Documente Academic

Documente Profesional

Documente Cultură

Improve Network Efficiency with Accurate DMS Data

Încărcat de

MirjanaBoskovicTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

Improve Network Efficiency with Accurate DMS Data

Încărcat de

MirjanaBoskovicDrepturi de autor:

Formate disponibile

CIRED 20th International Conference on Electricity Distribution Prague, 8-11 June 2009

Paper 0362

REDUCTION OF POWER LOSSES AND CO2 EMISSIONS:

ACCURATE NETWORK DATA TO OBTAIN GOOD PERFORMANCES OF

DMS SYSTEMS

Giorgio DI LEMBO Paola PETRONI Christian NOCE

ENEL Distribuzione – Italy ENEL Distribuzione – Italy ENEL Distribuzione – Italy

giorgio.dilembo@enel.com paola.petroni@enel.it Christian.noce@enel.com

the results of the calculation directly on the network

ABSTRACT diagram and updating them on each variation of the field.

The document describes the solution adopted in ENEL Therefore DMS increases the performance of network

DMS Systems to obtain precise results in network management in case of outages, work plan developments,

calculations and, consequently, real improvements in the medium-term and short-term network planning.

reduction of power losses and CO2 emissions. In particular, the main functions are:

• Load Flow;

• State estimation;

INTRODUCTION • Performance indexes;

There are several actions to be undertaken in order to • Supply restoration;

reduce the CO2 emission level; the cost impact of these • Fault calculations;

solutions is also different: for example the introduction of • Voltage control;

“green” sources (wind/hydro generators) can be effective • Energy losses;

but quite expansive. • Optimal switching.

The reduction of power losses through a better network By means of Performance indexes and Energy losses it is

operation is another method that can be effective and cheap possible to evaluate power and energy losses for all the

at the same time; moreover, it can be applied by network or analyze each single element.

Distributors directly, thanks to the new advanced Moreover, Optimal switching allows the operator to

Distribution Management Systems (DMS). optimize the network connection status so as to minimize

DMS is a powerful tool to improve the overall efficiency energy losses.

of the MV/LV distribution network, providing what/if

analysis, methods for the optimization of network

resources, cost/benefit analysis, education/training

facilities for the operators, planning facilities, etc.

However, accurate network data are crucial to obtain good

performances and results very close to the reality. In fact,

to perform network calculations, such as “State estimation”

or “Load Flow”, very quickly and precisely many inputs

are needed; for example it is important to have:

• the precise Network Topology, updated in real time

together with the real connection status of each

branch;

• the electrical characteristics of elements (transformers,

conductors, switches, ….),

• some basic measures from the field;

• reliable evaluation of customers’ load and generation.

ENEL found its solution to these problems in a pilot DMS

project set up in Milan in 2007 and, after more then one

year of experience, planned the introduction of the FIG. 1

application all over the Italian territory. System architecture

The DMS core application is based on a special Software

THE MAIN FEATURES OF THE SYSTEM developed by “DMS Group” of Novi Sad (Serbia). It runs

on a special client-server architecture directly connected to

Main functions the LAN of ENEL central systems for the remote control

DMS supports operators and technicians in the evaluation of the MV networks.

of electrical behaviour of the network, providing very fast As described later, this connection is fundamental to

and effective tools. These tools run usually in “Off line maintain data consistency with the real network.

mode” on freezed image of the network, nevertheless,

many of them can also run in “Real time mode”, providing

CIRED2009 Session 4 Paper No 0362

CIRED 20th International Conference on Electricity Distribution Prague, 8-11 June 2009

Paper 0362

Workstations for

Servers

remote control of the Load Description data are input manually by means of a

network

batch procedure that uploads them at least yearly (FIG.4).

As a matter of fact the load profiles are the most difficult to

be provided and at the same time are very critical to obtain

reliable calculation. Therefore mach effort has been spent

on this matter.

LAN

Load profiles

Load profiles of of MV/LV

MV Customers Transformers

DMS Clients DMS

SERVER

Yearly

FIG.2: System Architecture

In fact, to perform network calculations, such as “State

estimation” or “Load Flow”, very quickly and precisely the

following data are needed:

STATIC DATA DMS

• Network Topology;

• electrical characteristics of each element (equivalent FIG.4: Load description data input

circuit, impedances, etc);

DYNAMIC DATA LOAD DESCRIPTION DATA

• instantaneous connection status of the net (open/close

status of each switch); Each MV customer and each MV/LV transformer must be

• measures coming from SCADA systems (Voltage, represented with load profiles reproducing the effective

current ,active power, reactive power); load during the day, taking into account all the variations

LOAD DESCRIPTION DATA due to time, holidays, seasons, etc.

• load profiles of each MV customers connected to the Thanks to the application of electronic meters to all the

network; ENEL MV and LV customers, an enormous amount of

• load profiles of each MV/LV transformers in MV/LV data is available: each meter records the values of power

substations. flow every 15 minutes (P and Q); these values are stored in

Thanks to the direct connection with the Central remote the meter memory and downloaded periodically by the

control system and by means of a Data exchange protocol, Metering control Centres.

DMS receives Static and Dynamic information. MV/LV transformers are not metered but the archives

contain the number of supplied customers divided into

commercial categories and the average energy

Electrical

Data

consumption per year of each LV customer.

Network Load profiles for MV customers

Corporate

Data Base HV/MV Subs Nevertheless it is possible to extract load profiles of all the

SCADA customers, assigning to each MV customer its own load

data is not viable for two reason:

• DMS mass storage resources are not designed to

contain this amount of samples;

• the real time performances of the DMS application

DB changes should be negatively affected by this data

management.

Therefore load profiles have to be analyzed in order to

Continuous

MV/LV Subs

reduce the amount of Data and to reach a trade off among

DMS performance (precision and speed) and data

management resources.

With the aim of mutual comparison and sorting of MV

consumers, the first step is the “Normalization” of load

curves coming from energy meters. This is done dividing

the energy samples by the average absorbed energy of

each customer in the reference year.

Analyzing the change of load profiles all the year round,

the following assumptions can be made.

DMS Each passive load can be taken into account using 24

FIG.3: Static and Dynamic Data exchange daily load curves :

CIRED2009 Session 4 Paper No 0362

CIRED 20th International Conference on Electricity Distribution Prague, 8-11 June 2009

Paper 0362

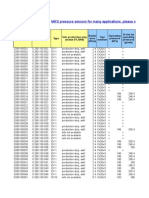

• Active Power (P): 4 seasons x 3 day type (working Load profiles for MV/LV transformer

day, Saturday, Holidays);

• Reactive power (Q): 4 seasons x 3 day type For each LV customer the following data are available

(working day, Saturday, Holidays); from electronic meter archives:

If the load is passive and active, even during the same day, • load curves;

it is necessary to use 48 daily load curves , 24 representing

• average annual energy consumption;

the active load and 24 representing the passive load.

The last step to achieve the goal is “Clustering”: • commercial category;

Mathematical and manual algorithms can be used to find • connection to the feeding MV/LV transformer.

“Similar consumers” and to group normalized load profiles

into clusters. Taking into account the available Data, Enel solution is

based on the following steps.

2

Determine a set of normalized load profiles to be

0 assigned to each LV customer

0 10 20 30 Spring-Pp

40 50 60 70

2

Taking into account that each customer belongs to a

specific commercial category, the analysis of the

0 behaviour of the customers from the load profile point of

0 10 20 30Summer-Pp

40 50 60 70

view, leads to:

2

• reduce the 120 ENEL commercial categories into

4 main types:

0 1. Residential customer;

0 10 20 30Autumn-Pp

40 50 60 70

2. Agricultural customer;

2

3. Industrial customer;

4. Commercial customer.

0 • assign a set of 24 normalized load curves to each

0 10 20 30 40 50 60 70

category, so as to represent any kind of LV customer.

FIG.5: Clustering

Each cluster is represented by a “Characteristic consumer”

that has a dummy profiles used to define the load of all the

customers belonging to the cluster.

At the end of the process 40 clusters are enough to describe

all the 5000 MV customers in Milan network (Lombardia).

At the end, the system can obtain the absolute load profile,

simply multiplying all the values of the normalized curve

by the average absorbed power of the customer.

A default set of Load profiles is assigned to new MV

customers or in case of lack of data.

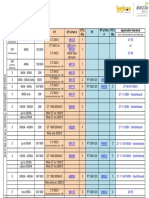

FIG.7: A Standard set of load curve (Active power)

Calculation of the load profile of each MV/LV

transformer

The set of curves to be assigned to a transformer are

calculated adding the Load curves of all the LV customers

fed by it. In practice the addition is performed by the

system that operates as follows:

1. a standard normalized load profile is assigned to each

LV customer according to its commercial category;

2. the absolute profile is calculated multiplying the curve

FIG.6: the load curves used to represent the Active by the average absorbed power;

power of a MV Customer in each season (Q1-Q4) 3. the profiles of all the customers are added point by

point.

CIRED2009 Session 4 Paper No 0362

CIRED 20th International Conference on Electricity Distribution Prague, 8-11 June 2009

Paper 0362

RESULTS FROM THE PILOT SITE OF MILAN not viable due to the cost of the operation and therefore,

only about one hundred of them could be performed,

In the real application of DMS in Milan, what foreseen has choosing:

been practically demonstrated. • all the remote controlled switches;

The results of calculation are very close to the reality and, • the most effective of the list, even in case of manually

far away from the values calculated with the old tools, in operated switches.

term of precision and output speed. These first actions lead to a saving of about 6.5% of the

losses: it is less then 10% but still a valuable gain.

For example, referring to the part of network highlighted in At the change of each season, the function was launched

FIG.8, apart from the time consuming activity of again to compute the new connection status of the network.

evaluating the loads in the traditional way, the value of In this case, for the described reasons, only about 40

190A (addition of nominal/average power values) is too switching operations are usually performed, obtaining a

high to be resupplied by the feeder “128Basigli” (max gain of 4%.

daily load = 130A, thermal limit= 240A).

On the contrary, DMS value of 98A is easily manageable In few words, it is possible to say that the steady gain that

during a normal “Working day”. is possible to maintain all the year round, after the first

optimizing process, is about 4%.

This small percentage will give a huge reduction of fuel

98 and, consequently, of CO2 emissions.

In terms of absolute values, starting from the year 2011, it

is possible to save about 144 GWh/year of energy,

corresponding to 75000 tCO2 / year.

To make the goal and evaluate the saving in a reliable way,

130/240 it is necessary to extend DMS all over the territory,

according to a deploying plan of 4 years (2008-2011).

According to this plan the energy savings will increase

year by year as described in Fig. 9.

Emissioni CO2

FIG: 8: Real example from Milan Network

80000

70000

60000

After one year of testing, the positive results coming from 50000

Tonn

the application in Milan lead ENEL to plan the extension 40000 CO2

of the system to its 28 Control Centers all over the country. 30000

20000

10000

Savings and operative improvements are foreseen in the 0

2008 2009 2010 2011

short and medium time application:

Years

• in everyday activities due to planned works in the MV

network; FIG: 9: Progressive reduction of CO2 emissions

• in supply restoration speed and reliability (continuity

of service);

• in reduction of Distribution Network losses.

REDUCTION OF LOSSES

DMS provides direct and indirect tools to optimize the

existing network resources and operation. Of course this

leads to a decrease in energy production and CO2

emissions.

Taking into account only the “Optimal Switching”

function, it is possible to minimize the losses,

reconfiguring the network at each change of season. The

function suggests a list of open/close actions on the

switches along the MV feeders, giving the contribution of

each action (percentage of the total value of saving).

Using the experience of the pilot site in Milan as reference,

the first time this function was lunched, the saving was

about 10% of the losses.

Of course, the execution of all the suggested actions was

CIRED2009 Session 4 Paper No 0362

S-ar putea să vă placă și

- Energy Loss Estimation in Distribution Networks For Planning PurposesDocument7 paginiEnergy Loss Estimation in Distribution Networks For Planning PurposesJeff RobertsonÎncă nu există evaluări

- Network Loss Study in PowerFactoryDocument4 paginiNetwork Loss Study in PowerFactoryAnonymous yD6Qpiq3Încă nu există evaluări

- DSP Based Control of Interleaved Boost ConverterDocument11 paginiDSP Based Control of Interleaved Boost ConverterDany ApablazaÎncă nu există evaluări

- 3 28Document7 pagini3 28Armand TAOUEMA SANHONGOUÎncă nu există evaluări

- Metrum PQ Controller DB System 4page Eng R24 WebbDocument4 paginiMetrum PQ Controller DB System 4page Eng R24 WebbRAJESH KUMARÎncă nu există evaluări

- Revitalization of Remote Control Centre at Elektro Primorska (SloveniaDocument4 paginiRevitalization of Remote Control Centre at Elektro Primorska (SloveniaAmany HamdyÎncă nu există evaluări

- Strategy For Technical LossesDocument13 paginiStrategy For Technical Lossesc katsanosÎncă nu există evaluări

- NEPLAN v10 DescriptionDocument8 paginiNEPLAN v10 DescriptionRUBIOÎncă nu există evaluări

- Practical Experiences from Running a Large SCADA/EMS/BMS ProjectDocument12 paginiPractical Experiences from Running a Large SCADA/EMS/BMS ProjectramsesiÎncă nu există evaluări

- Deep Reinforcement Learning For OnlineDocument13 paginiDeep Reinforcement Learning For Onlinekk notesÎncă nu există evaluări

- CIRED2011 0716 FinalDocument4 paginiCIRED2011 0716 FinalkotiniÎncă nu există evaluări

- Maximal Hosting Capacity (ICA) : Pss®SincalDocument2 paginiMaximal Hosting Capacity (ICA) : Pss®SincalDBachai84Încă nu există evaluări

- Cyme Modules2Document3 paginiCyme Modules2ArcGis TranscoÎncă nu există evaluări

- 2021 Price List: Power ToolsDocument7 pagini2021 Price List: Power ToolsRolando Albuquerque MartinsÎncă nu există evaluări

- PowerOutage PaperDocument6 paginiPowerOutage PaperUsman KhanÎncă nu există evaluări

- Predictive management of low-voltage gridsDocument5 paginiPredictive management of low-voltage gridsAndre GarciaÎncă nu există evaluări

- SKM 2019 Price ListDocument7 paginiSKM 2019 Price ListDaniel CamargoÎncă nu există evaluări

- CYME Power Engineering SoftwareDocument4 paginiCYME Power Engineering SoftwareMuhammad Faizan AwanÎncă nu există evaluări

- R 4-45 PDFDocument4 paginiR 4-45 PDFAhmed WestministerÎncă nu există evaluări

- Paper18 NW ReconfigurationDocument4 paginiPaper18 NW Reconfigurationtobu11276Încă nu există evaluări

- State Estimation at All India LevelDocument6 paginiState Estimation at All India Levelepe3630Încă nu există evaluări

- MMB & DFT 2012 Workshop ProceedingsDocument44 paginiMMB & DFT 2012 Workshop ProceedingsFelipe ToroÎncă nu există evaluări

- Vakilinia2016 PDFDocument13 paginiVakilinia2016 PDFVaibhav JainÎncă nu există evaluări

- 1b. Distribution Components Systems and Operations PDFDocument25 pagini1b. Distribution Components Systems and Operations PDFAnonymous 4k3M837gKÎncă nu există evaluări

- Quasi-Static Voltage Scaling For Energy Minimization With Time ConstraintsDocument14 paginiQuasi-Static Voltage Scaling For Energy Minimization With Time ConstraintsNguyen Van ToanÎncă nu există evaluări

- Methods For Power Quality Analysis According To EN 50160Document7 paginiMethods For Power Quality Analysis According To EN 50160gerardobarriaÎncă nu există evaluări

- Real-Time Measurement System of Laser Power in VC++Document3 paginiReal-Time Measurement System of Laser Power in VC++djicccÎncă nu există evaluări

- An Instructive Flow Chart For OptimisingDocument8 paginiAn Instructive Flow Chart For Optimisingmas zak danielÎncă nu există evaluări

- CPC 100 Brochure ESPDocument2 paginiCPC 100 Brochure ESPOriel Boldrini ValdiviaÎncă nu există evaluări

- Power Analysis - ABBDocument6 paginiPower Analysis - ABBIfit PrabowoÎncă nu există evaluări

- The Benefits of A Distribution Transformer Monitoring Solution at Network Waitaki LimitedDocument8 paginiThe Benefits of A Distribution Transformer Monitoring Solution at Network Waitaki LimitedMORELLI silvioÎncă nu există evaluări

- 7555-Article Text-24162-3-10-20230418Document14 pagini7555-Article Text-24162-3-10-20230418Victor BermejoÎncă nu există evaluări

- Operational Profiles for Testing Distribution Management System SoftwareDocument9 paginiOperational Profiles for Testing Distribution Management System SoftwareYAHIA MENASSELÎncă nu există evaluări

- NES EAP LVGM+EB Brochure - August 2017Document2 paginiNES EAP LVGM+EB Brochure - August 2017Dariusz KurowskiÎncă nu există evaluări

- White Paper - Why The World Needs Synchrophasors - enDocument3 paginiWhite Paper - Why The World Needs Synchrophasors - enLasith De SilvaÎncă nu există evaluări

- Adl Future of Enterprise NetworkingDocument5 paginiAdl Future of Enterprise NetworkingXavier HernánÎncă nu există evaluări

- ENERGY METERING SOLUTIONDocument4 paginiENERGY METERING SOLUTIONSanthosh KrishnanÎncă nu există evaluări

- 9 04348113 PDFDocument8 pagini9 04348113 PDFJitender KaushalÎncă nu există evaluări

- CIRED2009 0035 PaperDocument5 paginiCIRED2009 0035 PaperkotiniÎncă nu există evaluări

- Power Management Techniques For Wireless Sensor Networks: A ReviewDocument5 paginiPower Management Techniques For Wireless Sensor Networks: A ReviewLakshmi KÎncă nu există evaluări

- EE392n Lecture5GE PDFDocument21 paginiEE392n Lecture5GE PDFycchiranjeeviÎncă nu există evaluări

- 2208EE006.ourside DstatcomDocument7 pagini2208EE006.ourside DstatcomssÎncă nu există evaluări

- 07ATT00158Document7 pagini07ATT00158Swastik guptaÎncă nu există evaluări

- The Key Role of Intelligent Electronic Devices (IED) in Advanced Distribution Automation (ADA)Document7 paginiThe Key Role of Intelligent Electronic Devices (IED) in Advanced Distribution Automation (ADA)WOndewosen AbelÎncă nu există evaluări

- Power Stage Design of Fourth-Order DC-DC Converters by Means of Principal Components AnalysisDocument11 paginiPower Stage Design of Fourth-Order DC-DC Converters by Means of Principal Components AnalysiskamiyabÎncă nu există evaluări

- AD-SDI Electric Utility Data StandardDocument14 paginiAD-SDI Electric Utility Data StandardMomen HassanÎncă nu există evaluări

- WIFI-Based Smart Grid for Renewable Energy Monitoring and ControlDocument6 paginiWIFI-Based Smart Grid for Renewable Energy Monitoring and ControlAnonymous ytZsBOVÎncă nu există evaluări

- WSN-based Large Electrical Equipment MonitoringDocument6 paginiWSN-based Large Electrical Equipment MonitoringJeya RamanÎncă nu există evaluări

- Power Quality Monitoring of Distributed Generation Units Using A Web-Based ApplicationDocument6 paginiPower Quality Monitoring of Distributed Generation Units Using A Web-Based ApplicationVelu SamyÎncă nu există evaluări

- CHA1Document31 paginiCHA1Chalachew1212 mezgebuÎncă nu există evaluări

- Planning Modules For Power Distribution in BuildingsDocument28 paginiPlanning Modules For Power Distribution in BuildingsSaad rehmanÎncă nu există evaluări

- Evaluating Distributed Generation Impacts With A Multiobjective IndexDocument7 paginiEvaluating Distributed Generation Impacts With A Multiobjective IndexJohan ParradoÎncă nu există evaluări

- Smart Grids 2008Document4 paginiSmart Grids 2008lalocura_41Încă nu există evaluări

- vEPC Deployment WhitepaperDocument16 paginivEPC Deployment WhitepaperThomas YosefÎncă nu există evaluări

- R22 - D-STATCOM For Power Quality ImprovementDocument6 paginiR22 - D-STATCOM For Power Quality ImprovementAli Al-QattanÎncă nu există evaluări

- A Computation Task Offloading Scheme Based On Mobile-Cloud and Edge Computing For WBANsDocument6 paginiA Computation Task Offloading Scheme Based On Mobile-Cloud and Edge Computing For WBANsharinadhreddytammineniÎncă nu există evaluări

- Amtech Cable Sizing GuideDocument6 paginiAmtech Cable Sizing GuideKhanSA786Încă nu există evaluări

- CENECO Smart Meter Installation ProjectDocument4 paginiCENECO Smart Meter Installation ProjectNorman PollentesÎncă nu există evaluări

- An Objective Analysis of Micro-Synchrophasors Technology For Monitoring and Control of Active Distribution NetworkDocument10 paginiAn Objective Analysis of Micro-Synchrophasors Technology For Monitoring and Control of Active Distribution Networkmohd zuhaibÎncă nu există evaluări

- Radio Controlled Weather StationDocument167 paginiRadio Controlled Weather StationMirjanaBoskovicÎncă nu există evaluări

- Business Grammar Connecting Past and PresentDocument4 paginiBusiness Grammar Connecting Past and PresentJayne WojtasikÎncă nu există evaluări

- Telvent Dms Software Sept 08Document44 paginiTelvent Dms Software Sept 08MirjanaBoskovicÎncă nu există evaluări

- How Puppetry Boosts Preschool Language SkillsDocument54 paginiHow Puppetry Boosts Preschool Language SkillsMirjanaBoskovicÎncă nu există evaluări

- EkskurzijaDocument1 paginăEkskurzijaMirjanaBoskovicÎncă nu există evaluări

- Puppet As A Pedagogical Tool: A Literature Review: Tarja Kröger, Anne-Maria NupponenDocument9 paginiPuppet As A Pedagogical Tool: A Literature Review: Tarja Kröger, Anne-Maria NupponenMirjanaBoskovicÎncă nu există evaluări

- Puppetry Activities For Preschool Children and FamiliesDocument7 paginiPuppetry Activities For Preschool Children and FamiliesMirjanaBoskovicÎncă nu există evaluări

- Korosec SV62 4 PDFDocument26 paginiKorosec SV62 4 PDFMirjanaBoskovicÎncă nu există evaluări

- Evolution of Elektrovojvodina's MV SCADA System Using IEC 61870-5-101 ProtocolDocument4 paginiEvolution of Elektrovojvodina's MV SCADA System Using IEC 61870-5-101 ProtocolMirjanaBoskovicÎncă nu există evaluări

- Lenovo A916 - Lenovo A916 User GuideDocument24 paginiLenovo A916 - Lenovo A916 User GuideJean MatosÎncă nu există evaluări

- ClanakDocument4 paginiClanakMirjanaBoskovicÎncă nu există evaluări

- 6470 ManualDocument77 pagini6470 ManualMirjanaBoskovicÎncă nu există evaluări

- V PiramideDocument1 paginăV PiramideMirjanaBoskovicÎncă nu există evaluări

- Numerical Study of The Unsteady Aerodynamics of Rotating SeedsDocument6 paginiNumerical Study of The Unsteady Aerodynamics of Rotating SeedsademargcjuniorÎncă nu există evaluări

- PV connector technical specifications from JinkoSolarDocument1 paginăPV connector technical specifications from JinkoSolarqiTÎncă nu există evaluări

- Name: Amit Sanjay Manthekar. Reg No.: 18BME0597. Course: Material Science - Course Code: MEE1005 Faculty: Muthuchamy ADocument3 paginiName: Amit Sanjay Manthekar. Reg No.: 18BME0597. Course: Material Science - Course Code: MEE1005 Faculty: Muthuchamy AAmit ManthekarÎncă nu există evaluări

- Window U-Value ModuleDocument46 paginiWindow U-Value ModuleSze Yan LamÎncă nu există evaluări

- List of Licensed Wholesale Operators As of Dec 16 2Document3 paginiList of Licensed Wholesale Operators As of Dec 16 2Tumsifu SiaoÎncă nu există evaluări

- Analisis de Crudo B61Document1 paginăAnalisis de Crudo B61Xavier DiazÎncă nu există evaluări

- We n5523521 v7 Hendrix Covered ConductorDocument55 paginiWe n5523521 v7 Hendrix Covered ConductorJ. Mauricio A. BejaranoÎncă nu există evaluări

- Lzdzmobmvrtpctpfnstcm 0616 eDocument2 paginiLzdzmobmvrtpctpfnstcm 0616 eMomo1010Încă nu există evaluări

- Ductable Fan Coil Unit: Product Selection DataDocument26 paginiDuctable Fan Coil Unit: Product Selection DataNelson MartinsÎncă nu există evaluări

- Mi 3210 Teraohmxa 10Kv: Professional Insulation Testing With Powerful Diagnostic ToolsDocument2 paginiMi 3210 Teraohmxa 10Kv: Professional Insulation Testing With Powerful Diagnostic ToolsTuan Anh Le CongÎncă nu există evaluări

- Aluminum Electrolytic Capacitors Aluminum Electrolytic CapacitorsDocument6 paginiAluminum Electrolytic Capacitors Aluminum Electrolytic CapacitorsAvs ElectronÎncă nu există evaluări

- Bosch Injector Data SheetDocument124 paginiBosch Injector Data SheetThibaut Lrt56% (9)

- OMEGA Air Circuit Breaker DetailsDocument137 paginiOMEGA Air Circuit Breaker DetailsSIVA NAGA SUDHEER SIDDANIÎncă nu există evaluări

- An Impedance Source Multi-Level Three Phase Inverter With Common Mode Voltage Elimination and Dead Time CompensationDocument18 paginiAn Impedance Source Multi-Level Three Phase Inverter With Common Mode Voltage Elimination and Dead Time CompensationRadu GodinaÎncă nu există evaluări

- An overview of common vehicle indicatorsDocument9 paginiAn overview of common vehicle indicatorsNikhitaÎncă nu există evaluări

- TCA7Document1 paginăTCA7choirul dwiÎncă nu există evaluări

- Luminous PDFDocument1 paginăLuminous PDFKushal AkbariÎncă nu există evaluări

- Is SP 72 2010Document25 paginiIs SP 72 2010mkannanofficialÎncă nu există evaluări

- OZM-Katalog 2016Document23 paginiOZM-Katalog 2016Chonk LeeÎncă nu există evaluări

- Radiography Sai KripaDocument4 paginiRadiography Sai KripaSarthak EnterprisesÎncă nu există evaluări

- Small, High Efficiency, Recuperated Ceramic Turboshaft EngineDocument1 paginăSmall, High Efficiency, Recuperated Ceramic Turboshaft EngineU.S. Naval Research LaboratoryÎncă nu există evaluări

- Pump Inlet Piping DesignDocument2 paginiPump Inlet Piping DesignWayaya WaziwupyaÎncă nu există evaluări

- PAUT Course Material PDFDocument189 paginiPAUT Course Material PDFYassine Koot100% (3)

- Downstream - Processing - Lecture 5rnjDocument8 paginiDownstream - Processing - Lecture 5rnjqwertyuÎncă nu există evaluări

- 2013 - S2E Technical and Technological - Intro - Final PDFDocument28 pagini2013 - S2E Technical and Technological - Intro - Final PDFJose Kirby100% (1)

- Rope CouplingDocument4 paginiRope CouplingKamal KapaÎncă nu există evaluări

- Transient Stability Improvement of Power System Using UpfcDocument18 paginiTransient Stability Improvement of Power System Using UpfcMuhammadWaqarÎncă nu există evaluări

- BLW29Document12 paginiBLW29glow4Încă nu există evaluări

- CT/PT Selection Chart: Applicable Standard (A) (V) CT's Qty PT PT's Part # PT's Qty Service Size CT CT's Part # PhaseDocument1 paginăCT/PT Selection Chart: Applicable Standard (A) (V) CT's Qty PT PT's Part # PT's Qty Service Size CT CT's Part # PhasePrabakar PÎncă nu există evaluări

- Rwu90 SpecsDocument2 paginiRwu90 SpecsEduardo LuboÎncă nu există evaluări