Documente Academic

Documente Profesional

Documente Cultură

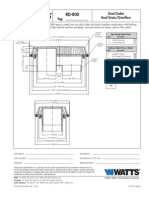

Series QF Radiator Steam Trap Replacement Kits Specification Sheet

Încărcat de

WattsDrepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Series QF Radiator Steam Trap Replacement Kits Specification Sheet

Încărcat de

WattsDrepturi de autor:

Formate disponibile

ES-QF

For Radiator Steam Trap Replacement Applications

Job Name Contractor Approval

Job Location Engineer Approval

Contractors P.O. No. Representative

Series QF

Radiator Steam Trap Replacement Kits

Series QF Radiator Steam Trap Replacement Kits are used to repair old or obsolete radiator steam traps without the cost of replacing the steam trap body or expensive repiping. The stainless steel capsule and valve seat are designed as original equipment parts for many hard to find or obsolete radiator steam traps. Remove the cover of the old steam trap and take out any remaining trap parts. Install the stainless steel Quik Fix seat and snap the stainless steel capsule onto the new seat. Replace the cover and the radiator steam trap has been repaired. Contact Watts for any model radiator traps not listed below.

QF-10

Quick-Fix Selection Chart

TRAPS WITH REPLACEABLE SEATS Model QF-1 QF-2 Manufacturer Warren Webster Warren Webster / " Traps 02H, 02V, 502, 502V-1 702, 702V-1, 712, 902V 512, 512H-1, 512G-1 522, 522H, 522HB 712HB, 722HB 902H E, H, S65, TB25, TS25 T65 R30 1G B1* 1 30 17C 7-50A B3 TH2A 1B, 1C, 1E, V1B B2 T25 T25 8 1T, 2T 122A, 122S, 3045 134A, 134S B1* B3 Series FT 3/4" 2" 686/55AL 3/4" 1" ALL

1 2

QUICK, EASY INSTALLATION

/ " Traps 503, 703, 713 513, 533 523A, 523H-1**, 5236-1** 713HB, 733, 733HB 723A 913A, 913H E, H, S65 TB25, TS25 T65 3GH

3 4

QF-3 QF-4 QF-5

Warren Webster Warren Webster Sarco

Remove cover of Install seat adapter, trap and old trap parts. then snap capsule onto it.

Replace original cover.

QF-6 QF-14 QF-15 QF-16

Erwel Illinois Trane Marsh Monash-Younker Hoffman Marsh Sterling Trane Dunham-Bush

Once the Quick-Fix kits are installed, any subsequent trap repairs require only replacement of the capsule, which is the same for all trap kits.

8C 2-4, 2-7

How it Works

Solid Stainless Valve Actuating Diaphragm with Volatile Liquid Welded Capsule and Seat Assembled

TRAPS WITH INTEGRAL SEATS QF-7 Dunham-Bush Trane Sarco QF-8 Sarco Hoffman QF-9 Illinois QF-10 Barnes & Jones QF-11 Barnes & Jones QF-12 Trane QF-13 Trane

1 2

/"

15/16" Actuating Capsule Solid Stainless Seats For Traps with Replaceable Seats For Traps with Integral Seats

REPLACEMENT AIR VENTS FOR F & T TRAPS (15 AND 30 PSI) QF-25 Sarco QF-26 Trane REPLACEMENT THERMAL CAPSULE ONLY QFC-10 ALL ALL *Except vertical models. **Old style omit -1" from symbol. For traps built since 1931 only.

Watts product specifications in U.S. customary units and metric are approximate and are provided for reference only. For precise measurements, please contact Watts Technical Service. Watts reserves the right to change or modify product design, construction, specifications, or materials without prior notice and without incurring any obligation to make such changes and modifications on Watts products previously or subsequently sold.

Typical Steam Trap with Replaceable Seat

Cover Body Bellow Assembly Contains Actuating Liquid Stainless Steel Bellows Contains Actuating Liquid Solid Stainless Steel Valve From Radiator Replaceable Seat Stainless Steel Capsule

Valve - Normally Open - Bellow Retracted Closed to Steam - Bellows Expanded

Replacement Seat Stainless Steel

Before

After

Application of Series QF Radiator Steam Trap Replacement Kits

In a Two Pipe Low Pressure Steam heating system, heat produced by burning fuel in a boiler is transferred to the water, causing the water to be converted into steam. The steam passes through the supply piping to heat distribution units (radiators) where it condenses and gives off heat. The condensed water (condensate) returns by gravity through the return piping back to the boiler (Figure 1). Two Pipe - One for steam supply and one for condensate return. Low Pressure - It only takes the very low pressure created in boiling water to force steam to the radiators. In order to get steam into a radiator we must first push the air out (Figure 2). If you dont, the radiator wont get hot. This is the first requirement of the Steam Trap, to allow the steam pressure to push the air out of the radiator. Failed radiator traps could result in air or condensate not being able to leave the radiator, creating a no heat condition. Once the radiator fills with steam we want to close the return (Figure3). The Steam Trap stays closed until the steam cools enough to turn into condensate. Then the trap opens allowing the condensate to drain from the radiator (Figure 4). How does the steam trap know when to open and close? By temperature. The bellows inside the trap is filled with a mixture that is set to boil at a temperature slightly lower than the steam. Air will pass through the trap. When steam begins to enter through the trap, the bellows expands and closes the trap. The trap remains closed until the steam cools and condenses into water. The bellows retracts to allow the water into the return piping. Why not allow the steam into the return piping and simply not use a steam trap? First, you would be wasting a lot of heat and money. It would be wasted in the return piping. Second, you could be overheating areas that there is no call for heat. Third, condensate pumps can be damaged by excessive temperature in condensate.

Steam In

Radiator Control Valve

Steam Trap

Steam Return Main To Boiler Thermostatic Trap Closed

Supply Main

From Boiler

Figure 1

Steam In

Figure 3

Steam In

System Heating

Steam Thermostatic Trap Open

Condensate Thermostatic Trap Open

Steam In

Air Out

Figure 2

Figure 4

System Heating

Condensate Out

USA: 815 Chestnut St., No. Andover, MA 01845-6098; www.wattsreg.com Canada: 5435 North Service Rd., Burlington, ONT. L7L 5H7; www.wattscanada.ca ES-QF 0334 Watts Regulator Co., 2003 Printed in U.S.A.

S-ar putea să vă placă și

- Best 25 Question and Answer For Boiler First and Second Class Operator Viva Examination 2017 - ASKPOWERPLANTDocument32 paginiBest 25 Question and Answer For Boiler First and Second Class Operator Viva Examination 2017 - ASKPOWERPLANTRaju Maity100% (3)

- For The Steam and Condensate LoopDocument12 paginiFor The Steam and Condensate Loopzoraze32Încă nu există evaluări

- ESSENTIAL OIL Steam Distillation Steam DistillerDocument8 paginiESSENTIAL OIL Steam Distillation Steam DistillerSerene InÎncă nu există evaluări

- Heating Help PDFDocument113 paginiHeating Help PDFchaitu348Încă nu există evaluări

- Chapter 8 Steam PipingDocument14 paginiChapter 8 Steam PipingChen WsÎncă nu există evaluări

- LGP REPORT #3 - SimpasaDocument15 paginiLGP REPORT #3 - SimpasaBeckham ChaileÎncă nu există evaluări

- Piping 30000Document14 paginiPiping 30000Prasanta Kumar BeheraÎncă nu există evaluări

- Series LF210-5 Specification SheetDocument2 paginiSeries LF210-5 Specification SheetWattsÎncă nu există evaluări

- Air PreheaterDocument8 paginiAir Preheaterabhishek01raiÎncă nu există evaluări

- All About Steam Traps 2Document84 paginiAll About Steam Traps 2Mad BhaÎncă nu există evaluări

- Engineering Letter: IndustrialsteamheatingsystemsDocument8 paginiEngineering Letter: Industrialsteamheatingsystemsmontie3Încă nu există evaluări

- 104 Final PaperDocument16 pagini104 Final PaperJeeEianYannÎncă nu există evaluări

- Good Piping Practice Prevents Water Hammer in Steam SystemsDocument4 paginiGood Piping Practice Prevents Water Hammer in Steam SystemsShubham GautamÎncă nu există evaluări

- Steam TrapDocument10 paginiSteam TrapvictorvikramÎncă nu există evaluări

- R900216060 HW-2 AnswersDocument5 paginiR900216060 HW-2 AnswersDevendra KhadeÎncă nu există evaluări

- PEP Session On Steam TurbinesDocument35 paginiPEP Session On Steam Turbinesdanish moinÎncă nu există evaluări

- Chapter 8 Steam PipingDocument14 paginiChapter 8 Steam PipingDak Serik100% (2)

- Vacuum Making1Document2 paginiVacuum Making1AnkurVermaÎncă nu există evaluări

- Lattner WLF Instruction Manual 2006 To 2007 PDFDocument66 paginiLattner WLF Instruction Manual 2006 To 2007 PDFAnonymous GRzQVXvDdÎncă nu există evaluări

- StallDocument16 paginiStallbhalchandrak1867100% (1)

- Series 210-5 Specification SheetDocument2 paginiSeries 210-5 Specification SheetWattsÎncă nu există evaluări

- Water Cooled Vacuum CondensersDocument2 paginiWater Cooled Vacuum CondensersRana Mubbashir IqbalÎncă nu există evaluări

- The Dead Weight Safety Valve Consists of A ValveDocument4 paginiThe Dead Weight Safety Valve Consists of A ValveAsif Saleem0% (1)

- Preventing Steam Coil FailureDocument3 paginiPreventing Steam Coil FailureSjeverÎncă nu există evaluări

- Venturi Nozzle Systems Questions and AnswersDocument1 paginăVenturi Nozzle Systems Questions and Answersbalaji12031988Încă nu există evaluări

- Condenser Vacuum MarEDocument4 paginiCondenser Vacuum MarEMayeiaElenorÎncă nu există evaluări

- Condensate & UtilisationDocument3 paginiCondensate & Utilisationmohamed faragÎncă nu există evaluări

- Mechanical Steam TrapsDocument6 paginiMechanical Steam TrapspramodtryÎncă nu există evaluări

- Steam Distribution Piping ManualDocument66 paginiSteam Distribution Piping ManualPanagiotis Giannakopoulos100% (1)

- Technical Reference Guide On Steam DistributionDocument66 paginiTechnical Reference Guide On Steam DistributionDainycious KibiwottÎncă nu există evaluări

- Physical Study of A Steam Generating UnitDocument13 paginiPhysical Study of A Steam Generating Unitashier dave calulot80% (5)

- Ball Float Steam Trap (Mechanical Steam Traps)Document7 paginiBall Float Steam Trap (Mechanical Steam Traps)Heri Fadli SinagaÎncă nu există evaluări

- Final Report IOCL GuwahatiDocument17 paginiFinal Report IOCL GuwahatiSonu KumarÎncă nu există evaluări

- Model N36-M1 Specification SheetDocument2 paginiModel N36-M1 Specification SheetWattsÎncă nu există evaluări

- FinalDocument77 paginiFinalAnup MinjÎncă nu există evaluări

- Expansion Tank ApplicationDocument16 paginiExpansion Tank Applicationarln_605551822Încă nu există evaluări

- Westco PumpDocument8 paginiWestco PumpWorapat PuttakasemÎncă nu există evaluări

- 2nd Lecture - Boiler Parts & Accessories, and Heat Loss Reduction in BoilerDocument35 pagini2nd Lecture - Boiler Parts & Accessories, and Heat Loss Reduction in BoilerHaseeb RazaÎncă nu există evaluări

- 62 enDocument6 pagini62 enshaonaaÎncă nu există evaluări

- Air Conditioner-600527Document5 paginiAir Conditioner-600527samir addidasÎncă nu există evaluări

- Steam Power PlantDocument39 paginiSteam Power PlantizharizumieÎncă nu există evaluări

- Steam Heating ApplicationDocument108 paginiSteam Heating ApplicationbryandownÎncă nu există evaluări

- BOILERfinal - Print Out PDFDocument25 paginiBOILERfinal - Print Out PDFRahulBhartiÎncă nu există evaluări

- Es Lf474aDocument2 paginiEs Lf474aWattsÎncă nu există evaluări

- Power Plant Control Chapter02Document11 paginiPower Plant Control Chapter02veerendraveeru_1014Încă nu există evaluări

- Boiler 2Document57 paginiBoiler 2azmisabran100% (1)

- WH Vacuum in Steam TurbineDocument2 paginiWH Vacuum in Steam Turbinemiths_0087Încă nu există evaluări

- CONDENSER SchemeDocument47 paginiCONDENSER SchemeAbhishek SinhaÎncă nu există evaluări

- Steam Power Plants: Rankine CycleDocument6 paginiSteam Power Plants: Rankine CycleRam NathÎncă nu există evaluări

- Project ReportDocument20 paginiProject ReportRahul GuptaÎncă nu există evaluări

- Status Report (Shaker)Document5 paginiStatus Report (Shaker)Youssef wagdyÎncă nu există evaluări

- The Early Days Of Motors And Motor-Driving - Steam CarsDe la EverandThe Early Days Of Motors And Motor-Driving - Steam CarsÎncă nu există evaluări

- Scientific American Supplement, No. 388, June 9, 1883De la EverandScientific American Supplement, No. 388, June 9, 1883Încă nu există evaluări

- Marvel Carbureter and Heat Control As Used on Series 691 Nash Sixes Booklet SDe la EverandMarvel Carbureter and Heat Control As Used on Series 691 Nash Sixes Booklet SÎncă nu există evaluări

- Scientific American Supplement, No. 633, February 18, 1888De la EverandScientific American Supplement, No. 633, February 18, 1888Încă nu există evaluări

- Scientific American Supplement, No. 623, December 10, 1887De la EverandScientific American Supplement, No. 623, December 10, 1887Încă nu există evaluări

- Installation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitDe la EverandInstallation and Operation Instructions For Custom Mark III CP Series Oil Fired UnitÎncă nu există evaluări

- Es WQ PWSRDocument2 paginiEs WQ PWSRWattsÎncă nu există evaluări

- Es FHBDocument1 paginăEs FHBWattsÎncă nu există evaluări

- Es WD TD 300 UsaDocument1 paginăEs WD TD 300 UsaWattsÎncă nu există evaluări

- ES WD DeadLevel Z USADocument1 paginăES WD DeadLevel Z USAWattsÎncă nu există evaluări

- ES PW SmartStream ADocument4 paginiES PW SmartStream AWattsÎncă nu există evaluări

- ES WD DeadLevel S USADocument1 paginăES WD DeadLevel S USAWattsÎncă nu există evaluări

- Es 757isrDocument2 paginiEs 757isrWattsÎncă nu există evaluări

- Es-Of1465tm 1665TMDocument3 paginiEs-Of1465tm 1665TMWattsÎncă nu există evaluări

- Basic Construction Operation Troubleshooting: WarningDocument2 paginiBasic Construction Operation Troubleshooting: WarningWattsÎncă nu există evaluări

- Es Lf474aDocument2 paginiEs Lf474aWattsÎncă nu există evaluări

- Es WD FD 930 UsaDocument1 paginăEs WD FD 930 UsaWattsÎncă nu există evaluări

- Es LFRC105Document2 paginiEs LFRC105WattsÎncă nu există evaluări

- Es WD RD 800 UsaDocument1 paginăEs WD RD 800 UsaWattsÎncă nu există evaluări

- Es WD Si 770 CanDocument1 paginăEs WD Si 770 CanWattsÎncă nu există evaluări

- Series LFMMV-HTK: Hot Water Tank EnhancerDocument2 paginiSeries LFMMV-HTK: Hot Water Tank EnhancerWattsÎncă nu există evaluări

- Es LFMMV HTKDocument2 paginiEs LFMMV HTKWattsÎncă nu există evaluări

- Es Acv M115F M1115FDocument4 paginiEs Acv M115F M1115FWattsÎncă nu există evaluări

- Es WD 100 L Csa CanDocument1 paginăEs WD 100 L Csa CanWattsÎncă nu există evaluări

- Es WD FD 320 Eg CanDocument1 paginăEs WD FD 320 Eg CanWattsÎncă nu există evaluări

- Series LFN55B-M1 Specification SheetDocument2 paginiSeries LFN55B-M1 Specification SheetWattsÎncă nu există evaluări

- Series LFN55B Specification SheetDocument2 paginiSeries LFN55B Specification SheetWattsÎncă nu există evaluări

- Es WD RD 800 CT UsaDocument1 paginăEs WD RD 800 CT UsaWattsÎncă nu există evaluări

- Es WD RD 300 CP15 85 UsaDocument1 paginăEs WD RD 300 CP15 85 UsaWattsÎncă nu există evaluări

- Es WD RD 100 CP 85 UsaDocument1 paginăEs WD RD 100 CP 85 UsaWattsÎncă nu există evaluări

- BSL Lab Tuttnauer en 29 07 21Document12 paginiBSL Lab Tuttnauer en 29 07 21Robinsson Tafur FloridaÎncă nu există evaluări

- Thermax Report 2 1Document87 paginiThermax Report 2 1rajeshtjadhav100% (2)

- Effects On NCGDocument3 paginiEffects On NCGMutiaraÎncă nu există evaluări

- ASME Steam Tables - Compact EditionDocument32 paginiASME Steam Tables - Compact EditionPuput NurlizanÎncă nu există evaluări

- Boilers NotesDocument10 paginiBoilers NotesDr-Bharath Vedashantha MurthyÎncă nu există evaluări

- This Experiment Marcet Boiler Engineering EssayDocument11 paginiThis Experiment Marcet Boiler Engineering EssayBerry101Încă nu există evaluări

- Calculation of Coal Requirement in Steam PlantDocument3 paginiCalculation of Coal Requirement in Steam PlantRavindra K BelapurkarÎncă nu există evaluări

- Process Description of Ammonia PlantDocument12 paginiProcess Description of Ammonia PlantSridharÎncă nu există evaluări

- Power Plant EngineeringDocument9 paginiPower Plant EngineeringBlessyJoyPunsalanÎncă nu există evaluări

- Flaktwoods Final DrawingDocument180 paginiFlaktwoods Final DrawingBui Duy ThanhÎncă nu există evaluări

- Heat Transfer and PumpsDocument10 paginiHeat Transfer and PumpsBjorn Martinez50% (4)

- Final CondensersDocument13 paginiFinal Condenserszubi13Încă nu există evaluări

- Drum Dryer PDFDocument13 paginiDrum Dryer PDFNiken SitoresmiÎncă nu există evaluări

- Steam Engineering TutorialsDocument208 paginiSteam Engineering Tutorialsaecsuresh35Încă nu există evaluări

- 3-A Sanitary Standards For Silo-Type Storage Tanks For Milk and Milk Products, Number 22-08Document15 pagini3-A Sanitary Standards For Silo-Type Storage Tanks For Milk and Milk Products, Number 22-08CHRISTIAN ZAVALAÎncă nu există evaluări

- Basis of Design NarrativeDocument25 paginiBasis of Design NarrativeNandan RajeÎncă nu există evaluări

- Section 5 Index: Proj. 2098 Pag. 5-1Document68 paginiSection 5 Index: Proj. 2098 Pag. 5-1kara_25Încă nu există evaluări

- ATRSDocument47 paginiATRSAbhishek Prakash Srivastava100% (1)

- 2) Multiple Effect Evaporators A) Forward Feed Multiple Effect EvaporatorsDocument12 pagini2) Multiple Effect Evaporators A) Forward Feed Multiple Effect EvaporatorsDr-Khalid Al-Shemmari100% (1)

- Pinch and Approach Point On HRSGDocument12 paginiPinch and Approach Point On HRSGluaguÎncă nu există evaluări

- 1999 - SANDIA - Solar Two Central Receiver PDFDocument232 pagini1999 - SANDIA - Solar Two Central Receiver PDFDavide FranziniÎncă nu există evaluări

- Lesson Plan in Science IV Water CycleDocument7 paginiLesson Plan in Science IV Water CycleninsantocildesÎncă nu există evaluări

- 6 44 0005 Rev5 PDFDocument439 pagini6 44 0005 Rev5 PDFprasadÎncă nu există evaluări

- ST 14.01 Insulation Planning and Executive Regulations For Thermal InsulationsDocument10 paginiST 14.01 Insulation Planning and Executive Regulations For Thermal InsulationsMaksim.em001Încă nu există evaluări

- Steam CondensersDocument32 paginiSteam CondensersaadhithyarajasekaranÎncă nu există evaluări

- Types of SteamDocument6 paginiTypes of SteamMohammad Ali ZamanÎncă nu există evaluări

- Pipeline Ancillaries Overview SB GST 41 enDocument9 paginiPipeline Ancillaries Overview SB GST 41 enSiva RamÎncă nu există evaluări