Documente Academic

Documente Profesional

Documente Cultură

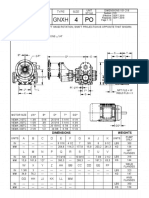

Autopipe Nozzle Report: Model Name - A53-B-P

Încărcat de

Paul Ticla PuenteTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Autopipe Nozzle Report: Model Name - A53-B-P

Încărcat de

Paul Ticla PuenteDrepturi de autor:

Formate disponibile

AutoPIPE Nozzle Report

Model Name - A53-B-P

Table of Contents

1.0: System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

2.0: Factors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

3.0: Geometry . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

4.0: Loads : Local Axis System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

5.0: Loads : DIV I(WRC107) Axis System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

6.0: Allowable Load Factors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

8.0: Allowable Loads : . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

10.0: Summary Stresses : At Edge of Attachment . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

11.0: Summary Stresses : At Edge of Pad . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

13.0: Shell stresses : At Edge of Attachment GRP1+T1 . . . . . . . . . . . . . . . . . . . . 4

14.0: Shell stresses : At Edge of Pad GRP1+T1 . . . . . . . . . . . . . . . . . . . . . . . . . . 5

15.0: Input/Results Summary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

16.0: Warning Messages : . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Jun 24 2019 AutoPIPE Nozzle 8.11.08.35 - A53-B-P

Project :

Company Name : REBIS Engineer : MU

Contract Name : TANK FT6/FT7/FT8 MODS1 Checked By : DF

Contract No. : 71456/1 File Name : Tk2081a

Description : TANK FT6,30in INLET ON 7900 Calculation No. Rebis/FT/2

LOAD CASES T1 TO T3 Rev No. 5

1.0 System :

Design Code : DIV I(WRC107) Material Library : ASME1996 VIII DIV I

Code Year : < 2001 Vessel Identifier : FT6

Design Pressure : (N/mm2) 2.571 Nozzle Identifier : A01

Design Temperature : (deg C) 20.0 Units : SI

Ambient Temperature : (deg C) 20.0

Property Shell Nozzle Pad

Type Cylinder Hollow-Pipe Round

Nominal n/a

OD (mm) 457.2 267 300

Schedule n/a n/a n/a

Thickness (mm) 20 2.769 3mm

Corrosion (mm) 0.00 n/a n/a

Weld Efficiency 1.00 1.000 n/a

Material Specification A53-B-P A516-70-PS A516-70-PS

Material Section Pipes Plates All

Material Youngs Modulus, E (N/mm2) 202,016 202,016 202,016

Allowable Stress (Ambient) (N/mm2) 103.4 0 < n/a

Allowable Stress (Design) (N/mm2) 103.4 0 < 120.7

Yield Stress (Ambient) (N/mm2) 241 262 n/a

Yield Stress (Design) (N/mm2) 0 0 n/a

* User defined material, < User defined allowable stresses

2.0 Factors :

Other Factors Occasional Factors Code Stress Factors Nozzle Pad

Membrane Stress Conc., Kn : 1.000 Load Case U1 : 1 Membrane : 1 1

Bending Stress Conc., Kb : 1.000 Load Case U2 : 1 Primary Combined : 1.5 1.5

Pressure Stress Conc., Kp : 1.000 Load Case U3 : 1 Secondary Combined : 3 3

Fillet Radius (mm) : .000 Buckling : 0 0

3.0 Geometry :

Nozzle Inside Proj. : 0.0 mm

Nozzle/Vessel Angle (B) : 0 deg

Hillside Offset from Shell Axis : 0.0 mm

Nozzle Oblique Angle (A) : 0 deg

External Projection (L) : 0.0 mm

Nozzle Location (C) : 0.0 mm

Cylinder Length (D) : 0.0 mm

Jun 24 2019 AutoPIPE Nozzle 8.11.08.35 - A53-B-P Page 1

Project :

Company Name : REBIS Engineer : MU

Contract Name : TANK FT6/FT7/FT8 MODS1 Checked By : DF

Contract No. : 71456/1 File Name : Tk2081a

Description : TANK FT6,30in INLET ON 7900 Calculation No. Rebis/FT/2

LOAD CASES T1 TO T3 Rev No. 5

4.0 Loads : Local Axis System

Forces (N) Moments (N-m)

Case Fx Fy Fz Mx My Mz

GR 1000 1000 1000 5000 5000 5000

T1 2000 2000 2000 2000 10000 10000

P1 0 0 0 0 0 0

5.0 Loads : DIV I(WRC107) Axis System

Forces (N) Moments (N-m)

Case Radial,P Long,VL Circ,VC Circ,MC Long,ML Tors,MT

GR -1000 -1000 -1000 5000 -5000 5000

T1 -2000 -2000 -2000 10000 -10000 2000

P1 0 0 0 0 0 0

WRC107 Axes Global Axes

Shell Axis = Y, Nozzle Axis = X, 3rd Axis = -Z

6.0 Allowable Load Factors :

Load Ratio Ratio Load Ratio Ratio

Circum. shear / Radial Load : 1 Longit. Moment / Radial Load : 1

Longit. Shear / Radial Load : 1 Circum. Moment / Radial Load : 1

Torsion Moment / Radial Load : 1 Internal Pressure / Radial Load : .5

Jun 24 2019 AutoPIPE Nozzle 8.11.08.35 - A53-B-P Page 2

Project :

Company Name : REBIS Engineer : MU

Contract Name : TANK FT6/FT7/FT8 MODS1 Checked By : DF

Contract No. : 71456/1 File Name : Tk2081a

Description : TANK FT6,30in INLET ON 7900 Calculation No. Rebis/FT/2

LOAD CASES T1 TO T3 Rev No. 5

8.0 Allowable Loads :

Forces (N) Moments (N-m)

Radial Load : 70234 Circumferential Moment: 21407

Circumferential Shear : 70234 Longitudinal Moment : 21407

Longitudinal Shear : 70234 Torsion Moment : 21407

Internal Pressure : (N/mm2) 0.1

10.0 Summary Stresses : (N/mm2) At Edge of Attachment

Combinations Stress Type Actual Allowable %

Pressure Membrane 24.9 103.4 24%

GR Membrane 34.0 155.1 22%

GR Combined 69.8 310.3 22%

GRP1+T1 Membrane 51.8 310.3 17%

GRP1+T1 Combined 159.5 310.3 51%

11.0 Summary Stresses : (N/mm2) At Edge of Pad

Combinations Stress Type Actual Allowable %

Pressure Membrane 28.4 103.4 27%

GR Membrane 39.5 155.1 25%

GR Combined 86.0 310.3 28%

GRP1+T1 Membrane 61.7 310.3 20%

GRP1+T1 Combined 201.2 310.3 65%

Jun 24 2019 AutoPIPE Nozzle 8.11.08.35 - A53-B-P Page 3

Project :

Company Name : REBIS Engineer : MU

Contract Name : TANK FT6/FT7/FT8 MODS1 Checked By : DF

Contract No. : 71456/1 File Name : Tk2081a

Description : TANK FT6,30in INLET ON 7900 Calculation No. Rebis/FT/2

LOAD CASES T1 TO T3 Rev No. 5

13.0 Shell stresses : At Edge of Attachment GRP1+T1

Vessel Nozzle ro Rm

Int. Pressure Material T (mm) Gamma kn kb

Type Type (mm) (mm)

2.571 N/mm2 A53-B-P Cylinder Cyl-Hol 133.50 220.10 23.00 9.6 1.000 1.000

Loads (N) Moments (N-m)

Radial,P Long,VL Circ,VC Circ,MC Long,ML Tors,MT

-3000 -3000 -3000 15000 -15000 7000

Fig.Value Beta Au AL Bu BL Cu CL Du DL

P(Nø) 1.232 \ 0.733 0.500 0.7 0.7 0.7 0.7 0.4 0.4 0.4 0.4

P(Mø) 0.024 \ 0.054 0.500 0.8 -0.8 0.8 -0.8 1.8 -1.8 1.8 -1.8

MC(Nø) 0.441 0.500 0.0 0.0 0.0 0.0 -11.9 -11.9 11.9 11.9

MC(Mø) 0.078 0.500 0.0 0.0 0.0 0.0 -120.4 120.4 120.4 -120.4

ML(Nø) 0.966 0.500 26.0 26.0 -26.0 -26.0 0.0 0.0 0.0 0.0

ML(Mø) 0.018 0.500 27.9 -27.9 -27.9 27.9 0.0 0.0 0.0 0.0

Pressure Stress 24.9 24.9 24.9 24.9 24.9 24.9 24.9 24.9

Circ.Membrane Sum Stress 51.6 51.6 -0.4 -0.4 13.4 13.4 37.2 37.2

Circumferential Sum Stress 80.3 22.9 -27.5 26.7 -105.1 132.0 159.4 -85.0

P(Nx) 0.733 \ 1.232 0.500 0.4 0.4 0.4 0.4 0.7 0.7 0.7 0.7

P(Mx) 0.041 \ 0.034 0.500 1.4 -1.4 1.4 -1.4 1.2 -1.2 1.2 -1.2

MC(Nx) 1.035 0.500 0.0 0.0 0.0 0.0 -27.9 -27.9 27.9 27.9

MC(Mx) 0.038 0.500 0.0 0.0 0.0 0.0 -58.5 58.5 58.5 -58.5

ML(Nx) 0.454 0.500 12.2 12.2 -12.2 -12.2 0.0 0.0 0.0 0.0

ML(Mx) 0.034 0.500 52.1 -52.1 -52.1 52.1 0.0 0.0 0.0 0.0

Pressure Stress 11.1 11.1 11.1 11.1 11.1 11.1 11.1 11.1

Long.Membrane Sum Stress 23.8 23.8 -0.7 -0.7 -16.0 -16.0 39.7 39.7

Longitudinal Sum Stress 77.3 -29.7 -51.4 50.1 -73.4 41.4 99.4 -19.9

Shear Stress (MT) 2.7 2.7 2.7 2.7 2.7 2.7 2.7 2.7

Shear Stress (VC) -0.3 -0.3 0.3 0.3 0.0 0.0 0.0 0.0

Shear Stress (VL) 0.0 0.0 0.0 0.0 0.3 0.3 -0.3 -0.3

Total Shear Stress 2.4 2.4 3.0 3.0 3.0 3.0 2.4 2.4

Maximum Membrane 51.8 51.8 3.6 3.6 16.3 16.3 41.2 41.2

Maximum Combined 81.6 29.8 51.8 50.5 105.4 132.1 159.5 85.1

WRC107 Axes Global Axes

Shell Axis = Y, Nozzle Axis = X, 3rd Axis = -Z

Maximum Stresses (N/mm2)

Max.Membrane 51.8

Max.Combined 159.5

Jun 24 2019 AutoPIPE Nozzle 8.11.08.35 - A53-B-P Page 4

Project :

Company Name : REBIS Engineer : MU

Contract Name : TANK FT6/FT7/FT8 MODS1 Checked By : DF

Contract No. : 71456/1 File Name : Tk2081a

Description : TANK FT6,30in INLET ON 7900 Calculation No. Rebis/FT/2

LOAD CASES T1 TO T3 Rev No. 5

14.0 Shell stresses : At Edge of Pad GRP1+T1

Vessel Nozzle ro Rm

Int. Pressure Material T (mm) Gamma kn kb

Type Type (mm) (mm)

2.571 N/mm2 A53-B-P Cylinder Cyl-Hol 150.00 218.60 20.00 10.9 1.000 1.000

Loads (N) Moments (N-m)

Radial,P Long,VL Circ,VC Circ,MC Long,ML Tors,MT

-3000 -3000 -3000 15000 -15000 7000

Fig.Value Beta Au AL Bu BL Cu CL Du DL

P(Nø) 1.340 \ 0.772 0.500 0.9 0.9 0.9 0.9 0.5 0.5 0.5 0.5

P(Mø) 0.021 \ 0.053 0.500 0.9 -0.9 0.9 -0.9 2.4 -2.4 2.4 -2.4

MC(Nø) 0.482 0.500 0.0 0.0 0.0 0.0 -15.1 -15.1 15.1 15.1

MC(Mø) 0.075 0.500 0.0 0.0 0.0 0.0 -154.7 154.7 154.7 -154.7

ML(Nø) 1.028 0.500 32.3 32.3 -32.3 -32.3 0.0 0.0 0.0 0.0

ML(Mø) 0.016 0.500 33.7 -33.7 -33.7 33.7 0.0 0.0 0.0 0.0

Pressure Stress 28.4 28.4 28.4 28.4 28.4 28.4 28.4 28.4

Circ.Membrane Sum Stress 61.5 61.5 -3.0 -3.0 13.7 13.7 44.0 44.0

Circumferential Sum Stress 96.1 27.0 -35.7 29.7 -138.5 166.0 201.1 -113.0

P(Nx) 0.772 \ 1.340 0.500 0.5 0.5 0.5 0.5 0.9 0.9 0.9 0.9

P(Mx) 0.037 \ 0.033 0.500 1.7 -1.7 1.7 -1.7 1.5 -1.5 1.5 -1.5

MC(Nx) 1.192 0.500 0.0 0.0 0.0 0.0 -37.4 -37.4 37.4 37.4

MC(Mx) 0.036 0.500 0.0 0.0 0.0 0.0 -74.3 74.3 74.3 -74.3

ML(Nx) 0.496 0.500 15.6 15.6 -15.6 -15.6 0.0 0.0 0.0 0.0

ML(Mx) 0.031 0.500 62.8 -62.8 -62.8 62.8 0.0 0.0 0.0 0.0

Pressure Stress 12.9 12.9 12.9 12.9 12.9 12.9 12.9 12.9

Long.Membrane Sum Stress 29.0 29.0 -2.2 -2.2 -23.6 -23.6 51.2 51.2

Longitudinal Sum Stress 93.5 -35.5 -63.3 59.0 -96.4 49.1 127.0 -24.5

Shear Stress (MT) 2.5 2.5 2.5 2.5 2.5 2.5 2.5 2.5

Shear Stress (VC) -0.3 -0.3 0.3 0.3 0.0 0.0 0.0 0.0

Shear Stress (VL) 0.0 0.0 0.0 0.0 0.3 0.3 -0.3 -0.3

Total Shear Stress 2.2 2.2 2.8 2.8 2.8 2.8 2.2 2.2

Maximum Membrane 61.7 61.7 5.4 5.4 23.8 23.8 51.8 51.8

Maximum Combined 97.3 35.6 63.6 59.2 138.7 166.1 201.2 113.1

WRC107 Axes Global Axes

Shell Axis = Y, Nozzle Axis = X, 3rd Axis = -Z

Maximum Stresses (N/mm2)

Max.Membrane 61.7

Max.Combined 201.2

Jun 24 2019 AutoPIPE Nozzle 8.11.08.35 - A53-B-P Page 5

Project :

Company Name : REBIS Engineer : MU

Contract Name : TANK FT6/FT7/FT8 MODS1 Checked By : DF

Contract No. : 71456/1 File Name : Tk2081a

Description : TANK FT6,30in INLET ON 7900 Calculation No. Rebis/FT/2

LOAD CASES T1 TO T3 Rev No. 5

15.0 Input/Results Summary

Design Code : DIV I(WRC107) Vessel Identifier : FT6

Design Pressure : (N/mm2) 2.571 Nozzle Identifier : A01

Design Temperature : (deg C) 20.0 Units : SI

Ambient Temperature : (deg C) 20.0 Membrane Stress Conc., Kn : 1.000

Bending Stress Conc., Kb : 1.000

External Nozzle Projection (L) : (mm) 0.0 Pressure Stress Conc., Kp : 1.000

Property Shell Nozzle Pad

Type Cylinder Hollow-Pipe Round

OD (mm) 457.2 267 300

Thickness (mm) 20 2.769 3

Corrosion (mm) 0.00 n/a n/a

Weld Efficiency 1.00 1.000 n/a

Material Specification A53-B-P A516-70-PS * A516-70-PS

Allowable Stress (Ambient) (N/mm2) 103.4 0

Allowable Stress (Design) (N/mm2) 103.4 0 120.7

* - User defined material

Maximum Loads : DIV I(WRC107) Axes System

Cases Forces (N) Moments (N-m)

Case Radial,P Long,VL Circ,VC Circ,MC Long,ML Tors,MT

GR -1000 -1000 -1000 5000 -5000 5000

T1 -2000 -2000 -2000 10000 -10000 2000

P1 0 0 0 0 0 0

Maximum Shell Summary Stresses : (N/mm2)

Combinations Stress Type Allowable Edge of Attach. Ratio Edge of pad Ratio

Pressure Membrane 103.4 24.9 24% 28.4 27%

GR Membrane 155.1 34.0 22% 39.5 25%

GR Combined 310.3 69.8 22% 86.0 28%

GRP1+T1 Membrane 310.3 51.8 17% 61.7 20%

GRP1+T1 Combined 310.3 159.5 51% 201.2 65%

Jun 24 2019 AutoPIPE Nozzle 8.11.08.35 - A53-B-P Page 6

Project :

Company Name : REBIS Engineer : MU

Contract Name : TANK FT6/FT7/FT8 MODS1 Checked By : DF

Contract No. : 71456/1 File Name : Tk2081a

Description : TANK FT6,30in INLET ON 7900 Calculation No. Rebis/FT/2

LOAD CASES T1 TO T3 Rev No. 5

16.0 Warning Messages :

Pad width is smaller than 1.65*SQR(Rm * Tshell)= 109.10 mm

as recommended by WRC297 & ASME VIII

where Rm = Mean radius of Shell and Tshell = Shell thickness

The value of 0.875*ro/Rm = .531 is outside

the range 0.01 to 0.5 of the WRC-107 curves.

Calculations continued with 0.875*ro/Rm = 0.5, for the nozzle.

The value of 0.875*ro/Rm = .6 is outside

the range 0.01 to 0.5 of the WRC-107 curves.

Calculations continued with 0.875*ro/Rm = 0.5, for the Pad.

Jun 24 2019 AutoPIPE Nozzle 8.11.08.35 - A53-B-P Page 7

S-ar putea să vă placă și

- AutoPIPE Nozzle Report for sss.Noz ModelDocument8 paginiAutoPIPE Nozzle Report for sss.Noz ModelRrrrrrrÎncă nu există evaluări

- Trunnion AnalysisDocument45 paginiTrunnion AnalysisChiragJansariÎncă nu există evaluări

- Nozzle Calculation - Primary Reformer Stack-R0Document22 paginiNozzle Calculation - Primary Reformer Stack-R0Aditya Jain100% (1)

- Document 1Document13 paginiDocument 1Prince SharmaÎncă nu există evaluări

- MC-001-DS-M-002-120 DS For Condensate Separator Rev ADocument4 paginiMC-001-DS-M-002-120 DS For Condensate Separator Rev AHeldiyan RamdhanÎncă nu există evaluări

- YS2-03-C10017-TL-DTS-M-004 Rev 0 (6 Inch Mobile Pig Receiver)Document4 paginiYS2-03-C10017-TL-DTS-M-004 Rev 0 (6 Inch Mobile Pig Receiver)Gajendra PatilÎncă nu există evaluări

- Nozzle Calculation - Auxiliary Boiler Stack-R0Document13 paginiNozzle Calculation - Auxiliary Boiler Stack-R0Aditya JainÎncă nu există evaluări

- Nozzlepro V2023.05.1192 Output Report: Title: Client: Contract: Engineer: Date: DescriptionDocument27 paginiNozzlepro V2023.05.1192 Output Report: Title: Client: Contract: Engineer: Date: DescriptionAstle DsouzaÎncă nu există evaluări

- Engineering mobile pig launcherDocument4 paginiEngineering mobile pig launcherGajendra PatilÎncă nu există evaluări

- Test ReportDocument18 paginiTest ReportBilel MahjoubÎncă nu există evaluări

- 00 UBF C 51 001 001 (Rev.X0)Document101 pagini00 UBF C 51 001 001 (Rev.X0)Amr AbdeinÎncă nu există evaluări

- Lifting CalcDocument12 paginiLifting Calcwisnu_bayusaktiÎncă nu există evaluări

- Appendix: Agitator Nozzle Analysis Wrc107 MethodDocument12 paginiAppendix: Agitator Nozzle Analysis Wrc107 MethodBilel MahjoubÎncă nu există evaluări

- Appendix A - DT-001Document24 paginiAppendix A - DT-001Adem AljoÎncă nu există evaluări

- Design Cal - Feed PreheaterDocument61 paginiDesign Cal - Feed PreheaterIrshad HussainÎncă nu există evaluări

- Analys990222 OutDocument31 paginiAnalys990222 Outmajmor-1Încă nu există evaluări

- Tank Calculations ReviewDocument44 paginiTank Calculations Reviewhgag selimÎncă nu există evaluări

- Duct Pressure Loss Calculations - V3Document3 paginiDuct Pressure Loss Calculations - V3pÎncă nu există evaluări

- V-340 OutDocument14 paginiV-340 OutSachin5586Încă nu există evaluări

- Trunnion CalculationDocument3 paginiTrunnion Calculationpradeep4545Încă nu există evaluări

- Dry / Empty Case: Section ADocument6 paginiDry / Empty Case: Section Aevrim77100% (1)

- UW-2 OutDocument48 paginiUW-2 Out966571016208Încă nu există evaluări

- KNM Process Systems Sdn. BHD.: Project Name: Ammonia & Urea Plant Revamp ProjectDocument32 paginiKNM Process Systems Sdn. BHD.: Project Name: Ammonia & Urea Plant Revamp ProjectrichardchiamÎncă nu există evaluări

- PVC-6907 Rev.3Document41 paginiPVC-6907 Rev.3rameshqcÎncă nu există evaluări

- Tank Design OutDocument26 paginiTank Design OutEyasin ArafatÎncă nu există evaluări

- Vessel Design CalculationDocument54 paginiVessel Design CalculationPohn Myint Han50% (2)

- Basering calculations and weld sizes for operating caseDocument6 paginiBasering calculations and weld sizes for operating caseevrim77Încă nu există evaluări

- Support Lug CalculationsDocument26 paginiSupport Lug CalculationsDinesh ChouguleÎncă nu există evaluări

- Effluent Crystalliser Feed Surge Tank 1 (LCP424-TK-010)Document37 paginiEffluent Crystalliser Feed Surge Tank 1 (LCP424-TK-010)hgag selimÎncă nu există evaluări

- Guide PV analysis resultsDocument4 paginiGuide PV analysis resultsSiri SiriÎncă nu există evaluări

- Fea N5 20in FeaDocument30 paginiFea N5 20in FeaAstle DsouzaÎncă nu există evaluări

- Sawari Khbar 2Document42 paginiSawari Khbar 2hgag selimÎncă nu există evaluări

- Skirt Support Analysis TransportDocument5 paginiSkirt Support Analysis TransportHunnymijie NorÎncă nu există evaluări

- Combinada Reporte DetalladoDocument23 paginiCombinada Reporte DetalladoGabriel RomeroÎncă nu există evaluări

- Firefhting Tank 320M3Document26 paginiFirefhting Tank 320M3hgag selim100% (1)

- Tank Calculations for Common Diesel StorageDocument28 paginiTank Calculations for Common Diesel Storageimran100% (1)

- SQUDFY212200052 - TPDDL & DTL - 33,66 & 220kV DC - Technical Offer DetailsDocument9 paginiSQUDFY212200052 - TPDDL & DTL - 33,66 & 220kV DC - Technical Offer DetailsSUJAL SHAH - SKIPPER LIMITEDÎncă nu există evaluări

- Design of Atmospheric Tanks - API650Document25 paginiDesign of Atmospheric Tanks - API650Faizal CAÎncă nu există evaluări

- LCP709 TK 003Document41 paginiLCP709 TK 003hgag selimÎncă nu există evaluări

- Static Calculation 10 - X - 15 - R0-1 PDFDocument17 paginiStatic Calculation 10 - X - 15 - R0-1 PDFsriramÎncă nu există evaluări

- Input EchoDocument6 paginiInput EchohgagÎncă nu există evaluări

- Summary Table For Dimensions and External Loads SSP01NDocument2 paginiSummary Table For Dimensions and External Loads SSP01NJ A S JASÎncă nu există evaluări

- T 190152Document27 paginiT 190152Mohd Izham IdrisÎncă nu există evaluări

- Tank 14m x12 M HeightDocument60 paginiTank 14m x12 M Heighthgag selim100% (1)

- Tabular ResultsDocument12 paginiTabular ResultsfurqanÎncă nu există evaluări

- Analyzing stresses on new lifting lugDocument4 paginiAnalyzing stresses on new lifting lugdharwinÎncă nu există evaluări

- Fea n6 14 in FeaDocument31 paginiFea n6 14 in FeaAstle DsouzaÎncă nu există evaluări

- PHE SelectionsDocument67 paginiPHE SelectionsSelva Kumar Selva KumarÎncă nu există evaluări

- Skid Is Located at Production Deck, EL+ 18000 and Motion Load For 1 Year Operating Is As Below.Document5 paginiSkid Is Located at Production Deck, EL+ 18000 and Motion Load For 1 Year Operating Is As Below.evrim77Încă nu există evaluări

- Pipeline Cathodic Protection Design - Compress PDFDocument20 paginiPipeline Cathodic Protection Design - Compress PDFBadi100% (1)

- Taroot QatifDocument37 paginiTaroot Qatifhgag selimÎncă nu există evaluări

- Psa Pad 10-1Document57 paginiPsa Pad 10-1DimasWijayantoÎncă nu există evaluări

- Output Summary: SI UnitsDocument42 paginiOutput Summary: SI UnitsAkhil JoseÎncă nu există evaluări

- Civil Engineering Foundation Analysis ReportDocument19 paginiCivil Engineering Foundation Analysis ReportGabriel RomeroÎncă nu există evaluări

- Sko0061283 R2Document52 paginiSko0061283 R2ciwidop390Încă nu există evaluări

- Tutorial Pressure VesselDocument19 paginiTutorial Pressure Vesseltahseenahsan100% (1)

- N3 Full ReportDocument22 paginiN3 Full ReportNabila AdityaÎncă nu există evaluări

- Futaba NA204SD01ACDocument18 paginiFutaba NA204SD01ACClemente JoseÎncă nu există evaluări

- British Commercial Computer Digest: Pergamon Computer Data SeriesDe la EverandBritish Commercial Computer Digest: Pergamon Computer Data SeriesÎncă nu există evaluări

- DR Dusan Ilic BE MECH PHD MIEAust Transfer Chute Analysis Techniques Including Continuum Modelling and The Discrete Element Method DEMDocument20 paginiDR Dusan Ilic BE MECH PHD MIEAust Transfer Chute Analysis Techniques Including Continuum Modelling and The Discrete Element Method DEMPaul Ticla PuenteÎncă nu există evaluări

- Eddie McGee Techniques For Improving Flow Performance in BunkersDocument20 paginiEddie McGee Techniques For Improving Flow Performance in BunkersPaul Ticla PuenteÎncă nu există evaluări

- DEM - Simulation of Conveyor Transfer Chutes: Franz KesslerDocument8 paginiDEM - Simulation of Conveyor Transfer Chutes: Franz KesslerluiasnadradeÎncă nu există evaluări

- Pump PositiveDocument3 paginiPump PositivePaul Ticla PuenteÎncă nu există evaluări

- Declan Barry A Step by Step Guide To Making Your Materials Handling Plant ATEX CompliantDocument32 paginiDeclan Barry A Step by Step Guide To Making Your Materials Handling Plant ATEX CompliantPaul Ticla PuenteÎncă nu există evaluări

- Pump PositiveDocument3 paginiPump PositivePaul Ticla PuenteÎncă nu există evaluări

- Ian Birkinshaw Drax The Application and Challenges of Keeping The UK Lights OnDocument13 paginiIan Birkinshaw Drax The Application and Challenges of Keeping The UK Lights OnPaul Ticla PuenteÎncă nu există evaluări

- Ian Atkinson Loading of Wood Pellets at UK PortsDocument28 paginiIan Atkinson Loading of Wood Pellets at UK PortsPaul Ticla PuenteÎncă nu există evaluări

- 188 Bulk2014 HiresDocument1 pagină188 Bulk2014 HiresPaul Ticla PuenteÎncă nu există evaluări

- Ian Atkinson Loading of Wood Pellets at UK PortsDocument28 paginiIan Atkinson Loading of Wood Pellets at UK PortsPaul Ticla PuenteÎncă nu există evaluări

- Intralox Thermodrive PDFDocument22 paginiIntralox Thermodrive PDFPaul Ticla PuenteÎncă nu există evaluări

- Neil Gardiner Graviflo The Fastest Cleanest Most Efficient Way To Completely Empty Large Storage VesselsDocument14 paginiNeil Gardiner Graviflo The Fastest Cleanest Most Efficient Way To Completely Empty Large Storage VesselsPaul Ticla PuenteÎncă nu există evaluări

- Mobile Concrete Batching PlantDocument15 paginiMobile Concrete Batching PlantPaul Ticla PuenteÎncă nu există evaluări

- 19 11 2018 - 82056 - Cimento SilolariDocument51 pagini19 11 2018 - 82056 - Cimento SilolariTesfaye GebryeÎncă nu există evaluări

- Arizona's Copper Solution Company: January, 2020Document26 paginiArizona's Copper Solution Company: January, 2020Paul Ticla PuenteÎncă nu există evaluări

- Fds Series: Fiber Dosing-Feeding SystemDocument15 paginiFds Series: Fiber Dosing-Feeding SystemPaul Ticla PuenteÎncă nu există evaluări

- Fibre Dosing: For All Types of Steel and Synthetic FibresDocument8 paginiFibre Dosing: For All Types of Steel and Synthetic FibresPaul Ticla PuenteÎncă nu există evaluări

- Fiber Dosing System Provides Perfect Solution for Concrete ProductionDocument14 paginiFiber Dosing System Provides Perfect Solution for Concrete ProductionPaul Ticla PuenteÎncă nu există evaluări

- Sopladores CentrifugosGDCF 1 300 SpanishDocument11 paginiSopladores CentrifugosGDCF 1 300 SpanishClaudino MiguelÎncă nu există evaluări

- Fully Automatic Equipment For Steel-And Synthetic FibresDocument8 paginiFully Automatic Equipment For Steel-And Synthetic FibresPaul Ticla PuenteÎncă nu există evaluări

- Intralox Thermodrive PDFDocument22 paginiIntralox Thermodrive PDFPaul Ticla PuenteÎncă nu există evaluări

- Warman WRT BrochureDocument8 paginiWarman WRT BrochurePaul Ticla PuenteÎncă nu există evaluări

- Tailings Alternative Assessment Yellowknife Gold Project: Report OnDocument65 paginiTailings Alternative Assessment Yellowknife Gold Project: Report OnPaul Ticla PuenteÎncă nu există evaluări

- Cep Exam Study PlanDocument1 paginăCep Exam Study PlanPaul Ticla PuenteÎncă nu există evaluări

- EA0809-003 Tyhee Yellowknife Gold Project Tailings Alternatives Assessment - Part 1Document1 paginăEA0809-003 Tyhee Yellowknife Gold Project Tailings Alternatives Assessment - Part 1Paul Ticla PuenteÎncă nu există evaluări

- Senior Reliability EngineerDocument1 paginăSenior Reliability EngineerPaul Ticla PuenteÎncă nu există evaluări

- Performance of MAT Foundations Due to Settlement ProblemDocument99 paginiPerformance of MAT Foundations Due to Settlement Problemchin_kb100% (1)

- Pressure GradientDocument3 paginiPressure GradientRoshan PateliaÎncă nu există evaluări

- In Situ Tests and The Pre-Failure Deformation Behaviour of SoilsDocument6 paginiIn Situ Tests and The Pre-Failure Deformation Behaviour of SoilsLTE002Încă nu există evaluări

- Mechanics of Fluids and Hydraulic Machines Question BankDocument7 paginiMechanics of Fluids and Hydraulic Machines Question Bankstalinrajesh143Încă nu există evaluări

- Construction and Building Materials: Sukhoon Pyo, Mo Alkaysi, Sherif El-TawilDocument10 paginiConstruction and Building Materials: Sukhoon Pyo, Mo Alkaysi, Sherif El-TawilKashif NaukhezÎncă nu există evaluări

- The Design of Vertical Pressure Vessels Subjected To Applied ForcesDocument3 paginiThe Design of Vertical Pressure Vessels Subjected To Applied ForcesMANOJ M100% (1)

- Assignment 2 - 2023 - SolutionsDocument23 paginiAssignment 2 - 2023 - SolutionsLinhan ChuÎncă nu există evaluări

- Hydraulic Schematic (ISO Control Pattern) 316 (S/N 522811001 AND ABOVE) (S/N 522911001 AND ABOVE)Document2 paginiHydraulic Schematic (ISO Control Pattern) 316 (S/N 522811001 AND ABOVE) (S/N 522911001 AND ABOVE)Леонид ЮртаевÎncă nu există evaluări

- The Radiant Time Series Cooling Load Calculation ProcedureDocument14 paginiThe Radiant Time Series Cooling Load Calculation ProcedureNor Firdaus Yunus100% (1)

- Questoin Paper JEN Civil Diploma Exam 2016Document29 paginiQuestoin Paper JEN Civil Diploma Exam 2016erparshotamÎncă nu există evaluări

- End plate shear connection designDocument7 paginiEnd plate shear connection designmaheshbandhamÎncă nu există evaluări

- Parametric Study of Structural Members by Considering AspectDocument7 paginiParametric Study of Structural Members by Considering AspectAnkita PalÎncă nu există evaluări

- Rigid vs. Flexible Pile Caps - Case Study For 235 M. Delhi T.V. ToDocument6 paginiRigid vs. Flexible Pile Caps - Case Study For 235 M. Delhi T.V. ToPrashant MuleÎncă nu există evaluări

- AP Physics Multiple Choice PracticeDocument5 paginiAP Physics Multiple Choice Practiceasmaa eÎncă nu există evaluări

- UFC 3-340-02 Structures To Resist The Effects of Accidental ExplosionsDocument5 paginiUFC 3-340-02 Structures To Resist The Effects of Accidental ExplosionsAnkit KhuranaÎncă nu există evaluări

- CH Technical Description PDFDocument19 paginiCH Technical Description PDFDANE80100% (2)

- Optimum LG RatioDocument8 paginiOptimum LG RatioSajal GuptaÎncă nu există evaluări

- 2-Solution ThermodynamicsDocument6 pagini2-Solution ThermodynamicsKristel LeeÎncă nu există evaluări

- Bit Mesra SyllabusDocument27 paginiBit Mesra SyllabusDrum SholtoÎncă nu există evaluări

- Computational Fluid Dynamics and Heat Transfer - Emerging Topics (Developments in Heat Transfer) (Developments in Heat Transfer Objectives) (PDFDrive)Document506 paginiComputational Fluid Dynamics and Heat Transfer - Emerging Topics (Developments in Heat Transfer) (Developments in Heat Transfer Objectives) (PDFDrive)Muhammad AlwayÎncă nu există evaluări

- The Second Law: The ConceptsDocument29 paginiThe Second Law: The ConceptsJerome JavierÎncă nu există evaluări

- Webinar Topics Covered: Hvac Webinar On 11 AprilDocument2 paginiWebinar Topics Covered: Hvac Webinar On 11 AprilFarisÎncă nu există evaluări

- Mokveld Product Sheet Axial Control Valve 1Document2 paginiMokveld Product Sheet Axial Control Valve 1Belos SahajiÎncă nu există evaluări

- Psychrometry ProblemsDocument33 paginiPsychrometry Problems19R21A0334 MATTA SHASHANKÎncă nu există evaluări

- Dynamic Increase Factors of Rock Strength: K. Liu, Q.B. Zhang & J. ZhaoDocument6 paginiDynamic Increase Factors of Rock Strength: K. Liu, Q.B. Zhang & J. Zhaojuan muneraÎncă nu există evaluări

- Prediction of Drying Time of Expanded Eps BlocksDocument126 paginiPrediction of Drying Time of Expanded Eps BlocksQuimicosgenericosgaffaro GaffaroÎncă nu există evaluări

- BitumenDocument8 paginiBitumenwanÎncă nu există evaluări

- 3-Torsion of Circular Shafts PDFDocument28 pagini3-Torsion of Circular Shafts PDFMohamad Zaid75% (4)

- Characteristic Features of Common Fluid Machines: Objective: Is To Transfer To A Flow MediumDocument26 paginiCharacteristic Features of Common Fluid Machines: Objective: Is To Transfer To A Flow MediumYohannes EndaleÎncă nu există evaluări

- RPs for equipment verification and drilling operationsDocument3 paginiRPs for equipment verification and drilling operationsJose BarcoÎncă nu există evaluări