Documente Academic

Documente Profesional

Documente Cultură

Process Flow For Order Execution

Încărcat de

Sathish RTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Process Flow For Order Execution

Încărcat de

Sathish RDrepturi de autor:

Formate disponibile

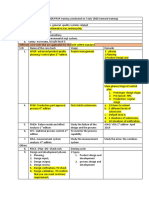

PROCESS FLOW FOR ORDER EXECUTION

Receiving Selection Quantity

Yarn pre booking get approval from management based on

selection results

Plan for the fabric & trims based on P3 and trims indent to be given

Po sheets or Forecast within a days to concern team

Program summary to be received

T&A meeting to be conducted for

every order’s for Fabric & Trims.

Line planning requirement for their

Factory wise style allocating to be

conformed orders with along forecast

discussed with Management

will discuss concern FM

Styles to be allocated to Order sheet to be Style meeting to be

respective merchandisers and given to concern done factory

plan with them factory

Printing & emb plan has to be

getting from concern

department

Pilot run to be plan in respective UE & PCB verify at that time of

factory and offer Buying team po sheet receiving

Meeting the factory manager’s regularly for

continuous line feeding and proper ex-factory of

the PO without any air shipment

Cutoff date for weekly shipment is

Weekly inspection offering plan will send Wednesday and need to maintain the

concern PL.tech & plsc and factory cutoff date , if any PO skips the cut off

need to get Management approval

Need to give more priority for Avoided 100% air shipment &

CBRS orders OT charges

Forecast to be maintained as per Decathlon

requirement and at the same time no excess

stock has to be maintained

Every 15 Days once forecast has to be For weekly receiving po sheets against forecast

updates from Buying office & discuss , need to verify the forecast stock and if any

with our marketing team maintain stock deviation need to prepare P3 & trims indent for

level the additional Qty.

Attending weekly status meeting

with marketing executive and PL

supply.

Shipment dispatch details Order closing for each

Inspection coordinate have to be given to logistics reference to be done and

with concern PL tech team on daily basis. tallied with IT team.

S-ar putea să vă placă și

- RCS: 90 & Above Round: Above 100: Heat. No. To Be Provided On Each BarDocument2 paginiRCS: 90 & Above Round: Above 100: Heat. No. To Be Provided On Each BarAmit Kumar UkeÎncă nu există evaluări

- IYM - Chennai Customer Complaint Register for 2017 PartsDocument6 paginiIYM - Chennai Customer Complaint Register for 2017 PartsKumaravelÎncă nu există evaluări

- Qualification RangeDocument1 paginăQualification RangeSARSAN NDTÎncă nu există evaluări

- QAP K-HouseDocument4 paginiQAP K-HouseAbhinash TamangÎncă nu există evaluări

- Process flow chart quality manualDocument1 paginăProcess flow chart quality manualDeepak DasÎncă nu există evaluări

- Performance Management Sytem of VKL (Vishnu) Spices PVT LTDDocument10 paginiPerformance Management Sytem of VKL (Vishnu) Spices PVT LTDAshwin Davis RCBSÎncă nu există evaluări

- COPQ Training - EPC (Repaired)Document15 paginiCOPQ Training - EPC (Repaired)syedfahadraza627Încă nu există evaluări

- Prevent Sheet Metal Burr Formation with Proper Tooling and Process ControlsDocument5 paginiPrevent Sheet Metal Burr Formation with Proper Tooling and Process ControlsMajad RazakÎncă nu există evaluări

- Permanent Change and Temporary Deviation Request FormDocument1 paginăPermanent Change and Temporary Deviation Request FormdrustagiÎncă nu există evaluări

- In Process QC FormatDocument9 paginiIn Process QC FormatSunil ChaubeyÎncă nu există evaluări

- Container Loading Procedure PDFDocument8 paginiContainer Loading Procedure PDFZAHID UMARÎncă nu există evaluări

- COUNTER MEASURE of Customer ComplaintDocument2 paginiCOUNTER MEASURE of Customer Complaintpreetam kumarÎncă nu există evaluări

- Root Cause Analysis - ToolDocument11 paginiRoot Cause Analysis - ToolmuneerppÎncă nu există evaluări

- Safety FMEADocument4 paginiSafety FMEAnormalÎncă nu există evaluări

- Process Flow ChartDocument11 paginiProcess Flow Chartsudar1477Încă nu există evaluări

- Contoh Form RMADocument1 paginăContoh Form RMAAgung NurfadillahÎncă nu există evaluări

- Prds & Piping QapDocument2 paginiPrds & Piping QapPavul RajÎncă nu există evaluări

- Efwe 2 e 4 GF 1 W 3Document1 paginăEfwe 2 e 4 GF 1 W 3BALACHANDAR SÎncă nu există evaluări

- Report No Date Customer Name Heat No Material Grade Size No of Pieces Weight Color CodeDocument1 paginăReport No Date Customer Name Heat No Material Grade Size No of Pieces Weight Color CodeRohit VishwakarmaÎncă nu există evaluări

- HDG Process Flow Chart PDFDocument1 paginăHDG Process Flow Chart PDFAnonymous vIbTFwAStxÎncă nu există evaluări

- Cutting SopDocument2 paginiCutting SopRaj SekarÎncă nu există evaluări

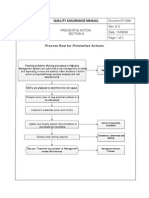

- Quality Assurance Manual Process FlowDocument2 paginiQuality Assurance Manual Process FlowNgonidzashe ZvarevasheÎncă nu există evaluări

- QSP Qad 08Document2 paginiQSP Qad 08prabha_1Încă nu există evaluări

- Process/Product FMEA AnalysisDocument2 paginiProcess/Product FMEA AnalysisAmair Marthz100% (1)

- Apqp PhasesDocument3 paginiApqp PhasesBharatÎncă nu există evaluări

- CUSTOMER Complaint - PrintDocument1 paginăCUSTOMER Complaint - PrintSachin Kumbhar100% (1)

- Audit ComplianceDocument1 paginăAudit ComplianceNitin SharmaÎncă nu există evaluări

- Layout ChecklistDocument2 paginiLayout Checklistvmohapatra8100% (1)

- PPAP Training OverviewDocument17 paginiPPAP Training OverviewRicky MarkÎncă nu există evaluări

- Boss Gears Rework Register FormDocument1 paginăBoss Gears Rework Register FormMohit SinghÎncă nu există evaluări

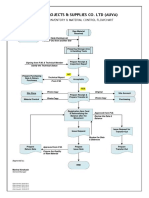

- Projects & Supplies Co. LTD (Auva) : Inventory & Material Control FlowchartDocument1 paginăProjects & Supplies Co. LTD (Auva) : Inventory & Material Control FlowchartdtvqatarÎncă nu există evaluări

- 07.01.05 Fabrication Galvanizing R1Document11 pagini07.01.05 Fabrication Galvanizing R1Bhanu Pratap ChoudhuryÎncă nu există evaluări

- Nikhil Quality 6YOEDocument3 paginiNikhil Quality 6YOENikhil DhimanÎncă nu există evaluări

- Rcca On P/N: XXX Supplier Name: XXX Person's Name: As Presented To Lam SE: Date: XXXDocument4 paginiRcca On P/N: XXX Supplier Name: XXX Person's Name: As Presented To Lam SE: Date: XXXTarun KaushalÎncă nu există evaluări

- CorrectiveDocument8 paginiCorrectivevg_vvgÎncă nu există evaluări

- Audit Report Ash HandlingDocument1 paginăAudit Report Ash HandlingchandrashekharÎncă nu există evaluări

- Estimating Process Section 11: Quality Assurance ManualDocument4 paginiEstimating Process Section 11: Quality Assurance ManualNgonidzashe ZvarevasheÎncă nu există evaluări

- Supplier Surveillance ChecklistDocument16 paginiSupplier Surveillance ChecklistaaqipaperÎncă nu există evaluări

- Gauge Validation ReportDocument71 paginiGauge Validation ReportPreetam GiteÎncă nu există evaluări

- Inspection Pass Inspection Pass Inspection PassDocument6 paginiInspection Pass Inspection Pass Inspection PassKhuda BukshÎncă nu există evaluări

- Customer Survey Form T2m 2009Document1 paginăCustomer Survey Form T2m 2009Peracha EngineeringÎncă nu există evaluări

- Tablas FmeaDocument4 paginiTablas FmeaPalmer Dionicio100% (1)

- Master list of quality documentsDocument1 paginăMaster list of quality documentsMuhammad ImranÎncă nu există evaluări

- MARATHAN MOTOR SOP Recruitment ProcedureDocument4 paginiMARATHAN MOTOR SOP Recruitment Procedurerishi gautamÎncă nu există evaluări

- Rejection Analysis 2021Document7 paginiRejection Analysis 2021Abhishek AllenÎncă nu există evaluări

- Manufacturing Readiness ChecklistDocument5 paginiManufacturing Readiness Checklistkhmorteza100% (1)

- MTP Micro Turn Proudtcs Apqp Timing Plan: S.No Description Resp. Status W1 W2Document9 paginiMTP Micro Turn Proudtcs Apqp Timing Plan: S.No Description Resp. Status W1 W2Sahil WadhwaÎncă nu există evaluări

- Scope Location 1 CC-2319 P TEJ CALIBRATION CENTREDocument64 paginiScope Location 1 CC-2319 P TEJ CALIBRATION CENTREkumarÎncă nu există evaluări

- Design Process and ControlDocument10 paginiDesign Process and Controlapi-3772329Încă nu există evaluări

- 390018-Lito Garcia Junio-Production Team LeaderDocument3 pagini390018-Lito Garcia Junio-Production Team LeaderATKÎncă nu există evaluări

- Lab Audit ChecklistDocument1 paginăLab Audit ChecklistPon ShanmugakumarÎncă nu există evaluări

- Annexure - 1 (Process Map)Document2 paginiAnnexure - 1 (Process Map)pcilopsÎncă nu există evaluări

- Continual Improvement Using Jishu Hozen Pillar of Total Productive Maintenance in Manufacturing OrganizationDocument7 paginiContinual Improvement Using Jishu Hozen Pillar of Total Productive Maintenance in Manufacturing OrganizationPE QAÎncă nu există evaluări

- Spesifikasi Painting PT INCODocument17 paginiSpesifikasi Painting PT INCOtitieÎncă nu există evaluări

- Notes Taken During 3 July APQP PPAP ClassDocument2 paginiNotes Taken During 3 July APQP PPAP Classrosemarie tolentinoÎncă nu există evaluări

- F-05 Corrective Action FormDocument1 paginăF-05 Corrective Action Formsuhara hussainÎncă nu există evaluări

- F-QC-05 Deviation NoteDocument1 paginăF-QC-05 Deviation NoteKaran MalhiÎncă nu există evaluări

- VDA6.3 Process Audit ChecklistDocument32 paginiVDA6.3 Process Audit Checklistpkj009Încă nu există evaluări

- Work Flow in The OrganisationDocument10 paginiWork Flow in The OrganisationVishwanath KrÎncă nu există evaluări

- Who Will Do WhatDocument28 paginiWho Will Do WhatJohn BihagÎncă nu există evaluări

- Checklist For Mold RemediationDocument2 paginiChecklist For Mold Remediation631052Încă nu există evaluări

- Wargames Illustrated #115Document64 paginiWargames Illustrated #115Анатолий Золотухин100% (1)

- ASCP User GuideDocument1.566 paginiASCP User GuideThillai GaneshÎncă nu există evaluări

- Bosch Committed to Outsourcing to Boost CompetitivenessDocument4 paginiBosch Committed to Outsourcing to Boost CompetitivenessPriya DubeyÎncă nu există evaluări

- Control Systems Engineering by S C Goyal U A Bakshi PDFDocument3 paginiControl Systems Engineering by S C Goyal U A Bakshi PDFShubham SinghÎncă nu există evaluări

- Online Music Courses With NifaDocument5 paginiOnline Music Courses With NifagksamuraiÎncă nu există evaluări

- Edexcel A2 Biology 6BI06Document7 paginiEdexcel A2 Biology 6BI06abhayÎncă nu există evaluări

- Assignment 2: Lesson Plan Analysis, Revision and Justification - Kaitlin Rose TrojkoDocument9 paginiAssignment 2: Lesson Plan Analysis, Revision and Justification - Kaitlin Rose Trojkoapi-408336810Încă nu există evaluări

- Yamaha RX-A3000 - V3067Document197 paginiYamaha RX-A3000 - V3067jaysonÎncă nu există evaluări

- Location: Connectivity To The MuseumDocument7 paginiLocation: Connectivity To The MuseumAbhishek AjayÎncă nu există evaluări

- Digestive System Song by MR ParrDocument2 paginiDigestive System Song by MR ParrRanulfo MayolÎncă nu există evaluări

- Where Are The Women in The Water Pipeline? Wading Out of The Shallows - Women and Water Leadership in GeorgiaDocument7 paginiWhere Are The Women in The Water Pipeline? Wading Out of The Shallows - Women and Water Leadership in GeorgiaADBGADÎncă nu există evaluări

- 2019 ASME Section V ChangesDocument61 pagini2019 ASME Section V Changesmanisami7036100% (4)

- Imp RssDocument8 paginiImp RssPriya SharmaÎncă nu există evaluări

- Mutaz Abdelrahim - Doa - MT-103Document17 paginiMutaz Abdelrahim - Doa - MT-103Minh KentÎncă nu există evaluări

- Capex Vs RescoDocument1 paginăCapex Vs Rescosingla.nishant1245Încă nu există evaluări

- 14 - Hydraulic Design of Urban Drainage Systems PDFDocument45 pagini14 - Hydraulic Design of Urban Drainage Systems PDFDeprizon SyamsunurÎncă nu există evaluări

- Country Profile - NigerDocument1 paginăCountry Profile - Nigernana kayÎncă nu există evaluări

- FIDIC delay and disruption standardsDocument7 paginiFIDIC delay and disruption standardsMohammad FayazÎncă nu există evaluări

- Module-1 STSDocument35 paginiModule-1 STSMARYLIZA SAEZÎncă nu există evaluări

- Rpo 1Document496 paginiRpo 1Sean PrescottÎncă nu există evaluări

- Basics of Duct DesignDocument2 paginiBasics of Duct DesignRiza BahrullohÎncă nu există evaluări

- Sci7 Q1 Wk-5 Module-5Document15 paginiSci7 Q1 Wk-5 Module-5Lester Noel RosalesÎncă nu există evaluări

- MP & MC Module-4Document72 paginiMP & MC Module-4jeezÎncă nu există evaluări

- 021SAACK Burner Operating Instructions PDFDocument136 pagini021SAACK Burner Operating Instructions PDFmekidmu tadesse100% (1)

- 2.5L ENGINE Chevy Tracker 1999Document580 pagini2.5L ENGINE Chevy Tracker 1999andres german romeroÎncă nu există evaluări

- Required Reading For Piano Technicians PDFDocument28 paginiRequired Reading For Piano Technicians PDFNinaÎncă nu există evaluări

- Surveying 2 Practical 3Document15 paginiSurveying 2 Practical 3Huzefa AliÎncă nu există evaluări

- Textile Finishing Different Types of Mechanical Finishes For TextilesDocument3 paginiTextile Finishing Different Types of Mechanical Finishes For TextilesMohammed Atiqul Hoque ChowdhuryÎncă nu există evaluări

- Indra: Detail Pre-Commissioning Procedure For Service Test of Service Water For Unit 040/041/042/043Document28 paginiIndra: Detail Pre-Commissioning Procedure For Service Test of Service Water For Unit 040/041/042/043AnhTuấnPhanÎncă nu există evaluări