Documente Academic

Documente Profesional

Documente Cultură

Checklist For Engineers

Încărcat de

Fungai M Chitsike0 evaluări0% au considerat acest document util (0 voturi)

134 vizualizări2 paginiA checklist of the information to be provided to steelwork contractors by employers or design engineers. The responsibility strategies are defined as follows: a. Employer provides fabrication drawings B. Steelwork contractor provides fabrication drawings C. Design and construct no.

Descriere originală:

Titlu original

ChecklistForEngineers[1]

Drepturi de autor

© Attribution Non-Commercial (BY-NC)

Formate disponibile

PDF, TXT sau citiți online pe Scribd

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentA checklist of the information to be provided to steelwork contractors by employers or design engineers. The responsibility strategies are defined as follows: a. Employer provides fabrication drawings B. Steelwork contractor provides fabrication drawings C. Design and construct no.

Drepturi de autor:

Attribution Non-Commercial (BY-NC)

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

0 evaluări0% au considerat acest document util (0 voturi)

134 vizualizări2 paginiChecklist For Engineers

Încărcat de

Fungai M ChitsikeA checklist of the information to be provided to steelwork contractors by employers or design engineers. The responsibility strategies are defined as follows: a. Employer provides fabrication drawings B. Steelwork contractor provides fabrication drawings C. Design and construct no.

Drepturi de autor:

Attribution Non-Commercial (BY-NC)

Formate disponibile

Descărcați ca PDF, TXT sau citiți online pe Scribd

Sunteți pe pagina 1din 2

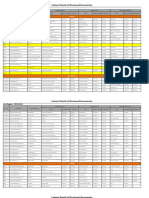

CHECKLIST FOR ENGINEERS

Information to be provided to steelwork contractor

The following is a checklist of the information to be provided to steelwork contractors by employers or design engineers, under various responsibility strategies.

The responsibility strategies are defined as follows:

A. Employer provides fabrication drawings

B. Steelwork contractor provides fabrication drawings

C. Design and construct

No. Description of information Responsibility strategy

A B C

1. GENERAL

1.1 General purpose of facility Yes Yes Yes

1.2 Employer preferences of all kinds, including aesthetics Yes Yes Yes

1.3 Mandatory requirements, including codes and specifications, loadings and materials to be used Yes Yes

1.4 How compliance with performance requirements will be evaluated (eg what to submit for approval) Yes Yes

1.5 Brief description of the structure Yes Yes

1.6 Interfaces with existing structures, plant, etc. Yes Yes

2. DESIGN AND RELATED

2.1 A statement describing the design concept, e.g. plastic design, braced frame, simple or continuous construction Yes

2.2 Design drawings showing all dimensions relevant to the steelwork Yes Yes

2.3 Details of any environmental conditions which may affect the detail design Yes

2.4 Constraints, including size and shape limitations for members Yes

2.5 Performance requirements, including deflections, vibration and durability Yes Yes

2.6 The design code of practice to be used for connection design, i.e. the relevant part of SABS 0162 Yes

2.7 Grade of material to be used Yes Yes

2.8 Any part of the steelwork where the manufacturing process must be restricted e.g. plastic hinge positions Yes

2.9 Details of any dynamic or vibrating forces acting on members, and where fatigue needs to be considered Yes Yes

2.10 The forces and moments and their combinations required to be transmitted by each connection Yes

2.11 For limit states design, whether the loads given are factored or unfactored Yes

2.12 Any specific positions where stiffeners need to be provided Yes Yes

2.13 Holding down bolt/interface drawings showing the details of the holding down bolts that will be provided Yes Yes Yes

2.14 Indication of the beams that are restrained against lateral torsion buckling where additional restraints to the

compression flange must be provided in the presence of a notch Yes

2.15 The details of all the connections designed by the engineer Yes Yes

2.16 Any specific prescriptions that need to be followed as required by structural, aesthetic or other considerations Yes Yes

2.17 Fabrication drawings, which may include attachments to facilitate erection Yes

2.18 Erection mark drawings Yes

2.19 Thickness of grout to be used under base plates Yes Yes

2.20 Requirements for particular types of fabrication details or connections to be used Yes Yes

2.21 Details of cutouts, holes or fittings for use by others Yes Yes Yes

2.22 Camber and presets to be provided Yes Yes

2.23 Procedures to be followed when the design is changed by either the employer or the steelwork contractor Yes Yes Yes

2.24 Procedure for approval of the design by the employer Yes Yes Yes

3. SITE – RELATED

3.1 Location of the site Yes Yes Yes

3.2 Accessibility of the site, constraints on transportation, or special transportation arrangements Yes Yes Yes

3.3 A site plan showing the position of the datum level and the setting-out lines Yes Yes Yes

2008 Source Book 105

No. Description of information Responsibility strategy

A B C

3.4 Width and level of the prepared working areas and access routes for site traffic, hard standings for cranes, and areas

available for storage, together with ground capacity limits for heavy loads, or details and capacity of suspended slabs from

which erection has to occur Yes Yes Yes

3.5 Availability of site services and any prearranged procedures for cooperation with other contractors Yes Yes Yes

3.6 Any limitation on dimensions or weights of components to be delivered to the site Yes Yes Yes

3.7 Details of any known underground services, overhead cables or site obstructions Yes Yes Yes

3.8 Constraints on working on the site or over site boundaries Yes Yes Yes

3.9 Whether any arrangements have to be made with neighbours or whether neighbouring properties need to be surveyed

(commonly not within the scope of the steelwork contractor) Yes Yes Yes

3.10 Whether any approvals need to be obtained or any arrangements made with any authority

(commonly not within the scope of the steelwork contractor) Yes Yes Yes

4. FABRICATION – RELATED

4.1 Areas on steelwork where hard stamping or other forms of notching or indentation may not occur Yes Yes

4.2 Parts of steelwork where holes may not be punched Yes Yes

4.3 Special welding procedures which have to be approved prior to the work commencing Yes Yes

4.4 Special requirements regarding fabrication or erection attachments Yes Yes

4.5 Any production test plates that are required Yes Yes Yes

4.6 Scope of weld inspection required Yes Yes Yes

4.7 Areas where scope of weld inspections has to be higher than the norm Yes Yes Yes

4.8 Inspections or tests to be carried out or witnessed by the employer or an inspection authority Yes Yes Yes

4.9 Period of advance notice required for these inspections or tests Yes Yes Yes

5. ERECTION – RELATED

5.1 Any design features which would affect the construction sequence, or which may create an unusual hazard during construction Yes Yes Yes

5.2 An outline of any specific method of erection envisaged by the engineer, giving the sequence for erecting the structure and

taking into account any phasing of the works Yes Yes

5.3 A description of any temporary works and any special requirements for temporary bracing required, the stage when it is

no longer necessary, or whether it is to be left in position after completion of the steelwork Yes Yes

5.4 The responsibilities at the interface between the steelwork and other trades Yes Yes Yes

5.5 Scope of inspection of site welding required Yes Yes Yes

5.6 Special site welding procedures which have to be approved prior to the work commencing Yes Yes Yes

5.7 Inspections or tests to be carried out or witnessed by the employer or an inspection authority Yes Yes Yes

5.8 Period of advance notice required for these inspections or tests Yes Yes Yes

6. PROTECTIVE TREATMENT

6.1 Areas of steelwork to receive specific protective surface treatment including painting, galvanizing, sprayed metal coatings

or fire protection Yes Yes Yes

6.2 Specifications for painting Yes Yes Yes

6.3 Special requirements for galvanizing Yes Yes Yes

6.4 Thickness and composition of sprayed metal coatings Yes Yes Yes

6.5 Responsibility for touch-up of damaged areas and cleaning of surface treatment on site, and the specification for this work Yes Yes Yes

6.6 Specifications for fire protective coating Yes Yes Yes

7. PROGRAMME

7.1 The date(s) of issue of the design drawings or data for construction and other information necessary for the progress of

the works Yes Yes Yes

7.2 The period to be provided in the steelwork contractor’s programme for acceptance of submitted information Yes Yes Yes

7.3 The date(s) by which the site is expected to be ready with foundations prepared, free from obstruction, and accessible;

with working surfaces, access roads and storage areas prepared and services available Yes Yes Yes

7.4 The proposed starting and completion dates for erection of steelwork and the dates when other contractors’ activities are

expected to interface with the steelwork erection programme Yes Yes Yes

106 Source Book 2008

S-ar putea să vă placă și

- Oisd STD 118Document26 paginiOisd STD 118Tarun SahuÎncă nu există evaluări

- Model Bills of Quantities: Federation of Piling SpecialistsDocument9 paginiModel Bills of Quantities: Federation of Piling SpecialistsAllahjurioÎncă nu există evaluări

- Workshop 3Document4 paginiWorkshop 3Ajiri IvoviÎncă nu există evaluări

- GLACIER LAr Tank Design (Deliverable 2.2)Document76 paginiGLACIER LAr Tank Design (Deliverable 2.2)atiqulaÎncă nu există evaluări

- Ladder and Self Closing Gate For Storage TankDocument15 paginiLadder and Self Closing Gate For Storage TankAkshat JainÎncă nu există evaluări

- Drawing Check PrintDocument2 paginiDrawing Check PrintSRINKAL1999Încă nu există evaluări

- Minor Project Weekly Progress ReportDocument2 paginiMinor Project Weekly Progress ReportRishabh Singh SethiÎncă nu există evaluări

- Design ReportDocument22 paginiDesign Reportamit_saxena_10Încă nu există evaluări

- Engineering Group: Kuwait Oil Company (K.S.C.)Document14 paginiEngineering Group: Kuwait Oil Company (K.S.C.)Aravindan Ganesh KumarÎncă nu există evaluări

- Anclajes Tunja1Document3 paginiAnclajes Tunja1Diana RamosÎncă nu există evaluări

- F-510-S04-0004 Specification For Tank Foundation and Earthen Bund WallsDocument12 paginiF-510-S04-0004 Specification For Tank Foundation and Earthen Bund WallssurÎncă nu există evaluări

- AMETank Product BrochureDocument6 paginiAMETank Product BrochureSYedZYnAleÎncă nu există evaluări

- Epoxy Floor Coating: Description FeaturesDocument2 paginiEpoxy Floor Coating: Description FeaturesRayon 9Încă nu există evaluări

- Concrete Ring Wall FoundationDocument16 paginiConcrete Ring Wall Foundationchenfs27531Încă nu există evaluări

- Demolition Notes: Mechanical Plan Demolition PlanDocument1 paginăDemolition Notes: Mechanical Plan Demolition PlanwalsarisÎncă nu există evaluări

- Drawing List: Rev. Date: API650 STORAGE TANK Chilled Water Tank (05T009) Irpc Plc. Technip (Thailand) B 7/22/2013Document4 paginiDrawing List: Rev. Date: API650 STORAGE TANK Chilled Water Tank (05T009) Irpc Plc. Technip (Thailand) B 7/22/2013chompink6900Încă nu există evaluări

- Part 14 - Crane & HoistsDocument11 paginiPart 14 - Crane & HoistsrickymmaÎncă nu există evaluări

- FHC-Hydraulic CalculationDocument4 paginiFHC-Hydraulic CalculationKiên Nguyễn Hữu100% (1)

- Flange Data, Bolt Patterns and Dimensions ComparisonDocument21 paginiFlange Data, Bolt Patterns and Dimensions ComparisonAlexÎncă nu există evaluări

- Calculation of FootingDocument5 paginiCalculation of FootingAnonymous kuW0obtJ4pÎncă nu există evaluări

- Composite Tank FinalDocument30 paginiComposite Tank FinalAmru AmruteshÎncă nu există evaluări

- XX X XXXX XX XXXX - Tank Foundation 45m Dia X 25m High On Earthen Bund FoundationDocument44 paginiXX X XXXX XX XXXX - Tank Foundation 45m Dia X 25m High On Earthen Bund FoundationKhairul JaggerÎncă nu există evaluări

- Prefabricated Building Size 81'x27' Thallian Camp FWODocument3 paginiPrefabricated Building Size 81'x27' Thallian Camp FWOSagheer Ahmed100% (1)

- Optimum Detailed Design of 13000 m3 Oil Storage TaDocument6 paginiOptimum Detailed Design of 13000 m3 Oil Storage TaHenrikÎncă nu există evaluări

- Another DWG of Vessel No 3Document1 paginăAnother DWG of Vessel No 3Nomi KhanÎncă nu există evaluări

- B2020-TDC-SR-006 Shell Rolling R0Document2 paginiB2020-TDC-SR-006 Shell Rolling R0Ramalingam PrabhakaranÎncă nu există evaluări

- Residential Sprinkler System Design Handbook: A Step-By-Step Introduction To Design and InstallationDocument7 paginiResidential Sprinkler System Design Handbook: A Step-By-Step Introduction To Design and InstallationPedro JonesÎncă nu există evaluări

- ASME CheckDocument14 paginiASME Checkfuransu777Încă nu există evaluări

- Ufgs 33 56 10Document38 paginiUfgs 33 56 10mohamed fathiÎncă nu există evaluări

- Rooftop Model Tender DocumentDocument92 paginiRooftop Model Tender DocumentRahul DasÎncă nu există evaluări

- AGC Plibrico Monolithic RefractoriesDocument15 paginiAGC Plibrico Monolithic RefractoriesUmashankar Govindappa0% (1)

- COP-WFP-CHK-03-2013-v1 Civil Foundations and Pile CapsDocument4 paginiCOP-WFP-CHK-03-2013-v1 Civil Foundations and Pile CapsMario OvejeroÎncă nu există evaluări

- EXPANSO - Rock and Concrete Breaking Non Explosive Mortar - Call - 7676001100Document14 paginiEXPANSO - Rock and Concrete Breaking Non Explosive Mortar - Call - 7676001100CA JamesÎncă nu există evaluări

- Tanky 53 KL Rev.1Document187 paginiTanky 53 KL Rev.1Priyo Jati WahyonoÎncă nu există evaluări

- Tekla Structures Catalog ProfilesDocument144 paginiTekla Structures Catalog ProfilesNeenu VsÎncă nu există evaluări

- WEG 02 2017 Standard Stock Catalog Three Phase General Purpose Motors Us100 Brochure English PDFDocument49 paginiWEG 02 2017 Standard Stock Catalog Three Phase General Purpose Motors Us100 Brochure English PDFArshad MahmoodÎncă nu există evaluări

- Ltrs. SMC Panel Tank EstimateDocument4 paginiLtrs. SMC Panel Tank EstimateShubham PokhriyalÎncă nu există evaluări

- SECURE SoR 09.07.2019Document39 paginiSECURE SoR 09.07.2019anuragÎncă nu există evaluări

- Arpita GantryDocument120 paginiArpita GantryAkshay Gottlieb100% (1)

- Concrete Slabs On GradeDocument4 paginiConcrete Slabs On Grademr.KramÎncă nu există evaluări

- Estimate of Duct For OFCDocument12 paginiEstimate of Duct For OFCrajinder kutaalÎncă nu există evaluări

- BPCL PuneDocument9 paginiBPCL PuneDeependra SinghÎncă nu există evaluări

- Valvula Reductora de Presion Bermad Area 675 720-ULDocument4 paginiValvula Reductora de Presion Bermad Area 675 720-ULChristian FherÎncă nu există evaluări

- QES PEVC-ENG256 - Checklist For 33kV DP Foundation Design & DrawingDocument2 paginiQES PEVC-ENG256 - Checklist For 33kV DP Foundation Design & Drawingrupesh417Încă nu există evaluări

- Significant Changes in AWWA D100-11Document6 paginiSignificant Changes in AWWA D100-11Leslie Scott100% (4)

- Name Designation JOB Job Description Crew NoDocument52 paginiName Designation JOB Job Description Crew NoattaullaÎncă nu există evaluări

- Tank GADocument1 paginăTank GASubramanian100% (1)

- Fdocuments - in API 650 Storage TanksDocument15 paginiFdocuments - in API 650 Storage TanksRAHUL THAKORÎncă nu există evaluări

- Scissor Shoe Installation Guide Jan 2005 PDFDocument32 paginiScissor Shoe Installation Guide Jan 2005 PDFMohsen Halweni50% (2)

- Pdms CommentsDocument2 paginiPdms Commentssteepa22Încă nu există evaluări

- Car Parking ShedDocument4 paginiCar Parking ShedMohan BabuÎncă nu există evaluări

- Asme Sec. Viii Div-1) : Shell Plate (Disk) ConversionDocument33 paginiAsme Sec. Viii Div-1) : Shell Plate (Disk) ConversionuzairmetallurgistÎncă nu există evaluări

- Hemispherical HeadDocument5 paginiHemispherical HeadPuRuiSen HelathchemicalÎncă nu există evaluări

- Time 2 - Technical Specification - Tower Design Requirements - Revision 1.0 - 10.05.05Document12 paginiTime 2 - Technical Specification - Tower Design Requirements - Revision 1.0 - 10.05.05John MelvinÎncă nu există evaluări

- Pontoon IFR Technical Specifications 07-18-06 PDFDocument15 paginiPontoon IFR Technical Specifications 07-18-06 PDFdndudcÎncă nu există evaluări

- Verco Floor Deck Catalog VF4 03-2012 PDFDocument100 paginiVerco Floor Deck Catalog VF4 03-2012 PDFFerdie TolosaÎncă nu există evaluări

- techNOTE 13 - GRC TolerancesDocument4 paginitechNOTE 13 - GRC TolerancesJoseph JayakanthanÎncă nu există evaluări

- CRSI Manual To Design RC Diaphragms - Part26Document4 paginiCRSI Manual To Design RC Diaphragms - Part26Adam Michael GreenÎncă nu există evaluări

- Gap Analysis Report: Sl. No. Process/Activity Compliance Remedial Action Comments Yes No N/A 1.0 Contract ReviewDocument16 paginiGap Analysis Report: Sl. No. Process/Activity Compliance Remedial Action Comments Yes No N/A 1.0 Contract Reviewtimir ghoseÎncă nu există evaluări

- 03-Steel DBSE-A PDFDocument168 pagini03-Steel DBSE-A PDFZadiel SmithÎncă nu există evaluări

- Double Roman Technical DataDocument1 paginăDouble Roman Technical DataFungai M ChitsikeÎncă nu există evaluări

- Retaining WallsDocument7 paginiRetaining WallsFungai M ChitsikeÎncă nu există evaluări

- Sample IEng PRRFeb 10Document9 paginiSample IEng PRRFeb 10Fungai M ChitsikeÎncă nu există evaluări

- Thin ShellsDocument13 paginiThin ShellsFungai M ChitsikeÎncă nu există evaluări

- Consulting Engineers ManualDocument50 paginiConsulting Engineers ManualFungai M ChitsikeÎncă nu există evaluări

- Nigeria Country Profile - 0Document4 paginiNigeria Country Profile - 0Nden SohbutÎncă nu există evaluări

- ProEXR ManualDocument44 paginiProEXR ManualSabine BÎncă nu există evaluări

- Nacc NCCRDocument6 paginiNacc NCCRChaitra Gn100% (1)

- One For All Urc-8350 Instruction Manual PDF DownloadDocument5 paginiOne For All Urc-8350 Instruction Manual PDF DownloademinaÎncă nu există evaluări

- BBBB - View ReservationDocument2 paginiBBBB - View ReservationBashir Ahmad BashirÎncă nu există evaluări

- Istqb Agile Tester Learning Objectives SingleDocument3 paginiIstqb Agile Tester Learning Objectives SingleSundarÎncă nu există evaluări

- Sick - Photoelectric 4-180 MM v2Document7 paginiSick - Photoelectric 4-180 MM v2Muhammad SumeetÎncă nu există evaluări

- Case 2:09-cv-02445-WBS-AC Document 625-1 Filed 01/21/15 Page 1 of 144Document144 paginiCase 2:09-cv-02445-WBS-AC Document 625-1 Filed 01/21/15 Page 1 of 144California Judicial Branch News Service - Investigative Reporting Source Material & Story Ideas100% (2)

- Measuring Food Safety Culture in Food Manufacturing-59-173!50!115Document66 paginiMeasuring Food Safety Culture in Food Manufacturing-59-173!50!115ômąŕ ĕżžãőůįÎncă nu există evaluări

- N G Ày 2 0 T H Á NG B A N Ă M 2 0 2 0: Brand ManagementDocument10 paginiN G Ày 2 0 T H Á NG B A N Ă M 2 0 2 0: Brand ManagementThịnh NguyễnÎncă nu există evaluări

- Islm ModelDocument7 paginiIslm ModelPrastuti SachanÎncă nu există evaluări

- Analog and Digital Electronics (Ade) Lab Manual by Prof. Kavya M. P. (SGBIT, BELAGAVI)Document74 paginiAnalog and Digital Electronics (Ade) Lab Manual by Prof. Kavya M. P. (SGBIT, BELAGAVI)Veena B Mindolli71% (7)

- Installation Instructions: LRM1070, LRM1080Document2 paginiInstallation Instructions: LRM1070, LRM1080Stefan JovanovicÎncă nu există evaluări

- Nil Queries Sheet: S. No. ProcessDocument24 paginiNil Queries Sheet: S. No. ProcessTarun BhardwajÎncă nu există evaluări

- IBEC BPL System ArchitectureDocument2 paginiIBEC BPL System ArchitectureAleksandar ConevÎncă nu există evaluări

- QuickTransit SSLI Release Notes 1.1Document12 paginiQuickTransit SSLI Release Notes 1.1subhrajitm47Încă nu există evaluări

- 10 BDDDocument39 pagini10 BDDEliana NaviaÎncă nu există evaluări

- Techniques Tips For Polishing PDFDocument6 paginiTechniques Tips For Polishing PDFrobin parmarÎncă nu există evaluări

- Application For Type Aircraft Training: Farsco Training Center IR.147.12Document1 paginăApplication For Type Aircraft Training: Farsco Training Center IR.147.12benyamin karimiÎncă nu există evaluări

- Map of The 110 and 220 KV Power Transmission Line and Substation Ulaanbaatar City " Ikh Toirog " ProjectDocument10 paginiMap of The 110 and 220 KV Power Transmission Line and Substation Ulaanbaatar City " Ikh Toirog " ProjectAltanochir AagiiÎncă nu există evaluări

- Top Notch 1, 3° Edicion Workbook Answer KeyDocument14 paginiTop Notch 1, 3° Edicion Workbook Answer KeyLuis Lopez90% (61)

- ALLOY 7150-T7751 PLATE AND 7150-T77511 EXTRUSIONS: Alcoa Mill ProductsDocument4 paginiALLOY 7150-T7751 PLATE AND 7150-T77511 EXTRUSIONS: Alcoa Mill Productshitesh_tilalaÎncă nu există evaluări

- 7 Hive NotesDocument36 pagini7 Hive NotesSandeep BoyinaÎncă nu există evaluări

- Material Submission Form Register - STR (20210929)Document1 paginăMaterial Submission Form Register - STR (20210929)HoWang LeeÎncă nu există evaluări

- Bagheri Gavkosh2021Document17 paginiBagheri Gavkosh2021Dan Alfred SebualaÎncă nu există evaluări

- HRDM 21 Midnotes - TwoDocument51 paginiHRDM 21 Midnotes - TwoTimÎncă nu există evaluări

- DBMS Imp QNDocument24 paginiDBMS Imp QNShivam kumarÎncă nu există evaluări

- Divisional Sec. Contact Details 2019-03-01-UpdateDocument14 paginiDivisional Sec. Contact Details 2019-03-01-Updatedotr9317Încă nu există evaluări