Documente Academic

Documente Profesional

Documente Cultură

A Review On Exergy of Food Production Processes

Încărcat de

Alex Samuel SilvaTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

A Review On Exergy of Food Production Processes

Încărcat de

Alex Samuel SilvaDrepturi de autor:

Formate disponibile

Ref: C0689

A review on exergy analysis of food production processes

Z. Deniz ALTA and Can ERTEKİN*, Department of Farm Machinery, Faculty of Agricultural

Engineering, Akdeniz University, 07070, Antalya, Turkey

Abstract

Exergetic analysis provides a tool for a more realistic view between energy losses to the en-

vironment and internal irreversibilities in the process. This paper investigates the impact of

food production processes in terms of energy and exergy utilization. The main defined ener-

gy utilization mechanisms in food production in this study are labour and energy consumption

by industrial processes to perform mixing, cooling, heating etc. The aim of this work is to

extract valuable guidelines for designing sustainable food processes from a thermodynamic

perspective. The present literature review also summarizes the using of exergy analysis in

food production unit operations and facilities, discovers it benefits and abilities, and identifies

prospects for future researches.

Keywords: energy, exergy, food, production, process

1 Introduction

The design of an energy-intensive system for lower cost and high efficiency is one of the es-

sential approaches for sustainable development. Due to the high prices of energy, environ-

mental concerns, increasing World population and decreasing fossil fuel resources, the opti-

mum application of energy and energy consumption management methods are vital

(Aghbashlo et al. 2013). Energy analysis based on the first law of thermodynamics is a basic

and traditional approach to estimate various energy conversion processes. However, it pro-

vides no information about the irreversibility aspects of processes. Due to the deficiencies

and shortcomings of energy analysis, the exergy analysis which provides a more realistic

view of the systems and processes has been widely used, recently (Dincer and Rosen 2007;

Çengel and Boles 2008). It is a powerful to study and optimize various types of energy sys-

tems.

The main objective of exergy analysis of the systems is to provide a clear picture of the pro-

cess, to quantify the sources of inefficiency, to distinguish the quality of energy consumption,

to select optimal operation conditions and reduce the experimental impacts. It can be suc-

cessfully used to choose the appropriate component design & operating procedure. Many

engineers and scientist suggest that the thermodynamic performance of a process is best

evaluated by performing an exergy analysis (Rosen and Dincer 2001). This study tried to

summarize some applications of exergy analysis for food production processes and systems

as an instance.

* Corresponding author; Tel: 90 242 3102481; Fax: 90 242 2274564;

E-mail address: ertekin@akdeniz.edu.tr (C. Ertekin)

Proceedings International Conference of Agricultural Engineering, Zurich, 06-10.07.2014 – www.eurageng.eu 1/8

2 Exergy analysis and exergy concept

The three balance equations (mass, energy, and exergy balance) were used to find the heat

input, rate of exergy destruction, and energy and exergy efficiencies for a general steady-

state and steady-flow process (Figure 1).The law of conservation of mass and energy states

that mass and energy can neither be created nor destroyed, whereas the second law of

thermodynamics deals with the quality of energy to cause change, degradation of energy

during a process, entropy generation and the lost opportunities to do work.The total mass of

material entering the plant must equal the total mass of material leaving the plant. And in

similar, the total energy in the materials entering the processing plant, plus the energy added

in the plant, must equal the total energy leaving the plant. Exergy is not subject to a conser-

vation law, but is destroyed due to irreversibilities during any of the thermal processes, in-

cluding drying, heating, boiling, freezing etc. for food industry. It means that reducing the ir-

reversibilities in a production system will increase the exergy (i.e. availability) and hence the

efficiency of the system (Dincer 2002).

Exergy

destruction

Exergy

Exergy

Figure 1: Schematic of flows in a unit operation

The mass balance equation can be expressed in the rate form as;

where is the mass flow rate, and the subscript in stands for inlet and out for outlet.

The general energy balance can be expressed below as the total energy inputs equal to

total energy outputs;

Exergy is defined as the maximum amount of work that can be produced by a stream of mat-

ter, heat or work as it comes to equilibrium with a reference environment. The general exergy

balance can be written as follows;

Exergy destruction associated with the irreversibilities (entropy generation) within the system

boundaries and exergy losses associated with the transfer of the exergy (through material

and energy streams) to the surroundings are given by;

Proceedings International Conference of Agricultural Engineering, Zurich, 06-10.07.2014 – www.eurageng.eu 2/8

where ex is the specific exergy of the components, such as water, product, and air.

Here, in a similar way, exergy efficiency is defined as the ratio of total exergy output to

total exergy input;

Maximum improvement in the exergy efficiency for a process or system is obviously achie-

ved when the exergy destruction or irreversibility is minimized.

3 Application of exergy analysis to the food production process and facilities

The study of process engineering is an attempt to combine all forms of physical processing

into a small number of basic operations, which are called unit operations. The essential con-

cept is therefore to divide physical food processes into basic unit operations, each of which

stands alone and depends on coherent physical principles. Because of the dependence of

the unit operation on a physical principle, or a small group of associated principles, quantita-

tive relationships in the form of mathematical equations can be built to describe them. The

equations can be used to follow what is happening in the process and to control and modify

the process if required (Earle 1966).

Important unit operations in the food industry are fluid flow, heat transfer, drying, evaporation,

boiling, freezing, contact equilibrium processes (which include distillation, extraction, gas

absorption, crystallization, and membrane processes), mechanical separations (which inclu-

de filtration, centrifugation, sedimentation, sieving, pitting, peeling, slicing etc.), size reduction

and mixing.

Application of exergy analysis of food processing plants has been reported quite few studies

since the early 1980s.

The investigation of heat recovery and exergy balance in tomato paste plant was first studied

by Forciniti et al. (1985). Sogut et al. (2010) also studied on energetic and exergetic perfor-

mance evaluation of the quadruple-effect evaporator unit (QEEU) in the same sector. It was

found that the highest exergy destruction occurs in the first effect because of high tempera-

ture differences between steam and tomato paste inlet. Automatic control system was sug-

gested to eliminate the pressure loss caused from the collection of steam into a large tank

before entering the evaporator unit.

Waheed et al. (2008) carrying out energy and exergy studies conducted in an orange juice

manufacturing industry. The exergy analysis revealed that, the pasteurizer was responsible

for most of the inefficiency (over 90%) followed by packaging (6.60%). It was suggested that

the capacity of the pasteurizer could be increased to reduce the level of inefficiency of the

plant.

Sorguven and Ozilgen (2012) analyzed the production of strawberry-flavored yogurt, which

involves utilization of solar energy by plants to produce agricultural goods; feed consumption

by herbivores to produce meat and milk; fossil fuel consumption by industrial processes to

perform mixing, cooling, heating, etc. The extremely high exergy losses were accounted in

the study and the direction for the development of new technology in food processing was

suggested to decrease waste of energy and carbon dioxide accumulation in the atmosphere.

Fadare et al. (2010) presented the energy requirements and exergy inefficiencies for pro-

cessing of malt drink for a Nigerian brewery. The results are showed that, the pasteurization

Proceedings International Conference of Agricultural Engineering, Zurich, 06-10.07.2014 – www.eurageng.eu 3/8

process alone accounted for over 50% inefficiency of the overall system. Increasing the ca-

pacity of pasteurizer unit and utilization of process heat integration between pasteurizer and

other units were suggested to reduce the load on the boiler and also improve the energy effi-

ciency of the system.

Bozoglan and Hepbaslı (2010) observed the exergy efficiency of an olive oil refining plant

and determined the exergetic destructions in each devices in the plant. The functional ex-

ergetic efficiency of the plant is obtained to be 12%, while the exergy efficiency on the ex-

ergetic fuel–product basis is found to be about 65%.The maximum value of the exergy de-

struction rate was found in boiler, followed by distillation unit and stream generator. To in-

crease the exergy efficiency of the plant, examination of reverse osmosis and PH control

system to prevent corrosion in the boiler and usage of more efficient pumps were suggested.

Ozilgen and Sorguven (2011) assessed energy and exergy utilization and carbon dioxide

emission during production of soybean, sunflower, and olive oils. It was emphasized that,

agriculture is the most energy and exergy intensive process and emits most of the carbon

dioxide, and diesel is the dominant energy and exergy source. The most energy intensive

process was found as olive oil production, whereas the soybean agriculture results in a ra-

ther large CO2 emission. Decreasing the diesel consumption with good agricultural practices

and employing biodiesel were suggested.

Most of the studies in literature has been found regarding the exergy analysis of sugar pro-

duction plants. Tekin and Bayramoglu (1998) applied the exergy analysis to the industrially

important process of sugar production from sugar beets. The process is partitioned into five

main units, namely, raw juice production, juice clarification, juice concentration, sugar refining

and steam-power production, and two auxilliary units, namely; vacuum system and hot water

processing-storage system. 74.4% of relative exergy losses occurs in steam-power system

due to the irreversible nature of combustion and also by means of waste exergies of stack

gases. An improved thermal recuperation, e.g. preheating of combustion air with hot com-

bustion gases, and oxygen enrichment of the combustion air were suggested for significant

reductions in exergy losses.

Bayrak et al. (2003) investigated the energy and exergy analyses of an sugar production

plant which composed of four stages including sherbet production, sherbet distillation, sher-

bet thickening and refinery (sherbet crystallization). It was concluded that the exergy loses

took place mostly during the sherbet production process. It is generally suggested that the

irreversibility, mostly stem from the finite temperature differences at the production stages,

should be reduced to conduct more productively the sugar production process.

Other studies were carried out in sugar cane factories, such as the work by Raghu Ram and

Banerjee (2003), who evaluated two evaporation system designs using exergy analysis. Sa-

hin et al. (2010) studied improvements on a sugar production plant and determined energy

and exergy efficiencies of the system and sub-systems. Taner and Sivrioglu (2013) present-

ed the methods and equations for energy and exergy analysis of sugar factories. The im-

portance of the application of these analyses to the sugar production processes for the in-

crease of productivity was highlighted.

Ensinas et al. (2009) applied the exergy balance analysis in an integrated sugar, ethanol and

electricity process representing the current situation of sugarcane factories in Brazil. Produc-

tion process was divided into eight sub-systems; juice exraction, juice treatment, juice evapo-

ration, sugar boiling, fermentation, distillation, cogeneration system, condensate tank and

water cooling system. It was found that, the cogeneration system is responsible for 63% of

the total irreversibility generated in the base case with an exergetic efficiency of 18%. The

exergetic efficiency calculated for the whole plant in the base case, which represents a typi-

cal sugar and ethanol plant in Brazil, was 35%.Using of boilers with higher thermal efficien-

cies together with the process steam demand reduction was suggested.

Proceedings International Conference of Agricultural Engineering, Zurich, 06-10.07.2014 – www.eurageng.eu 4/8

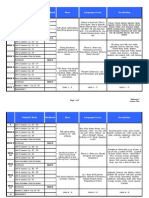

Table 1: Some of the recent studies and the most important results obtained using exergy analysis to

evaluate the food processing operations performance

_________________________________________________________________________

Author(s): Tekin and Bayramoglu (1998)

Product(s): Sugar

Operation units: Raw juice production, juice clarification, juice concentration, sugar refining and steam-

power production, and two auxilliary units, namely; vacuum system and hot water processing-storage

system.

Aim: To apply exergy analysis to sugar production process from sugar beet.

Outcome: The stream-power system is responsible for the highest exergy losses.

Author(s): Bayrak et al. (2003)

Product(s): Sugar

Operation units: Sherbet production, sherbet distillation, sherbet thickening, and refinery (sherbet crys-

tallization)

Aim: To apply energy and exergy analyses to sugar production stages by using the operational data.

Outcome: The exergy losses took place mostly during the sherbet production process

(ηI=96.8% ηII=49.3%) because of the irreversibility in the sub-operation stages, which are vapour pro-

duction, circulation sherbet mixing and bagasse compression.

Author(s): Raghu Ram and Banerjee (2003)

Product(s): Sugar

Operation units: Evaporation

Aim: To apply pinch analysis to evaporators in a sugar factory

Outcome: The amount of steam consumption will reduce by 9 T/h and exergy losses are reduced by

48% of its original value if the existing quadruple effect is modified to a quintuple effect

Author(s): Waheed et al. (2008)

Product(s): Fruit juice

Operation units: Fruit reception, bin house, sorting, cleaning, grating, crusher, screw finisher, centri-

fuge, holding tank, pasteurizer, packaging, warehouse

Aim: To determine energy consumption pattern and exergy destructions in an orange juice production

process

Outcome: The major exergy loss took place at the pasteurizer with an inefficiency of over 90%

Author(s): Ensinas et al. (2009)

Product(s): Sugar and etanol

Operation units: Juice exraction, juice treatment, juice evaporation, sugar boiling, fermentation, distilla-

tion, cogeneration system, condensate tank and water cooling system

Aim: To apply the exergy balance analysis in an integrated sugar, ethanol and electricity process

Outcome: Improvements in the cogeneration system were found to be the most important to reduce

exergy destruction

Author(s): Sahin et al. (2010)

Product(s): Sugar

Operation units: Sugarcane slaughter and sherbet production, sherbet distillation, sherbet thickening,

and refinery (sherbet crystallization)

Aim: To apply the exergy analysis in sugar production processes

Outcome: The best values of the energy and exergy efficiencies were obtained as 95·1% for the juice

production process and 74·3% for the juice concentration process respectively.

Author(s): Sogut et al. (2010)

Product(s): Tomato paste

Operation units: Evaporator unit

Aim: To evaluate the performance of quadruple-effect evaporator unit (QEEU) by using exergy analy-

sis based on actual operational data

Outcome: The highest and lowest exergetic improvement potential occurs in first and third effect of

QEEU system, respectively.

Author(s): Fadare et al. (2010a)

Product(s): Malt drink

Operation units: Silo house, brew house, filter room, and packaging house

Aim: To estimate the energy requirements and exergy inefficiencies for processing of malt drink

Proceedings International Conference of Agricultural Engineering, Zurich, 06-10.07.2014 – www.eurageng.eu 5/8

Table 1: (continued)

_________________________________________________________________________________

Outcome: The exergy analysis revealed that the packaging house operation was responsible for most

of the inefficiency (92.16%) and the most exergy loss took place in the pasteurizer, which accounted

for 59.75% of the overall system inefficiency.

Author(s): Bozoglan and Hepbaslı (2010)

Product(s): Olive oil

Operation units: Steam generators, several tanks, heat exchangers, a distillation column, flash tanks

and several pumps

Aim: To identify improvements in olive oil refinery plants’ performance

Outcome: The maximum exergy destruction rate takes place in the boiler with 490.7 kW, followed by

the distillation unit and the steam generator with 127 and 60.5 kW, respectively.

Author(s): Ozilgen and Sorguven (2011)

Product(s): Soybean oil, sunflower oil and olive oil

Operation units: Agriculture of olive, sunflower and soybean plants, conveying, cleaning, grinding,

mixing, decantation, pressing, extraction and phase, refining, bottling, pasteurization, packaging and

all transportations

Aim: To assess energy and exergy utilization and carbon dioxide emission during production of three

different vegetable oils.

Outcome: The most energy intensive process was found as olive oil production, whereas the soybean

agriculture results in a rather large CO2 emission.

Author(s): Sorguven and Ozilgen (2012)

Product(s): Strawberry-flavored yogurt

Operation units: Milk production, non-fat yogurt production, strawberry agriculture, sugar beet agricul-

ture, sugar production, strawberry jam production and flavored yogurt production

Aim: To investigate the impact of food production processes on the environment in terms of energy

and exergy utilization and carbon dioxide emission.

Outcome: 53% of the total exergy loss occurs during the milk production and 80% of the total work

input is consumed during the plain yogurt making.

Author(s): Taner and Sivrioglu (2013)

Product(s): Sugar

Operation units: Sugarcane slaughter and sherbet production, sherbet distillation, sherbet thickening,

refinery, drying, power supply

Aim: To present the methods and equations for energy and exergy analyses of sugar factories

Outcome: For the profitability of enterprises, to maximum saving in energy must be achieved and min-

imization of exergy losses is needed.

_________________________________________________________________________

Another issue mostly studied on is deal with exergy analysis of drying processes of several

food products. Drying is one of the oldest methods of preserving food and mostly used in

food processing operations. Utilization of high amount of energy in the drying industry makes

drying one of the most energy-intensive operations with a great industrial significance (Dincer

2002). In the drying industry, the goal is to use a minimum amount of energy for maximum

moisture removal for the desired final conditions of the product. Several studies have been

conducted on exergy analysis of food drying process. The drying process was thermodynam-

ically modeled by (Dincer and Sahin 2004) and drying of different products such as wheat

kernel (Syahrul et al. 2003), pistachio (Midilli and Kucuk 2003), plum (Hepbasli et al. 2010),

red pepper slices (Akpinar 2004), potato (Aghbashlo et al. 2008), apple slices (Akpınar et al.

2005), broccoli florets (Icier et al. 2010), pasta (Ozgener 2007), carrot slices (Aghbashlo et

al. 2009), milk (Jin and Chen 2011), white cheese (Erbay and Koca 2012). In this paper,

using of exergy analysis in drying operations and facilities was not explained in detail. It

could be helpful to glance at the research written by Aghbashlo et al. (2013) in this regard.

Proceedings International Conference of Agricultural Engineering, Zurich, 06-10.07.2014 – www.eurageng.eu 6/8

4 Conclusions

This paper summarized some aspects of exergy analysis and its applications in food produc-

tion processes. Literature survey showed that exergy analysis has been used in a variety of

applications for analyzing of production systems and could help to overcome problems in

many fields including efficiency improvement, energy resource utilization, and find the caus-

es, locations, and magnitude of irreversibilities for food production systems. We hope that

this study will be a reference for the future researches.

5 References

Aghbashlo, M., Kianmehr, M.H., & ARabhosseini, A. (2008). Energy and exergy analyses of

thin-layer drying of potato slices in a semi-industrial continuous band dryer. Drying

Technology, 26 (12), 1501-1508.

Aghbashlo, M., Kianmehr, M.H., & Arabhosseini, A. (2009). Performance analysis of drying

of carrot slices in a semi-industrial continuous band dryer. Journal of food

engineering, 91 (1), 99-108.

Aghbashlo, M., Mobli, H., Rafiee, S., & Madadlou, A. (2013). A review on exergy analysis of

drying processes and systems. Renewable and Sustainable Energy Reviews, 22, 1-

22.

Akpinar, E., Midilli, A., & Bicer, Y. (2005). Thermodynamic analysis of the apple drying

process. Proceedings of the Institution of Mechanical Engineers, Part E: Journal of

Process Mechanical Engineering, 219 (1), 1-14.

Akpinar, E.K. (2004). Energy and exergy analyses of drying of red pepper slices in a

convective type dryer. International Communications in Heat and Mass Transfer, 31

(8), 1165-1176.

Bayrak, M., Midilli, A., & Nurveren, K. (2003). Energy and exergy analyses of sugar

production stages. International Journal of Energy Research, 27 (11), 989-1001.

Bozoglan, E., & Hepbasli, A. (2010). Performance improvements for olive oil refining plants.

International Journal of Energy Research, 34 (6), 476-493.

Çengel, Y.A., & Boles, M.A. (2008). Termodinamik, Mühendislik Yaklaşımıyla.İzmir: İzmir

Güven Kitabevi.

Dincer, I. (2002). On energetic, exergetic and environmental aspects of drying systems.

International Journal of Energy Research, 26 (8), 717-727.

Dincer, I., & Sahin, A. (2004). A new model for thermodynamic analysis of a drying process.

International Journal of Heat and Mass Transfer, 47 (4), 645-652.

Dincer, İ., & Rosen, M.A. (2007). EXERGY: Energy, Environment and Sustainable

Development. London: Elsevier.

Earle, D. (1966). Unit operations in food processing. New Zealand: New Zealand Institute of

food Science & Technology (NZIFST).

Ensinas, A., Modesto, M., Nebra, S., & Serra, L. (2009). Reduction of irreversibility

generation in sugar and ethanol production from sugarcane. Energy, 34 (5), 680-688.

Erbay, Z., & Koca, N. (2012). Energetic, exergetic, and exergoeconomic analyses of spray-

drying process during white cheese powder production. Drying Technology, 30 (4),

435-444.

Fadare, D., Nkpubre, D., Oni, A., Falana, A., Waheed, M., & Bamiro, O. (2010). Energy and

exergy analyses of malt drink production in Nigeria. Energy, 35 (12), 5336-5346.

Forciniti, D., Rotstein, E., & Urbicain, M. (1985). Heat Recovery and Exergy Balance in a

Tomato Paste Plant. Journal of Food Science, 50 (4), 934-939.

Hepbasli, A., Erbay, Z. Colak, N., Hancioglu, E. and Icier, F. (2010). An exergetic

performance assessment of three different food driers. Journal of Power and Energy,

224 (1), 1-11.

Icier, F., Colak, N., Eerbay, Z., Kuzgunkaya, E.H., & Hepbasli, A. (2010). A comparative

study on exergetic performance assessment for drying of broccoli florets in three

different drying systems. Drying Technology, 28 (2), 193-204.

Jin, Y., & Chen, X.D. (2011). Entropy production during the drying process of milk droplets in

an industrial spray dryer. International Journal of Thermal Sciences, 50 (4), 615-625.

Proceedings International Conference of Agricultural Engineering, Zurich, 06-10.07.2014 – www.eurageng.eu 7/8

Midilli, A., & Kucuk, H. (2003). Energy and exergy analyses of solar drying process of

pistachio. Energy, 28 (6), 539-556.

Ozgener, L. (2007). Exergoeconomic analysis of small industrial pasta drying systems.

Proceedings of the Institution of Mechanical Engineers, Part A: Journal of Power and

Energy, 221 (7), 899-906.

Özilgen, M., & Sorguven, E. (2011). Energy and exergy utilization, and carbon dioxide

emission in vegetable oil production. Energy, 36 (10), 5954-5967.

Raghu Ram, J., & Banerjee, R. (2003). Energy and cogeneration targeting for a sugar

factory. Applied Thermal Engineering, 23 (12), 1567-1575.

Rosen, M.A., & Dincer, İ. (2001). Exergy as the confluence of energy, environment and

sustainable development. Exergy Int. J., 1 (1), 3-13.

Sorgüven, E., & Özilgen, M. (2012). Energy utilization, carbon dioxide emission, and exergy

loss in flavored yogurt production process. Energy, 40 (1), 214-225.

Sogut, Z., Ilten, N., & Oktay, Z. (2010). Energetic and exergetic performance evaluation of

the quadruple-effect evaporator unit in tomato paste production. Energy, 35, 3821-

3826.

Syahrul, S., Dincer, I., & Hamdullahpur, F. (2003). Thermodynamic modeling of fluidized bed

drying of moist particles. International Journal of Thermal Sciences, 42 (7), 691-701.

Şahin, H., Acır, A., Altunok, T., Baysal, E., & Kocyigit, E. (2010). Analysis of exergy and

energy of sugar production process in sugar plant. Journal of the Energy Institute, 83

(3), 178-185.

Taner, T., & Sivrioglu, M. (2013). Sugar Factories' Analysis of Energy and Exergy methods.

Engineer & the Machinery Magazine, 54 (637), 54-58.

Tekin, T., & Bayramoglu, M. (1998). Exergy analysis of the sugar production process from

sugar beets. Int. J. Energy Res., 22, 591-601.

Waheed, M., Jekayinfa, S., Ojediran, J., & Imeokparia, O. (2008). Energetic analysis of fruit

juice processing operations in Nigeria. Energy, 33 (1), 35-45.

Nomenclature

Specific exergy (kJ/kg)

Energy rate (kJ)

Exergy rate (kJ)

Exergy destruction (kJ)

Mass flow rate (kg/h)

T Temperature (K)

Exergy efficiency (%)

Subscripts

in Inlet

out Outlet

0 Reference (dead) state (303.15 K and 101.325

kPa)

Proceedings International Conference of Agricultural Engineering, Zurich, 06-10.07.2014 – www.eurageng.eu 8/8

S-ar putea să vă placă și

- Experiments in Diffusion Gases Liquids and Solids For Under Five DollarsDocument6 paginiExperiments in Diffusion Gases Liquids and Solids For Under Five DollarsAlex Samuel SilvaÎncă nu există evaluări

- Procedure For DBS CollectionDocument7 paginiProcedure For DBS CollectionAlex Samuel SilvaÎncă nu există evaluări

- Integrating Teaching Styles and Learning Styles With Instructional TechnologyDocument10 paginiIntegrating Teaching Styles and Learning Styles With Instructional TechnologyAlex Samuel SilvaÎncă nu există evaluări

- Tel Is Romero 2006Document7 paginiTel Is Romero 2006Alex Samuel SilvaÎncă nu există evaluări

- Student Participation in Engineering Practices and Discourse: An Exploratory Case StudyDocument22 paginiStudent Participation in Engineering Practices and Discourse: An Exploratory Case StudyAlex Samuel SilvaÎncă nu există evaluări

- (Our Sustainable Future) Robert P. King, Michael S. Hand, Miguel I. Gomez-Growing Local - Case Studies On Local Food Supply Chains-University of Nebraska Press (2015)Document383 pagini(Our Sustainable Future) Robert P. King, Michael S. Hand, Miguel I. Gomez-Growing Local - Case Studies On Local Food Supply Chains-University of Nebraska Press (2015)Alex Samuel SilvaÎncă nu există evaluări

- Susan Wilks Designing A Thinking Curriculum PDFDocument151 paginiSusan Wilks Designing A Thinking Curriculum PDFAlex Samuel Silva100% (1)

- (Graduate Texts in Physics) Peter Hertel-Quantum Theory and Statistical Thermodynamics - Principles and Worked Examples-Hertel, Peter, Springer Verlag (2017)Document382 pagini(Graduate Texts in Physics) Peter Hertel-Quantum Theory and Statistical Thermodynamics - Principles and Worked Examples-Hertel, Peter, Springer Verlag (2017)Alex Samuel Silva100% (1)

- (Mechanical Engineering Series) Hamid Arastoopour, Dimitri Gidaspow, Emad Abbasi (Auth.) - Computational Transport Phenomena of Fluid-Particle Systems-Springer International Publishing (2017)Document114 pagini(Mechanical Engineering Series) Hamid Arastoopour, Dimitri Gidaspow, Emad Abbasi (Auth.) - Computational Transport Phenomena of Fluid-Particle Systems-Springer International Publishing (2017)Alex Samuel SilvaÎncă nu există evaluări

- Carson 2014Document3 paginiCarson 2014Alex Samuel SilvaÎncă nu există evaluări

- Heat ConductionDocument11 paginiHeat ConductionAlex Samuel SilvaÎncă nu există evaluări

- How To Estimate The Heat Penetration Factor FH of Packaged Foods PDFDocument71 paginiHow To Estimate The Heat Penetration Factor FH of Packaged Foods PDFAlex Samuel SilvaÎncă nu există evaluări

- Mathematical Models in Food Engineering Angel Manuel Ramos, Nadia SmithDocument8 paginiMathematical Models in Food Engineering Angel Manuel Ramos, Nadia SmithAlex Samuel SilvaÎncă nu există evaluări

- 9-Food and WaterTHE MICROBIOLOGICAL EXAMINATION OF FOODS & WATERDocument16 pagini9-Food and WaterTHE MICROBIOLOGICAL EXAMINATION OF FOODS & WATERArri KurniawanÎncă nu există evaluări

- 001 - Performance Analysis of Solar Drying System For Red Chili PDFDocument8 pagini001 - Performance Analysis of Solar Drying System For Red Chili PDFAlex Samuel SilvaÎncă nu există evaluări

- Editorial BoardDocument1 paginăEditorial BoardAlex Samuel SilvaÎncă nu există evaluări

- Chapter 15: Chemical and Phase Equilibrium: CH O N DCO ECO FO GHO BNDocument0 paginiChapter 15: Chemical and Phase Equilibrium: CH O N DCO ECO FO GHO BNAlex Samuel SilvaÎncă nu există evaluări

- 07 Unit Operations in Food ProcessingDocument36 pagini07 Unit Operations in Food ProcessingAlex Samuel Silva75% (4)

- DraftDocument1 paginăDraftAlex Samuel SilvaÎncă nu există evaluări

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceDe la EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceEvaluare: 4 din 5 stele4/5 (895)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeDe la EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeEvaluare: 4 din 5 stele4/5 (5794)

- Shoe Dog: A Memoir by the Creator of NikeDe la EverandShoe Dog: A Memoir by the Creator of NikeEvaluare: 4.5 din 5 stele4.5/5 (537)

- Grit: The Power of Passion and PerseveranceDe la EverandGrit: The Power of Passion and PerseveranceEvaluare: 4 din 5 stele4/5 (588)

- The Yellow House: A Memoir (2019 National Book Award Winner)De la EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Evaluare: 4 din 5 stele4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingDe la EverandThe Little Book of Hygge: Danish Secrets to Happy LivingEvaluare: 3.5 din 5 stele3.5/5 (400)

- Never Split the Difference: Negotiating As If Your Life Depended On ItDe la EverandNever Split the Difference: Negotiating As If Your Life Depended On ItEvaluare: 4.5 din 5 stele4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureDe la EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureEvaluare: 4.5 din 5 stele4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryDe la EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryEvaluare: 3.5 din 5 stele3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerDe la EverandThe Emperor of All Maladies: A Biography of CancerEvaluare: 4.5 din 5 stele4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaDe la EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaEvaluare: 4.5 din 5 stele4.5/5 (266)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersDe la EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersEvaluare: 4.5 din 5 stele4.5/5 (345)

- On Fire: The (Burning) Case for a Green New DealDe la EverandOn Fire: The (Burning) Case for a Green New DealEvaluare: 4 din 5 stele4/5 (74)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyDe la EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyEvaluare: 3.5 din 5 stele3.5/5 (2259)

- Team of Rivals: The Political Genius of Abraham LincolnDe la EverandTeam of Rivals: The Political Genius of Abraham LincolnEvaluare: 4.5 din 5 stele4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaDe la EverandThe Unwinding: An Inner History of the New AmericaEvaluare: 4 din 5 stele4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreDe la EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreEvaluare: 4 din 5 stele4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)De la EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Evaluare: 4.5 din 5 stele4.5/5 (121)

- Her Body and Other Parties: StoriesDe la EverandHer Body and Other Parties: StoriesEvaluare: 4 din 5 stele4/5 (821)

- Business Plan EconomicsDocument3 paginiBusiness Plan EconomicsKen UrielÎncă nu există evaluări

- ADITIVI - Beer and Malt Beverages 14.2.1Document2 paginiADITIVI - Beer and Malt Beverages 14.2.1VLASTARÎncă nu există evaluări

- A Study of Acute Malnutrition Among Children in NRCDocument11 paginiA Study of Acute Malnutrition Among Children in NRCkharemixÎncă nu există evaluări

- "Facts Are Not Science - As The Dictionary Is Not Literature." Martin H. FischerDocument16 pagini"Facts Are Not Science - As The Dictionary Is Not Literature." Martin H. FischerVivek TripathyÎncă nu există evaluări

- Perfect Puppy in 7 Days - Potty TrainingDocument0 paginiPerfect Puppy in 7 Days - Potty Trainingingrid_morales_10% (1)

- The Story of Cotton 73k PDFDocument3 paginiThe Story of Cotton 73k PDFmarianaÎncă nu există evaluări

- Galette Des Rois - Chocolate Academy X Isigny Ste-MèreDocument18 paginiGalette Des Rois - Chocolate Academy X Isigny Ste-MèreCwt ChanÎncă nu există evaluări

- Karakteristik Lactobacillus Spesies Yang Diisolasi Dari Daging SapiDocument5 paginiKarakteristik Lactobacillus Spesies Yang Diisolasi Dari Daging SapiSyahrul HidayatÎncă nu există evaluări

- AB Card - A12-004 Samsung B-30K 24-04-12Document3 paginiAB Card - A12-004 Samsung B-30K 24-04-12wtwilightwÎncă nu există evaluări

- PCI Food and Farming TransitionDocument41 paginiPCI Food and Farming TransitionDaisy100% (3)

- Microwave-Assisted Extraction of Phenolic Compounds From Olive Leaves A Comparison With MacerationDocument8 paginiMicrowave-Assisted Extraction of Phenolic Compounds From Olive Leaves A Comparison With MacerationThu LeÎncă nu există evaluări

- Comparative Study of Rate of Fermentation of Fruit JuicesDocument30 paginiComparative Study of Rate of Fermentation of Fruit JuicesSubrat KumarÎncă nu există evaluări

- Listening Section06-08Document11 paginiListening Section06-08puvaneeÎncă nu există evaluări

- NCM105 (Lec) - Prelim ReviewerDocument3 paginiNCM105 (Lec) - Prelim ReviewerAlthea ManarpiisÎncă nu există evaluări

- My Cook BookDocument66 paginiMy Cook BookAkshay KumariÎncă nu există evaluări

- Keto ResearchDocument2 paginiKeto ResearchNidza DzonsÎncă nu există evaluări

- Narrative Paragraphs Part 2Document14 paginiNarrative Paragraphs Part 2hyfsh hdgdysgÎncă nu există evaluări

- Programa Welcome 2Document6 paginiPrograma Welcome 2Aleksandra Krstovska0% (1)

- Voh 11Document19 paginiVoh 11Siphiwe Christopher MathebulaÎncă nu există evaluări

- Thesis About Del Monte Farm and WorkersDocument96 paginiThesis About Del Monte Farm and WorkersMarry Ellorig100% (1)

- PREPARE - 4 - Culture Video Answer KeyDocument4 paginiPREPARE - 4 - Culture Video Answer KeyCarmen ReyesÎncă nu există evaluări

- Read The Following Selection BelowDocument2 paginiRead The Following Selection BelowRamyres David0% (1)

- BQT Buffet - Single LineDocument2 paginiBQT Buffet - Single LineVivekanand SinghÎncă nu există evaluări

- A Detailed Lesson Plan in Grade 5 Adjectives ObjectivesDocument7 paginiA Detailed Lesson Plan in Grade 5 Adjectives ObjectivesLovely ParaisoÎncă nu există evaluări

- Bananasap FinalDocument20 paginiBananasap FinalKarina Lingan100% (1)

- Winter Detox Moroccan Sweet Potato Lentil Soup (Slow Cooker) - Little Spice JarDocument2 paginiWinter Detox Moroccan Sweet Potato Lentil Soup (Slow Cooker) - Little Spice JarConsultorio Ibette ChinchillaÎncă nu există evaluări

- Stranded IIDocument11 paginiStranded IIJonathan Alonzo GarciaÎncă nu există evaluări

- Training DayDocument12 paginiTraining DayKristie Rose LiswidÎncă nu există evaluări

- Physical Hazards in FoodDocument5 paginiPhysical Hazards in FoodStella Lupita June TjandraÎncă nu există evaluări

- Case Study ProjDocument24 paginiCase Study ProjAnonymous eMOb79RNt5Încă nu există evaluări