and cross-travel speeds

38926-2

Single-girder overhead travelling Double-girder overhead travelling

Crane type Suspension cranes (EPDE/EKDE)

cranes (EPKE/EKKE) cranes (ZKKE)

Load capacity* up to 8t 12.5 t 50 t

Span dimension* up to 24 m 35 m

Long-travel speed* up to 40 m/min

Cross-travel speeds* up to 30 m/min 25 m/min

Hoist speed* up to 12.5 m/min

Stepless motions 3 axes

* Other specifications on request

20855744-0210-EN MHE Standardkrane RZ.indd 2 09.08.10 09:50

39343-2

Infinitely variable speed control facilitates particularly gentle handling of the load

Single-girder overhead

travelling crane

Suspension crane

with rolled-profile girder (EPKE)

(EPDE / EKDE)

Single-girder overhead Double-girder over-

head travelling crane

travelling crane with

box-section girder (EKKE) (ZKKE)

20855744-0210-EN MHE Standardkrane RZ.indd 3 09.08.10 09:50

Attention to detail for total quality

39559 40242-6 37371-1

Crane end carriage Power supply line

■■ Rigid box-section design with a reinforced connection ■■ Demag DCL compact conductor line for 4 to 7 poles

area featuring welded diaphragm plates as well as and screw-type connections ensures long-term power

engineering tolerances in the crane girder connection supply and minimises unplanned downtime

guarantee high stability and inherent rigidity as well as ■■ Pre-assembled elements for simple assembly or replace-

optimum travel characteristics with minimum wear on ment of current collector trolleys or complete straight

the crane runway and travel wheels sections provide optimum serviceability

■■ The precise travel wheel arrangement and exact adjust- ■■ IP 23 or IP 24 high protection against accidental

ment of the crane span dimension thanks to inter- contact with sealing lip and integrated expansion

changeable spacer elements ensure optimum travel compensation for optimum safety

characteristics and high adaptability to possible crane

runway tolerances

■■ Crane travel unit design with the aid of in-house static

design programs and simple assembly thanks to good

accessibility offer safety and efficiency, which reduces

maintenance costs

Travel unit

■■ Maintenance-free drives with anti-friction bearings

lubricated for life, generous bearing arrangement to

accommodate horizontal forces and travel wheels made

of spheroidal graphite cast iron provide for favourable

travel characteristics and minimum wear on the crane

runway and travel wheels

■■ Infinitely variable travel speeds thanks to frequency

inverter-fed drives with speeds up to 80 m/min without

the need for any additional cabling and wiring ensure

low-vibration travel as well as precise positioning and

reduce the load on the overall installation

37427-4

20855744-0210-EN MHE Standardkrane RZ.indd 4 09.08.10 09:50

38972-2-1 39589-4 39030-1 39330-1

Crab Control

■■ DR rope hoist of C-shaped design optimised for crane Ergonomically designed control units for safe, fatigue-

applications with increased hoist and cross-travel free handling. The standard display provides complete

speeds offers higher handling rates and efficiency transparency for control of the installation. The CAN Bus

for cranes with load capacities up to 50 t control system corresponds to Category 3 to

■■ Compact designs with minimum approach dimensions DIN / EN 954.

and long hook path ensure optimum utilization of the ■■ Demag DLC line control

available space and height and reduce construction and Height-adjustable control pendant suspended for

running costs separate travel on the crane girder

■■ Infinitely variable hoist and travel motions ensure low- ■■ Demag DRC radio control

sway handling. Precise and gentle positioning provides Radio controls with proportional pushbuttons for

for greater safety and convenient operation wireless control with variable radio frequency operation

■■ CAN Bus technology to meet tomorrow's demands for for unimpeded radio transmission

high data transmission reliability, corresponding to ■■ Demag DRC-J joystick transmitter

Category 3 to DIN / EN 954, ensures optimum monitor- Radio control with a practical belt that can be carried

ing for greater efficiency thanks to preventive mainte- comfortably

nance

Bottom block

■■ Perfect bottom block design with standard load hook

for ease of load connection

■■ Rope lead-in guard eliminates the risk of being caught

between the rope and sheave

■■ Handle recesses on both sides simplify handling of the

bottom block and increase operating safety

38962

20855744-0210-EN MHE Standardkrane RZ.indd 5 09.08.10 09:50

Single-girder overhead travelling cranes with box-section girders

EKKE single-girder overhead travelling cranes provide you Your benefits:

with Demag technology at a particularly attractive price. ■■ Computer-optimised box section as the crane girder

These cranes feature maximum rigidity for a minimum ■■ End carriages of torsionally rigid, welded box-section

deadweight. This keeps the load on the crane runway design

low, and a cost-effective design can be selected for the ■■ Travel wheels of highly wear-resistant GGG 70 spheroidal

building. They also offer the benefits of outstanding cast iron with self-lubricating properties

crane geometry, resulting in exceptional travel character- ■■ Connections between the main girder and end carriages

istics. The Demag DR rope hoist, for example, is of opti- manufactured to mechanical engineering tolerances for

mum design for crane applications. Therefore, the entire minimum wear

crane meets your demands for greater efficiency. ■■ Crab of low-headroom design with chain hoist or rope

hoist, offering particularly favourable hook approach

dimensions to serve the largest possible area

■■ Power supply to the crab by means of highly flexible flat

cable with protective earth conductor

■■ Control pendant suspended for separate travel on the

crane girder, with display for installation monitoring

■■ Optional: radio control with display and proportional

pushbuttons

■■ Optimum anti-corrosion protection of all parts thanks to

pre-treatment of steel components to industry standard

■■ Paint finish in semi-matt golden yellow. Travel drives in

azure blue. Crab powder-coated in azure blue and silver

grey

EKKE single-girder overhead travelling crane Optimum adaptation to the building design

Technical data

Load capacity up to 10 t

Span up to 30 m

Long-travel speed up to 40 m/min

Cross-travel speed up to 30 m/min

Hoist speed up to 12.5 m/min

Other specifications on request

Type 1 Type 2

Options

See additional equipment, page 14

Technical data sheet

ident. no. 203 529 44

Type 3 Type 4/5

20855744-0210-EN MHE Standardkrane RZ.indd 6 09.08.10 09:50

38972-1

Your benefits with the Demag DR rope hoist ■■ Monitoring for improved installation transparency

optimised for crane applications ■■ Improved utilisation of your production area thanks to

■■ Increased efficiency thanks to extended Demag minimum approach dimensions

service life (1,900-hour full-load service life)

■■ Improved load handling thanks to increased lifting and

cross-travel speeds

■■ Low-sway load motions thanks to infinitely variable

cross-travel speeds

20855744-0210-EN MHE Standardkrane RZ.indd 7 09.08.10 09:50

Single-girder overhead travelling cranes with rolled-profile girders

EPKE single-girder overhead travelling cranes with a control pendants. When fitted with features such as

rolled-profile girder as the load bearing structure offer infinitely variable-speed cross-travel drives, they also

outstanding value for money. The use of rolled-steel make it possible to achieve low-sway travel motions

sections for the crane girder and specially designed for gentle handling and precise positioning of loads.

travelling rope hoists or chain hoists make these cranes In addition, they also offer high reliability and safety

the optimum solution for light loads and relatively small as well as a long service life combined with high levels

spans. of operating efficiency by all components.

As a particularly inexpensive entry-level model offering Benefits and features

the usual high level of Demag quality, single-girder over- ■■ Available with Demag DR rope hoists and Demag DC

head travelling cranes with rolled-section girders can be chain hoists

integrated into existing workshops or new buildings as ■■ You benefit from the proven advantages of single-

workshop cranes, for example. EPKE standard cranes girder overhead travelling cranes

ensure efficient and fatigue-free load handling thanks to

the higher cross-travel speed and optimised ergonomic

Optimum adaptation to the

building design

EPKE single-girder overhead travelling crane

Technical data

Load capacity up to 12.5 t

Span up to 18 m

Long-travel speed up to 40 m/min

Cross-travel speed up to 30 m/min Type 1

Hoist speed up to 12.5 m/min

Other specifications on request

Options

See additional equipment, page 14

Technical data sheet

Ident. no. 203 728 44 (with DR)

Type 2

Ident. no. 203 729 44 (with DC)

Type 3

20855744-0210-EN MHE Standardkrane RZ.indd 8 09.08.10 09:50

40227-7

EPKE single-girder overhead travelling cranes are optionally fitted with DR rope hoists or DC chain hoists

20855744-0210-EN MHE Standardkrane RZ.indd 9 09.08.10 09:50

Suspension cranes – the column-free alternative

Demag suspension cranes operate on crane runways that Your benefits

are attached to the existing roof structure. This design ■■ Consistently high quality with all the advantages

eliminates the need to install crane runway columns. In offered by overhead travelling cranes (pages 6/7)

this way, the entire workshop area is available for pro- ■■ Optimised end carriage design

duction. In addition, any sections of the workshop can ■■ Rigid I-beam girders or welded box-section girders

be served. The overhangs on either side can be used to for optimum load distribution

extend the travel path of the travelling hoist beyond the ■■ Loads can be handled immediately adjacent to the

span dimension. Optional latching devices make it pos- building wall by means of girder ends tailored to meet

sible to transfer the travelling hoist from the crane girder application requirements

to a branch track and backagain without having to

deposit the load.

EPDE / EKDE suspension crane

Technical data

Optimum adaptation to the

Load capacity up to 8 t

building design

Span up to 24 m

Long-travel speed up to 40 m/min

Cross-travel speed up to 30 m/min

Hoist speed up to 12.5 m/min

Other specifications on request

Options

Type 1

See additional equipment, page 14

Technical data sheet

Ident. no. 203 719 44,

203 722 44,

203 725 44

Type 2

10

20855744-0210-EN MHE Standardkrane RZ.indd 10 09.08.10 09:50

39437-3

Radio control systems enable your cranes to be controlled from any position

11

20855744-0210-EN MHE Standardkrane RZ.indd 11 09.08.10 09:50

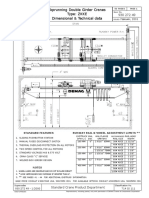

Double-girder overhead travelling cranes –

high load capacities combined with wide spans

Demag double-girder overhead travelling cranes offer you Your benefits

a virtually unmatched load capacity for their deadweight. ■■ Consistently high quality with all the advantages

They are also characterised by their outstanding crane offered by overhead travelling cranes (pages 6/7)

geometry, which ensures extremely favourable travel ■■ Particularly high performance thanks to the double-

characteristics and, therefore, minimises wear. The particu- girder design for high long and cross-travel speeds

larly large lifting height results from the ability to raise the ■■ Low deadweight reduces investment layout

load hook between the two crane girders. ■■ Possible fittings

■■ Optional maintenance platform for building repairs

Depending on requirements, our double-girder overhead ■■ Operator cab control as a crane control variant

travelling cranes can also be fitted with radio or operator

cab controls. Optional maintenance platforms and acces-

sible crabs not only make it easier for you to maintain the

crane, but also ensure that your hall fittings such as lamps,

heating elements or supply lines can be reached quickly

and easily.

Optimum adaptation to the

building design

ZKKE double-girder overhead travelling crane

Technical data

Load capacity up to 50 t

Span up to 30 m Type 1

Long-travel speed up to 40 m/min

Cross-travel speed up to 25 m/min

Hoist speed up to 12.5 m/min

Other specifications on request

Options

See additional equipment, page 14

Technical data sheet

Type 2

Ident. no. 203 561 44 (up to 16 t)

Ident. no. 203 660 44 (over 16 t)

Type 2

12

20855744-0210-EN MHE Standardkrane RZ.indd 12 09.08.10 09:50

39343-5

The double-girder design provides for particularly high load capacities and sensitive load handling

thanks to infinitely variable speed control

13

20855744-0210-EN MHE Standardkrane RZ.indd 13 09.08.10 09:50

Demag crane accessories and additional equipment

39343-3 39294-2 39008-2

With our wide range of accessories and additional equip- ■■ Cranes fitted with two crabs make it easy to handle

ment, we are able to adapt our standard cranes to the long and awkward loads

individual requirements of your application. ■■ A comprehensive range of load handling attachments

satisfies the most varied requirements

■■ Height adjustment of the control pendant switch

makes it easier for you to attach the load Planners and plant designers are provided with a full

■■ Control by means of a pendant switch or, if required, range of technical documentation for each crane type,

bi-directional radio control with proportional push- either as a conventional document or in electronic form

buttons on CD-ROM (order no. 227 049 44). Send order via

■■ Variable-speed motors with frequency inverters help e-mail to: standardcranes@demagcranes.com, subject:

to avoid load sway “TIP-CD”. This will enable you to incorporate Demag

Standard Crane solutions in your plant design right from

the start, thus providing you with reliable planning infor-

mation to save time and money.

14

20855744-0210-EN MHE Standardkrane RZ.indd 14 09.08.10 09:51

37970-1

Double-girder overhead travelling crane with tandem end carriages for transporting and turning engine blocks

15

20855744-0210-EN MHE Standardkrane RZ.indd 15 09.08.10 09:51

Demag Service – always ready to help

Demag Cranes & Components offers you comprehensive Monitoring reduces downtime

and reliable service with its global network of Demag Our monitoring system keeps track of the performance

expert service teams and Demag partners. They ensure and safety status of your installation. A diagnostics tool

maximum possible availability and safety in your installation. constantly shows the operator or maintenance engineer

the relevant status information and any unusual operat-

Rapid and reliable spare part supply ing status, if applicable. This enables any necessary main-

Customers all over the world are supplied with the tenance and repair work to be identified and carried out

required spare parts quickly and flexibly by Demag in good time. Regular monitoring reduces downtime and

Cranes & Components and its service network. cuts maintenance and operating costs in the long term.

Efficient training of your employees Your individual service package

Your employees learn all they need to know about hoists Demag Service offers a comprehensive portfolio of

and crane installations in Demag training courses lasting services to ensure the lasting availability of your

one or more days. Operator and product training courses installation throughout its entire life-cycle:

increase productivity, familiarisation with the relevant ■■ Recurring inspections according to relevant accident

regulations contributes towards maximum safety at the prevention regulations and general overhauls

workplace. Training courses can be held at our training ■■ Inspection and maintenance according to contract

centres or at your company. schedules

■■ Fault elimination both with and without an on-call

standby agreement

■■ Crane and crane runway surveys

■■ Service training for operators and maintenance

engineers

On this basis, we can assemble a package tailored to

meet your individual production and operating needs.

16

20855744-0210-EN MHE Standardkrane RZ.indd 16 09.08.10 09:51

39022

Crane system data can be read out for predictive and scheduled service

17

20855744-0210-EN MHE Standardkrane RZ.indd 17 09.08.10 09:51

Crane Designer – precise planning saves time, space and money

Demag Cranes & Components is not only a strong part- Only a few parameters have to be entered – the rest is

ner for perfect technical solutions to meet your in-house done by the Crane Designer system. From the compre-

logistics requirements. We also provide you with support hensive Demag product range, it selects a crane with the

during the planning phase for overhead transport logistics. specifications and features that precisely match your

needs. Demag Crane Designer completes planning tasks

One of the first steps towards efficient planning is selec- in a minimum of time, for both single and double-girder

tion of a crane tailored to meet your needs at the click cranes.

of a mouse. With the Demag Crane Designer system, a

crane installation designed to meet individual customer

needs can be configured in just a few minutes using

purely interactive on-screen features at:

www.demag-cranedesigner.com

Dimensions

Welcome to Crane Designer for standard cranes

Your configurator for universal Demag standard cranes.

n Improved handling rates,

n Higher availability,

n Extended service life,

are only some of the highlights of the latest Demag development. We are pleased to support

you, also in the planning phase. Fill in the enquiry form so that we can help you quickly and

efficiently.

Interactive online planning tool – configure your crane Crane Designer calculates all relevant dimensions for your

installations to meet your needs. specific application.

18

20855744-0210-EN MHE Standardkrane RZ.indd 18 09.08.10 09:51

Your benefits Visit our virtual planning consultant at

■■ Requires no installation and no hard disk space www.demag-cranedesigner.com

■■ Fast and individual selection ■■ Application examples with text and illustration

■■ The latest online technical data and dimensions for ■■ “How to speak Demag” crane glossary explains

your specified crane configuration technical terms

■■ The latest documentation in various languages ■■ Online configuration of cranes

■■ All information available 24/7 worldwide ■■ Quotation texts

■■ Fast and reliable transmission of your enquiry ■■ Technical information

■■ Connection to our online order system ■■ Static design information

(www.demag-shop.com) ■■ Individual CAD file

Loads/forces

You are provided with information on loads and forces You can download the drawing file generated for your

for further planning, e.g. to calculate your factory build- application to process all relevant data offline.

ing dimensions.

19

20855744-0210-EN MHE Standardkrane RZ.indd 19 09.08.10 09:51

MHE-Demag Network

SINGAPORE Perak Service centre PHILIPPINES

No 605, Kawasan Komersial Cilandak,

Head office & factory Jalan Sultan Azlan Shah Utara, 108-S Head office & factory

MHE-Demag (S) Pte Ltd Taman Tasik Baru, 31400 Ipoh Jl. KKO Raya, Jakarta 12560 MHE-Demag (P) Inc.

33 Gul Circle, Singapore 629570 Tel: (60-5) 546 3761 Tel: (62-21) 2753 7250 Main Avenue, Severina Diamond

Tel: (65) 6305 3500 Fax: (60-5) 547 3357 Fax: (62-21) 2753 7251 Industrial Estate, Km. 16 West Service

Fax: (65) 6862 1933 Road, South Expressway,

Service Hotline: (65) 6862 1123 Sabah Branch office & factory Parañaque City, 1700

Ground Floor, Lot 4, Surabaya Tel: (63-2) 786 7500

MALAYSIA Lorong Iramanis 2, Kawasan Rungkut Industri Fax: (63-2) 786 7555

Taman Iramanis, Jalan Lintas, Jl. Rungkut Industri I/3 Service Hotline: (63-2) 821 5149

Head office and factory 88450 Kota Kinabalu. Surabaya 60292

MHE-Demag Malaysia Sdn Bhd Tel: (60-88) 389402 Jawa Timur Branch office

MHE-Demag Logistics Fax: (60-88) 389253 Tel: (62-31) 843 9000 Cebu

Malaysia Sdn Bhd Fax: (62-31) 843 9287 Door 1, Annex, Rozen Building,

PT 79, Jalan 26/6, Sec 26 Sarawak Service Hotline: (62-31) 843 9001 A. C. Cortes Avenue,

Kawasan Perindustrian Hicom, No. E1-3, 16 Jalan Petanak, Mandaue City 6014

40000 Shah Alam, Selangor Wisma Horizon, 93100 Kuching Branch offices Tel: (63-32) 346 1672, 346 1959

Tel: (60-3) 5517 0888 Tel: (60-82) 233163 / 234163 Medan Fax: (63-32) 3461967

Fax: (60-3) 5517 0998/9 Fax: (60-82) 254163 Komplek Graha Niaga, Blok C-16

Service Hotline: (60-3) 5517 0980/1 Jl. Kol. Yos Sudarso No. 20 VIETNAM

VIETNAM Medan 20115, Sumatera Utara

Factory Tel: (62-61) 4551460 / 4557411 Head office

Johor Head office Fax: (62-61) 4557441 MHE-Demag Vietnam

Plot 5, Jalan Simpang Renggam MHE-Demag (T) Ltd Company Limited

No. 12 Kaw Perindustrian 23/110-117 Sorachai Bldg., Pekanbaru Unit 1204 – 12th Floor

Simpang Renggam, 25-29th Fl., Komplek Riau Business Center, Blok Sailing Tower, 111A Pasteur,

86200, Simpang Renggam Sukhumvit 63 (Ekamai), B-9 Ben Nghe Ward, District 1, HCMC.

Tel: (60-7) 7558833 Sukhumvit Rd., Jl. Riau, Pekanbaru 28292, Riau Tel: (84-8) 3823 6540

Fax: (60-7) 7558822 Klongton Nua, Wattana, Tel: (62-0761) 860890 Fax: (84-8) 3823 6776

Bangkok 10110 Fax: (62-0761) 860889 Service Hotline: (84-8) 3823 6540

Branch Offices Tel: (66-2) 7878 500

Melaka Fax: (66-2) 7878 501-2 Batam Factory

No 45, Jalan PM 1, Komplek Pertokoan Inti Batam, E-5 15 VSIP Street 2, Vietnam Singapore

Taman Perindustrian Merdeka, Factory Jl. Laksamana Bintan, Sei Panas Industrial Park,

75350 Melaka 64 Moo 2, Hi-Tech I.E., Batam 29432, Kepulauan Riau Thuan An District,

Tel: (60-6) 3174 900 T.Banpho, A. Bang Pa In Tel: (62-0778) 430 469 Binh Duong Province

Fax: (60-6) 3174 500 Ayutthaya 13160 Fax: (62-0778) 430 471 Tel: (84-650) 3784 080-1

Tel: (66-2) 787 8540 Fax: (84-650) 3784 082

Penang Fax: (66-3) 535 0376-7 Balikpapan

No. 2712 (Ground floor) Block H1 No. 5 Branch Offices

Jalan Chain Ferry, Service centre Balikpapan Permai Complex Ha Noi

Taman Kimsar, 13700 Perai, 294/1 Soi Soonvijai 4, Jl. Jend. Sudirman 5th Floor, Kinh Do Building

Province Wellesley Rama IX Rd, Huay Kwang Balikpapan 76114 292 Tay Son Street

Tel: (60-4) 399 7222 Bangkok, 10320 Tel: (62-542) 749459 Dong Da District, Hanoi City

Fax: (60-4) 390 8444 Tel: (66-2) 7878 555 Fax: (62-542) 744925 Tel: (84-4) 3514 6697

Service Hotline: (60-4) 399 7222 Fax: (66-2) 716 8028 - 9 Fax: (84-4) 3514 6698

Timika

Johor Branch office Jl. C. Heatubun / Jl. Baru Affiliate

11, Jalan Canggih 8, Chonburi Branch / Borwin Timika 99910, Mimika, Papua Katrolin Co. Ltd

Taman Perindustrian Cemerlang, 331/73 Moo. 6 331 Rd., Borwin, Tel: (62-901) 3302063 Unit 1204A – 12th Floor

81800 Ulu Tiram Sriracha, Chonburi 20230 Fax: (62-901) 3302063 Sailing Tower, 111A Pasteur,

Tel: (60-7) 863 1748 Tel: (66-38) 346057-9 Ben Nghe Ward, District 1, HCMC.

Fax: (60-7) 863 1753 Fax: (66-38) 346060 Service depot Tel: (84-8) 3823 6727

Karawang Fax: (84-8) 3823 6728

No 20, Jalan Bistari 4/8, INDONESIA Komplek Bumi Karawang Baru Blok A3

Taman Yayasan, No. 5

85000 Segamat Head office Desa Teluk Jambe, TAIWAN

Tel: (60-7) 944 4788 PT MHE-Demag Indonesia Kecamatan Teluk Jambe

0210 EN/MHE 208 557 44 MHE 701 IS 100

Fax: (60-7) 944 4789 Graha Inti Fauzi Building, Lantai 7 Karawang 41361, Jawa Barat Head office

No liability for errors or omissions. Subject to change.

Jl. Buncit Raya No. 22 Tel: (62-267) 643 941 MHE-Demag Taiwan

Pahang Jakarta 12510 Company Limited

B-378 Jalan Air Puteh, Tel: (62-21) 2753 7200 Batu Hijau 62 Min Chuan 2nd Road

25300 Kuantan Fax: (62-21) 2753 7201 Komplek Indra Foto 01 Kaohsiung 806, Taiwan R.O.C.

Tel: (60-9) 567 6129 Maluk, Sumbawa Barat Tel: (866-7) 3335185

Printed in Germany S+S/300810/5T

Fax: (60-9) 567 6143 Nusa Tenggara Barat Fax: (866-7) 3327927

Tel: (62-372) 635643

Branch Offices

Taipei

6F-1, No. 18, Lane 321

Yang Guang Street

Taipei 114, Taiwan R.O.C.

www.mhe-demag.com

Tel: (886-2) 87976501

E-mail: sales_mhe@mhe-demag.com Fax: (886-2) 87976602

A Joint Venture between Jebsen & Jebsen (SEA) Pte Ltd and Demag Cranes & Components GmbH

20855744-0210-EN MHE Standardkrane RZ.indd 20 09.08.10 09:51

S-ar putea să vă placă și

- DEMAG Universal Cranes PDFDocument20 paginiDEMAG Universal Cranes PDFHîrșu George RăzvanÎncă nu există evaluări

- Compact and Fast The New Demag DR Rope Hoist: More Efficiency For Cranes With Capacities Up To 10 TDocument12 paginiCompact and Fast The New Demag DR Rope Hoist: More Efficiency For Cranes With Capacities Up To 10 Tadijuniarko100% (1)

- Katalog Stahlplus EngDocument254 paginiKatalog Stahlplus EngNilesh MahajanÎncă nu există evaluări

- DIEPA AnswersDocument52 paginiDIEPA AnswersMohamed HarbÎncă nu există evaluări

- Crane Components For Standard CraneDocument20 paginiCrane Components For Standard CraneMacan SumatraÎncă nu există evaluări

- Overhead Crane DesignDocument50 paginiOverhead Crane DesignjuanÎncă nu există evaluări

- Abus CraneDocument32 paginiAbus CraneIbnu F MoelyodiharjoÎncă nu există evaluări

- Chapter 7 Overhead and Gantry CranesDocument33 paginiChapter 7 Overhead and Gantry Cranesmail.to.anjum8318Încă nu există evaluări

- Crane Wheel Load PDFDocument1 paginăCrane Wheel Load PDFShanthakumar PandianÎncă nu există evaluări

- Demag - Jib CranesDocument22 paginiDemag - Jib CranesGogyÎncă nu există evaluări

- Crane Wheel Load EccentricityDocument2 paginiCrane Wheel Load Eccentricitypranit_rai0% (1)

- Efficiency at Height: Tower CranesDocument16 paginiEfficiency at Height: Tower Cranesmd.amer mohiuddinÎncă nu există evaluări

- Overview of Eclectric Overhead Traveling Cranes PDFDocument121 paginiOverview of Eclectric Overhead Traveling Cranes PDFSamik Mukherjee100% (1)

- Crane Owner and Operator Manual - 180918 PDFDocument112 paginiCrane Owner and Operator Manual - 180918 PDFVaibhav67% (3)

- Technical Guide Crane SystemDocument111 paginiTechnical Guide Crane SystemStiven PeñaÎncă nu există evaluări

- ABUS 120.0t EOT Layout - 22.0m SpanDocument1 paginăABUS 120.0t EOT Layout - 22.0m Spanfud3n100% (1)

- Double Girder Gantry CraneDocument12 paginiDouble Girder Gantry CranePhanHatham100% (1)

- AS2550 (1) AbstractDocument14 paginiAS2550 (1) AbstractkeepcalmandcarryonÎncă nu există evaluări

- Datasheet SPMT ScheuerleDocument1 paginăDatasheet SPMT Scheuerle허윤호Încă nu există evaluări

- Designing of Cranes With StandardsDocument95 paginiDesigning of Cranes With Standardsank_mehraÎncă nu există evaluări

- TGN 08 Crane Rail Selection 2Document3 paginiTGN 08 Crane Rail Selection 2Prasad PatilÎncă nu există evaluări

- E & M of E.O.T.Document10 paginiE & M of E.O.T.bisweswar100% (1)

- Operation Manual of Overhead Crane EnglishDocument21 paginiOperation Manual of Overhead Crane EnglishParthiban Karuna83% (6)

- The Crane ComponentsDocument24 paginiThe Crane ComponentsLeon SanchezÎncă nu există evaluări

- Crane GirdersDocument15 paginiCrane GirdersRaduku RaduÎncă nu există evaluări

- GONDOLADocument26 paginiGONDOLAMarvanÎncă nu există evaluări

- Tower Crane Life ExpectancyDocument19 paginiTower Crane Life ExpectancyJogiÎncă nu există evaluări

- Abus-Double Girder CraneDocument3 paginiAbus-Double Girder CraneAlwin Victor WilliamsÎncă nu există evaluări

- CraneDocument11 paginiCranesamuelÎncă nu există evaluări

- Load Chart CK 2500Document28 paginiLoad Chart CK 2500ArisÎncă nu există evaluări

- Crane Drive Basics r0101Document68 paginiCrane Drive Basics r0101SisithaÎncă nu există evaluări

- ELMECKDocument7 paginiELMECKEpure GabrielÎncă nu există evaluări

- SC10876B - Hoist DrawingDocument1 paginăSC10876B - Hoist DrawingMotlatjo RakgothoÎncă nu există evaluări

- Demag CataloqueDocument204 paginiDemag CataloqueEu100% (1)

- Tower Crane ComplianceDocument51 paginiTower Crane ComplianceAnonymous ePcnZoBE100% (1)

- Crane Stability and Ground PressureDocument17 paginiCrane Stability and Ground PressureAvinash Lal100% (3)

- Design and Behavior of Jib CranesDocument20 paginiDesign and Behavior of Jib Cranesdicktracy1180% (5)

- ABUS Overhead CranesDocument36 paginiABUS Overhead CranesAya AlgalladÎncă nu există evaluări

- Report On Gantry Crane and Overhead CraneDocument23 paginiReport On Gantry Crane and Overhead CraneAbhay UpadhyayÎncă nu există evaluări

- Technical Specification of CraneDocument6 paginiTechnical Specification of Cranetema satu baja konstruksiÎncă nu există evaluări

- Wire Rope Hoist 5 Ton Capacity 6 MTR LiftDocument7 paginiWire Rope Hoist 5 Ton Capacity 6 MTR LiftEricÎncă nu există evaluări

- Crane Load D Mag PDFDocument50 paginiCrane Load D Mag PDFrahul ranjanÎncă nu există evaluări

- Crane PDFDocument102 paginiCrane PDFBrook KingÎncă nu există evaluări

- Demag DMR (Brochure)Document20 paginiDemag DMR (Brochure)Hendra HalimÎncă nu există evaluări

- Lifting GuideDocument59 paginiLifting GuidenayakyaÎncă nu există evaluări

- Design Procedure For Crane Runway Girders - bk105 PDFDocument7 paginiDesign Procedure For Crane Runway Girders - bk105 PDFFWICIPÎncă nu există evaluări

- Overhead CranesDocument36 paginiOverhead CranesSingchinese WongÎncă nu există evaluări

- Crane SafetyDocument10 paginiCrane Safetykevin_au18Încă nu există evaluări

- Gantry GirderDocument5 paginiGantry GirderDas TadankiÎncă nu există evaluări

- Crane Wheel Load DataDocument1 paginăCrane Wheel Load Datasyedabdulhannan100% (1)

- Guide For EOT Crane SelectionDocument15 paginiGuide For EOT Crane SelectionMaulik Patel100% (1)

- Slew Jib Crane StandardsDocument23 paginiSlew Jib Crane StandardsMichael Miotk100% (2)

- Demab Kran DizajnerDocument20 paginiDemab Kran DizajnerSlavce ZdravevÎncă nu există evaluări

- Standard CraneDocument20 paginiStandard CranecehaiguÎncă nu există evaluări

- Demag Standard Crane (Brochure)Document20 paginiDemag Standard Crane (Brochure)MadhaneÎncă nu există evaluări

- Demag Standard Crane ManualDocument160 paginiDemag Standard Crane ManualEddy WongÎncă nu există evaluări

- Catálogo Polipastos PDFDocument4 paginiCatálogo Polipastos PDFAdolfo Rodriguez GuevaraÎncă nu există evaluări

- BR SZ As en 2108 WebDocument28 paginiBR SZ As en 2108 WebEng-anwer kadhimÎncă nu există evaluări

- Rope HoistDocument12 paginiRope HoistKa Hau TeyÎncă nu există evaluări

- 110730Document20 pagini110730Hebert CcahuanaÎncă nu există evaluări

- GH 05 New Hoists Generation 2018Document12 paginiGH 05 New Hoists Generation 2018Wanto SitinjakÎncă nu există evaluări

- GH-Crane Component CatalogDocument88 paginiGH-Crane Component CatalogWanto SitinjakÎncă nu există evaluări

- JDN - Trolleys 112012 PDFDocument5 paginiJDN - Trolleys 112012 PDFWanto SitinjakÎncă nu există evaluări

- 2 Rmg-BrochureDocument2 pagini2 Rmg-BrochureWanto SitinjakÎncă nu există evaluări

- DEMAG Brakemotor and Gear MotorDocument2 paginiDEMAG Brakemotor and Gear MotorWanto SitinjakÎncă nu există evaluări

- Pipeliner 16P: Typical Applications Key FeaturesDocument2 paginiPipeliner 16P: Typical Applications Key FeaturesWanto SitinjakÎncă nu există evaluări

- Pipeliner 16P: Typical Applications Key FeaturesDocument2 paginiPipeliner 16P: Typical Applications Key FeaturesWanto SitinjakÎncă nu există evaluări

- Hitung Hitungan MarketingDocument2 paginiHitung Hitungan MarketingWanto SitinjakÎncă nu există evaluări

- Nbme Usmle Score TableDocument1 paginăNbme Usmle Score TableThara Foreste-Magloire70% (10)

- Question 197: (Forces Moments) : (At The 50cm Mark)Document8 paginiQuestion 197: (Forces Moments) : (At The 50cm Mark)ekjon1Încă nu există evaluări

- Advantage of Oil CoolingDocument2 paginiAdvantage of Oil CoolingYin ThoÎncă nu există evaluări

- 6.Hartl-Clark-Principles of Population GeneticsDocument6 pagini6.Hartl-Clark-Principles of Population GeneticsTeflon SlimÎncă nu există evaluări

- Folded PlatesDocument23 paginiFolded Platesbhushruti100% (1)

- Neural-Network-Based Maximum Power Point Tracking Methods For Photovoltaic Systems Operating Under Fast Changing EnvironmentsDocument12 paginiNeural-Network-Based Maximum Power Point Tracking Methods For Photovoltaic Systems Operating Under Fast Changing EnvironmentsAbderrezak BadjiÎncă nu există evaluări

- Tutorial Summary: 3D Example: Magneto Thermal ApplicationDocument3 paginiTutorial Summary: 3D Example: Magneto Thermal ApplicationAndrewÎncă nu există evaluări

- 18 Sanket Chases, Recesses and HolesDocument10 pagini18 Sanket Chases, Recesses and HolesVaibhav PatelÎncă nu există evaluări

- The Comparison of Two Activation Techniques To Prepare Activated Carbon From Corn CobDocument7 paginiThe Comparison of Two Activation Techniques To Prepare Activated Carbon From Corn CobRafaelaMarinhoFonsecaÎncă nu există evaluări

- Economics 101: Interactive BrokersDocument11 paginiEconomics 101: Interactive BrokersDennys FreireÎncă nu există evaluări

- C05 - Stationary Potential EnergyDocument73 paginiC05 - Stationary Potential Energyyttan1116Încă nu există evaluări

- DS350 Tadano Faun 1368Document61 paginiDS350 Tadano Faun 1368Mohamed Harb100% (2)

- AC Commutator Motors Repulsion Series Motor UniversalDocument3 paginiAC Commutator Motors Repulsion Series Motor UniversalwhrferÎncă nu există evaluări

- Analog Communications-Notes PDFDocument110 paginiAnalog Communications-Notes PDFjyothimunjam100% (1)

- KPS Alignment Procedure & FormulaDocument4 paginiKPS Alignment Procedure & FormulaWidhyatmika RestuÎncă nu există evaluări

- GOC & EAS CPP-II - PMDDocument14 paginiGOC & EAS CPP-II - PMDVansh sareenÎncă nu există evaluări

- Compiled Blue Print and Syllabus XI HY 2022Document6 paginiCompiled Blue Print and Syllabus XI HY 2022shrutiÎncă nu există evaluări

- KinematicsDocument5 paginiKinematicsUnicornpop PopÎncă nu există evaluări

- 9702 w22 QP 36 PDFDocument16 pagini9702 w22 QP 36 PDFsangdeepÎncă nu există evaluări

- Fasteners For Use With PC BoardsDocument25 paginiFasteners For Use With PC BoardsJustin PhanÎncă nu există evaluări

- Handout 3 TMR4305 Lecture 13 09 2007Document5 paginiHandout 3 TMR4305 Lecture 13 09 2007sujaydsouza1987Încă nu există evaluări

- Actuarial Science Program at The University of ConnecticutDocument9 paginiActuarial Science Program at The University of ConnecticutRohit VenkatÎncă nu există evaluări

- Testing & Maintenance of Rotating Machines Type Tests, Routine Tests & Special Tests of 1 & 3 Phase Induction MotorsDocument12 paginiTesting & Maintenance of Rotating Machines Type Tests, Routine Tests & Special Tests of 1 & 3 Phase Induction MotorsPKÎncă nu există evaluări

- Powerflex 750-Series Ac Drives: Technical DataDocument242 paginiPowerflex 750-Series Ac Drives: Technical DataJosé Santiago Miranda BernaolaÎncă nu există evaluări

- Secure Remote Services Installation Guide PDFDocument70 paginiSecure Remote Services Installation Guide PDFDavid GiriÎncă nu există evaluări

- Babikian Et Al Historical Fuel Efficiencies 2002Document12 paginiBabikian Et Al Historical Fuel Efficiencies 2002irockdudeÎncă nu există evaluări

- BookSellerFlyer 9781484241660Document1 paginăBookSellerFlyer 9781484241660超揚林Încă nu există evaluări

- Flight Control SurfacesDocument28 paginiFlight Control Surfacesjan paul de leonÎncă nu există evaluări

- 13 38 Casing Preparation and Running ChecklistDocument3 pagini13 38 Casing Preparation and Running ChecklistrajkumarfÎncă nu există evaluări