Documente Academic

Documente Profesional

Documente Cultură

1206 - Bando V Belt Tension Gauge Instructions 2017 10 09 PDF

Încărcat de

rabmusuke0 evaluări0% au considerat acest document util (0 voturi)

389 vizualizări2 paginiTitlu original

1206_Bando-V-Belt-Tension-Gauge-Instructions-2017-10-09.pdf

Drepturi de autor

© © All Rights Reserved

Formate disponibile

PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

389 vizualizări2 pagini1206 - Bando V Belt Tension Gauge Instructions 2017 10 09 PDF

Încărcat de

rabmusukeDrepturi de autor:

© All Rights Reserved

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 2

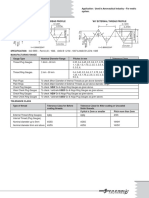

V-Belt Tension Gauge

Proper tension is the key to long, efficient, trouble-free belt

operation. When you install a new set of belts, use the gauge

to establish correct tension. Then, to maintain performance,

re-check belt tension after 24-48 hours. The payoff is

maximum belt life, reduced downtime and uninterrupted

equipment service.

Save these Instructions for Future Use

1. CAUTION: Before doing maintenance or tensioning on belt drives, turn

equipment off and lock out the

Deflection

power source. Use guards on 1/64" per

Small O-ring

machinery when running. inch of span

Plunger with

Deflection Place a matched set of Bando Span L

ength, L

Force Scale belts over the sheave grooves.

Take up the slack until the belts

appear fairly taut.

2. With the drive stopped,

measure the belt span length of Force

your drive (see sketch). Set the

rubber O-ring on the body of

the tension gauge at the

dimension equal to 1/64" for every inch of span length. For example, the

deflection for a 32" span is 1/64" x 32 or 1/2".

3. Set the O-ring on the plunger at zero against the body of the tension gauge.

4. With the tension gauge perpendicular to the span apply a force to a belt in the

center of the span. Deflect the belt until the bottom of the large O-ring is even

with the top of the next belt, or the bottom of the straight edge laid across the

Body with top of other belts on the drive.

Deflection Release pressure and read pounds of force used at o-ring plunger.

Distance

Scale Note: when new belts are installed on a drive, the tension will drop rapidly

during the first few hours. Thus, for new belts, tighten to the initial installation

deflection force shown in the tables on back. Re-check tension after the first

24-48 hours of operation. Subsequent re-tensioning should fall between the

Large O-ring

minimum and maximum forces shown in the tables.

5. Compare the force required in Step 4 with the ranges in the tables on back.

Tighten or loosen belts to bring them into the recommended range.

Note: the proper tension for a v-belt drive is the lowest tension at which the

belts won’t slip under peak load conditions.

Recommended Recommended Recommended

Deflection Force (lbs.) Deflection Force (lbs.) Deflection Force (lbs.)

Small Re-tensioning Small Re-tensioning Small Re-tensioning

V-Belt Pulley V-Belt Pulley V-Belt Pulley

Cross Diameter Initial Cross Diameter Initial Cross Diameter Initial

Section Range (in.) Installation Max. Min. Section Range (in.) Installation Max. Min. Section Range (in.) Installation Max. Min.

1.5 - 2.0 1.4 1.1 0.8 3.0 - 3.4 3.3 2.9 2.2 2.65 - 3.35 5.5 4.8 3.9

3L 2.1 - 2.7 1.9 1.4 1.1 A 3.6 - 4.2 3.5 3.1 2.4 3.65 - 4.12 6.4 5.7 4.4

3V

2.8 - 4.0 2.5 2.0 1.5 4.6 - 6.0 3.7 3.3 2.5 4.50 - 5.60 7.5 6.6 5.1

1.5 - 2.0 2.1 1.6 1.2 4.6 - 5.4 6.0 5.1 4.0 6.00 - 10.60 8.6 7.5 5.7

4L 2.1 - 2.7 2.4 1.8 1.4 B 5.6 - 7.4 6.3 5.5 4.2 7.10 - 8.50 19.2 16.7 13.0

2.8 - 4.0 3.1 2.3 1.8 7.5 - 9.4 6.6 5.7 4.4 5V 9.00 - 11.80 23.3 20.3 15.6

3.0 - 3.5 3.2 2.5 1.9 7.0 - 8.5 13.2 11.5 8.5 12.50 - 16.00 27.3 23.9 18.5

5L 3.6 - 4.5 4.1 3.2 2.4 C 9.0 - 12.0 13.9 12.1 9.3 12.50 - 16.00 50.9 44.3 34.4

4.6 - 6.0 5.1 3.9 3.0 13.0 - 16.0 14.6 12.6 9.7 8V 17.00 - 20.00 57.1 49.8 38.6

12.0 - 15.5 26.5 22.9 17.6 21.20 - 24.60 61.3 53.3 41.4

D 16.0 - 21.0 27.9 24.3 18.7 2.20 - 3.35 5.5 4.8 3.9

22.0 - 27.0 29.1 25.6 19.6 3.65 - 4.12 6.4 5.7 4.4

3VX

17.7 - 23.6 39.7 34.4 26.5 4.50 - 5.60 7.5 6.6 5.0

E 23.7 - 31.5 41.7 36.2 27.8 6.00 - 10.60 8.6 7.5 5.7

31.6 - 39.3 43.7 37.9 29.1 4.40 - 8.50 19.2 16.7 13.0

2.1 - 3.4 4.4 3.7 2.9 5VX 9.00 - 11.80 23.3 20.3 15.6

AX 3.6 - 4.2 4.6 4.0 3.1 12.50 -16.00 27.3 23.8 18.5

4.6 - 6.0 4.9 4.2 3.3

3.7 - 5.4 7.7 6.6 5.1

BX 5.6 - 7.4 8.2 7.1 5.5

8.6 - 9.4 8.6 7.5 5.7

5.8 - 8.5 17.2 15.0 11.5

CX 9.0 - 12.0 18.1 15.7 12.1

13.0 - 16.0 19.0 16.5 12.8

See your Bando distributor for a complete line of top quality

V-belts, timing belts, sheaves and pulleys.

Customer Service: 800-829-6612

serviceexpress@bandousa.com

www.BandoUSA.com BUI 4011

S-ar putea să vă placă și

- Rambold - Katalog 2004 ENDocument53 paginiRambold - Katalog 2004 END.T.Încă nu există evaluări

- Belt Tension IngDocument2 paginiBelt Tension Ingmallick099Încă nu există evaluări

- Building Technologies: HVAC ProductsDocument7 paginiBuilding Technologies: HVAC Productsshivv230Încă nu există evaluări

- Suggested Modifications To ASTM E477Document14 paginiSuggested Modifications To ASTM E477Jerry LillyÎncă nu există evaluări

- MTA-2000 Paper and Board Bursting Strength TesterDocument1 paginăMTA-2000 Paper and Board Bursting Strength TesterAndi FebriantoÎncă nu există evaluări

- Conveyor Chain Installation, Maintenance, & Best Practices - 001Document19 paginiConveyor Chain Installation, Maintenance, & Best Practices - 001num fistismÎncă nu există evaluări

- Sweeney 503 Assembly Paste Now in IndiaDocument1 paginăSweeney 503 Assembly Paste Now in IndiaProject Sales CorpÎncă nu există evaluări

- Barra Chata e Perfis Laminados Especificações TécnicasDocument52 paginiBarra Chata e Perfis Laminados Especificações TécnicasDimitra Katsiorchi50% (2)

- CNV 03 BDocument4 paginiCNV 03 BMaitry ShahÎncă nu există evaluări

- Application Note Hardness Testing EnglishDocument12 paginiApplication Note Hardness Testing EnglishAnubhav LakhmaniÎncă nu există evaluări

- Industrial belt tension tester guideDocument3 paginiIndustrial belt tension tester guidedaniel castilloÎncă nu există evaluări

- Držači Osovina DIN 15058 PDFDocument1 paginăDržači Osovina DIN 15058 PDFMartin JurmanÎncă nu există evaluări

- Pc280174 System ADocument50 paginiPc280174 System AMírian Ribeiro100% (1)

- Carbon Steel Tee Rails: Standard Specification ForDocument7 paginiCarbon Steel Tee Rails: Standard Specification ForAAYÎncă nu există evaluări

- Cronograma VulcanizaçãoDocument1.605 paginiCronograma VulcanizaçãoEiquibertoÎncă nu există evaluări

- Sonic Scan DatasheetDocument4 paginiSonic Scan DatasheetChandravadanÎncă nu există evaluări

- Supply Flange ANSI B16.5 Slip On Flange, SORF Flange, Class 150LBS To 1500LBS - Jinan Hyupshin Flanges Co., LTDDocument3 paginiSupply Flange ANSI B16.5 Slip On Flange, SORF Flange, Class 150LBS To 1500LBS - Jinan Hyupshin Flanges Co., LTDSandipÎncă nu există evaluări

- International Standard: Fans - Performance Testing Using Standardized AirwaysDocument19 paginiInternational Standard: Fans - Performance Testing Using Standardized AirwaysviniciusschwabÎncă nu există evaluări

- General Documentation - RecrystallizationDocument11 paginiGeneral Documentation - RecrystallizationAlbokeaÎncă nu există evaluări

- A 269 - 04 Qti2oqDocument6 paginiA 269 - 04 Qti2oqfekihassan100% (1)

- Regulador Elster Serie 040Document4 paginiRegulador Elster Serie 040Juan JuanÎncă nu există evaluări

- Pulp and PaperDocument8 paginiPulp and PaperDevanshGoenkaÎncă nu există evaluări

- SKF TKGR Shaft Grounding Ring Kit: Installation InstructionsDocument2 paginiSKF TKGR Shaft Grounding Ring Kit: Installation InstructionsRoque Huaraya EdwinÎncă nu există evaluări

- Ejemplo de Variables de InstrumentacionDocument16 paginiEjemplo de Variables de InstrumentacionEduardo JiménezÎncă nu există evaluări

- Achievable perpendicularity tolerances up to 40mm thick materialsDocument1 paginăAchievable perpendicularity tolerances up to 40mm thick materialsMihai StanÎncă nu există evaluări

- SC-2103681-ME1a - Manual 660.YTC. (1x6.5kW) .6 M1546-51G K460-4522-12FO-FC-R M9PG-OT-WP-LCBT + DG90-DB120 + 2xDG45 4xM1Document61 paginiSC-2103681-ME1a - Manual 660.YTC. (1x6.5kW) .6 M1546-51G K460-4522-12FO-FC-R M9PG-OT-WP-LCBT + DG90-DB120 + 2xDG45 4xM1kiên phạm trungÎncă nu există evaluări

- Tabela de Tubos Schedule: Tubos em Aço Carbono Com E Sem Costura Até 6"Document4 paginiTabela de Tubos Schedule: Tubos em Aço Carbono Com E Sem Costura Até 6"nevesgoÎncă nu există evaluări

- Difference Between Ac DC WeldingDocument2 paginiDifference Between Ac DC WeldingLokeshwari GopinathÎncă nu există evaluări

- Bray ValvesDocument6 paginiBray ValvesiksajidscribdÎncă nu există evaluări

- Rockwell 170112202238Document2 paginiRockwell 170112202238vasanthanil100% (1)

- Installation Equipment: Sanitary Fittings and ValvesDocument89 paginiInstallation Equipment: Sanitary Fittings and ValvesSebassde0% (1)

- Tabela de Roscas X FurosDocument2 paginiTabela de Roscas X FurosEdino Braz Do CantoÎncă nu există evaluări

- Longitudinal Oscillations of Vehicle/Trailer CombinationsDocument20 paginiLongitudinal Oscillations of Vehicle/Trailer CombinationsSteven SunÎncă nu există evaluări

- Experimental Testing and Fem Analysis of Corrugated TanksDocument2 paginiExperimental Testing and Fem Analysis of Corrugated TanksBash MatÎncă nu există evaluări

- Material Comparison F316L Vs F321Document1 paginăMaterial Comparison F316L Vs F321Vivi OktaviantiÎncă nu există evaluări

- Manual TB WoodsDocument92 paginiManual TB WoodsjoadÎncă nu există evaluări

- Belt Scale Installation GuideDocument47 paginiBelt Scale Installation GuideViong Danon100% (1)

- Boil Out ProceduresDocument11 paginiBoil Out ProceduresJorge DiazÎncă nu există evaluări

- Embaladora de Partes Com Puxador EPUP-3000: UsinoxDocument14 paginiEmbaladora de Partes Com Puxador EPUP-3000: UsinoxDyeison SiqueiraÎncă nu există evaluări

- Molykote® P-37 Datasheet Eng PDFDocument2 paginiMolykote® P-37 Datasheet Eng PDFBib GmzÎncă nu există evaluări

- Hex Head Bolts, Steel: Maryland MetricsDocument2 paginiHex Head Bolts, Steel: Maryland MetricsEva Ibáñez Ramos100% (1)

- Norma de Rosca Metrica MJDocument1 paginăNorma de Rosca Metrica MJXANAÎncă nu există evaluări

- GE Industrial Motor Data SheetsDocument8 paginiGE Industrial Motor Data SheetsEdgar CanelasÎncă nu există evaluări

- Z28-250 THREDA ROLLING MACHINE SpecificationsDocument15 paginiZ28-250 THREDA ROLLING MACHINE SpecificationsFarihatus SholehahÎncă nu există evaluări

- Backstop p5c4 VulkanDocument32 paginiBackstop p5c4 VulkanrodrigoÎncă nu există evaluări

- Tool Steel Alloy Cr12MoVDocument5 paginiTool Steel Alloy Cr12MoVMujjo Sahb100% (1)

- Decorator 2 Actual Machine ManualDocument386 paginiDecorator 2 Actual Machine ManualAhmed NabilÎncă nu există evaluări

- Rausand 1998Document12 paginiRausand 1998Fernando ConsuegraÎncă nu există evaluări

- Catalogos de Motores Electricos Eberle - DelcrosaDocument1 paginăCatalogos de Motores Electricos Eberle - DelcrosaMiguel Guillermo Zelaya DamianÎncă nu există evaluări

- Norma - UL 125-2007 Standard For Valves For Anhydrous Ammonia and LP-Gas (Other Than Safety Relief)Document28 paginiNorma - UL 125-2007 Standard For Valves For Anhydrous Ammonia and LP-Gas (Other Than Safety Relief)André AmaralÎncă nu există evaluări

- V-Belt Tension Gauge Guide for Proper TensionDocument2 paginiV-Belt Tension Gauge Guide for Proper TensionBeni MulyanaÎncă nu există evaluări

- 1206 - Bando V Belt Tension Gauge Instructions 2017 10 09 PDFDocument2 pagini1206 - Bando V Belt Tension Gauge Instructions 2017 10 09 PDFboyka yuriÎncă nu există evaluări

- 1206 Bando V Belt Tension Gauge Instructions 2017-10-09Document2 pagini1206 Bando V Belt Tension Gauge Instructions 2017-10-09dzkamiraÎncă nu există evaluări

- 1206 Bando V Belt Tension Gauge InstructionsDocument2 pagini1206 Bando V Belt Tension Gauge InstructionsJasperken2xÎncă nu există evaluări

- Belt Tension Gauge InstructionsDocument2 paginiBelt Tension Gauge InstructionsTodor HuklevÎncă nu există evaluări

- 2021.05.29 - Martinetto T22-726 Man - CE e Collaudo ENGDocument9 pagini2021.05.29 - Martinetto T22-726 Man - CE e Collaudo ENGEdomÎncă nu există evaluări

- Kolver Usa CatalogoDocument24 paginiKolver Usa CatalogoMartin DavilaÎncă nu există evaluări

- Head CalculationDocument13 paginiHead CalculationRamadan RashadÎncă nu există evaluări

- Mueller Equivalent Lengths PDFDocument1 paginăMueller Equivalent Lengths PDFkuchaitanyaÎncă nu există evaluări

- Low Frequency Machinery Monitoring - Measurement ConsiderationsDocument18 paginiLow Frequency Machinery Monitoring - Measurement Considerationsluciano GarciaÎncă nu există evaluări

- Fuel Injection & Timing IgnitionDocument8 paginiFuel Injection & Timing IgnitionrabmusukeÎncă nu există evaluări

- Item PM CMDocument1 paginăItem PM CMrabmusukeÎncă nu există evaluări

- KR#2 UHSelDocument1 paginăKR#2 UHSelrabmusukeÎncă nu există evaluări

- ISO Standards Std. DescriptionDocument21 paginiISO Standards Std. DescriptionrabmusukeÎncă nu există evaluări

- Cross Dial AlignmentDocument4 paginiCross Dial AlignmentrabmusukeÎncă nu există evaluări

- Vertical: Dimension Vert Dim Horz SM MM O Front Foot Rear FootDocument4 paginiVertical: Dimension Vert Dim Horz SM MM O Front Foot Rear FootrabmusukeÎncă nu există evaluări

- Fire Extinguisher Location and Placement: Fact SheetDocument2 paginiFire Extinguisher Location and Placement: Fact SheetEli NaguitÎncă nu există evaluări

- Sourav Roy - Loan IQ AnalystDocument4 paginiSourav Roy - Loan IQ AnalystSourav RoyÎncă nu există evaluări

- Install and Configure SAPROUTER on IBM iDocument29 paginiInstall and Configure SAPROUTER on IBM iNelida PérezÎncă nu există evaluări

- Productdatasheet en or 088423855cDocument1 paginăProductdatasheet en or 088423855cpieroÎncă nu există evaluări

- Jockey Pump BrochureDocument8 paginiJockey Pump BrochuregbogboiweÎncă nu există evaluări

- Jacoby TarboxDocument7 paginiJacoby TarboxBayu Permana RydhaÎncă nu există evaluări

- Low-Power Digital Signal Processor Architecture For Wireless Sensor NodesDocument9 paginiLow-Power Digital Signal Processor Architecture For Wireless Sensor NodesGayathri K MÎncă nu există evaluări

- Jsa-Wif-9 Pulling CableDocument12 paginiJsa-Wif-9 Pulling CableY a n i. A h m e dÎncă nu există evaluări

- Foundation Examples 9.7.2Document4 paginiFoundation Examples 9.7.2Muhannad AbdulRaoufÎncă nu există evaluări

- Series CH4200: Chemical Feed Equipment Floor-Mounted Gas DispenserDocument5 paginiSeries CH4200: Chemical Feed Equipment Floor-Mounted Gas DispenserCandra Tier'z100% (1)

- Chem 31.1 Midterms Reviewer Experiment 1: Solubility of Organic CompoundsDocument6 paginiChem 31.1 Midterms Reviewer Experiment 1: Solubility of Organic CompoundsSteffi GatdulaÎncă nu există evaluări

- Richard GrisenthwaiteDocument25 paginiRichard GrisenthwaitecaarthiyayiniÎncă nu există evaluări

- JR CVDocument5 paginiJR CVMostafa MohmmedÎncă nu există evaluări

- VW T-Cross 2019+ - Connector ViewsDocument220 paginiVW T-Cross 2019+ - Connector ViewsMucowera AshaÎncă nu există evaluări

- Acoustic Emission-Based Monitoring Approach For Friction Stir Welding of Aluminum Alloy AA6063-T6 With Different Tool Pin ProfilesDocument10 paginiAcoustic Emission-Based Monitoring Approach For Friction Stir Welding of Aluminum Alloy AA6063-T6 With Different Tool Pin ProfileslarryÎncă nu există evaluări

- Adobe 2017 Download LinksDocument4 paginiAdobe 2017 Download LinksDaśhīñg ÆžīÎncă nu există evaluări

- SLD Magic 2Document12 paginiSLD Magic 2Deny Arisandi DarisandÎncă nu există evaluări

- Preliminary: SPCA702ADocument60 paginiPreliminary: SPCA702Avetchboy0% (1)

- Aoc Le32w136 TVDocument82 paginiAoc Le32w136 TVMarcos Jara100% (4)

- Mobile Robots & Kinematics: Session 2: Nicol As Ilich Samus February 27, 2014Document5 paginiMobile Robots & Kinematics: Session 2: Nicol As Ilich Samus February 27, 2014Nicolás Ilich SamusÎncă nu există evaluări

- Advance Diploma For CivilDocument4 paginiAdvance Diploma For CivilAung Naing Latt AungÎncă nu există evaluări

- Installation Manual: Automatic TWIN Greasing SystemDocument62 paginiInstallation Manual: Automatic TWIN Greasing SystemWill FrontÎncă nu există evaluări

- HandRail Specsgf For CfvdrfsDocument3 paginiHandRail Specsgf For CfvdrfsTarek TarekÎncă nu există evaluări

- I RoboDocument40 paginiI RoboTuấn NguyễnÎncă nu există evaluări

- WSST - FW - Flyer Changi EN PDFDocument5 paginiWSST - FW - Flyer Changi EN PDFAmlan Banerjee0% (1)

- Railway Signaling Concepts and DefinitionsDocument92 paginiRailway Signaling Concepts and DefinitionsGopipavanÎncă nu există evaluări

- Weather and Aviation PDFDocument10 paginiWeather and Aviation PDFSergio GasparriÎncă nu există evaluări

- Article 5 - How To Purge Husqvarna Hydrostatic TransmissionDocument3 paginiArticle 5 - How To Purge Husqvarna Hydrostatic TransmissionSofia AlyaÎncă nu există evaluări

- Variational Asymptotic BeamDocument43 paginiVariational Asymptotic BeamAdimasu AyeleÎncă nu există evaluări

- Cisco IT Case Study India VoIP RegulationsDocument11 paginiCisco IT Case Study India VoIP Regulationswalter2458257Încă nu există evaluări