Documente Academic

Documente Profesional

Documente Cultură

ECOMax-HE Brochure - Eco Green

Încărcat de

MC EstimationTitlu original

Drepturi de autor

Formate disponibile

Partajați acest document

Partajați sau inserați document

Vi se pare util acest document?

Este necorespunzător acest conținut?

Raportați acest documentDrepturi de autor:

Formate disponibile

ECOMax-HE Brochure - Eco Green

Încărcat de

MC EstimationDrepturi de autor:

Formate disponibile

Eco Friendly Technologies

About ECO GREEN Systems LLP : Authorized Representative:

Eco Green Systems LLP is a leading manufacturer & supplier of Clean

TM

Technology Products such as ECOMax-HE Automatic Tube Cleaning

System for HVAC Chillers, Power Plants & Process Condensers and

TM

ECOMax-CT Electrolytic CT Water Treatment System. Eco Green, a Pune

India based company is committed to offer clean technology based

innovative solutions which result in substantial Energy Saving and Water

Saving for its clients. Eco Green is incorporated under laws of Government

of India.

Vision :

To become one of the leading and most preferred company offering Eco

Friendly Technologies and contribute substantially towards sustainable

development of this planet.

Mission : TM

To innovate & offer the cutting edge niche Eco Friendly Technologies at an

affordable price and to help our clients conserve precious natural

resources and maximize customer profits by creating Wealth out of Waste. ECOMax-HE

Automatic Tube Cleaning System

Eco Friendly Technologies

ECO GREEN SYSTEMS LLP

Corporate Address: C Wing, Parmar Trade Centre, 12 Connaught Road, Sadhu Waswani Chowk, Pune- 411 001, INDIA

Tel : +91 20 65605100; Email : sales@ecogreensys.com Web : www.ecogreensys.com *Patent Pending

Eco Green Systems LLP Eco Green Systems LLP

The Solution Applications

TM

ECOMax-HE uses sponge balls to keep heat exchanger tubes clean. TM

ECOMax-HE our Patent Pending technology; is an automatic tube The ECOMax-HETM provides online solution to overcome fouling

The sponge balls are injected almost simultaneously at the heat cleaning system used for keeping the inner walls of heat exchanger problem in Shell & Tube Heat Exchanger in following applications:

exchanger tube sheet with the help of injection pump thereby tubes clean. Central Air Conditioning Systems

giving effective spread to the sponge balls in various tubes, the Power Plants

sponge balls would pass through the tubes and clean the fouling / It is very effective in keeping the tubes of shell & tube heat Process Industries

scales deposits inside the tubes. Once the sponge balls come out of exchanger clean thereby improving the efficiency & performance Industrial Refrigeration Systems

the heat exchanger tubes they are collected at ball trap, they are of HVAC Chillers, Power plants & Processes.

sent back to the ball collector with the help of collection pump. The

Effect of Fouling in Water Cooled Chillers:

entire process is a batch operation automatically controlled by PLC TM

and occurs at predefined interval. These pumps run hardly for few Condenser Pictures without ECOMax-HE

Basic Vapor Compression Refrigeration Cycle

seconds for injection and collection of sponge balls. ECOMax-HETM

is maintenance free and designed to have long life & trouble free

Heat rejected to

4' atmosphere 3'

4 Coolant out 3

TM

Key Features of ECOMax-HE Liquid

Coolant in Condenser

3a

3b

?Fully automatic, no manual intervention required

Expansion device

Zero ball loss system, no balls can escape to cooling tower

Pressure

?

Evaporator Compressor

Ensures 100% clean tubes

Single System for Multiple Chillers even if the Chiller capacity is

1 2

TM

different Condenser Pictures with ECOMax-HE Heat removed Gas

Smart System, gives an alarm for Sponge Ball Replacement

Wet vapour

from process

Automatically operates a cleaning cycle on the running chiller

? (saturated condition)

Enthalphy

User Friendly Graphical User Interface (GUI)

? Cooling Capacity

Motor input

Touch screen Multi Color HMI

Power

Heat rejected in condenser

Completes the cleaning cycle even if the chiller is stopped during

the cycle

No water wastage from the system

Design COP with Clean Condenser

No mixing of CW inlet and CW outlet water during operation

Reduced COP with Fouled Condenser

Negligible power consumption by the booster pumps

Compact, smaller foot print

Flexibility of operation of CW Pumps in case of multiple chillers in

Scale Thickness Vs Power Consumption

the plant room Fouling Challenges in Condensers 50

Simultaneous injection cycle in one chiller and collection in

Fouling is an accumulation of scale & dirt on the inner walls of the

another chiller is possible

tubes. As the fouling builds up, it reduces the heat transfer

Green Technology

40

coefficient and has various effects on different processes:

power consumption

Percent increase in

TM ? Water Cooled HVAC Chillers: Decreases the operating capacity

Benefits of ECOMax-HE of chillers, increases the energy required to produce the cooling & 30

?Results in up to 20% energy saving in HVAC chillers increases the stress on chiller components due to elevated

Results in up to 5% increase in the power output in case of

operating pressures & temperatures

20

Power Plants ? Power Plants: Affects the vacuum and hence reduces the power

Increases cooling capacity of HVAC Chillers

? output from power plants

Improves Condenser tube life

? Process Heat Exchanger: Reduces the temperature drop across 10

Improves Comprerssor Life

the heat exchanger and reduces the process throughput,

?Avoids costly shutdown and downtime necessitates the process shutdown affecting plant reliability

Eliminates offline cleaning completely 0

Reduces Carbon Foot Print (0.25) (0.50) (0.75) (1.0) (1.2) (1.5)

Cost effective technology& offers very attractive ROI, usually

less than 1 Year Thickness of scale in (mm)

(1 mm) Thick Scale Increases Power Consumption ~ 30 %

Eco Green Systems LLP Eco Green Systems LLP

S-ar putea să vă placă și

- Safety Manual 2018Document96 paginiSafety Manual 2018MC Estimation100% (2)

- 6 Tech Specs Hvac 130116 PDFDocument186 pagini6 Tech Specs Hvac 130116 PDFBay MưaÎncă nu există evaluări

- E& M Dar 2018Document794 paginiE& M Dar 2018VIMAL MAMTA MAMTA63% (16)

- Heat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsDe la EverandHeat Transfer: Non-Stationary Heat Transfer Through Walls, Measurement of Thermal Conductivity, Heat Transfer with Two Phase RefrigerantsEvaluare: 5 din 5 stele5/5 (1)

- 1989 Aker Predicting Gas Turbine Performance Degradation Due To Compressor Fouling Using Computer Simulation TechniquesDocument8 pagini1989 Aker Predicting Gas Turbine Performance Degradation Due To Compressor Fouling Using Computer Simulation TechniquesArgenomSaubiÎncă nu există evaluări

- Basic Information TJ100 - AJ Revision 5Document12 paginiBasic Information TJ100 - AJ Revision 5Mohammad Lavasani100% (1)

- Process Combustion Corporation: A Presentation Prepared ForDocument35 paginiProcess Combustion Corporation: A Presentation Prepared ForSteve WanÎncă nu există evaluări

- Atlas Copco ZH 350 ENDocument12 paginiAtlas Copco ZH 350 ENAtlas Copco Compressor Technique100% (1)

- Seed Germination ChamberDocument6 paginiSeed Germination ChamberAcmas IndiaÎncă nu există evaluări

- LM2500 PerformanceDocument2 paginiLM2500 PerformanceLi Fang HuangÎncă nu există evaluări

- Ehandbook Strategize Your Steam SystemDocument18 paginiEhandbook Strategize Your Steam SystemMPham100% (1)

- Steam or Thermal OilDocument3 paginiSteam or Thermal OilCharith Liyanage100% (1)

- Design of Water Tanks-CE 05014 p3 6Document65 paginiDesign of Water Tanks-CE 05014 p3 6engineerkranthi4055100% (1)

- 4 - Water Storage Tank Safety StandardsDocument35 pagini4 - Water Storage Tank Safety StandardsWidiyanto WidiyantiÎncă nu există evaluări

- ECOTHERM - Steam Solutions PDFDocument56 paginiECOTHERM - Steam Solutions PDFsouparna dutta100% (1)

- Genie: Hot Water Driven Vapor Absorption MachineDocument39 paginiGenie: Hot Water Driven Vapor Absorption MachineObayomi KennyÎncă nu există evaluări

- English Grammar BookDocument7 paginiEnglish Grammar BookTiaNắngNgọtÎncă nu există evaluări

- BOGE IA Screw CompressorDocument51 paginiBOGE IA Screw CompressorTaifurÎncă nu există evaluări

- Hydrocyclones DeoilingDocument2 paginiHydrocyclones DeoilingJ SlaterÎncă nu există evaluări

- BoilerDocument5 paginiBoilerJeremy Lim Choon KeatÎncă nu există evaluări

- Advanced Temperature Measurement and Control, Second EditionDe la EverandAdvanced Temperature Measurement and Control, Second EditionÎncă nu există evaluări

- PCM APAC - Deltech - 50hz - E - 1908Document4 paginiPCM APAC - Deltech - 50hz - E - 1908sales-admin.bdgÎncă nu există evaluări

- Mobilemax Series: 2-Speed Portable CoolerDocument4 paginiMobilemax Series: 2-Speed Portable CoolerKeren QiÎncă nu există evaluări

- Water Cooled PACAug 2018Document17 paginiWater Cooled PACAug 2018Iwan RusmanaÎncă nu există evaluări

- Breezair Reference BookDocument32 paginiBreezair Reference BookFaith ZhongÎncă nu există evaluări

- Catalog KaeserDocument24 paginiCatalog KaeserAnonymous mZEUquÎncă nu există evaluări

- EnotecDocument8 paginiEnotecarafatÎncă nu există evaluări

- Tray Drying ChamberDocument4 paginiTray Drying ChamberParveen SharmaÎncă nu există evaluări

- 016 - Mikropor Mcy Brosur-Avr - 200821Document11 pagini016 - Mikropor Mcy Brosur-Avr - 200821Mohsen ParpinchiÎncă nu există evaluări

- Extrusion Blow Molding With Eastman CopolyestersDocument16 paginiExtrusion Blow Molding With Eastman CopolyestersJuan Felipe Valencia VélezÎncă nu există evaluări

- Presentation Siemens ORCDocument12 paginiPresentation Siemens ORCCarlos Fernando Alfonso BallesterosÎncă nu există evaluări

- Evaporation For Instant Coffee Plants Tcm11 54061Document1 paginăEvaporation For Instant Coffee Plants Tcm11 54061Hung DoÎncă nu există evaluări

- 2003 09 Refrigeration Applications - Efficiency For R-717 and R-22 Systems, Part 3 - BrileyDocument1 pagină2003 09 Refrigeration Applications - Efficiency For R-717 and R-22 Systems, Part 3 - BrileymeomeportabÎncă nu există evaluări

- 41 - Mol - Heat Exchanger Fouling and Cleaning - 2019Document7 pagini41 - Mol - Heat Exchanger Fouling and Cleaning - 2019Eurotech Tra TranÎncă nu există evaluări

- Chem Process Ethylene Glycol BrochureDocument1 paginăChem Process Ethylene Glycol BrochurecandhareÎncă nu există evaluări

- 0 Air-Cooled Condenser Brochure (Feb 2020)Document4 pagini0 Air-Cooled Condenser Brochure (Feb 2020)David PierreÎncă nu există evaluări

- HGE-PyramidSeries BrochureDocument4 paginiHGE-PyramidSeries BrochureCesar HernandezÎncă nu există evaluări

- Lithium Bromide Absorption Chiller For Waste Heat Recovery - GMS InterneerDocument9 paginiLithium Bromide Absorption Chiller For Waste Heat Recovery - GMS InterneerUmut Sinan ÇetinbaşÎncă nu există evaluări

- 450 AllDocument16 pagini450 AllAnik AichÎncă nu există evaluări

- Thermoengineering Brochure ENGDocument6 paginiThermoengineering Brochure ENGaliÎncă nu există evaluări

- STM Folder Blow Moulding Machines A4 ENG 2018 Opt 1Document16 paginiSTM Folder Blow Moulding Machines A4 ENG 2018 Opt 1Jauhari Mohd SeranÎncă nu există evaluări

- Mark MSM Mini 22-55 LeafletDocument6 paginiMark MSM Mini 22-55 LeafletzuzinoleksandrÎncă nu există evaluări

- C150 PCS 08 04 en Us - 2015 PDFDocument4 paginiC150 PCS 08 04 en Us - 2015 PDFRania ToumiÎncă nu există evaluări

- Building Technology From Ebm-Papst: The Engineer's ChoiceDocument4 paginiBuilding Technology From Ebm-Papst: The Engineer's Choicespscribd1Încă nu există evaluări

- White Paper - Condenser Pre Cooling PDFDocument7 paginiWhite Paper - Condenser Pre Cooling PDFRenotech salesÎncă nu există evaluări

- Pompa de Caldura Hoval ThermaliaDocument12 paginiPompa de Caldura Hoval Thermaliamarian77usÎncă nu există evaluări

- Thermax Single Effect Hot Water Driven ChillerDocument12 paginiThermax Single Effect Hot Water Driven ChillerKetan ChandravadiyaÎncă nu există evaluări

- Trimech CatalogueDocument8 paginiTrimech Cataloguecaprolactamcl4571Încă nu există evaluări

- ThermostatDocument3 paginiThermostatAdem YavuzÎncă nu există evaluări

- Humidification ManualDocument31 paginiHumidification ManualAshutosh SinghÎncă nu există evaluări

- Biogas Purification PlantDocument2 paginiBiogas Purification PlantMD. NAHIDUZZAMANÎncă nu există evaluări

- CSM 3 - 4 - 5,5 - 7,5 HP: Otary Crew OmpressorDocument6 paginiCSM 3 - 4 - 5,5 - 7,5 HP: Otary Crew OmpressorVolodymуr VorobetsÎncă nu există evaluări

- Thermal Desorption 1208Document2 paginiThermal Desorption 1208Leite AddyÎncă nu există evaluări

- Secador HPET SerieDocument4 paginiSecador HPET SerieThomas MazzoleniÎncă nu există evaluări

- Max.e3-Pool ENGDocument4 paginiMax.e3-Pool ENGDamVent DamVentÎncă nu există evaluări

- Boge C Series BrochureDocument14 paginiBoge C Series Brochuremuhammad.sadiqÎncă nu există evaluări

- Boge S Series Screw CompressorsDocument12 paginiBoge S Series Screw Compressorsagus yohanesÎncă nu există evaluări

- Globaltherm Omnipure Product Information SheetDocument4 paginiGlobaltherm Omnipure Product Information SheetMalek MahmoudÎncă nu există evaluări

- 69Document2 pagini69Kenny RuizÎncă nu există evaluări

- Delbag Filter System MultiAir Eco 2000-MWFDocument12 paginiDelbag Filter System MultiAir Eco 2000-MWFnileshÎncă nu există evaluări

- Diverter Damper BrosurDocument3 paginiDiverter Damper Brosurstriker190100% (2)

- General Product - Ultrafilter IndonesiaDocument17 paginiGeneral Product - Ultrafilter IndonesiaYogi HandaruÎncă nu există evaluări

- 2003 10 Refrigeration Applications - Efficiency For R-717 and R-22 Systems, Part 4 - BrileyDocument1 pagină2003 10 Refrigeration Applications - Efficiency For R-717 and R-22 Systems, Part 4 - BrileymeomeportabÎncă nu există evaluări

- SMART Styrene 12 PDFDocument2 paginiSMART Styrene 12 PDFAntonela PortaÎncă nu există evaluări

- BF Dry GCP S-13 PDFDocument2 paginiBF Dry GCP S-13 PDFgautamcool100% (1)

- Kitchen Exhaust Filtration Unit: The Revolution in Air FiltrationDocument12 paginiKitchen Exhaust Filtration Unit: The Revolution in Air FiltrationMohammad SadikÎncă nu există evaluări

- Feature Monforts PDFDocument1 paginăFeature Monforts PDFShahzadÎncă nu există evaluări

- AAConsultrade Catalog 2018Document8 paginiAAConsultrade Catalog 2018rodolphopizy1Încă nu există evaluări

- Leaflet HRD2Document8 paginiLeaflet HRD2Miroslav LuladžićÎncă nu există evaluări

- Tdu Presentation EngDocument18 paginiTdu Presentation EngDJ WALET100% (1)

- Arch-En-Design New Delhi / LucknowDocument12 paginiArch-En-Design New Delhi / LucknowMC EstimationÎncă nu există evaluări

- Arch-En-Design New Delhi / LucknowDocument12 paginiArch-En-Design New Delhi / LucknowMC EstimationÎncă nu există evaluări

- Price List: With Effect From 1 September 2019Document28 paginiPrice List: With Effect From 1 September 2019MC EstimationÎncă nu există evaluări

- Ispat Post Graduate Institute and Super Specialty Hospital Atigh, Rourkela, OdishaDocument53 paginiIspat Post Graduate Institute and Super Specialty Hospital Atigh, Rourkela, OdishaMC EstimationÎncă nu există evaluări

- DSR 2018Document138 paginiDSR 2018Rahil100% (2)

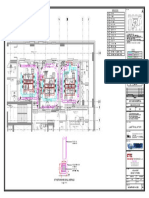

- Mci MFH Ac L7 Ot 111 PDFDocument1 paginăMci MFH Ac L7 Ot 111 PDFMC EstimationÎncă nu există evaluări

- Price List of Isi Hdpe Pipes: KELVIN BRAND HDPE PIPE IS:4984:1995, PE-63 (RS/MTR)Document1 paginăPrice List of Isi Hdpe Pipes: KELVIN BRAND HDPE PIPE IS:4984:1995, PE-63 (RS/MTR)Anshuman Pandey100% (1)

- PREODKEICIICIKLFLFDocument1 paginăPREODKEICIICIKLFLFMC EstimationÎncă nu există evaluări

- Colling Tower Installation 1Document6 paginiColling Tower Installation 1MC EstimationÎncă nu există evaluări

- Chiller Comparison ToolDocument25 paginiChiller Comparison ToolMC EstimationÎncă nu există evaluări

- DSRElectrical 2012Document62 paginiDSRElectrical 2012MC EstimationÎncă nu există evaluări

- Sdfajklsjklxcmz, XVNCM, XZNXVCMNX, CZMN, XVCZMNDocument1 paginăSdfajklsjklxcmz, XVNCM, XZNXVCMNX, CZMN, XVCZMNMC EstimationÎncă nu există evaluări

- Chilled Water Systems Design Issues PDFDocument6 paginiChilled Water Systems Design Issues PDFElmerÎncă nu există evaluări

- Bath Fittings PDFDocument29 paginiBath Fittings PDFMC EstimationÎncă nu există evaluări

- PREODKEICIICIKLFLFDocument1 paginăPREODKEICIICIKLFLFMC EstimationÎncă nu există evaluări

- PDI FA Device Mounting Heights Detail PDFDocument1 paginăPDI FA Device Mounting Heights Detail PDFMC EstimationÎncă nu există evaluări

- PREODKEICIICIKLFLFDocument1 paginăPREODKEICIICIKLFLFMC EstimationÎncă nu există evaluări

- A 245 W 3 SdfsaDocument1 paginăA 245 W 3 SdfsaMC EstimationÎncă nu există evaluări

- Application Form / ChecklistDocument34 paginiApplication Form / ChecklistMC EstimationÎncă nu există evaluări

- Technical Specifications - FPSDocument18 paginiTechnical Specifications - FPSMC EstimationÎncă nu există evaluări

- LW LogDocument3 paginiLW LogArturo SalazarÎncă nu există evaluări

- PDI FA Device Mounting Heights Detail PDFDocument1 paginăPDI FA Device Mounting Heights Detail PDFMC EstimationÎncă nu există evaluări

- TMM Hospital at Thiruvalla. Approved Make of Materials For Fire Protection SystemDocument2 paginiTMM Hospital at Thiruvalla. Approved Make of Materials For Fire Protection SystemMC EstimationÎncă nu există evaluări

- Technical Specifications - FPSDocument18 paginiTechnical Specifications - FPSMC EstimationÎncă nu există evaluări

- HOVAL Pompa Di Calore Genius ThermaliaDocument8 paginiHOVAL Pompa Di Calore Genius ThermaliaKasdy MtsÎncă nu există evaluări

- Characteristics of The Dosing PumpDocument1 paginăCharacteristics of The Dosing PumppramodtryÎncă nu există evaluări

- SP961 车辆保函Document2 paginiSP961 车辆保函1033699842Încă nu există evaluări

- ATTOMDocument2 paginiATTOMWendyÎncă nu există evaluări

- Solar Power, A Sustainable Energy Source An Initiative of DMRC, at Dwarka Metro Sector - 21 StationDocument28 paginiSolar Power, A Sustainable Energy Source An Initiative of DMRC, at Dwarka Metro Sector - 21 StationPRACHI MANTRIÎncă nu există evaluări

- Boiler Light Up ChecklistDocument8 paginiBoiler Light Up ChecklistHolly SmithÎncă nu există evaluări

- Aux Steam SystemDocument14 paginiAux Steam Systemsanjeevchhabra100% (1)

- Week 3 Ipe Review ModuleDocument2 paginiWeek 3 Ipe Review ModuleDarren Ian MaalihanÎncă nu există evaluări

- ME6701 SCAD MSM by WWW - Learnengineering.inDocument136 paginiME6701 SCAD MSM by WWW - Learnengineering.inKarthikeyan GovindarajÎncă nu există evaluări

- 2023 Beacon New Machine CatalogueDocument51 pagini2023 Beacon New Machine CatalogueJair OmarÎncă nu există evaluări

- Condenser ProblemsDocument12 paginiCondenser ProblemsJagdeesh R100% (1)

- PylonTech PDFDocument4 paginiPylonTech PDFatifamanÎncă nu există evaluări

- University of Khartoum Francis Turbine Report: IntroductionDocument5 paginiUniversity of Khartoum Francis Turbine Report: IntroductionAhmed ElnemaÎncă nu există evaluări

- Shop Drawing Boq Number Pipe-ModelDocument1 paginăShop Drawing Boq Number Pipe-Modelاحمد محمودÎncă nu există evaluări

- Behailu 2Document13 paginiBehailu 2tedy yidegÎncă nu există evaluări

- Lecture Objectives:: - Analysis of Absorption Cooling CyclesDocument16 paginiLecture Objectives:: - Analysis of Absorption Cooling CyclesMohamed Al-OdatÎncă nu există evaluări

- Junker's Gas CalorimeterDocument4 paginiJunker's Gas CalorimeterShanti Kiran ZÎncă nu există evaluări

- Concept of Heat Pump and RefrigeratorDocument8 paginiConcept of Heat Pump and RefrigeratorNamesh KorkeÎncă nu există evaluări

- Assignment Che239Document2 paginiAssignment Che239fatien zakariaÎncă nu există evaluări

- SVM 05036 2Document78 paginiSVM 05036 2calvin.bloodaxe4478Încă nu există evaluări

- CEP - SavingDocument6 paginiCEP - SavingManoj UpadhyayÎncă nu există evaluări

- MAN - Firetube Installation HWDocument27 paginiMAN - Firetube Installation HWseif elsaieÎncă nu există evaluări

- Pressure Relief Valve - : Future Technology Supply Co., LTD - : F047-520000-P0000048, F047-520000Document318 paginiPressure Relief Valve - : Future Technology Supply Co., LTD - : F047-520000-P0000048, F047-520000Le Van HieuÎncă nu există evaluări

- Air Heater KW2.0 5.0 ManualDocument24 paginiAir Heater KW2.0 5.0 ManualJohn CortesÎncă nu există evaluări

- Energy Storage System AssignmentDocument13 paginiEnergy Storage System AssignmentAniket LukadeÎncă nu există evaluări